Professional Documents

Culture Documents

Distillation of Ethyl Alcohol From Fermented Sweet Sorghum Solution by Solar Energy

Uploaded by

Agam Duma Kalista WibowoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Distillation of Ethyl Alcohol From Fermented Sweet Sorghum Solution by Solar Energy

Uploaded by

Agam Duma Kalista WibowoCopyright:

Available Formats

1

Distillation of Ethyl Alcohol from Fermented Sweet Sorghum Solution by Solar Energy

by

Anil K. Rajvanshi

Director, Nimbkar Agricultural Research Institute (NARI),

PHALTAN-415523, Maharashtra, India

E-mail: nariphaltan@gmail.com

(This report was submitted to DNCES, New Delhi in June 1984. Since then lot of work both

on sweet sorghum (http://nariphaltan.virtualave.net/sorghum.htm ); solar distillation

http://nariphaltan.virtualave.net/ethanoldist.pdf) and low concentration(50% w/w) ethanol

stoves (www.nariphaltan.org/ethstove.pdf ) has been done at our Institute. This report to our

knowledge was the first attempt anywhere in developing technology for solar distillation of

ethanol using sweet sorghum.

ABSTRACT

The proof of concept for solar distillation of ethanol from sweet sorghum juice has been

established. Heat and mass transfer data for a laboratory single effect solar still has been

generated. It is found that it will require 8 stills to distill 70% ethanol/water mixture starting

from 7% ethanol in fermented solution.

Various vacuum distillation units have been tested and analyzed. It is possible to distill 40-

60% ethanol by solar energy using these units. An average day ( 5 kWhr/m

2

-day insolation)

yields 1.4 kg/m

2

-day of 40% ethanol. The amount of ethanol distilled is inversely

proportional to its percentage and directly proportional to the solar radiation. Consequently

linear regression equations for these relationships have been established.

A simple method of predicting the percentage of ethanol distilled by knowing the solution

temperature has also been developed. The efficiency of the distillation unit for distilling 40%

ethanol is about 13% and compares extremely favorably as compared to 2-3% obtained from

existing fossil fuel fired ethanol distillation plants.

The energy output/input analysis for production of ethanol for sweet sorghum has been done

(Table 1 and 2). This ratio is 3.94 and thus shows that ethanol production from sweet

sorghum has a highly positive energy balance. On an average one can produce about 2000

liters/ha of ethanol per year, from the present sorghum lines bred at the Institute.

2

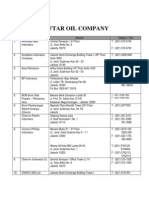

Table 1. Energy input in growing and crushing sweet sorghum (Plot size 2800 m

2

)

Sr.

No.

Operation Device Number

& system

Time

(hrs.)

Energy unit Total

Energy MJ

Ref.

AGRICULTURE

Tractor 13 liters

Diesel

3.15 37.7 MJ /lit. 490 22 1. Land preparation

Tractor

production energy

110 22

Muscle 1 man 7 1.05 MJ /hr 7.35 26 2. Furrow opening

Power 2 bullocks 7 2.66 MJ /hr 18.62 26

3. Small row op. Agricart 1 man +

2 bullocks

7 +7 -do- +7.35

18.62

26

4. Sowing Muscle 2 women 7 0.84 MJ /hr 11.76 26

5. Weeding Muscle 15 women 7 0.84 MJ /hr 88.2 22

Irrigation Ele. Motor

10 HP

1.2

million

liters of

water

10 27 MJ /hr 270 22 6.

Prod. of Elec. for

motor running

11.4 MJ /kWh 850 22

FERTILIZERS

Carbofuran 5 kg 454 MJ /kg 2270 27

Urea 100 kg 35 MJ /kg 3500 27

Superphosphate 18% P

2

O

5

130 kg 2.48 MJ /kg 323 27

7.

Muriate potash 60% K

2

O 40 kg 4.8 MJ /kg 192 27

Pesticides

Thiodan 125 ml 100 MJ /kg 12.5 27

8.

Metasystox 120 ml 100 MJ /kg 12.0 27

9. Application of

fertilizer +

insecticide

Muscle

Power

13 women

2 men

7

3.5

0.84 MJ /hr

1.05 MJ /hr

76.44

7.35

26

26

10. Harvesting Muscle 14 women 7 0.84 MJ /hr 82.32 26

CRUSHING

11. Crushing Elec.

crusher

3 H.P. 34.6 278.7 22

12. Elec. Prod. 11.4 MJ /kWh 882.5 22

13. Labour for

crushing

Muscle 1 man 12.2 105 MJ /hr 12.82 26

TOTAL 9521.6 MJ

3

Table 2. Energy output from sweet sorghum (RM line)

(Plot size 2800 m

2

)

Material Quantity Unit Energy Total

Energy

MJ

% of

Total

Ref.

Grain 700 kg 14.5 MJ /kg 10150 27 27

Alcohol 290 lit. 22.3 MJ /liter

a, b, c

6467 17.3 22

Bagasse 1494 kg 14 MJ /kg at 20% M.C. 20916 55.7 27

TOTAL 37533 100

a) This is the maximum possible alcohol obtainable from RM lines with 10-14%

fermentable sugars and 50% conversion rate for alcohol.

b) Actual bagasse is 1868 kg. at 50% moisture content (M.C.).

c) Besides being a high energy output quantity, sweet sorghum bagasse is an excellent

fodder for animals. Thus the quality of energy is far superior to simply burning.

The use of 40-60% ethanol as an excellent cooking fuel has been established. A wickless stove

has been designed, fabricated and tested to use this percentage and the efficiency of this stove

has been found to be between 30-35%. Since 1984 we have developed extremely efficient

stoves and lanterns to run on 50 %( w /w) ethanol/water mixtures.

HOME NARI, March 2008

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Thermodynamics in HysysDocument26 pagesThermodynamics in HysysRajesh AmmathilNo ratings yet

- Thermodynamics in HysysDocument26 pagesThermodynamics in HysysRajesh AmmathilNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- What is a TransformerDocument11 pagesWhat is a TransformerAnonymous sAmJfcV33% (3)

- Nilesh Y. Jadhav Auth. Green and Smart Buildings Advanced Technology OptionsDocument188 pagesNilesh Y. Jadhav Auth. Green and Smart Buildings Advanced Technology OptionsNicolasan21100% (1)

- Pipe Fitting Symbol Guide Under 40 CharactersDocument5 pagesPipe Fitting Symbol Guide Under 40 CharactersErnalyn ValenciaNo ratings yet

- Chemistry of Transition Elements 2018/2019Document12 pagesChemistry of Transition Elements 2018/2019chong56No ratings yet

- Training On Equipment Sizng of Process EquipmentDocument15 pagesTraining On Equipment Sizng of Process EquipmentAgam Duma Kalista WibowoNo ratings yet

- F13EDR-A F13WDR-A: E11 Hub Development SchematicDocument2 pagesF13EDR-A F13WDR-A: E11 Hub Development SchematicAgam Duma Kalista WibowoNo ratings yet

- Green ArchitectureDocument272 pagesGreen ArchitectureIuliu Nicolae Borsa96% (24)

- Reactions in HYSYSDocument7 pagesReactions in HYSYSWagus GinanjarNo ratings yet

- Daftar Dan Alamat Oil CompanyDocument16 pagesDaftar Dan Alamat Oil Companysetia wirawan100% (7)

- Knock Out Drum PDFDocument5 pagesKnock Out Drum PDFAgam Duma Kalista WibowoNo ratings yet

- Knock Out Drum PDFDocument5 pagesKnock Out Drum PDFAgam Duma Kalista WibowoNo ratings yet

- Volume Ver1.1Document8 pagesVolume Ver1.1Agam Duma Kalista WibowoNo ratings yet

- Fire Protection For PVDocument3 pagesFire Protection For PVAgungNo ratings yet

- Case Study - Well Mixing 1. Make 3 Streams, A, B & Water, Use The Composition & Conditions StatedDocument5 pagesCase Study - Well Mixing 1. Make 3 Streams, A, B & Water, Use The Composition & Conditions StatedAgam Duma Kalista WibowoNo ratings yet

- Liquid Level Control RangeDocument1 pageLiquid Level Control RangeAgam Duma Kalista WibowoNo ratings yet

- Hysys IntroDocument10 pagesHysys IntroMoslem DaneshNo ratings yet

- 335 595 1 PB PDFDocument8 pages335 595 1 PB PDFrifaldiNo ratings yet

- Simulating Chemical Systems in Fortran90 and MatlabDocument9 pagesSimulating Chemical Systems in Fortran90 and MatlabAgam Duma Kalista WibowoNo ratings yet

- CAE AgendaDocument1 pageCAE AgendaAgam Duma Kalista WibowoNo ratings yet

- Latihan Soal Packed Bed AbsorberDocument7 pagesLatihan Soal Packed Bed AbsorberAgam Duma Kalista WibowoNo ratings yet

- Distillation ColumnDocument4 pagesDistillation ColumnAgam Duma Kalista WibowoNo ratings yet

- Endogenous ProcessDocument2 pagesEndogenous ProcessAgam Duma Kalista WibowoNo ratings yet

- MOTIVATION LETTER Efrian's Plan for MSc in Forest EconDocument1 pageMOTIVATION LETTER Efrian's Plan for MSc in Forest EconJonasGäolchen100% (1)

- Untitled 0Document46 pagesUntitled 0Agam Duma Kalista WibowoNo ratings yet

- Tabel HBDocument4 pagesTabel HBAgam Duma Kalista WibowoNo ratings yet

- Handbook OF Industrial Membrane Technology: Mark C. PorterDocument4 pagesHandbook OF Industrial Membrane Technology: Mark C. PorterAgam Duma Kalista WibowoNo ratings yet

- Chapter 10Document43 pagesChapter 10dalbaasNo ratings yet

- Latihan Soal Packed Bed AbsorberDocument7 pagesLatihan Soal Packed Bed AbsorberAgam Duma Kalista WibowoNo ratings yet

- LOGIC-40Document2 pagesLOGIC-40phanindra_prasad_1No ratings yet

- 5070 s03 ErDocument11 pages5070 s03 ErSumaira AliNo ratings yet

- Handbook OF Industrial Membrane Technology: Mark C. PorterDocument4 pagesHandbook OF Industrial Membrane Technology: Mark C. PorterAgam Duma Kalista WibowoNo ratings yet

- High Performance GEARDocument18 pagesHigh Performance GEARcaothucodon322No ratings yet

- Mobile Power: Battery Technology and Future ApplicationsDocument31 pagesMobile Power: Battery Technology and Future ApplicationsBalaji KannanNo ratings yet

- The Prospect of Solar Energy in BangladeshDocument7 pagesThe Prospect of Solar Energy in BangladeshMD IMON HOSSENNo ratings yet

- Voltage Stability Enhancement of Wind Energy Conversion System Using SVPWM ControllerDocument13 pagesVoltage Stability Enhancement of Wind Energy Conversion System Using SVPWM ControllerpremsonyNo ratings yet

- Physics 2nd Year CH#15Document3 pagesPhysics 2nd Year CH#15Rashid JalalNo ratings yet

- Increase Performance and Flexibility with GT26 MXL2 UpgradeDocument4 pagesIncrease Performance and Flexibility with GT26 MXL2 UpgradeMai DangNo ratings yet

- Chapter 3,4,5 Essay QuestionsDocument15 pagesChapter 3,4,5 Essay QuestionskenenathNo ratings yet

- Office of the Chief Engineer solar net metering guidelinesDocument15 pagesOffice of the Chief Engineer solar net metering guidelinesRitesh DhawaleNo ratings yet

- Exhibition in India 2014 2015Document40 pagesExhibition in India 2014 2015Abhishek ParkarNo ratings yet

- Scooter VaneDocument32 pagesScooter VaneFre Man LeOrNo ratings yet

- WSHPDR 2013 Final Report-Updated VersionDocument466 pagesWSHPDR 2013 Final Report-Updated VersionManuel CañadasNo ratings yet

- State: Andhra Pradesh District: Prakasam Periodicity (And Latest Available)Document4 pagesState: Andhra Pradesh District: Prakasam Periodicity (And Latest Available)Munnangi NagendrareddyNo ratings yet

- Step-By-Step Self-Assembled Hybrids That Feature Control Over Energy and Charge TransferDocument7 pagesStep-By-Step Self-Assembled Hybrids That Feature Control Over Energy and Charge TransferLuciano PereiraNo ratings yet

- Power Qualty ConditionersDocument20 pagesPower Qualty ConditionersRavinder RangaNo ratings yet

- Efficient Trigeneration - An Energy Solution for BusinessesDocument10 pagesEfficient Trigeneration - An Energy Solution for Businessesjpsingh75No ratings yet

- Listening Anh 7Document6 pagesListening Anh 7Thanh TâmNo ratings yet

- Erisha InternationalDocument6 pagesErisha InternationalAntora HoqueNo ratings yet

- Digital Lab OvenDocument3 pagesDigital Lab Ovenananda_beloshe75No ratings yet

- CV Ashiqur RahmanDocument2 pagesCV Ashiqur Rahmanapi-282978046No ratings yet

- Jacob BondeDocument137 pagesJacob BondeĐặng Vũ Hoàng ĐứcNo ratings yet

- NPTEL – Chemical Engineering – Nuclear Reactor Technology BreedingDocument7 pagesNPTEL – Chemical Engineering – Nuclear Reactor Technology BreedingManish SharmaNo ratings yet

- Siemens Technical Paper Fuel Flexibility SGT 400Document11 pagesSiemens Technical Paper Fuel Flexibility SGT 400Hicham BenkhalifaNo ratings yet

- Vishwabhanu Oct '18 - Jan '19Document26 pagesVishwabhanu Oct '18 - Jan '19vedicvision99100% (3)

- Godspower Sabastine Bruno: JANUARY, 2022Document37 pagesGodspower Sabastine Bruno: JANUARY, 2022godspower brunoNo ratings yet

- Assignment No. 2 OngocoDocument3 pagesAssignment No. 2 OngocoRelvin OngocoNo ratings yet

- WBJEE Sample Paper-7 (WBJEE 2014 Physics Chemistry Keys Solution)Document30 pagesWBJEE Sample Paper-7 (WBJEE 2014 Physics Chemistry Keys Solution)Firdosh KhanNo ratings yet