Professional Documents

Culture Documents

Transmissão Voith Retarder 115 E 147 Pag.

Uploaded by

Carlos Lao100%(6)100% found this document useful (6 votes)

4K views147 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(6)100% found this document useful (6 votes)

4K views147 pagesTransmissão Voith Retarder 115 E 147 Pag.

Uploaded by

Carlos LaoCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 147

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

Aftersales Service Manual

Voith Retarder 115 E

Table of Content

Table of Content

Page 2

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

1. Preface.................................................................................. 4

2. General ................................................................................. 9

2.1 Assembly Overview ....................................................................................10

2.2 Retarder Data Plate ....................................................................................12

2.3 Data Plate of Retarder-Control Unit ............................................................13

2.4 Function- and Operation Scheme...............................................................15

3. Maintenance ....................................................................... 19

3.1 Maintenance Work / Oil Change Intervals ..................................................20

3.2 Inspection of Oil Level.................................................................................23

3.3 Oil Change..................................................................................................26

4. Diagnosis / Troubleshooting ............................................... 32

4.1 Electrical Connections Diagram..................................................................33

4.2 Overview of Control Parts...........................................................................37

4.3 Troubleshooting Diagram............................................................................38

4.4 Troubleshooting and Remedies..................................................................41

4.5 Checking Supply-Air Pressure (p

v

) .............................................................77

4.6 Checking Constant-Air Pressure (p

y

) and Pump Pressure (p

dyn

) ...............78

4.7 Checking Control Current of Proportional Valve.........................................86

4.8 Checking Pressure Sensor .........................................................................88

4.9 Checking Temperature Adaption ................................................................90

4.10 Table of Measurements ..............................................................................93

Table of Content

Table of Content

Page 3

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

5. Removing, Installing Retarder............................................. 99

6. Repair Retarder ................................................................ 110

6.1 Overall Illustration of Main Components ...................................................111

6.2 Removing, Checking and Installing Casing Ventlation .............................112

6.3 Removing, Cleaning and Installing Silencer .............................................122

6.4 Removing and Installing Water Neck........................................................123

6.5 Removing, Checking, Installing Heat Exchanger......................................124

6.6 Removing, Installing Oil Tank Cover.........................................................133

6.7 Removing, Installing Non-Return Valve Outlet .........................................136

7. Control Parts..................................................................... 139

7.1 Removing, Installing Proportional Valve and Damping Plate....................140

7.2 Removing, Installing Temperature Sensor Cooling Water........................141

7.3 Removing, Installing Temperature Sensor Oil ..........................................142

7.4 Removing, Installing Pressure Sensor......................................................143

8. Appendix........................................................................... 144

8.1 Retarder Data Sheet .................................................................................145

8.2 Tightening Torques...................................................................................146

Preface

Preface

Page 4

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 03-01

1. Preface

This Aftersales Service Manual provides information and instructions on maintenance and repair

of the Voith Retarder 115 E. These instructions present the basis for performing appropriate and

expert maintenance and repair.

It is indispensable that you observe the safety instructions and warning notes in this manual.

Nevertheless, the user is obliged to exercise pertinent and professional care when handling

machines, aggregates and hot media such as for example oil or water.

Attention!

... points out safety instructions and warning notes where persons are endangered, quality of work-

manship is reduced or property damage may occur.

Notice

... points out information on improved handling of work at the retarder.

Preface

Preface

Page 5

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 03-01

Attention!

Maintenance and repair work may only be carried out by accordingly qualified personnel.

Make sure that the retarder is fully functional during all vehicle manoeuvres!

Non-observance may inflict damages to the retarder!

When towing the vehicle, the following restrictions apply for the retarder:

- tow distance: up to 100 km

- towing speed: max 40 km/h.

The activated retarded may not be used as parking brake!

During failure of the retarder, or while temperature adaptation is active, use the service brake to

slow down the vehicle and switch into the lowest possible gear (target: high engine speed). This

vehicle state must be maintained until the retarder resumes full operation.

Unauthorized changes to the retarder, the use of spare parts, accessories, attachments and spe-

cial features not tested and released by Voith may negatively affect the security of the entire ve-

hicle. Voith does not assume any liability for damages arising as a result.

Preface

Preface

Page 6

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 03-01

Attention!

The retarder is constructed according to the state of the art in technology and acknowledged

safety regulations. Nevertheless, hazardous situations and property damages may occur during

improper use, maintenance and repair.

Therefore, Voith is not capable of warning the user in this Aftersales Service Manual about any

situation conceivable in which he may suffer injuries and/or cause damage to the retarder. As a

consequence, it is indispensable that any person engaged in operation, servicing, maintenance

and repair of the retarder does not endanger his or her personal safety with the work and that

the retarder is not affected adversely, particularly with regard to the safety regulations.

Voith assumes no liability for personal and/or property damage caused by improper and

unprofessional work.

Absolute cleanliness is essential during all stages of the work process. The presence of dirt due

to improper handling may cause considerable material damages or malfunctions.

Be careful when handling hot media! Risk of burning and scalding!

Preface

Preface

Seite 7

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 03-01

Notice

The item numbers used in this documentation are the same as the item numbers in the spare

parts lists.

Exception:

Items and components with one- or two-digit item numbers are no spare parts and therefore are

not included in the spare parts lists.

Also items and components with dash numbers are no spare parts and therefore not included in

the spare parts lists.

The relevant regulations for prevention of accidents, other generally acknowledged safety

regulations and occupational health rules as well as the Motor Vehicle Regulations must be

observed. Voith assumes no liability for damages resulting from non-observance of these

regulations.

When handling oil, grease and other chemical substances, the pertinent safety regulations for

these products must be heeded!

For the sake of environmental protection, drained fuels and fluids must be disposed of according

to the relevant statutory regulations.

Information on the safe, technically correct and economical operation of the Voith Retarder 115

E are given in the operating instructions.

The valves and the pressure sensor of the retarder must be protected from the direct jet of a high-

pressure cleaner (steam-jet device).

When troubleshooting, do not replace parts on mere speculation. Warranty or goodwill service

will only be rendered if there is proof that the parts in question are really defective.

Preface

Preface

Seite 8

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 03-01

If you have any questions or if you are uncertain about work steps, which are not described in this

documentation, please ask your contact person responsible for your country or contact:

Voith Turbo GmbH & Co. KG

Department Retarder

PO box 1555

D-74555 Crailsheim

Phone: ++49 +7951 / 32-0

Fax: ++49 +7951 / 32-756

E-mail: service-retarder@voith.com

Direct dials:

Customer service line and spare parts:

32-401

32-422

32-1860

General

General

Page 9

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

2. General

2.1 Assembly Overview ....................................................................................10

2.2 Retarder Data Plate ....................................................................................12

2.3 Data Plate of Retarder-Control Unit ............................................................13

2.4 Function- and Operation Scheme...............................................................15

General Assembly Overview

Page 10

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

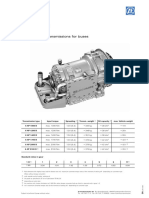

General Assembly Overview

Illustration: Voith Retarder R115 E

2.1 Assembly Overview

Basic Group with Heat Exchanger

4100

100

6400

3700

11001

100 Retarder housing

3700 Proportional valve

4100 Oil filler plug

M 30 x 1,5

6400 Heat exchanger

General Assembly Overview

Page 11

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

General Assembly Overview

Basic Group with Heat Exchanger

Illustration: Voith Retarder 115 E

11002

103

107

4200

3700

6400

3500

5500/1

103 Screw plug

M 12 x 1,5

107 Oil drain plug

M 24 x 1,5

3500 Screw plug with sieve

M 30 x 1,5

3700 Proportional valve

4200 Oil drain plug

M 24 x 1,5

5500/1 Ventilation

6400 Heat exchanger

General Retarder Data Plate

Page 12

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

General Retarder Data Plate

Illustration: Retarder Data Plate

2.2 Retarder Data Plate

The data plate is mounted on the left below of

the retarder housing in right direction of tra-

velling.

The following details are on the data plate:

a

d

e f

b

Voith-item-No

c

Type R 115 E

11003e

Serial No

Year of Man.

Cust. item No

Kd.-Sach-Nr.

Voith-Sach-Nr.

a) Type of Retarder

b) Serial number

6-digit number

c) Year of manufacturing

d) Retarder ratio (i

Ret

)

e) Customer-item number

f) Voith-item number

8-digit number

Notice

Please, always quote the retarder data when

submitting queries or ordering spare parts.

In this case a quick and working is possible.

General Data Plate of Retarder-Control

Page 13

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

General Data Plate of Retarder-Control

Illustration: Data Plate of Retarder Control Unit Digiprop

2.3 Data Plate of Retarder-Control

Unit Digiprop

The data plate of the Digiprop-control unit

is mounted on the control unit and

contains following information:

B

a

s

is

-N

r.:

5

3

.x

x

x

x

.1

2

C

o

d

e

-N

r.:

x

x

x

S

e

rie

n

-N

r.:

x

x

x

x

/

V

O

IT

H

Basic-No.:

Code-No.:

Serial-No.:

VOITH

11004e

1. Basic-number

8-digit number

The last t wo digits show the

soft ware version.

Example: .12 = version 1.2

2. Code-number

3-digit number

(Adjusting of control unit)

3. Serial-number

5-digit number

with date of coding

4. Voith precast unit number as

well as customer number, if ne-

cessary

Notice

Please, always quote the retarder data and

retarder control unit data when submitting

queries or ordering spare parts.

In this case a quick and working is possible.

General Data Plate of Retarder-Control

General Data Plate of Retarder-Control

Page 14

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

Illustration: Data Plate of Retarder Control Unit VERA

Data Plate of Retarder-Control

Unit VERA

The data plate of the VERA-control unit is moun-

ted on the control unit and contains following

information:

Retarder Control Unit VE RA.STD

Serial-No. XXXX / 2002-08-01

Part-No. 67.2763.20

OEM-No.

V

O

I

T

H

T

U

R

B

O

X1 X2 X3

e

1

*

7

2

/

2

4

5

*

9

5

/

5

4

*

2

0

8

4

*

0

0

R

e

ta

r

d

e

r

C

o

n

tr

o

l

U

n

it V

E

R

A

.S

T

D

S

e

r

ia

l-N

o

. X

X

X

X

/

2

0

0

2

-0

8

-0

1

P

a

r

t-N

o

.

6

7

.2

7

6

3

.2

0

O

E

M

-N

o

.

V

O

I T

H

T

U

R

B

O

X

1

X

2

X

3

e

1

* 7

2

/ 2

4

5

* 9

5

/ 5

4

* 2

0

8

4

* 0

0

11005

1. Serial-number

4-digit number / date

2. Spare-part-number

8-digit number

3. OEM-number

Notice

Please, always quote the retarder data and

retarder control unit data when submitting

queries or ordering spare parts.

In this case a quick and working is possible.

General Function- and Operation Scheme

General - Function- and Operation Scheme

Page 15

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

2.4 Function- and Operation Scheme

Illustration: Functional Drawing Retarder 115 E Digiprop

Notice

Example of application hand control Digiprop. Further OEM-specific versions are possible.

The given position numbers aren't identical with the position numbers of the spare part lists.

1 Heat exchanger complete 41 Filling duct

1/1 Retarder-oil cooling circuit 42 Oil tank

1/2 Gearbox-oil cooling circuit 43 Oil sump

19 Temperature sensor cooling water 44 Stator

20 Temperature sensor oil 46 Rotor

21 Proportional valve 55 Oil drain plugs

22 Ventilation 62 Pressure regulating valve

23 Casing ventilation 63 Non-return valve (inlet)

25 Air-pressure line A constant-air pressure (p

y

) 64 Non-return valve (outlet)

26 Air-pressure line supply-air pressure (p

v

) 72 Pressure sensor (OEM-specific)

36 Exhaust line R

25

26

23

36

1

19

63

20

43

46

22

44

62

55

64

A R

21

42

Oil sump

Supply-air pressure p

Constant-air pressure p

y

Coolant (water)

11006e

Pump pressure p

P

41

1/1 1/2

72

Vehicle

electronic

v

General Function- and Operation Scheme

General Function- and Operation Scheme

Page 16

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

Functional Description

The Voith Retarder 115 E is a powerful, hydrodynamic continous brake of compact design.

The retarder is driven and braking torque is transmitted by pinions in the gearbox. The transmission ratio

enables the retarder to achieve high braking torques right down to low r.p.m. ranges with the compactest

configuration (small rotor/stator).

Retarder braking torque is sustained even when gear changes are made.

Do not use the switched-on retarder as handbrake while vehicle is in still-stand!

During a failure of the retarder, or while the temperature-adaptation is effective, the vehicle-speed must

be settled by using the service-brake and the lowest possible gear.

General Function- and Operation Scheme

General Function- and Operation Scheme

Page 17

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

Temperature Sensor Cooling Water (19), Oil (20)

The temperature sensors are installed in the cooling system of the vehicle (cooling-return circle from the

retarder to the the heat exchanger) and in the retarder oil duct and transmit signals on cooling water and

oil temperature to the control unit (2).To prevent the temperatures preset in the control unit (2) for water

and oil being exceeded, the retarder braking torque is adapted to protect the vehicle cooling system and

the retarder.

The braking torque and consequently the heat generated are reduced until a balance is obtained between

the braking energy of the retarder and the amount of heat which can be dissipated by the vehicle cooling

system.

If the cooling water temperature rises into the temperature adaption range, the consequence is an adap-

tion of the retarder braking torque to protect the vehicle cooling system. If the temperature rises above

the temperature adaption range, there is no more braking torque output.

While the temperature adaption is effective or if there is a retarder failure, the service brake must be used

to control the vehicle.

Additionally the control unit cuts back braking torque if oil temperature rises too rapidly - irrespective of

actual oil temperature.

Pressure regulating valve (62)

The pressure regulating valve (62) adjusts the lubrication in the no-load operation of the retarder.

General Function- and Operation Scheme

General Function- and Operation Scheme

Page 18

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

Pressure sensor (72)

The pressure sensor (72) observes the pneumatic constant-air pressure. At deviation of the permissible

pressure tolerance an error is stored from the control unit displayed in the vehicle display in dependence

of the OEM equipment.

Casing ventilation (23)

During braking, the oil displaces the air present in the working circuit via the casing ventilation (23) and

the ventilation system (22) out of the retarder.

Once the working circuit is free of air, a float rises and closes the casing ventilation.

Non-return valve (63) inlet

When the retarder is switched on, the oil sump is pressurized, causing the check valve (63) to open and

the oil to enter the working space.

Non-return valve (64) outlet

The oil pressure in the working space opens the check valve (64), causing the oil to enter the heat

exchanger (1), to be cooled and to be returned to the working circuit.

Proportional valve (21)

Depending on the size of the electrical input signal a pneumatic constant-air pressure gets controlled from

the proportional valve to the oil tank of the retarder.

Maintenance

Maintenance

Page 19

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

3. Maintenance

3.1 Maintenance Work / Oil Change Intervals ..................................................20

3.2 Inspection of Oil Level.................................................................................23

3.3 Oil Change..................................................................................................26

Maintenance Maintenance Work / Oil Change Intervals

Maintenance Maintenance Work / Oil Change Intervals

Page 20

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

3.1 Maintenance Work / Oil Change Intervals

Maintenance work

At each oil change:

- Clean sieve of pressure regulating valve

- Check fastening screws of the retarder heat exchanger

- Check all screw plugs on leak and correct fitment

- Carry out visual inspection on possible leak and existing damages

Please note the following data into the service overview of the Operation Manual

Gearbox-Retarder-System / GO170 - GO210 with R 115 E :

- maintenance work been carried out

- the oil grade used for the oil change

Maintenance Maintenance Work / Oil Change Intervals

Maintenance Maintenance Work / Oil Change Intervals

Page 21

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

Oil change intervals, operating specification

1) according operating specification

2) carry out change oil at the latest after 1 year, if fewer kilometres are travelled

3) carry out change oil at the latest after 2 year, if fewer kilometres are travelled

Please take into account the oil recommendation list (Voith code number 67.2246.11).

Single grade-mineral oil

1)

Synth. / part synth. oil

1)

Synthetic oil

1)

Normal duty 135.000 km

2)

180.000 km

3)

300.000 km

3)

Heavy duty 60.000 km

2)

90.000 km

3)

300.000 km

3)

Classification let-

ter

to DIN 51502

HD HC HC

Class of viscosity

to DIN 51511

SAE 10W

SAE 20W20

SAE 30

SAE 0W40

SAE 5W30

SAE 5W40

SAE 5W50

SAE 10W30

SAE 10W40

SAE 75W80

Performance

category

API - CC/SF

and higher

API - CC/SF

and higher

Emgard

MTF,Henkel

Maintenance Maintenance Work / Oil Change Intervals

Maintenance Maintenance Work / Oil Change Intervals

Page 22

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

1. Normal duty

Example:

Long distance traffic

2. Heavy duty

Subject to more than normal stress.

Examples:

Use in regions with high ambient temperature (e.g. Saudi-Arabia)

High max. permissible weight with low rated engine power (< 6 kW / metric ton)

Streches with lots of hills and valleys

Extreme short-distance traffic with lots of gradients

The given maximum specified figures can be lowered, if overall maintenance cycles for the vehicle are

improved.

With a total-life of the retarder of more than 10%, covered on the vehicle-performance, as well as other

factors not mentioned here also affect the ageing of the oil, it may be necessary to shorten the intervals

between oil changes in individual cases.

For use in extremely cold zones, oils in an appropriately lower viscosity class must be used.

In doubts please contact our customer service.

Maintenance Inspection of Oil Level

Maintenance Inspection of Oil Level

Page 23

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

3.2 Inspection of Oil Level

Notice

For satisfactory retarder operation it is important to adhere to the specified service filling of 7,0 litres and

to use only oils specified in the operating specifications for operating the retarder in the relevant applica-

tion.

The oil level check must be carried out with the vehicle in a horizontal position.

For the inspection of oil level, temperature of retarder oil must have reached the operating temperature.

Caution!

Two version of the screw plugs (107, 4100, 4200) are possible:

A) Version with integrated FPM-sealing ring; these corresponds the standard version at the time going to

print.

The integrated sealing rings must be checked for possible damages during the inspection of oil level;

replace completely if necessary.

B) Version with loose inserted copper-sealing ring.

In this Aftersales Workshop Manual is excluding the variant A (series version) described.

If screw plugs with loose inserted copper-sealing rings (variant B) are used, the tightening torques in

brackets are valid.

The copper-sealing rings have to be renewed in general.

Maintenance Inspection of Oil Level

Maintenance Inspection of Oil Level

Page 24

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

Work scope

1. Push a clean vessel under retarder.

2. Screw out oil drain plugs and drain oil in clean vessel.

3. Check sealing rings of oil drain plugs for damages, renew oil drain plugs if necessary.

4. Screw in oil drain plugs and screw them tight.

Tightening torque oil drain plugs (107, 4200): 47 Nm (80 Nm)

5. Measure drained oil.

6. Top up any lacking oil according to the operating specifications, page 29.

4200

107

11007

107 Oil drain plug M 24 x 1,5

Inhex-head w.a.f. 12,

47 Nm (80 Nm)

4200 Oil drain plug M 24 x 1,5

Inhex.head w.a.f. 12,

47 Nm (80 Nm)

Caution! Risk of injury!

The oil drain plugs (107, 4200) and oil filler plug (4100) are hot (oil temperature)!

The retarder must be switched-off during the inspection of oil level!

If the retarder is switched-on during working step 2 and screwed out oil drain plugs and/or oil filler plug,

high risk of injury exist by hot leaving oil (increased pressure)!

Maintenance Inspection of Oil Level

Maintenance Inspection of Oil Level

Page 25

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

7. Fill in slowly over a time period longer than 3 minutes the quantity of oil specified, in the bore of the

oil filler plug (4100).

8. Check sealing ring of oil filler plug for possible damages, renew oil filler plug if necessary.

9. Screw in oil filler plug and screw it tight.

Tightening torque oil filler plug (4100): 100 Nm (100 Nm)

10. Operate the retarder after the oil change only during the drive at a speed of at least 50 km/h 5 times

for respectively approx. 5 seconds in position 2 at the retarder stage switch or brake stage 1.

Take the OEM specific using variants into account to this.

The vehicle must not go slower than 20 km/h at this.

Caution!

The retarder must only be filled with oil via the bore of the oil filler plug (4100)!

Notice

With determined lacking oil quantity check retarder for possible outer leak.

Hinweis

The following work step is required to the correct ventilation of the retarder system.

Nonobservance can cause oil leak via the ventilation.

If available, the foot control of the retarder must be switched off and switched on first after the described

work process again.

Maintenance Oil Change

Maintenance Oil Change

Page 26

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

3.3 Oil Change

Notice

The gearbox- and retarder oil tanks are seperated from each other at the gearbox-retarder-system. Both

oil circuits are cooled down independently in a 3-chamber steel heat exchanger of the retarder

- without limited compromizes.

For satisfacory retarder operation, it is important to adhere to the specified service filling (see table

page 29) and to use only oils specified in the operating specifications page 21 for operating the retarder

in the relevant application.

For draining the oil the temperature of the retarder oil must have reached the operating temperature.

Ensure that during the entire oil change no constant-air pressure acts on the retarder, that means the

retarder must be switched off!

Maintenance Oil Change

Maintenance Oil Change

Page 27

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

Attention!

Two versions of screw plugs (107, 3500, 4100, 4200) are possible:

A) Version with integrated FPM-sealing ring; these corresponds the standard version at the time going to

print.

The integrated sealing rings must be checked for possible damages during the inspection of oil level;

replace completely if necessary.

B) Version with loose inserted copper-sealing ring.

In this Aftersales Workshop Manual is excluding the variant A (series version) described.

If screw plugs with loose inserted copper-sealing rings (variant B) are used, the tightening torques in

brackets are valid.

The copper-sealing rings have to be renewed in general.

Maintenance Oil Change

Page 28

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

Maintenance Oil Change

Illustration: Oil change Retarder R 115 E

Lubricants and cleaning agents

3500

4100

4200 4200

107

11008

Kd.-Sach-Nr.

Voith-Sach-Nr.

107 Oil drain plug

M 24 x 1,5

Inhex-head w.a.f. 12

47 Nm (80 Nm)

3500 Screw plug with sieve

M 30 x 1,5

Inhex-head w.a.f. 17

100 Nm (100 Nm)

Clean sieve with appropriate

cleaning agent and blow out with

compressed-air

4100 Oil filler plug

M 30 x 1,5

Inhex-head w.a.f. 17

100 Nm (100 Nm)

4200 Oil drain plug oil tank

M24x1,5

Inhex-head w.a.f. 12

47 Nm (80 Nm)

Sieve in screw plug Benzine

Maintenance Oil Change

Maintenance Oil Change

Page 29

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

Work scope

1. Push an oil collecting pan under the retarder.

2. Screw out the oil drain plugs (107 and 4200) and drain the oil.

3. Check integrated sealing rings of oil drain plugs on possible damages,

renew oil drain plugs if necessary.

4. Screw in the oil drain plugs tight.

Tightening torque oil drain plugs (107, 4200): 47 Nm (80 Nm)

Oil filling with heat exchanger

Service filling (oil change, inspection of oil level) 7,0 l

After exchange of heat exchanger 7,5 l

Attention! Risk of injury!

The oil drain plugs (107, 4200) are hot! Oil temperature!

4200

107

4200

11009

Maintenance Oil Change

Maintenance Oil Change

Page 30

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

5. Screw screw plug with sieve (3500) out of the retarder.

6. Clean sieve in screw plug with appropriate cleaning agent (Benzine) and blow it out with

compressed-air.

7. Check integrated sealing ring of screw plug with sieve on possible damages,

renew screw plug if necessary.

8. Screw in screw plug with sieve hand-tight then tighten it.

Tightening torque screw plug (3500): 100 Nm (100 Nm)

9. Screw out oil filler plug (4100).

10. Fill in slowly over a time period longer than 3 minutes the quantity of oil, via the bore of the oil filler

plug, specified in accordance to the service filling (see table page 29).

This work step is required to the correct ventilation of the retarder system.

3500

11010

Kd.-Sach-Nr.

Voith-Sach-Nr.

4100

11011

Attention!

The retarder must only be filled with oil via the bore of the oil filler plug (4100)!

Maintenance Oil Change

Maintenance Oil Change

Page 31

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

11. Check integrated sealing ring of oil filler plug on possible damages, renew oil filler plug if necessary.

12. Fit oil filler plug and screw it tight.

Tightening torque oil filler plug (4100): 100 Nm (100 Nm)

13. Operate the retarder after the oil change only during the drive at a speed of at least 50 km/h 5 times

for respectively approx. 5 seconds in position 2 at the retarder stage switch or brake stage 1.

Take the OEM specific using variants into account to this.

The vehicle must not go slower than 20 km/h at this.

Achtung!

The following work step is required to the correct ventilation of the retarder system.

Nonobservance can cause oil leak via the ventilation.

If available, the foot control of the retarder must be switched off and switched on first after the described

work process again.

Diagnosis / Troubleshooting

Diagnosis / Troubleshooting

Page 32

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

4. Diagnosis / Troubleshooting

4.1 Electrical Connections Diagram..................................................................33

4.2 Overview of Control Parts...........................................................................37

4.3 Troubleshooting Diagram............................................................................38

4.4 Troubleshooting and Remedies..................................................................41

4.5 Checking Supply-Air Pressure (p

v

) .............................................................77

4.6 Checking Constant-Air Pressure (p

y

) and Pump Pressure (p

dyn

) ...............78

4.7 Checking Control Current of Proportional Valve.........................................86

4.8 Checking Pressure Sensor .........................................................................88

4.9 Checking Temperature Adaption ................................................................90

4.10 Table of Measurements ..............................................................................93

Diagnosis / Troubleshooting Elektrical Connections Diagram

Page 33

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

Diagnosis / Troubleshooting Elektrical Connections Diagram

4.1 Elektrical Connections

Diagram

(Voith-Wiringharness Digiprop without

CAN)

18

70 47 15 21

-

- +

+

+ -

19 20

17

4

16

69

4

2

X1

X2 X3

8 9 4 5 6 1 3 2 3 2 1 6 5 4 9 7 12 10 11 8

14

8

7

8

7

a

3

0

13 11 12 10 1 9 5 8 4 3 2 7 6

18 17 16 6 5 4 8 9 10 11 12 13 14 15 7

4

3 2 1 4

8 3 2 5 6 7

3 1 2

7

11012

1 2 4

.

.

.

.

P

U 72

2 Control unit

4 Connection terminal 15

15 ABS-signal

16 Retarder stage switch

17 Retarder pilot light

18 Brake light relay

19 Temperature sensor

cooling water

20 Temperature sensor oil

21 Proportional valve

47 Speedometer signal

69 Plug ISO-interface

70 Plug optional function

72 Pressure sensor

(OEM-specific)

Diagnosis / Troubleshooting Elektrical Connections Diagram

Page 34

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

Diagnosis / Troubleshooting Elektrical Connections Diagram

Digiprop with CAN

21

- - + + + -

19 20

17

4

16

4

2

X1

X2 X3

8 9 4 5 6 1 3 2 3 2 1 6 5 4 9 7 12 10 11 8

18 17 16 6 5 4 8 9 10 11 12 13 14 15 7 3 1 2

7

1 2 4

.

P

U 72

CAN

11013

2 Control unit

4 Connection terminal 15

16 Retarder stage switch

17 Retarder pilot light

19 Temperature sensor

cooling water

20 Temperature sensor oil

21 Proportional valve

72 Pressure sensor

(OEM-specific)

Diagnosis / Troubleshooting Elektrical Connections Diagram

Page 35

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

Diagnosis / Troubleshooting Elektrical Connections Diagram

VERA general

11014

47

4

2

X1

X2 X3

8 9 4 5 6 1 3 2 3 2 1 6 5 4 9 7 12 10 11 8

18

8

7

8

7

a

3

0

21

18 17 16 6 5 4 8 9 10 11 12 13 14 15 7 3 1 2

7

- +

19

+ -

20

1 2 4

P

U 72

17

4

.

CAN

80

- + - +

16 15

83

82 81

2 Control unit

4 Connection terminal 15

15 ABS-signal

16 Retarder stage switch

17 Retarder pilot light

18 Brake light relais

19 Temperature sensor

cooling water

20 Temperature sensor oil

21 Proportional valve

47 Speedometer signal

72 Pressure sensor

(OEM-specific)

80 On/off valve

81 Input (3 times)

82 Output (3 times)

83 ISO-diagnosis

Diagnosis / Troubleshooting Elektrical Connections Diagram

Page 36

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

Diagnosis / Troubleshooting Elektrical Connections Diagram

VERA DAFBUS

11015

4

2

X1

X2 X3

8 9 4 5 6 1 3 2 3 2 1 6 5 4 9 7 12 10 11 8

18

8

7

8

7

a

3

0

21

18 17 16 6 5 4 8 9 10 11 12 13 14 15 7 3 1 2

7

- +

19

+ -

20

1 2 4

P

U

72

93

CAN

- +

90

94

16

92

91

4

.

96

95

2 Control unit

4 Connection terminal 15

16 Retarder stage switch

18 Brake light relais

19 Temperature sensor

cooling water

20 Temperature sensor oil

21 Proportional valve

72 Pressure sensor

(OEM-specific)

90 Fan relais

91 Brake valve

92 Diagnosis K-Lead

93 Fault light

94 Operating light

95 Foot Off/On

96 Indication light

Diagnosis / Troubleshooting Overview of Control Parts

Page 37

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

Diagnosis / Troubleshooting Overview of Control Parts

4.2 Overview of Control Parts

71

32

33

31

34 35

40

61

11016

39

19

1

20

2

21

26

72

P

36

11

25 A

R

Notice

The given position-numbers are not identical

with position-numbers of spare parts lists.

1 Heat exchanger

2 Control unit (e.g. Digiprop/

VERA)

11 Connection control current of

proportional valve

19 Temperature sensor

cooling water

20 Temperature sensor oil

21 Proportional valve

25 Compressed-air pressure line

constant-air pressure (p

y

)

26 Compressed-air pressure line

suppla-air pressure (p

v

)

31 Compressed-air pressure line

(pressure regulator - four-

circuit protection valve)

32 Compressed-air pressure line

(four-circuit protection valve -

air tank for auxiliary equip-

ment) with with test connec-

tion

33 Compressed-air pressure line

(brake circuit 1)

34 Compressed-air pressure line

(brake circuit 2)

35 Compressed-air pressure line

(parking brake)

36 Ventilation line

connection R

39 Electrical lead (temperature

sensor cooling water) to

control unit, 2 wires)

40 Electrical lead (temperature

sensor oil) to control unit,

2 wires)

61 Four-circuit protection valve

71 Air tank for auxiliary

equipment

72 Pressure sensor

(OEM-specific)

Diagnosis / Troubleshooting Troubleshooting Diagram

Diagnosis / Troubleshooting Troubleshooting Diagram

Seite 38

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

4.3 Troubleshooting Diagram

Complaint

Retarder

R 115 E

A

Retarder

Pilot Light

(Standard

version)

B

Oil leak via

ventilation

and / or non

or too low

braking

efficiency

*

* Notice:

OEM-specific is an on-board-diagnosis

possible (display).

Notice the information from the vehicle

manufacturer to it.

11017e

Diagnosis / Troubleshooting Troubleshooting Diagram

Diagnosis / Troubleshooting Troubleshooting Diagram

Page 39

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

Illustration: Complaint main group A

Activate

flash code

and read out

fault code *

* Retarder

Pilot L ight

(Standard

version)

A

Permanent light in

position 0 after

lamp test?

Clear fault

and

erase

fault memory *

no function?

Check pilot light

and renew,

if necessary

flashes?

Temperature

adaption

OK NOK

Check operation

(during Retarder

braking

most possible

engine

nominal speed)

Instruct driver!

OK NOK

Check

temp.-sensors

(oil / water)

(page 90 ff)

Replace

temp.-sensos

(page 141, 142)

Check vehicle

cooling system:

- coolant level

- Thermostat

- Coolant pump

- Radiator fan

- Radiator on

pollution

11018e

Check

fuse

ABS or

idle switch

active?

* OE M-specific is an on-board-diagnosis

possible (display).

Notice the information from the vehicle

manufacturer to it.

* Notice the information of the

vehicle manufacturer

Diagnosis / Troubleshooting Troubleshooting Diagram

Diagnosis / Troubleshooting Troubleshooting Diagram

Seite 40

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

Prior work

Check retarder system on outer leaks (apart from ventilation)

Check whether running in instruction was carried out after oil change, carry out if necessary

Illustration: Complaint main group B

11019e

Check retarder

oil level

(page 23 ff)

OK NOK

Yes No

Water in oil

(emulsion)

(page 124 ff)

Check

heat exchanger

Correct

retarder oil level

OK NOK

NOK OK

Check p (dynam.)

and py (statisch)

(page 78 ff)

For examination the retarder

oil level must be correct!

NOK OK

Check temperature

adaption or

temp.-sensors (oil/water)

and pressure sensor or

leads

(page 88 ff)

OK NOK

Check

gearbox oil level

check p (static)

(page 78 ff)

y

Replace

temperature sensors

or leads

(page 141, 142)

Consultation

Voith

B

Check

retarder oil level

too

low

too

high

NOK OK

Check

gear box oil level

Check

gear box oil level

too

high

too

low

Correct

retarder- and

gearbox oil level

Check

gearbox oil level

too

high

too

low

Correct

retarder- and

gearbox oil level

Yes No

Outer Leak

(apart ventilation)

Repair

Retarder

Correct

retarder- and

gearbox oil level

If problem occours again:

Consultation Voith

OK NOK

Check

gearbox ventilation

Correct retarder-

and gearbox

oil level

If problem occours again:

Consultation Voith

For examination the retarder

oil level must be correct!

At complaint "non or

too low braking

efficiency":

Consultation Voith

At complaint

"Oil leak via

ventilation":

continue with

checking casing

ventilation

NOK OK

Check vehicle

compressed-air

system

NOK OK

Check supply-

air pressure

(page 77)

Proportional valve or

damping plate

mechanically defect

NOK OK

Check

casing ventilation

(page 112 ff)

OK NOK

Replace

casing ventilation

(page 112 ff)

p (dynamic)

NOK

p (static)

NOK

y

Check

proportional valve

(page 86 ff)

NOK OK

Replace

proportinal valve

(page 140)

If problem occours again:

Consultation Voith

No Yes

Outlet valve

.11 and higher?

Replace

outlet valve

(page 136 ff)

If problem occours again:

Replace

proportional valve.

Contact

vehicle

manufacturer

Compressed-air pressure

line to prop. valve

interrupted or

leaking

Oil leak via ventilation

and / or non or

too low

brake efficiency

Check control

current of prop.

valve as well as

leads und

plug connections

(page 86 ff)

Repair gearbox

ventilation;

correct retarder- and

gearbox oil level

Diagnosis / Troubleshooting Troubleshooting and remedies

Diagnosis / Troubleshooting Troubleshooting and remedies

Page 41

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

4.4 Troubleshooting and remedies

Requirements for check

Battery voltage 18 - 32 V

Vehicle electrical system checked in accordance with the Owners Manual for the vehicle and found

satisfactory.

Fuse for retarder control unit checked and found satisfactory.

Compressed-air pressure 6 - 11 bar

Version Digiprop with and without CAN:

for check with multimeter must be at the control unit

pin 15 (plug X1) Ground (terminal 31),

at pin 7 and pin 13 (plug X1) must be connected terminal 15

Version VERA:

for check with multimeter must be at the control unit

pin 14 (plug X1) Ground (terminal 31),

at pin 7 (plug X1) must be connected terminal 15

Note

Prior to any troubleshooting, the retarder oil level must be checked and corrected, if necessary

(see page 29).

Diagnosis / Troubleshooting Troubleshooting and remedies

Diagnosis / Troubleshooting Troubleshooting and remedies

Page 42

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

Note

The retarder pilot light additionally has the function of a fault code. An on-board-diagnosis (display) is

OEM-specific possible. Heed herefore the statements of the vehicle manufacturer:

slight fault

Permanent light in position 0 - 5 of retarder stage switch, braking is still possible to limited

extent.

serious fault

Permanent light in position 0 - 5 of retarder stage switch,, braking is no longer possible -

the retarder is switched off.

Note

If ignition is switched off and on, the retarder is in operation again and the retarder pilot light goes off.

If a serious fault remains present or reoccurs, the retarder switches off again and the retarder pilot light

comes on permanently in position 0 to 5 of the retarder stage switch.

Diagnosis / Troubleshooting Troubleshooting and remedies

Diagnosis / Troubleshooting Troubleshooting and remedies

Page 43

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

Connector arrangement and pin assignment

Plug X1 control unit (Digiprop)

Note

All plugs illustrated from plug-in side (i.e. leads at back).

11020

1 4 7 10 13 16

2 5 8 11 14 17

3 6 9 12 15 18

1 Not in use or CAN-LOW

2 Not in use or CAN-GROUND

3 Not in use or CAN-HIGH

4 Retarder stage switch, Position 3

5 Retarder stage switch, Position 2

6 Retarder stage switch, Position 1

7 Terminal 15

8 Retarder stage switch, Position 5

9 Retarder stage switch, Position 4

10 Retarder stage switch +

11 ISO-interface, L-lead

12 ISO-interface, K-lead

13 Connected with terminal 15

14 Not in use

15 Terminal 31

16 Output / high side 2 HS2

17 Not in use

18 Output / high side 1 HS1

Diagnosis / Troubleshooting Troubleshooting and remedies

Diagnosis / Troubleshooting Troubleshooting and remedies

Page 44

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

Plug X2 control unit (Digiprop)

Plug X3 control unit (Digiprop)

11021

1 4 7

2 5 8

3 6 9

1 Not operational

2 Proportional valve -

3 Proportional valve +

4 Cooling-water temperature-sensor -

5 Cooling-water temperature-sensor +

6 Not operational

7 Not in use

8 Oil-temperature sensor -

9 Oil-temperature sensor +

11022

1 4 7 10

2 5 8 11

3 6 9 12

1 Input / pull up DIU 1

2 Speedometer signal

3 ABS-signal

4 Input / pull down DID 2

5 Input / pull down DID 1

6 Pressure-sensor ground

7 Pressure-sensor signal voltage

8 Retarder pilot light

9 Input / pull down DID 3

10 Pressure-sensor supply voltage

11 Stop light relais

12 Input / pull down / PWM-in DID4

Diagnosis / Troubleshooting Troubleshooting and remedies

Diagnosis / Troubleshooting Troubleshooting and remedies

Page 45

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

Plug optional functions (cable Digiprop)

Plug ISO-interface (cable Digiprop)

2

1

4

3

6

5

8

7

10

9

12

11

14

13

11023

1 Retarder stage switch +

2 Input / pull down DID 1

3 Input / pull down DID 2

4 Input / pull down DID 3

5 Input / pull down / PWM -in DID 4

6 Input / pull up DIU 1

7 Pressure-sensor Ground

8 Pressure-sensor signal voltage

9 Pressure-sensor supply voltage

10 Output / high side HS1

11 Output / high side 2 HS2

12 Not operational

13 Terminal 15

14 Terminal 31

2 1

4 3

11024

1 K-lead

2 L-lead

3 Terminal 15

4 Terminal 31

Diagnosis / Troubleshooting Troubleshooting and remedies

Diagnosis / Troubleshooting Troubleshooting and remedies

Page 46

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

Connector arrangement and pin assignment

Plug X1 control unit (VERA)

Note

All plugs illustrated from plug-in side (i.e. leads at back).

11025

1 4 7 10 13 16

2 5 8 11 14 17

3 6 9 12 15 18

1 CAN-LOW

2 CAN-GROUND

3 CAN-HIGH

4 Retarder stage switch, Position 0

5 Retarder stage switch, Position 1

6 Retarder stage switch, Position 2

7 Terminal 15 = battery voltage

8 Retarder stage switch, Position 3

9 Retarder stage switch, Position 4

10 Retarder stage switch +

11 Speedometer signal

12 ISO-interface, K-lead

13 ABS-signal

14 Terminal 31 = Ground

15 Retarder pilot light

16 Brake light relais

17 Engine speed

18 Retarder stage switch, Position 5

Diagnosis / Troubleshooting Troubleshooting and remedies

Diagnosis / Troubleshooting Troubleshooting and remedies

Page 47

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

Plug X2 control unit (VERA)

Plug X3 control unit (VERA)

11026

1 4 7

2 5 8

3 6 9

1 Output / highside OUT 1

2 Output / highside OUT 2

3 Output / highside OUT 3

4 Input / analog IN 3

5 Input / analog IN 1

6 Not in use (boot 1)

7 Not in use (boot 2)

8 Not in use (boot 3)

9 Input / digital IN 2

11027

1 4 7 10

2 5 8 11

3 6 9 12

1 Cooling-water temperature-sensor -

2 Cooling-water temperature-sensor +

3 Proportional valve +

4 Proportional valve -

5 Oil-temperature sensor +

6 Oil-temperature sensor -

7 Pressure-sensor signal voltage

8 Pressure-sensor Ground

9 Pressure-sensor supply voltage

10 Not in use (switch valve +)

11 Not in use (switch valve -)

12 Not in use

Diagnosis / Troubleshooting Troubleshooting and remedies

Diagnosis / Troubleshooting Troubleshooting and remedies

Page 48

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

Plug cooling-water temperature pick-up

Plug oil temperature pick-up

Plug proportional valve

11028

1

2

3

4

11029

1 Proportional valve +

2 Proportional valve

3 Not in use

4 Not in use

Diagnosis / Troubleshooting Troubleshooting and remedies

Diagnosis / Troubleshooting Troubleshooting and remedies

Page 49

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

Plug retarder stage switch

11030

1 2 3 4

5 6 7 8

1 Not in use

2 Position 5

3 Position 4

4 Retarder stage switch +

5 Position 3

6 Position 2

7 Position 1

8 Bridge to pin 4

Diagnosis / Troubleshooting Troubleshooting and remedies

Diagnosis / Troubleshooting Troubleshooting and remedies

Page 50

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

A. With fault code, e.g. retarder control unit reports fault

Special tool

Service cable (only Digiprop)

Commercially available tool

Multimeter recommended: Fluke 87

Note

The fault memory can be read-out from blinking code of retarder pilot light via service-cable (53.8224.10

only Digiprop), if this function is realised.

An on-board-diagnosis (display) is OEM-specific possible. Heed herefore the statements of the vehicle

manufacturer.

53.8224.10

Diagnosis / Troubleshooting Troubleshooting and remedies

Diagnosis / Troubleshooting Troubleshooting and remedies

Page 51

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

Fault memory readout via retarder pilot light blinking code

Fault memory readout with service cable (only Digiprop)

Requirements

Retarder stage switch in position O.

Vehicle at standstill, ignition ON

1. L-lead of service interface connected to ground 2s. For this pupose, press L - pushbutton on

service cable

2. First fault as blinking code output.

3. Item 2 and 3 repeated for more blinking code outputs.

Meaning

Long blinking signals (2 sec.) tens unit.

Short blinking signals (0,5 sec.) single unit.

Note

If sveral faults have been stored in the memory, they are output in the sequence of their occurence,

but always only one fault per triggering.

Exception:

The fault Coding Fault is not held in the memory but is output via the blinking code.

The blinking code can be read-out of control unit by using the service cable (only Digiprop) or

retarder stage switch.

Diagnosis / Troubleshooting Troubleshooting and remedies

Diagnosis / Troubleshooting Troubleshooting and remedies

Page 52

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

Fault memory read out with retarder stage switch

The blinking code can be triggered with the retarder stage switch during the service function

(vehicle ignition system ON and v = 0):

1. Retarder stage switch in position 0

2. Retarder stage switch in position 1

3. Retarder stage switch in position 0

4. First fault as blinking code

5. Items from ...3 for more blinking code outputs

There is a break of 3 seconds before and after each blinking code output, during this time the retarder

pilot light is switched off.

Display example for fault code 23 (Digiprop)

E Retarder pilot light ON

A Retarder pilot light OFF

t Time

Display example for fault code 23 (Digiprop):

The number of tens units first indicated as long ON time: each 2 seconds

The number of single unit then is indicated as short ON time: each 0,5 seconds

Breaks between each ON time: each 1 second

If an actual fault occours (before triggering blinking code of retarder pilot light is switched ON) the retarder

pilot light switches to permanent light again after the blinking code.

Is there only one stored fault, the retarder pilot light is OFF after the output (only for Digiprop).

2

s

e

c

1

s

e

c

0

,

5

s

e

c

1

s

e

c

1

s

e

c

1

s

e

c

0

,

5

s

e

c

0

,

5

s

e

c

2

s

e

c

11031

Diagnosis / Troubleshooting Troubleshooting and remedies

Diagnosis / Troubleshooting Troubleshooting and remedies

Page 53

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

Display example for fault code 23 (VERA)

E Retarder pilot light ON

A Retarder pilot light OFF

t Time

Display example for fault code 20 (only for VERA):

The number of tens units first indicated as long ON time: each 2 seconds

Then blinking code goes off, no single unit in this method

Breaks between each ON time: each 1 second

2

s

e

c

1

s

e

c

2

s

e

c

11032

Diagnosis / Troubleshooting Troubleshooting and remedies

Diagnosis / Troubleshooting Troubleshooting and remedies

Page 54

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

Delete fault memory (only for Digiprop)

No marginal notes in accordance with fault memory read out.

1. Vehicle ignition system: OFF

2. Servcie interface L-lead connected to ground. For this purpose, press L-pushbutton of

service cable.

3. Vehicle ignition system: ON

4. Release L-lead from ground after 2 sec.

Delete fault memory (only for VERA)

It is only possible to delete fault memory via WinDia.

Diagnosis / Troubleshooting Troubleshooting and remedies

Diagnosis / Troubleshooting Troubleshooting and remedies

Page 55

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

Version Digiprop

1)

X 1/15 = ground control unit

2)

Only, if no fault is recognizable after a complete check of the periphery: change control unit.

Note

Meaning of entries in Measurement/test connection column: X 1/15 X3/11

Pin 15 to plug X1, Multimeter set for Ohms, Pin 11 to plug X3

Fault Fault text Fault

class

Trigger time Requirement /

Operation

Measurement/

Test

connection

1)

Result/

Set point

Cause/

Remedy

2)

Code Test step

01 Stop light relay/

Short circuit to

ground

slight 1 s - Ignition: OFF

- Pull plug X3 out of

control unit

X 3/11 X 1/15 Relay is

installed:

250-350

Check lead, plugs

and relay or

consumers

Diagnosis / Troubleshooting Troubleshooting and remedies

Diagnosis / Troubleshooting Troubleshooting and remedies

Page 56

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

Fault Fault text Fault

class

Trigger time Requirement /

Operation

Measurement/

Test connection

Result/

Set point

Cause/

Remedy

Code Test step

03 HS 1 output

Short circuit

slight 1 s - Ignition: OFF

- Pull plug X1 out of

control unit

X 1/18 X 1/15 Relay is

installed:

250-350

Check lead, plugs

and relay

or consumers

04 HS 2 output

Short circuit

slight 1 s - Ignition: OFF

- Pull plug X1 out of

control unit

X 1/16 X 1/15 Relay is

installed:

250-350

Check lead, plugs

and relay

or consumers

05 Terminal 15

Undervoltage

serious 60 s - Ignition: OFF

- Pull plug X1 out of

control unit

- Ignition: ON

X 1/7 V X 1/15 17,5 V Check lead, plugs

and fuses

06 Terminal 15

Overvoltage

serious 10 s - Ignition: OFF

- Pull plug X1 out of

control unit

- Ignition: ON

- Start engine

(idle speed)

X 1/7 V X 1/15 32,5 V Checking electrical

installation of vehicle

(see manufacturer

instructions)

Diagnosis / Troubleshooting Troubleshooting and remedies

Diagnosis / Troubleshooting Troubleshooting and remedies

Page 57

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

* Fault is in serious class, if temperature sensor for oil and water are defect at the same time.

Fault Fault text Fault

class

Trigger time Requirement /

Operation

Measurement/

Test connection

Result/

Set point

Cause/

Remedy

Code Test step

08

09

Cooling-water

temperature

sensor

Discontinuity /

Short circuit to

battery

serious/

slight *

1 s - Ignition: OFF

- Pull plug X2 out of

control unit

X 2/5 X 2/4 20C 10C =

1039 - 1117

60C 10C =

1194 - 1271

80C 10C =

1271 - 1347

Notice:

The measuring

in one tempera-

ture range

normally is

sufficient.

Check lead and

sensor

Diagnosis / Troubleshooting Troubleshooting and remedies

Diagnosis / Troubleshooting Troubleshooting and remedies

Page 58

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

* Fault is in serious class, if temperature pick-up for oil and water are defect at the same time.

Fault Fault text Fault

class

Trigger time Requirement /

Operation

Measurement/

Test connection

Result/

Set point

Cause/

Remedy

Code Test step

11

12

Oil temperature

sensor

Discontinuity /

Short circuit to

battery

serious/

slight *

1 s - Ignition: OFF

- Pull plug X2 out of

control unit

X 2/9 X 2/8 20C 10C =

1039 - 1117

60C 10C =

1194 - 1271

80C 10C =

1271 - 1347

Notice:

The measuring

in one tempera-

ture range

normally is

sufficient.

Check lead and

sensor

Diagnosis / Troubleshooting Troubleshooting and remedies

Diagnosis / Troubleshooting Troubleshooting and remedies

Page 59

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

Fault Fault text Fault

class

Trigger time Requirement /

Operation

Measurement/

Test connection

Result/

Set point

Cause/

Remedy

Code Test step

13 1 Retarder stage

switch

Undefined

switch state

serious 1s - Ignition: ON

- Retarder stage

switch:

Position 0

X 1/10 V X 1/15

X 1/6 V X 1/15

X 1/5 V X 1/15

X 1/4 V X 1/15

X 1/9 V X 1/15

X 1/8 V X 1/15

17,5 V

0 V

0 V

0 V

0 V

0 V

Check lead, plug and

retarder stage switch

13 2 - Ignition: ON

- Retarder stage

switch:

Position 1

X 1/10 V X 1/15

X 1/6 V X 1/15

X 1/5 V X 1/15

X 1/4 V X 1/15

X 1/9 V X 1/15

X 1/8 V X 1/15

17,5 V

17,5 V

0 V

0 V

0 V

0 V

Check lead, plug and

retarder stage switch

13 3 - Ignition: ON

- Retarder stage

switch:

Position 2

X 1/10 V X 1/15

X 1/6 V X 1/15

X 1/5 V X 1/15

X 1/4 V X 1/15

X 1/9 V X 1/15

X 1/8 V X 1/15

17,5 V

17,5 V

17,5 V

0 V

0 V

0 V

Check lead, plug and

retarder stage switch

Diagnosis / Troubleshooting Troubleshooting and remedies

Diagnosis / Troubleshooting Troubleshooting and remedies

Page 60

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

Fault Fault text Fault

class

Trigger time Requirement /

Operation

Measurement/

Test connection

Result/

Set point

Cause/

Remedy

Code Test step

13 4 - Ignition: ON

- Retarder stage

switch:

Position 3

X 1/10 V X 1/15

X 1/6 V X 1/15

X 1/5 V X 1/15

X 1/4 V X 1/15

X 1/9 V X 1/15

X 1/8 V X 1/15

17,5 V

17,5 V

17,5 V

17,5 V

0 V

0 V

Check lead, plug and

retarder stage switch

13 5 - Ignition: ON

- Retarder stage

switch:

Position 4

X 1/10 V X 1/15

X 1/6 V X 1/15

X 1/5 V X 1/15

X 1/4 V X 1/15

X 1/9 V X 1/15

X 1/8 V X 1/15

17,5 V

17,5 V

17,5 V

17,5 V

17,5 V

0 V

Check lead, plug and

retarder stage switch

13 6 - Ignition: ON

- Retarder stage

switch:

Position 5

X 1/10 V X 1/15

X 1/6 V X 1/15

X 1/5 V X 1/15

X 1/4 V X 1/15

X 1/9 V X 1/15

X 1/8 V X 1/15

17,5 V

17,5 V

17,5 V

17,5 V

17,5 V

17,5 V

Check lead, plug and

retarder stage switch

Diagnosis / Troubleshooting Troubleshooting and remedies

Diagnosis / Troubleshooting Troubleshooting and remedies

Page 61

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

Fault Fault text Fault

class

Trigger time Requirement / Operati-

on

Measurement/

Test connec-

tion

Result/

Set point

Cause/

Remedy

Code Test step

14 Retarder stage

switch

Short circuit to

battery

serious 10 s - Ignition: OFF

- Pull plug X1 out of

control unit

- Ignition: ON

- Retarder stage switch:

Position 0

X 1/10 V X 1/15 0 V Check lead and

plug

15 Retarder stage

switch

Short circuit to

battery

serious 1 s - Ignition: OFF

- Pull plug X1 out of

control unit

- Retarder stage switch:

Position 5

X 1/10 X 1/15 Resistor

endless

Single check of

stages for

short circuit

16 Speedometer

signal

Discontinuity

serious 2 s - Ignition: ON X 3/2 V X 1/15 1 V Check lead and

speedometer

Diagnosis / Troubleshooting Troubleshooting and remedies

Diagnosis / Troubleshooting Troubleshooting and remedies

Page 62

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

Fault Fault text Fault

class

Trigger time Requirement /

Operation

Measurement/

Test connection

Result/

Set point

Cause/

Remedy

Code Test step

18 Speedometer signal

Short circuit to battery

undefined signal

serious 2 s - Ignition: OFF

- Pull plug X3 out of

control unit

- Ignition: ON

X 3/2 V X 1/15 9 V Check lead and

speedometer

19 ABS

Short circuit to ground

serious 60 s - Ignition: ON X 3/3 V X 1/15 3,5 V Check lead,

relay and

ABS-control unit

21 ABS-Signal undefined serious 1 s - Ignition: ON X 3/3 V X 1/15 16,5 V Check lead,

relay and

ABS-control unit

22 Internal fault

ABS-current path

serious 1 s - - - Replace control

unit

23 Proportional valve

Fault No. 1:

Short circuit to battery

serious 1 s - Ignition: OFF

- Pull plug X2 out of

control unit

- Ignition: ON

X 2/3 V X 1/15 10 V Check lead

Diagnosis / Troubleshooting Troubleshooting and remedies

Diagnosis / Troubleshooting Troubleshooting and remedies

Page 63

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

Fault Fault text Fault

class

Trigger time Requirement /

Operation

Measurement/

Test connection

Result/

Set point

Cause/

Remedy

Code Test step

24 1 Proportional valve

Fault No. 2:

- Short circuit proportional

valve magnetic

- Short circuit connection

lead proportional valve

- Discontinuity proportio-

nal valve magnetic

Valve magnetic

- Discontinuity connec-

tion lead proportional

valve

- Short circuit to ground at

proportional valve

- Prop.- and shift valve

interchanged

serious 1 s - Ignition: ON

- Pull plug X2 out

of control unit

X 2/2 X 2/3 18-25 Check lead and

proportional

valve

(valve block)

2 - Ignition: OFF

- Pull plug X2 out

of control unit

X 2/3 X 1/15 Resistor

endless

Check lead and

proportional

valve

(valve block)

3 - Ignition: OFF

- Pull plug X2 out

of control unit

X 2/2 X 1/15 Resistor

endless

Check lead and

valve block

Diagnosis / Troubleshooting Troubleshooting and remedies

Diagnosis / Troubleshooting Troubleshooting and remedies

Page 64

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

Fault Fault text Fault

class

Trigger time Requirement /

Operation

Measurement/

Test connection

Result/

Set point

Cause/

Remedy

Code Test step

25 Valve block

Fault No. 3:

defective control unit

serious 10 s Replace

control unit

27 Valve block

Fault No. 5:

defective control unit

serious 2 s Replace

control unit

28 Terminal 30

Undervoltage

serious 60 s - Ignition: OFF

- Pull plug X1 out of

control unit

- Ignition: ON

X 1/13 V X 1/15 17,5 V Check lead,

plug and fuse

29 Fault control unit serious 180 ms Replace

control unit

31 Control unit:

Coding fault

serious 100 ms Provide new

parameters for

control unit

32 Retarder pilot light:

Discontinuity /

Short circuit to ground

serious 3 s - Ignition: OFF

- Pull plug X3 out of

control unit

- Ignition: ON

X 3/8 V X 1/15 17,5 V Check lead,

retarder pilot

light and fuse

Diagnosis / Troubleshooting Troubleshooting and remedies

Diagnosis / Troubleshooting Troubleshooting and remedies

Page 65

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

Fault Fault text Fault

class

Trigger time Requirement /

Operation

Measurement/

Test connection

Result/

Set point

Cause/

Remedy

Code Test step

33 Retarder pilot light:

Short circuit to battery

serious 3 s - Ignition: ON

- Retarder stage

switch:

Position 1

X 3/8 V X 1/15 2 V Check lead and

retarder pilot

light

35 Fault control unit serious 500 ms / 123 s Replace

control unit

37 Fault foot operation slight 100 ms / 1 s Check installation in

accordance with

OEM - as well as

Voith requirements

38 1 Fault constant-air

pressure

slight 1 s to 10 s Ignition: ON

Position 0

X 3/7 V X 1/15

and

X 3/10 V X 1/15

0,3-0,7 V

4,75-5,25

V

Pressure sensor

wiring harness

If deviation: step 2

2 Troubleshooting in

wiring harness,

pressure sensor,

proportional valve,

supply-air pressure,

ECU

(Contact Voith)

Diagnosis / Troubleshooting Troubleshooting and remedies

Diagnosis / Troubleshooting Troubleshooting and remedies

Page 66

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

Version VERA

Note

- X1 / 14 = Ground control unit

- replace control unit first, if complete check of periphery did not yield any faults

- Project specifically is normally only a part of the listed pins used (e.g.: ABS not via pin X1/13, but via CAN)

Fault Fault text Fault

class

Trigger time Requirement /

Operation

Measurement/

Test connection

Result/

Set point

Cause/

Remedy

Blink-

Code

Test step

1 1 Data set

fault

heavy immediately af-

ter ignition ON

Parameter setting fault,

new parameter setting

2 1 EEprom

fault

heavy immediately af-

ter ignition ON

Replace control unit

3 1 ROM

fault

heavy approx. 10s after

ignition ON

Replace control unit

4 1 SIBA

fault

heavy 60 ms Replace control unit

5 1 Proportional-

valve chasssis

ground end,

interruption,

short circuit,

connecting lead

heavy 1s - Ignition: OFF

- disconnect

plug X3

X 3/3 X 3/4 18 ... 25 Check electrical lead

and proportional valve

Diagnosis / Troubleshooting Troubleshooting and remedies

Diagnosis / Troubleshooting Troubleshooting and remedies

Page 67

Aftersales Service Manual Voith Retarder 115 E

15300009710 / cbtsd 02-11

Fault Fault text Fault

class

Trigger time Requirement /

Operation

Measurement/

Test connection

Result/

Set point

Cause/

Remedy

Blink-

Code

Test step

5 2 X 3/3 X 1/14 Resistor endless Check electrical lead

and proportional val-

ve

5 3 X 3/3 X 1/14 Resistor endless Check electrical lead

and proportional val-

ve

6 1 Proportional-

valve

battery short cir-

cuit

heavy 1s - Ignition: OFF

- Pull off plug X1,

X3

- Ignition: ON

X 3/3 V X 1/14 10 V Check electrical lead

and plug

8 1 Proportional-

valve-control,

int. fault at con-

trol unit

heavy 3s Replace control unit

9 1 Terminal 15

undervoltage

heavy 60s - Ignition: OFF

- Pull off plug X1

- Ignition: ON

X 1/7 V X 1/14 17,5 V Check electrical lead,

fuse and plug

10 1 Terminal 15

overvoltage

heavy 10s - Ignition: OFF