Professional Documents

Culture Documents

BT Road From Akshitha Hospital (Srinivasapuram Road) To By-Pass Road

Uploaded by

sasidharkatari91572Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BT Road From Akshitha Hospital (Srinivasapuram Road) To By-Pass Road

Uploaded by

sasidharkatari91572Copyright:

Available Formats

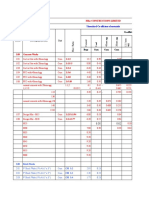

L B D

1

1 X 1 1010.00 4.30 0.15 651.45 cum 2,741.64 1cum 1786042

2

1 X 1 1010.00 4.00

4040.00 sqm

8.83

1sqm 35664

3

1 X 1 1010.00 4.00 0.025 101.00 cum 7236.92 1cum 730929

4

1 X 1 1010.00 4.00 4040.00 sqm 38.54 1 sqm 155697

5

1 x 2 1010.00 1.00 0.20 404.00 cum 460.76 1cum 186147

2894479

6 Provision for VAT at 5.00% 144724

7 Provision for labour cess @ 1% 28945

8 Provision for TC & SC CHarges @ 3 % 86834

9 provision for unforeseen items 5000

Total 3159982

Say 3160000

Quantity

Granular sub-base/base/surface course with local materials (Table 400.13) by mix in

place method normal Construction of granular sub-base by providing local material

spreading in uniform layers with motor grader on prepared surface, mixing by mix in

place method with hand roller and ramming to achieve the desired density complete as

per Clause 401.4 as per Technical Specification Clause 408 MORD. - for side berms

Rate

Providing laying, spreading and compacting graded HBG crushed stone aggregate to Wet

Mix macadem specifictation including cost, seigniorage of all materials and including

premixing the material with water at OMC in Mechanical mix plant carriage of mixed

material by tripper to site, laying in uniform layers with paver in base coursed on well

prepared surface and compacting with Vibratory rooler to acheive the desired density

etc., complete as per SS and as directed by the departmental officer in charge of the

work. (in Two layers)

Providing and applying tack coat with bitumen emulsion using emulsion pressure

distributor at the rate of 0.20 kg per sqm on the prepared bituminous/granular surface

cleaned with mechanical broom as per Tech. specification No 503 MORTH

Providing 25 mm thick compacted Semi-Dense Bituminous Concrete by hot mix plant

using hard blasted granite crushed aggregates of Grading -2 as per table 500-15 of

specification 508 of MoRT&H (4th Revision), premixed with bituminous binder 60/70

grade @ 5% of mix and filler, transporting the hot mix to work site, laying with

mechanical paver finisher to the required grade, level and alignment, rolling with smooth

wheeled,vibratory and tandem rollers to achieve the desired compaction as per

MoRT&H Specification 508 (4th Revision) complete for finished item of work in all

respects as directed by Engineer-in-charge.

Providing and laying surface dressing in single coat using 6 mm nominal size IRC HBG

machine crushed stone aggregates @ 0.004 cum / sqm on a layer of bitumen binder of

80/100 grade @ 0.75 kg / sqm laid on prepared surface and rolling with 8-10 T Power

JANGAREDDYGUDEM NAGARPANCHAYAT

Estimate Amt: Rs. 31,60,000.00

per Amount

Detailed cum Abstract Estimate

Name of Work: Providing B.T. road from Akshitha Hospital (Srinivasapuram Road) to By-Pass Road via Saibaba

Temple, in 18th Ward of Jangareddygudem Nagarpanchayat

Sl.

No

Description of Item Nos

Measurments

Sl.

No.

Description

Source (name

of quarry)

Unit

Basic

Rate

Lead in K.M.

Conveyan

ce

Charges

Total

Deduct 14 %

contractor

profit

Total Rate.

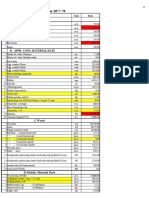

1 Cost of Cement OPC Local 4800.00 0.00 4800.00 4800.00

2 Cost of Cement SRC Local 0.00

3 Cost of Sand for Motor Siddantham 1 Cum 130.00 27 246.60 376.60 34.52 342.08

4 Cost of Sand for filling R Bada 1 Cum 110.00 16 152.00 262.00 21.28 240.72

5 Aggregates 6 mm Nominal size EGK Road 1 Cum 655.00 64 517.20 1172.20 72.41 1099.79

6 Aggregates 9.5 to 11.2mm size EGK Road 1 Cum 560.00 64 517.20 1077.20 72.41 1004.79

7 Aggregates 5 to 7mm size EGK Road 1 Cum 430.00 64 517.20 947.20 72.41 874.79

8 Aggregates 10 mm Nominal size EGK Road 1 Cum 820.00 64 517.20 1337.20 72.41 1264.79

9 Aggregates 13.2/12.5 mm Nominal size EGK Road 1 Cum 980.00 64 517.20 1497.20 72.41 1424.79

10 Aggregates 20 mm Nominal size EGK Road 1 Cum 1175.00 64 517.20 1692.20 72.41 1619.79

11 Aggregates 25 mm Nominal size EGK Road 1 Cum 1155.00 64 517.20 1672.20 72.41 1599.79

12 Aggregates 40 mm Nominal size EGK Road 1Mton 745.00 64 517.20 1262.20 72.41 1189.79

13 Aggregates below 5.6mm EGK Road 1Mton 505.00 64 517.20 1022.20 72.41 949.79

14 Aggregates 22.4 mm to 2.36mm EGK Road 1Mton 805.00 64 517.20 1322.20 72.41 1249.79

15 Aggregates 22.4 mm to 5.60 mm EGK Road 1 Cum 905.00 64 517.20 1422.20 72.41 1349.79

16 Aggregates 45 mm to 22.4 mm EGK Road 1 Cum 975.00 64 517.20 1492.20 72.41 1419.79

17 Aggregates 63 mm to 45 mm EGK Road 1 Cum 595.00 64 517.20 1112.20 72.41 1039.79

18 Aggregates 11.2 mm to 0.09 mm EGK Road 1 Cum 630.00 64 517.20 1147.20 72.41 1074.79

19 Aggregates 13.2 mm to 0.09 mm EGK Road 1 Cum 705.00 64 517.20 1222.20 72.41 1149.79

20 Aggregates 13.2 mm to 5.6 mm EGK Road 1 Cum 805.00 64 517.20 1322.20 72.41 1249.79

21 Aggregates 53 mm to 22.4 mm EGK Road 1 Cum 765.00 64 517.20 1282.20 72.41 1209.79

22 Aggregates10 mm to 5 mm EGK Road 1 Cum 750.00 64 517.20 1267.20 72.41 1194.79

23 Cost of Gravel Aragolanu 1 Cum 72.50 52 430.80 503.30 60.31 442.99

24 Cost of Stone Dust/ Quarry rubbish EGK Road 1 Cum. 255.00 64 517.20 772.20 72.41 699.79

25 Cost of Steel Local 1 MT 39000 39000 39000.00

26 Cost of Mild Steel Local 1 MT 39000 39000 39000.00

27 Cost of Bitumen - 80/100 Vizag 1 MT 240 33055.09

28 Cost of Bitumen - 60/70 Vizag 1 MT 240 33970.45

29 Cost of Emulsion Vizag 1 MT 240 33055.09

30 20 MM HBG Metal 0.70 cm 1619.79 1133.85

0.10 cm 1424.79 142.48

0.10 cm 1264.79 126.48

0.10 cm 1099.79 109.98

1512.79

PALACOLE MUNICIPALITY

Material Lead Statement for 2010-11

20mmHBG Metal

12mmHBG Metal

10 mm HBG Metal

6 mm HBG Metal

CM (1:2) CM (1:3) CM (1:4) CM (1:5) CM (1:6)

720 Kgs 480 kgs 360 Kgs 288 Kgs 240 Kgs

1 Cost of Cement 3456.00 2304.00 1728.00 1382.40 1152.00

2

Sand for Motor 1.05 x342.08

CUM 359.18 359.18 359.18 359.18 359.18

3 Seigniorage charges 1.05 x 40 0.00 0.00 0.00 0.00 0.00

4 Mixing Charges - 0.20 Men x 196 39.20 39.20 39.20 39.20 39.20

5 20% MA 7.84 7.84 7.84 7.84 7.84

TOTAL 3862.22 2710.22 2134.22 1788.62 1558.22

PALACOLE Cement Motors OPC

S.No Description of Material

Sl.

No

Description Unit Quantity Rate Amount

1 Earthwork in excavation for structures as per drawing and technical

specifications Clause 305.1 including setting out, construction of

shoring and bracing, removal of stumps and other deleterious

material and disposal upto a lead of 50 m, dressing of sides and

bottom and backfilling in trenches with excavated suitable material

as per Technical Specification 305 MORD / 304 MORTH (Page

No.484)

Ordinary soil

Manual Means Upto 3 m depth unit - 1 cum

Taking out put 10 cum

a) Labour

Mate

Mazdorr (Unskiled) day 3.64 196.00 713.44

20 % labour 142.69

856.13

(b+c) over heads & contractor profit 14% 119.86

975.99 /10Cum

Rs.97.60 1 cum

2

Filling in foundation trenches as per drawing and technical

specification Clause 305.3.9 MORD & 304 MORTH ( Page No.

488) RBR FN-DN-2

Sand filling

a) Labour

Mate

Mazdoor (Unskilled) day 0.31 196.00 60.76

20 % on Labour (Rs.60.76) 12.15

b) Material (Filling)

Cost of sand 1 cum 1 cum 240.72 240.72

Add Seionarage charges 1 cum - -

313.63

( C& D) over heads & contractor profit 14% 43.91

357.54 /1cum

3

Unit 1 cum

A.Materials

Cement kg 162.00 4.80 777.60

coarse aggregate 40 mm cum 0.90 1189.79 1070.81

fine aggregate (sand) Motor cum 0.45 342.08 153.94

Seiniorage charges for CA cum 0.90 0.00 0.00

Seiniorage charges for FA cum 0.45 0.00 0.00

Water (including for curing) (M189 P.No.34) kl 1.20 70.00 84.00

B. Machinery

Concrete mixer 10/7 cft (0.2/0.8 cum capacity hour 1.00 222.80 222.80

C.Labour (300/200 Diesel P.No.130

Mason 1st class day 0.10 258.00 25.80

Mazdoor Unskilled day 1.39 196.00 272.44

20 % on Labour (Rs.298.24) 59.65

Water charges 1% Rs.298.24 2.98

2670.02

Contractor profit 14% 373.80

3043.82 /cum

4 Supplying, fitting and placing HYSD bar reinforcement in

foundation complete as per drawings and technical specifications

for Bars below 36 mm dia including over laps and wastage, where

they are not welded

Unit = t

(a) Material

HYSD bars including 5 per cent for overlaps and wastage t 1.05 39000.00 40950.00

Binding wire kg 6.00 52.00 312.00

(b) Labour for cutting, bending, shifting to site, tying and placing in

position

Blacksmith / Bar bender day 2.00 258.00 516.00

Mazdoor (Unskilled) day 6.40 196.00 1254.40

Labour on 20% 354.08

Sundries on Material 43386.48

(c) Overheads on (a+b) 6074.11

(d) Contractors profit on (a+b+c) 49460.59 /1ton

49.46 /1 Kg

Plain Cement concrete (1:4:8) using 40 mm metal with concrete mixer. All work upto

PALACOLE MUNICIPALITY DATA 2010-2011

5 PLASTERING

Plastering with CM (1:3), 12 mm thick (page No.680)

Unit = 10 sqm

A. MATERIALS:

Cement Mortar (1:3) cum 0.15 2710.22 406.53

Seigniorage charges for F.A cum 0.15 0.00 0.00

B. LABOUR:

Mason 1

st

class

day 0.60 258.00 154.80

Mazdoor (unskilled) day 0.96 196.00 188.16

Labour on 20 % 68.59

818.08

contractor profit 14% 114.53

932.62 /10 sqm

6 Plastering with CM (1:4), 12 mm thick (page No.680)

Unit = 10 sqm

A. MATERIALS:

Cement Mortar (1:4) cum 0.15 2134.22 320.13

Seigniorage charges for F.A cum 0.15 0.00 0.00

B. LABOUR:

Mason 1

st

class

day 0.60 258.00 154.80

Mazdoor (unskilled) day 0.96 196.00 188.16

Labour on 20 % 68.59

731.68

contractor profit 14% 102.44

834.12 /10 sqm

7 Plain Cement concrete Naminal mix (1:3:6) using 20 mm graded

metal with machine mixing. (Page No.661)

Unit 1 cum

a. Materials

Cement kg 220.00 4.80 1056.00

coarse aggregate 20 mm cum 0.90 1512.79 1361.51

fine aggregate (sand) cum 0.45 342.08 153.93

Seiniorage charges for CA cum 0.90 0.00 0.00

Seiniorage charges for FA cum 0.45 0.00 0.00

Water (including for curing) kl 1.20 70.00 84.00

B. Machine mixing Hour 0.40 222.80 89.12

Water tanker 6Kl capacity hour 0.13 417.80 54.31

c. Labour

Mason 1st class day 0.10 258.00 25.80

Mazdoor Unskilled day 1.39 196.00 272.44

20 % on Labour 59.65

3156.77

d) Form work @ 4% on cost of material, labour and machinery 126.27

3283.04

Contractor profit 14% 459.63

3742.67 /cum

8 RCC grade M20 ( Nominal Mix) for culvert slabs & Bed blocks

a) Material

Cement MT 0.33 4800.00 1584.00

Coarse sand Cum 0.45 342.08 153.93

20mm aggregates Cum 0.54 1619.79 874.69

10mm aggregates Cum 0.36 1264.79 455.33

b) Labour

Mason I class day 0.10 258.00 25.80

Mazdoor (Unskilled) day 1.39 196.00 272.44

Add 20% Mpl. Allowance 59.65

c) Machinery

Mechanical concrete mixer 0.40/0.26 cum capacity hour 0.40 222.80 89.12

Generator 33KVA hour 0.40 0.00 0.00

3514.96

d) Form work @10% on cost of material, labour and machinery 351.50

3866.45

Over head & contractors profit @ 14% 541.30

Rate/ 1 cum 4407.75 /cum

9

Dismantling of existing structures comprising of Cement Concrete

including T&P and scaffolding wherever necessary, sorting the

dismantled material, disposal of unserviceble material and stacking

the serviceble material with all lifts and lead of 1000m as per

technical specification

Manual Means : Output 1.25 cum

a) Labour

Mazdoor day 1.3 196.00 254.80

Add 20% Mpl. Allowance 50.96

b) Machinery

Tractor with trolley (557.10x3/10) Hour 0.27 167.13 45.13

350.89

Over head & contractors profit @ 14% 49.12

Rate/1.25 cum 400.01

Rate/ cum 320.01 /cum

10

Carting away of excavated earth/ debris to a lead of 2 Km. The rate

including conveyance charges, labour charges for loading,

unloading, etc., complete as directed by the departmental officer in

charge of the work

Conveyance for 2 Km 1 30.2 30.20 /cum

11

Unit = t

(a) Material

Mild Steel bars including 5 per cent for wastage t 1.05 39000.00 40950.00

Binding wire kg 6.00 0.00 0.00

(b) Labour for cutting, bending, shifting to site, tying and

placing in position

Blacksmith / Bar bender day 2.00 258.00 516.00

Mazdoor (Unskilled) day 6.40 196.00 1254.40

Labour on 20% 354.08

Sundries on Material 43074.48

(c) Overheads on (a+b) 6030.43

(d) Contractors profit on (a+b+c) 14 % 49104.91 1 Tonne

49.10 /1 Kg

12

Unit = sqm

Taking out put - 100 sqm

(a) Machinery

Tractor with ripper attachment @ 60 cum per hour hour 0.080 345.00 27.60

Front end loader 1 cum bucket capacity @ 50 cum per hour hour 0.200 1320.00 264.00

Tipper 5.5 cum capacity, 4 trips per hour hour 0.230 629.80 144.85

(b) Labour

Mate day 0.00

Mazdoor day 0.26 196.00 50.96

Labour on 20% 10.19

Sundries on Material 497.61

(c) Overheads on (a+b) 69.66

(d) Contractors profit on (a+b+c) 14 % 567.27 1 Tonne

5.67 /1 Kg

13

Unit = 1 MT 80/100 60/70

Basic Cost

APGST @ 16.32%

Conveyance for bulk @ Rs. 1.50 per Km (240 KM) 720.00 720.00

33,055.09 33,970.45

14

Unit = 1 MT 80/100

Basic Cost

APGST @ 16.32%

Conveyance for bulk @ Rs. 1.50 per Km (240 KM) 720.00

33,055.09

32335.09

Picking - Sacrifying existing B.T / WBM surface to a depth of 50mm by mechanical means

and disposal of sacrified material with all leads and lifts upto 1000mts as per MORT & H

(4th Revision) Specn No.305.4.3

Providing Mild Steel Dowel bars of 25mm dia of Grade S240, 500mm long at Construction

joint as per standards

Cost of Bitumen

Cost of Bitumen emulsion / BT-80/100

32335.09 33250.45

a)Labour

Mate day -

Mason (1st class) day 5.00 258.00 1290.00

Mason (2nd class) day 5.00 237.00 1185.00

Mazdoor (Unskilled) day 150.00 196.00 29400.00

Mazdoor (Skilled) day 6.00 196.00 1176.00

Surveyor day 2.00 0.00 0.00

Mazdoor (Semi-Skilled) day 6.00 196.00 1176.00

Municipal Allowance on Labour 20% (Rs.34227) 6845.40

Blacksmith for cutting of dowel bars including removal of burrs,

fabrications & fixing of dowel bars.

day 1.00 0.00 0.00

b) Machinery

Concrete mixer 0.28 / 0.4 cum capacity (6 mixers) with weigh

batcher and suitable capacity calibrated water tank

hour 36.00 222.80 8020.80

Needle vibrator hour 9.00 108.60 977.40

Screed vibrator hour 9.00 0.00 0.00

Plate vibrator hour 9.00 0.00 0.00

Concrete joint cutting machine for initial & final cuts hour 4.00 0.00 0.00

Water tanker 6 kl capacity hour 5.00 417.80 2089.00

Air Compressor (1 hour initial + 1 hour final) hour 2.00 0.00 0.00

c) Material

Crushed stone coarse aggregates, grading will be as per Clause

1501.2.4.1 (Table 1500.1) of specifications @ 0.90 cum/cum of

concrete (25 mm & 12.5 mm blending)

cum 67.50 0.00 0.00

25mm HBG metal 2/3 45.00 1599.79 71990.64

12.5mm HBG metal 1/3 22.50 1424.79 32057.82

Add Seigniorage 67.50 0.00 0.00

Sand as per IS:383 and conforming to Clause 1500.2.4.2 @ 0.45

cum/cum of concrete

cum 33.75 342.08 11545.07

Add Seigniorage 33.75 0.00 0.00

Cement @ 350 kg/ cum of concrete t 30.00 4800.00 144000.00

Polythene sheet 125 micron sqm 412.50 10.00 4125.00

Mild steel dowel bar 25 mm dia of grade S 240. 500 mm long 20

Nos. at culvert/bridge slab and at construction joint including 5 per

cent wastage.

0.00 0.00

(4 x 20 x 0.500) + 5 per cent wastage = 42 m @ 2.80 kg per m =

117.6 kg.

t 0.118 0.00 0.00

Bitumen primer @ 200 ml per joint for 23 joints kg 5.00 35.00 175.00

Bituminous sealant 800 ml per joint for 23 joints litre 19.00 0.00 0.00

Jute rope 12 mm dia including 5 per cent wastage m 90.00 0.00 0.00

Debonding strips 3.75 m (length) x 10 mm (width) x 5 mm (thick)

cut-out of rubber filler board or similar material including 5 per cent

wastage

m 90.00

0.00 0.00

Polythene sheathing, covering 2/3rd dowel bars (20x23) and tight

fit including 5 per cent wastage

No. 483.00

0.00 0.00

Plasticizer 0.5 per cent by weight of cement litre 122.00 0.00 0.00

Curing compound (if used) @ 0.33 litre per sqm litre 131.25 0.00 0.00

Water for curing kl 18.00 70.00 1260.00

Joint filler board 20 mm thick as per IS:1838

(4 x 3.75 x 0.200 = 3 sqm)

sqm 3.00 520.00 1560.00

318873.13

d) Formwork @ 3% of (a+b+c) 9566.19

328439.32

e&f) Overheads & Contractors Profit 45981.50

Cost for 75 cum = a+b+c+d+e+f 374420.82

Rate per cum = (a+b+c+d+e+f)/75

4992.28 /Cum

Cement Concrete Pavement

Construction of un-reinforced plain cement concrete pavement, thickness as per design, over a prepared sub base,

with 43 grade cement or any other type as per Clause 1501.2.2 M30 (Grade), coarse and fine aggregates

conforming to IS : 383, maximum in a concrete mixer of not less than 0.2 cum capacity and appropeiate weigh

batcher using approved mix design, laid in approved fixed side formwork (steel channel, laying and fixing of 125

mictron thick polythene film, wedges, steel plates including levelling the formwork as per drawing), spreading the

concrete with sholvels, rakes, compacted using needle, scareed and plate vibrators and finished in continuous

operation including provision of contraction and expansion, construction joints, admixtures as approved, curing of

concrete slabs for 14- days, curing compound (where specified) and water finishing to lines and grade as per

drawing and Technical

RBR-

CCPV-

5

RB

R-

SB

BS-

12

ii

Unit = cum

Taking output = 300 cum

a)Labour

Mate day -

Mazdoor (Skilled) day 2.40 196.00 470.40

Mazdoor (Unskilled) day 8.00 196.00 1568.00

2038.40

Add 20 % labour 407.68

b) Machinery

Motor grader 110 HP 50 cum per hour hour 6.00 - -

Three wheel 80-100 kN static roller @10 cum per hour hour 30.00 0.00

Water tanker 6 kl capacity hour 5.00 417.80 2089.00

Tractor with Rotavator 25 cum per hour hour 12.00 - -

c) Material

Soil gravel mixture/quarry waste (Local material as per

Table400.13) (Gravel) -for side berms

cum 300.00

Gravel 300.00 442.99 132896.40

Seigniorage Gravel 300.00 0.00 0.00

Seigniorage Sand 96.00 0.00 0.00

Water kl 30.00 70.00 2100.00

139531.48

d&e) Overheads & Contractors Profit @ 14% 19534.41

Cost for 300 cum = a+b+c+d+e 159065.89

Rate per cum = (a+b+c+d+e)/300

530.22 /Cum

RB

R-

SB

BS-

12

ii

Unit = cum

Taking output = 300 cum

a)Labour

Mate day -

Mazdoor (Skilled) day 2.48 196.00 486.08

Mazdoor (Unskilled) day 10.00 196.00 1960.00

M.A 20% on Labour 489.22

b) Machinery

Motor grader 110 HP 50 cum per hour hour 6.00 0.00 0.00

Three wheel 80-100 kN static roller @10 cum per hour P.No.131

hour 30.00 746.50 22395.00

Water tanker 6 kl capacity hour 5.00 417.80 2089.00

Tractor with Rotavator 25 cum per hour hour 12.00 0.00 0.00

c) Material

Naturally Occuring Stone Dust (local materials as per Table

400.13)

cum 384.00 699.79 268720.13

Seigniorage 384.00 0.00 0.00

Water - P-34 KL 30.00 70.00 2100.00

298239.42

d&e) Overheads & Contractors Profit @ 14% 41753.52

Cost for 300 cum = a+b+c+d+e 339992.94

Rate per cum = (a+b+c+d+e)/300 1133.31 /Cum

Granular sub-base/base/surface course with local materials (Table 400.13) by mix in place method normal

Construction of granular sub-base by providing local material spreading in uniform layers with motor

grader on prepared surface, mixing by mix in place method with rotavator at once and compacting with

smooth wheel roller to achieve the desired density complete as per Clause 401.4 as per Technical

Specification Clause 408 MORD - RBR-SBBS-12 P.338 - With Stone dust

Granular sub-base/base/surface course with local materials (Table 400.13) by mix in place method normal

Construction of granular sub-base by providing local material spreading in uniform layers with motor

grader on prepared surface, mixing by mix in place method with hand roller and ramming to achieve the

desired density complete as per Clause 401.4 as per Technical Specification Clause 408 MORD. - for side

berms

Index

Code

Description Unit Quantity

Rate

Rs.

Amount Rs.

Remar

ks

WBM Grade 3(Using Graded Metal)

Providing, laying, spreading and compacting stone

agregates of specific sizes to water bound macadam

specification including spreading in uniform thickness,

hand packing, rolling with three wheel 80-100 KN in stages

to proper grade and camber, appplying and broomning,

crushable screening to fill-up the interstices of coarse

aggregate, watering and compacting to the required density

Grading 2 as per Technical Specification, Clause 405

MORD/404 MORTH. RBR-SBBS-10 (P334)

(A) By Manual Means

Unit=cum

Taking output=360 cum

a) Labour

Mate Day

Mazdoor (Skilled) Day 12.08 295.00 3563.6

Mazdoor (Unskilled) Day 250.00 295.00 73750.00

20% Municipal Allowance 15462.72

b) Machinery

Three wheel 80-100 KN static roller @ 10 cum per hour for

Rural Area Works (P-131)

Hour 36.00 0.00 0.00

(OR)

Three wheel 80-100 KN static roller @ 30 cum per hour for

R&B&Urban Works

Hour 12.00 746.50 8958.00

(OR)

Vibratory Roller 80-100 KN @60 cum per hour Hour 6.00 0.00 0.00

Water Tanker 6 kl capacity Hour 24.00 80.48 1931.52

c) Material (Refer Tables 400.7,8,9&10

MORD/400.6,7,8&9 MORTH)

Aggregate

Grading 3 53 mm to 22.4 mm @ 0.91 cum per 10 sqm for

compacted thickness of 75 mm

cum 435.60 1452.25 632600.10

Add Seigniorage charges cum 435.60 0.00 0.00

Crushable type such as Moorum or Stone dust for Grading

3 @ 0.22 cum per 10 sqm

cum 105.59 895.25 94529.45

Add Seigniorage charges cum 105.59 0.00 0.00

Binding Material

Binding Material @ 0.06 cum per 10 sqm for Grading 3

material (for R&B&Urban Works only)

cum 28.80 699.79 20154.01

Add Seigniorage charges cum 28.80 0.00 0.00

kl 144.00 103.00 14832.00

Cost for 360 cum=a+b+c+d+e(3 Wheel Roller) 865781.40

Contractor Profit @ 14% 121209.40

986990.79

2741.64 /Cum

A

RBR-SBBS-11 Wet Mix Macadam

By Mechanical Means with 1 km lead

R&B and Urban Area Works :

Unit = cum

Taking output = 225 cum (495 tonnes)

a) Labour

Mate day -

Mazdoor skilled day 2.48 295.00 731.60

Mazdoor day 10.00 295.00 2950.00

Add 20% onlabour 736.32

b) Machinery

Wet mix plant of 75 tonne hourly capacity hour 9.00 1320.00 11880.00

Electric generator 125 KVA hour 6.00 1090.00 6540.00

Front end loader 1 cum capacity hour 6.00 1320.00 7920.00

Paver finisher hour 6.00 1090.00 6540.00

Vibratory roller 8 - 10 tonne hour 3.90 1704.60 6647.94

or

Smooth 3 wheeled steel roller @ 8-10 tonnes. hour 22.50

Water tanker 6 KL capacity hour 3.00 80.48 241.44

Tipper 10t t.km 495 x L 4.50 2227.50

c) Material ( Table 400-11) 0.00

45 mm to 22.4 mm@ 30 per cent cum 89.10 1683.25 149977.58

22.4 mm to 2.36 mm @ 40 per cent cum 118.80 1452.25 172527.30

2.36 mm to 75 micron@ 30 per cent cum 89.10 1095.25 97586.78

Cost of water KL 18.00 103.00 1854.00

468360.45

d&e) Overheads & Contractors Profit 65570.46

Cost for 225 cum = a+b+c+d+e (Vibratory Roller) 533930.91

Rate per cum = (a+b+c+d+e)/225 2373.03

Cost for 225 cum = a+b+c+d+e (Smooth Roller)

Rate per cum = (a+b+c+d+e)/225

B RBR-BASC-8 Semi-Dense Bituminous Concrete

Unit = cum

Taking output = 195 cum (450 tonnes)

a) Labour

Mate day -

Mazdoor (Unskilled) working with HMP, mechanical

broom, paver, roller, asphalt cutter and assistance

for setting out lines, levels and layout of construction

day 14.000 295.00 4130.00

Skilled mazdoor for checking line & levels day 5.840 295.00 1722.80

Add 20% onlabour 1170.56

Providing, laying, spreading and compacting graded stone aggregate to wet mix macadam specification

including premixing the material with water at OMC in mechanical mixer (Pug Mill), carriage of mixed

material by tipper to site, laying in uniform layers in sub-base/base course on a well prepared sub-base

and compacting with smooth wheel roller of 80 to 100kN / Vibratory Roller 80-100 kN weight to achieve

the desired density including lighting, barricading and maintenance of diversion, etc as per Tables 400.11

& 400.12 and Technical Specification Clause 406 MORD / MORTH.

Providing and laying semi dense bituminous concrete with 40-60 TPH batch type HMP producing an

average output of 37.5 tonnes per hour using crushed aggregates of specified grading, premixed with

bituminous binder @ 4.5 to 5 per cent of mix and filler, transporting the hot mix to work site, laying with

a hydrostatic paver finisher with sensor control to the required grade, level and alignment, rolling with

smooth wheeled, vibratory and tandem rollers to achieve the desired compaction as per MoRTH

specification clause No. 508 complete in all respects

Note : 1. Though vibratory roller is required only for 3 hours as per norms, the same is required to be available at site for 6 hours to

match with other machines. The usage rates of vibratory roller may be multiplied with a factor of 0.65

2. As three wheeled smooth steel rollers are commonly in use, the same has been provided as an alternative which can be used if the

thickness of individual layer does not exceed 100 mm.

b) Machinery

HMP 40-60 TPH hour 11.000 15525.00 170775.00

Paver finisher hydrostatic with sensor control @ 75

cum per hour

hour 6.000 2530.00 15180.00

Generator 250 KVA hour 6.000 1550.00 9300.00

Front end loader 1 cum bucket capacity hour 6.000 1320.00 7920.00

Smooth wheeled roller 8-10 tonnes for initial break

rolling. (6 x 0.65)

hour 3.900 746.50 2911.35

Vibratory roller 8 tonnes for intermediate rolling. hour 3.900 1704.60 6647.94

Finish rolling with 6-8 tonnes smooth wheeled

tandem roller

hour 3.900 1320.00 5148.00

c) Material

Grading I: 13 mm (Nominal Size)

i) Bitumen@ 4.5 per cent of weight of mix t 20.250

ii) Aggregate

Total weight of mix = 450 tonnes

Weight of bitumen = 20.25 tonnes

Weight of aggregate = 450-20.25 = 429.75 tonnes

Taking density of aggregate = 1.5 ton/cum

Volume of aggregate = 286.5 cum

13.2 - 10 mm20 per cent cum 57.300

10 - 5 mm 38 per cent cum 108.870

5 mm and below 40 per cent cum 114.600

Filler @ 2 per cent of weight of

aggregates.(Cement)

t 8.620

or

Grading II: 10 mm (Nominal Size)

Bitumen 80/100 Grade @ 5 per cent of weight of mix t 22.500

OR

Bitumen 60/70 Grade @ 5 per cent of weight of mix t 22.500 33970.45 764335.13

weight of mix = 450 tonne

Aggregate

Total weight of mix = 450 tonnes

Weight of bitumen = 22.5 tonnes

Weight of aggregate = 450 -22.50 = 427.50 tonnes

Taking density of aggregate = 1.5 ton/cum

Volume of aggregate = 285 cum

9.5 - 11.2 mm IRC HBG M/C Chips cum 81.225 1004.79 81614.23

5 - 7 mm IRC HBG M/C Chips cum 81.225 874.79 71054.98

5 - 7 mm IRC HBG M/C Chips cum 58.425 874.79 51109.72

Below 2.36 mm cum 58.425 699.79 40885.35

Filler @ 2 per cent of weight of aggregates. cum 5.700 699.79 3988.81

1237893.87

*Any one of the alternative may be adopted as

per approved design

(i) For Grading I ( 13 mm nominal size )

d&e) Overheads & Contractors Profit 173305.14

Cost for 195 cum = a+b+c+d+e 1411199.01

Rate per cum = (a+b+c+d+e)/195 7236.92

(ii) For Grading II (10 mm nominal size)

d&e) Overheads & Contractors Profit

Cost for 195 cum = a+b+c+d+e (80 / 100 Grade BT)

Rate per cum = (a+b+c+d+e)/195

Cost for 195 cum = a+b+c+d+e (60 / 70 Grade BT)

Rate per cum = (a+b+c+d+e)/195

C

Unit = sqm

Taking output = 3500 sqm

a) Labour

Mate day -

Mazdoor (Unskilled) day 2.080 295.00 613.60

Add 20%on labour 122.72

b) Machinery

Mechanical broom @ 1250 sqm per hour hour 2.800 290.00 812.00

Air compressor 250 cfm hour 2.800 370.00 1036.00

Emulsion pressure distributor @ 1750 sqm per hour hour 2.000 690.00 1380.00

c) Material

Bitumen emulsion @ 0.2 kg per sqm t 0.700 33055.09 23138.56

27102.88

d&e) Overheads & Contractors Profit 14.00% 3794.40

Cost for 3500 sqm = a+b+c+d+e 30897.29

Rate per sqm = (a+b+c+d+e)/3500 8.83

D

Unit = sqm

Taking output = 9000 sqm

a)Labour

Mate day -

Mazdoor (Unskilled) day 9.000 295.00 2655.00

Mazdoor skilled day 2.440 295.00 719.80

Add 20% on labour 674.96

b) Machinery

Mechanical broom @ 1250 sqm/hr. hour 7.200 290.00 2088.00

Air compressor 250 cfm hour 7.200 370.00 2664.00

Hydraulic self propelled chip spreader @ 1500 sqm/hr. hour 6.000 2070.00 12420.00

Tipper 10Tonne capacity for carriage of stone chips

from stock pile on road side to chip spreader

hour 6.000 629.80 3778.80

Front end loader 1 cum bucket capacity hour 6.000 1320.00 7920.00

Bitumen pressure distributor @1750 sqm/hr hour 6.000 690.00 4140.00

Smooth wheeled roller 8 Ton hour 6.000 746.50 4479.00

c) Material 0.00

Bitumen 80/100 @0.75 Kg/sqm MT 6.750 33055.09 223121.86

or 0.00

Bitumen 60/70 @0.75 Kg/sqm MT 6.750 0.00

Crushed stone chippings 6 mm nominal size @0.004

cum/sqm

cum 36.000 1099.79 39592.51

304253.93

d&e) Overheads & Contractors Profit 42595.55

Cost for 9000 sqm = a+b+c+d (80/100 BT) 346849.48

Rate per sqm = (a+b+c+d)/9000 38.54

Cost for 9000 sqm = a+b+c+d (60/70 BT)

Rate per sqm = (a+b+c+d)/9000

2. Quantity of Bitumen has been taken for analysis purpose. The actual quantity will depend upon job mix formula.

3. Labour for traffic control, watch and ward and other miscellaneous duties at site including sundries have been included in

administrative overheads of the contractor.

4. In case SDBC is laid over freshly laid tack coat, provision of broom and 2 mazdoor shall be deleted as the same has been

included in the cost of tack coat.

Providing and applying tack coat with bitumen emulsion using emulsion pressure distributor

at the rate of 0.20 kg per sqm on the prepared bituminous/granular surface cleaned with

mechanical broom as per Tech. specification No 503 MORTH

Providing and laying surface dressing in single coat using 6 mm nominal size IRC HBG

machine crushed stone aggregates @ 0.004 cum / sqm on a layer of bitumen binder of

80/100 grade @ 0.75 kg / sqm laid on prepared surface and rolling with 8-10 T Power

Road Roller etc., complete for finished item of work as per MoRT&H Specification 510 (4th

Revision) and as directed by the Engineer-in-charge.

Note : 1. Bitumen emulsion has been provided @ 0.20 kg per sqm as per clause 503.8. Payment shall

be made with adjustment, plus or minus, for the variation between this quantity and actual quantity

approved by the Engineer after preliminary trials referred to in clause No. 503.4.3

2. An output of 3500 sqm has been considered in case of prime coat and tack coat which can be

covered by bituminous courses on the same day.

5. The quantity of Bitumen to be adjusted as per job mix formula.

Note : 1. Although the rollers are required only for 3 hours as per norms of output, but the same have to be available at site for six

hours as the hot mix plant and paver will take six hours for mixing and paving the output of 450 tonnes considered in this analysis.

To cater for the idle period of these rollers, their usage rates have been multiplied by a factor of 0.65

You might also like

- S.W. Gully TrapDocument16 pagesS.W. Gully TrapAnonymous 9b8vCz1W100% (1)

- Rate AnalysisDocument64 pagesRate Analysissachin_mate60% (5)

- Rate Analysis BMDocument6 pagesRate Analysis BMparth088No ratings yet

- Brick Masonry RateDocument3 pagesBrick Masonry RateSam Roger100% (1)

- Kerb Stone Rate AnalysisDocument2 pagesKerb Stone Rate AnalysisYashashree Group100% (1)

- Cement ConsuptionDocument1 pageCement Consuptionjkg197350% (2)

- Analysis of Rate S. No. Code Description Unit Quantity Rate Amount 1Document3 pagesAnalysis of Rate S. No. Code Description Unit Quantity Rate Amount 1Shashank Shekhar MishraNo ratings yet

- Arunachal Pradesh Analysis of Rates For Road and Bridge Works 2010Document232 pagesArunachal Pradesh Analysis of Rates For Road and Bridge Works 2010Harish Kumar MahavarNo ratings yet

- Labour Output ConstantDocument14 pagesLabour Output ConstantJanesha100% (1)

- GP Build Karlapalem 01.03.17Document63 pagesGP Build Karlapalem 01.03.17Thota RevanthNo ratings yet

- Rate AnalysisDocument38 pagesRate AnalysisSarin0% (1)

- Material ConsumptionDocument5 pagesMaterial ConsumptionMANIKANDAN Selvam100% (1)

- Analysis For BuildingDocument51 pagesAnalysis For BuildingPerkresht PawarNo ratings yet

- RATES For 2073-74: A. Approved Labour RateDocument40 pagesRATES For 2073-74: A. Approved Labour Rateक्षितिज चौलागाईंNo ratings yet

- Mfar Constructions Limited: SL - No Description of Item UnitDocument12 pagesMfar Constructions Limited: SL - No Description of Item UnitNaveen TibbaNo ratings yet

- Item No. Description Unit Rate Code Rate (RS) Quantity Labour Cost (RS) Material Cost (RS)Document1 pageItem No. Description Unit Rate Code Rate (RS) Quantity Labour Cost (RS) Material Cost (RS)RANADIP100% (2)

- 22 02 2016 Shuttering Work Rate AnalysisDocument22 pages22 02 2016 Shuttering Work Rate Analysissplashierprince50% (2)

- Rate Analsis Chapter No. 7 (Brick Work)Document1 pageRate Analsis Chapter No. 7 (Brick Work)M HAFEEZ RAJANo ratings yet

- Material RequiredDocument2 pagesMaterial RequiredNikhil88% (8)

- 1-Factory Shed 5.8.21Document72 pages1-Factory Shed 5.8.21Harsh BhavsarNo ratings yet

- Cement Constant Latest - 2011Document7 pagesCement Constant Latest - 2011keshav1980100% (1)

- Road Estimation 1Document11 pagesRoad Estimation 1kmmansafNo ratings yet

- Rate Analysis For Gypsum Board Ceiling WorksDocument19 pagesRate Analysis For Gypsum Board Ceiling WorksSourav100% (1)

- Analysis of Rates of Various Building ItemsDocument3 pagesAnalysis of Rates of Various Building Itemsveera_swamy250% (2)

- Rate Analysis 2Document7 pagesRate Analysis 2Naveen TibbaNo ratings yet

- Cost Analysis of Hot-Cold MixDocument8 pagesCost Analysis of Hot-Cold MixChManikumarNo ratings yet

- How To Use Rate Analysis of Brick Work Calculator Rate Analysis of Brick WorkDocument7 pagesHow To Use Rate Analysis of Brick Work Calculator Rate Analysis of Brick WorkM iqbalNo ratings yet

- ConsumptionDocument3 pagesConsumptionmilindk35100% (1)

- Brick Work Calculation: Please Put All Dimenssion in MetreDocument20 pagesBrick Work Calculation: Please Put All Dimenssion in MetresnehalataNo ratings yet

- Maharashtra Jeevan Pradhikaran Rate Analysis 2012 2013Document177 pagesMaharashtra Jeevan Pradhikaran Rate Analysis 2012 2013ulhas_nakasheNo ratings yet

- Rate Analysis-MS Ladder at TerraceDocument1 pageRate Analysis-MS Ladder at TerraceRajagopal CRNo ratings yet

- RateAnalysis 22ndjanDocument412 pagesRateAnalysis 22ndjanYusuf You Can0% (1)

- EstimateDocument1 pageEstimateNiranjan ShresthaNo ratings yet

- Factual Civil Engineering: Cement ReconcilationDocument5 pagesFactual Civil Engineering: Cement ReconcilationDeepak Kaushik100% (1)

- Rate Analysis Morang - FinalDocument27 pagesRate Analysis Morang - Finalnitish JhaNo ratings yet

- Rate Analysis For ShutteringDocument2 pagesRate Analysis For ShutteringSarin100% (2)

- Rate Analysis For Concrete With GgbsDocument13 pagesRate Analysis For Concrete With GgbsyashupalgowdaNo ratings yet

- Civil Rate AnalysisDocument72 pagesCivil Rate AnalysissameershedgeNo ratings yet

- Rate Analysis For Site Concept All ItemDocument268 pagesRate Analysis For Site Concept All ItemraviNo ratings yet

- Material Consumption Norms For Various Civil WorksDocument3 pagesMaterial Consumption Norms For Various Civil Worksunni mohan100% (2)

- Material ConsumptionDocument12 pagesMaterial Consumptionshanky22No ratings yet

- Tile Rate Analysis PDFDocument3 pagesTile Rate Analysis PDFSangam Suresh100% (1)

- Date-070209 SR - No. Description Unit Rate A Rcc. WorkDocument6 pagesDate-070209 SR - No. Description Unit Rate A Rcc. WorkNiroshan Naguleswaran0% (1)

- Important Thumb Rules Used in Construction by Civil EngineersDocument5 pagesImportant Thumb Rules Used in Construction by Civil Engineersramesh_hinukaleNo ratings yet

- D Market Rate Analysis BuildingDocument74 pagesD Market Rate Analysis BuildingAnonymous Of0C4dNo ratings yet

- Rate Analysis-IlyasDocument9 pagesRate Analysis-IlyasEr Bharat PrajapatiNo ratings yet

- Labour EstimateDocument1 pageLabour EstimateManasNo ratings yet

- B S R - Buildings Dept - BatticaloaDocument263 pagesB S R - Buildings Dept - Batticaloaudithairesha100% (1)

- Rate Analysis-All ActivitiesDocument25 pagesRate Analysis-All ActivitiesmuraliNo ratings yet

- Rate Analysis: 7 Wall Paneling - Akustik + Wood Wall PanelsDocument2 pagesRate Analysis: 7 Wall Paneling - Akustik + Wood Wall PanelsDeepa Junnarkar DegwekarNo ratings yet

- Analysis of Boundary WallDocument7 pagesAnalysis of Boundary WallsamirNo ratings yet

- Building SSR 2019-20Document333 pagesBuilding SSR 2019-20NagabhushanamNo ratings yet

- Material ConstantsDocument4 pagesMaterial ConstantsraviNo ratings yet

- 32mm Thick Flush Doors Rs 140Document9 pages32mm Thick Flush Doors Rs 140lkovijayNo ratings yet

- Civil Rate ExcelDocument81 pagesCivil Rate Excelyo5208100% (2)

- Rate 2077-2078Document63 pagesRate 2077-2078क्षितिज चौलागाईंNo ratings yet

- BT Road Estimate ModelDocument5 pagesBT Road Estimate Modelsasidharkatari91572No ratings yet

- Valve Pits Estimate 2014-15Document15 pagesValve Pits Estimate 2014-15Sasidhar KatariNo ratings yet

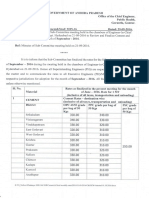

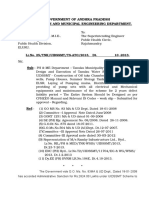

- Government of Andhra Pradesh: Panchayatraj Engineering DepartmentDocument12 pagesGovernment of Andhra Pradesh: Panchayatraj Engineering DepartmentD.V.Srinivasa RaoNo ratings yet

- Huzurnagar 220kV line-BOQDocument22 pagesHuzurnagar 220kV line-BOQzakir242No ratings yet

- Details of Bill StatusDocument2 pagesDetails of Bill Statussasidharkatari91572No ratings yet

- TPG MPLADS Estimate To Print - Xls 05-12-2015Document12 pagesTPG MPLADS Estimate To Print - Xls 05-12-2015sasidharkatari91572No ratings yet

- SFC RjyDocument3 pagesSFC Rjysasidharkatari91572No ratings yet

- Bore EstimateDocument11 pagesBore Estimatesasidharkatari91572No ratings yet

- Detailed Cum Abstract Estimate: Municipal Corporation, Eluru Name of Work: Construction of CC DrainDocument1 pageDetailed Cum Abstract Estimate: Municipal Corporation, Eluru Name of Work: Construction of CC Drainmurali100% (1)

- Repairs To Motors 30-07-2017Document32 pagesRepairs To Motors 30-07-2017sasidharkatari91572No ratings yet

- TPG MPLADS Estimate On Bhimavaram Bypass RoadDocument15 pagesTPG MPLADS Estimate On Bhimavaram Bypass Roadsasidharkatari91572No ratings yet

- Quotation: S.N o Particulars Qty Rate Rs. Amount RsDocument2 pagesQuotation: S.N o Particulars Qty Rate Rs. Amount Rssasidharkatari91572No ratings yet

- Comparative Statement 03122016Document4 pagesComparative Statement 03122016sasidharkatari91572No ratings yet

- TPG EOT Request Letter by The Agency 13-04-2016Document5 pagesTPG EOT Request Letter by The Agency 13-04-2016sasidharkatari91572No ratings yet

- 6 - Annual Account Slip - 2015 - 2016Document1 page6 - Annual Account Slip - 2015 - 2016vasheekarNo ratings yet

- Smart Pulse Survey Report On 26-11-2016 On 19-42 HoursDocument4 pagesSmart Pulse Survey Report On 26-11-2016 On 19-42 Hourssasidharkatari91572No ratings yet

- 6 - Annual Account Slip - 2015 - 2016Document1 page6 - Annual Account Slip - 2015 - 2016vasheekarNo ratings yet

- 6 - Annual Account Slip - 2015 - 2016Document1 page6 - Annual Account Slip - 2015 - 2016vasheekarNo ratings yet

- Comparative Statement 03122016Document4 pagesComparative Statement 03122016sasidharkatari91572No ratings yet

- Bathing GhatDocument56 pagesBathing Ghatsasidharkatari9157233% (3)

- Sivaji ProbationDocument2 pagesSivaji Probationsasidharkatari91572No ratings yet

- Smart Pulse Survey Report On 23-11-2016 On 11.59 A.MDocument4 pagesSmart Pulse Survey Report On 23-11-2016 On 11.59 A.Msasidharkatari91572No ratings yet

- Quotation: S.N o Particulars Qty Rate Rs. Amount RsDocument2 pagesQuotation: S.N o Particulars Qty Rate Rs. Amount Rssasidharkatari91572No ratings yet

- Bill All Forms - JRG 11th Ward RoadDocument60 pagesBill All Forms - JRG 11th Ward Roadsasidharkatari91572No ratings yet

- 42 ND Div - Yoga School BillDocument123 pages42 ND Div - Yoga School Billsasidharkatari91572No ratings yet

- IndexDocument4 pagesIndexsasidharkatari91572No ratings yet

- Drilling of Bores (ASC Grant) 2015Document12 pagesDrilling of Bores (ASC Grant) 2015sasidharkatari91572No ratings yet

- Approved Monthly Rates - September - 2016Document2 pagesApproved Monthly Rates - September - 2016sasidharkatari91572No ratings yet

- VMC Drains West Assembly LengthsDocument6 pagesVMC Drains West Assembly Lengthssasidharkatari91572No ratings yet

- 43rd BillDocument42 pages43rd Billsasidharkatari91572No ratings yet

- TNK - Work Slip On 30.10.2013.Document7 pagesTNK - Work Slip On 30.10.2013.sasidharkatari91572No ratings yet

- Quotation For Groove CuttingDocument2 pagesQuotation For Groove Cuttingsasidharkatari91572100% (1)

- TPG MPLADS Work Slip For 20.00 Lakhs - 23!06!2016Document20 pagesTPG MPLADS Work Slip For 20.00 Lakhs - 23!06!2016sasidharkatari91572No ratings yet

- JR Gudem Est Revisedwith Electrical EstimateDocument201 pagesJR Gudem Est Revisedwith Electrical Estimatesasidharkatari91572No ratings yet

- Concrete Vs AsphaltDocument2 pagesConcrete Vs AsphaltGregor GrbecNo ratings yet

- Light Weight Block Work ProcedureDocument4 pagesLight Weight Block Work ProceduresubhaschandraNo ratings yet

- SS S 210aDocument10 pagesSS S 210akeithc01No ratings yet

- Rhino 590 Specifications Jan 06-1Document6 pagesRhino 590 Specifications Jan 06-1MohdFarid100% (1)

- Chap 015Document32 pagesChap 015fadzliza_83No ratings yet

- Construction Technology Assignment 01Document13 pagesConstruction Technology Assignment 01Hashan PereraNo ratings yet

- Daraz Packaging GuidelinesDocument22 pagesDaraz Packaging GuidelinesDaraz Seller Support80% (5)

- FlightSafety Cessna Citation III VI VIIDocument11 pagesFlightSafety Cessna Citation III VI VIIDaniloNo ratings yet

- RFQ RFT RFP RFI - Training in Procurement Processes - Negotiation ExpertsDocument7 pagesRFQ RFT RFP RFI - Training in Procurement Processes - Negotiation Expertsdsgandhi6006No ratings yet

- Tosyali Holding-Wire RodDocument42 pagesTosyali Holding-Wire Rodecaph244No ratings yet

- CimtasDocument26 pagesCimtasvolcanox12No ratings yet

- User's Manual and Construction Requirements For WareHouses in Industrial Cities PDFDocument147 pagesUser's Manual and Construction Requirements For WareHouses in Industrial Cities PDFBendis BendisNo ratings yet

- Acrp RPT 017v2 PDFDocument123 pagesAcrp RPT 017v2 PDFPeter AkweteyNo ratings yet

- Michigan Driving Automatic Failures List For Driving TestDocument0 pagesMichigan Driving Automatic Failures List For Driving TestSrinivas ChinnamNo ratings yet

- Chapter 2 Highway Functional Classification 1Document14 pagesChapter 2 Highway Functional Classification 1Tewodros Abate100% (3)

- BarillaDocument22 pagesBarillaWeiwei ShaoNo ratings yet

- Quality Procurement ClausesDocument6 pagesQuality Procurement Clausesprasad_kcpNo ratings yet

- STD Spec SHP Field PNTG PDFDocument5 pagesSTD Spec SHP Field PNTG PDFBoby ThomasNo ratings yet

- Engineering Consulting Guidelines For Highway, Bridge 2002Document368 pagesEngineering Consulting Guidelines For Highway, Bridge 2002Carl Williams50% (2)

- Loake Catalogue 2015Document17 pagesLoake Catalogue 2015martin9947No ratings yet

- (Brochure) Wirtgen Complete ProductDocument20 pages(Brochure) Wirtgen Complete Productogreenmood28No ratings yet

- Metallurgical Plant Design and LayoutDocument15 pagesMetallurgical Plant Design and LayoutMeschac-Bill Kime100% (2)

- TEA Pamphlet 55-22 Lifting Handbook For Marine MovementsDocument121 pagesTEA Pamphlet 55-22 Lifting Handbook For Marine Movementsdieudecafe100% (2)

- Building A Business by Building Buildings by The Vatican Empire Nino Lo BelloDocument17 pagesBuilding A Business by Building Buildings by The Vatican Empire Nino Lo Bellovanveen1967No ratings yet

- Port Shipping Warehouse Business Develop Etc1Document9 pagesPort Shipping Warehouse Business Develop Etc1Subhankar MahapatraNo ratings yet

- Stevenson 4ce PPT - Ch12Document78 pagesStevenson 4ce PPT - Ch12tgrand21100% (1)

- Minimum Fire Sprinkler Design CriteriaDocument14 pagesMinimum Fire Sprinkler Design Criteriajun005100% (3)

- Astm B673Document3 pagesAstm B673Alexandre FreitasNo ratings yet

- Lufthansa CargoDocument10 pagesLufthansa CargoLucas GädekeNo ratings yet