Professional Documents

Culture Documents

EES612 Lab1

Uploaded by

Levan LomidzeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EES612 Lab1

Uploaded by

Levan LomidzeCopyright:

Available Formats

Page 1 of 1

Faculty of Engineering, Architecture and Science

Department of Electrical and Computer Engineering

Course Number

EES 612

Course Title

Electrical Machines and Actuators

Semester/Year

Instructor

Lab Report #

Lab Title

Lab Date

Lab Section

TAs Name

Student Name Student ID Signature*

*By signing above you attest that you have contributed to this written lab report

and confirm that all work you have contributed to this lab report is your own

work. Any suspicion of copying or plagiarism in this work will result in an

investigation of Academic Misconduct and may result in a 0 on the work, an

F in the course, or possibly more severe penalties, as well as a Disciplinary

Notice on your academic record under the Student Code of Academic Conduct,

which can be found online at: www.ryerson.ca/senate/current/pol60.pdf.

Faculty of Engineering, Architecture and Science

Department of Electrical and Computer Engineering

LAB INSTRUCTIONS

EES 612 ELECTRICAL MACHINES AND ACTUATORS

EXPERIMENT # 1: SEPARATELY EXCITED DC MOTOR

Introduction

DC motors are widely employed in such devices as power shovels, printing presses,

traction equipment, golf carts, power wheelchairs, cooling fan drivers, car engine starters,

wind-shield wipers, and power mirrors, to name just a few. They are also used in

manufacturing and processing applications where easy speed (and/or torque) control is

needed. Small DC motors are also used as servomotors in position control applications.

This experiment investigates the characteristics of a separately excited DC motor.

In general, a DC motor is described by the two following fundamental equations:

=

(1)

= (2)

where denotes the developed (internal) torque; denotes the counter electromotive

force (c-emf);

denotes the armature current; is the shaft speed (in rad/s); and is

the so-called flux constant of the machine (in Nm/A or Volt-Second).

In a shunt or a separatel y excited motor, the armature terminal voltage

is given by

= +

(3)

where

denotes the armature resistance. Thus, the so-called torque-speed

characteristic of a shunt or a separatel y excited DC motor can be found by combining

the Equations (1) through (3), as

=

()

2

(4)

The shaft speed expressed in rpm, , is related to that expressed in rad/s, , by

= 9.55 or = /9.55 (5)

In permanent-magnet machines the value of is fixed by the magnets establishing the

air-gap magnetic field, whereas in separately excited machines the value of is a

function of the field current

and, therefore, can be varied by either the field voltage

or

the field resistance

, or by both.

Pre-Lab Assignment

The DC motor you will be using in the lab has been spun by another motor at a constant

speed of 1745 , and its open-circuit armature voltage (which is the same as ) has

been measured for different values of the field current

. Table P1 shows the result.

Table P1:

characteristic at = .

() () (/)

0 10.9

50 27.8

100 50.4

150 76.5

160 88.4

175 94.3

200 94.6

225 111.8

250 112.1

275 125.0

300 127.0

325 136.1

350 137.8

370 143.6

375 144.1

400 146.8

410 148.6

P1- Calculate corresponding to each value of

, and complete Table P1. Then plot

versus

on Graph P1. Comment on the variation of , as

is increased.

Graph P1: Magnetizing curve of the DC motor.

()

()

P2- For the machine described above, calculate the no-load speed (in rpm) at an

armature voltage of

= 120 and a field current of

= 250 . Ignore the

rotational losses.

P3- If the field current is reduced to

= 175 , what should the armature voltage

be

changed to, in order for the no-load speed to remain at the same value as that in P2?

Lab Work

1. General safety note

To prevent injuries or damage to equipment, the power source must be turned

OFF prior to wiring up the circuit. Ask your TA to check.

2. Equipment

DC machine module EMS 8211

DC power supply module EMS 8821 (for applying armature and field voltages)

Dynamometer module EMS 8911 (for applying a load torque)

Hand-held tachometer (for measuring the shaft speed)

Bench-top digital multimeter (for measuring the armature voltage)

Hand-held clamp ammeters (for measuring the armature and field currents)

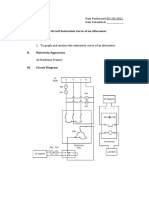

3. Circuit

Connect the circuit of Figure 1 which ensures that the DC machine is to be controlled

as a separately excited motor. In the circuit of Figure 1, the field voltage

is constant

at about 120 , while the field resistance

(and therefore the field current

) can be

varied by the rheostat . Clockwise rotation of the rheostat reduces the field

resistance and, thus, increases

. The armature voltage, however, can be varied by

the voltage knob . The shaft torque applied by the dynamometer can be varied by

the torque knob . A clockwise rotation of each knob increases the

corresponding quantity that the knob controls.

Figure 1: DC machine configured as a separately excited motor.

4. Experiments

E1: Torque-Speed Characteristic at Full Field and Armature Voltage

E1.1 With the power supply module off, turn both knobs and the rheostat fully

counterclockwise (to ensure zero armature voltage, zero shaft torque, and minimum

field current). Then turn on the power supply and adjust the rheostat to bring the

field current up to 250 (monitor the field current by the clamp ammeter). The

motor must not spin at this stage (since the armature voltage is zero); if it does,

something is terribly wrong!

E1.2 Gradually turn the voltage knob clockwise and raise the armature voltage to 120 .

This should result in clockwise rotation of the motor. The torque knob must still be

kept at its fully counterclockwise position, such that the dynamometers scale

displays zero. Thus, the motor experiences no shaft torque. However, it nonetheless

combats the rotational losses and, consequently, its armature current is not zero.

E1.3 Wait for a few minutes to allow the armature and field windings to warm up. This

mitigates the drift of the resistances. Thereafter, if needed, readjust the armature

voltage and the field current to, respectively, 120 and 250 . Report the shaft

speed (measured by the tachometer) and armature current (measured by the

corresponding clamp ammeter) in Table E1.3.

Table E1.3: No-load shaft speed and armature current, for

= and

= .

()

()

E1.4 Gradually increase the shaft torque by turning the torque knob clockwise. Measure

the armature current and shaft speed for each of the dynamometers reading listed in

Table E1.4. If needed, readjust

to 120 and

to 250 , before each

measurement.

Table E1.4: Different

pairs, for

= and

= .

Dynamometers

reading

()

()

() ()

0.1 120 250

0.2 120 250

0.3 120 250

0.4 120 250

0.5 120 250

0.6 120 250

0.7 120 250

0.8 120 250

0.9 120 250

1.0 120 250

1.1 120 250

1.2 120 250

1.3 120 250

1.4 120 250

E1.5 Turn the torque knob fully counterclockwise, but do not turn off the power supply.

E2: Torque-Speed Characteristic at Full Field, but Reduced Armature Voltage

E2.1 Continuing from Step E1.5 above, reduce the armature voltage to 100 by turning

the voltage knob counterclockwise, but maintain the field current at 250

(readjust if necessary). Notice the shaft speed reduction. The dynamometers scale

should display a shaft torque of about zero. Thus, the motor operates with no shaft

load, at a reduced armature voltage.

E2.2 Note down the shaft speed and armature current in Table E2.2.

Table E2.2: No-load shaft speed and armature current, for

= and

= .

()

()

E2.3 Gradually increase the shaft torque by turning the torque knob clockwise. Measure

the armature current and shaft speed for each of the dynamometers readings listed

in Table E2.3. If needed, readjust

to 100 and

to 250 , before each

measurement.

Table E2.3: Different

pairs, for

= and

= .

Dynamometers

reading

()

()

() ()

0.1 100 250

0.2 100 250

0.3 100 250

0.4 100 250

0.5 100 250

0.6 100 250

0.7 100 250

0.8 100 250

0.9 100 250

1.0 100 250

1.1 100 250

1.2 100 250

1.3 100 250

1.4 100 250

E2.4 Turn the torque knob fully counterclockwise, but do not turn off the power supply.

E3: Torque-Speed Characteristic at Reduced Field and Armature Voltage

E3.1 Continuing from Step E2.4 above, bring the field current down to 175 by turning

the rheostat counterclockwise, but maintain the armature voltage at 100 (readjust

if necessary). Notice that this increases the shaft speed. The dynamometers scale

should display a shaft torque of about zero. Therefore, the motor works with no shaft

load, at a reduced armature voltage and field current.

E3.2 Note down the shaft speed and armature current in Table E3.2.

Table E3.2: No-load shaft speed and armature current, for

= and

= .

()

()

E3.3 Gradually load the shaft by turning the torque knob clockwise. Measure the

armature current and shaft speed for each of the dynamometers readings listed in

Table E3.3. If needed, readjust

to 100 , and

to 175 .

Table E3.3: Different

pairs, for

= and

= .

Dynamometers

reading

()

()

() ()

0.1 100 175

0.2 100 175

0.3 100 175

0.4 100 175

0.5 100 175

0.6 100 175

0.7 100 175

0.8 100 175

0.9 100 175

1.0 100 175

E3.4 Turn the torque knob fully counterclockwise. Then, turn the voltage knob

counterclockwise, such that the motor comes to a standstill. Turn off the power

supply and all the meters.

Conclusions and Remarks

C1.1 Using equations (2), (3), and (5), and any two

points from Table E1.4,

calculate and

of the machine, for

= 120 and

= 250 ; for better

accuracy, the two points should be the extremes, i.e., one from the top and the

other from the bottom of the table. Show all the work. Report the results in Table

C1.1, below. Then, compare this value of with the value of you found in P1.

Calculate their difference as a percent of the latter, i.e., as a percent of the value of

you found in P1.

Table C1.1:

and , for

= and

= .

() (/)

C1.2 Using the calculated value of from Table C1.1, and the measured armature

currents from Table E1.4, calculate the developed torque for each corresponding

shaft speed. Report the result in Table C1.2 below. Then, plot versus on Graph

C1 (show on the horizontal axis); label the curve as experimental . Use

appropriate data ranges and ticks for the axes, such that graphs space is efficiently

utilized (for example, should range from 0 to 2.5 , in steps of 0.1, etc.). Next, on

the same graph, plot the straight line that Equation (4) represents, and title it

theoretical . Again, assume the values of

and from Table C1.1.

Comment on the torque-speed characteristic of the motor and the disagreements

between the experimental and theoretical curves. State your reasons for the

discrepancies.

Table C1.2: Cal culated developed torque versus shaft speed, for

= and

= .

Dynamometers

reading from

Table E1.4

()

From Table E1.4

()

From Table E1.4

=

()

Take from Table C1.1

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

1.4

n (rpm)

T (N.m)

Graph C1: Theoretical and experimental torque-speed curves

for

= 120 and

= 250 .

C2.1 Using equations (2), (3), and (5), and any two

points from Table E2.3,

calculate and

of the machine, for

= 100 and

= 250 ; show all the

work. Report the results in Table C2.1. Then, compare this value of with the

value of you found in P1; calculate their difference as a percent of the latter.

Table C2.1:

and , for

= and

= .

() (/)

C2.2 Using the calculated value of from Table C2.1, and the armature currents from

Table E2.3, calculate the developed torque for each corresponding shaft speed.

Report the result in Table C2.2 below. Then, plot versus on Graph C2 (show

on the horizontal axis); label the curve as experimental . Use appropriate data

ranges and ticks for the axes, such that graphs space is efficiently utilized (for

example, should range from 0 to 2.5 , in steps of 0.1, etc.). Next, on the same

graph, plot the straight line that Equation (4) represents, and title it theoretical .

Again, assume the values of

and from Table C2.1.

Comment on the torque-speed characteristic of the motor and the disagreements

between the experimental and theoretical curves. State your reasons for the

discrepancies.

Table C2.2: Cal culated developed torque versus shaft speed, for

= and

= .

Dynamometers

reading from

Table E2.3

()

From Table E2.3

()

From Table E2.3

=

()

Take from Table C2.1

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

1.4

n (rpm)

T (N.m)

Graph C2: Theoretical and experimental torque-speed curves

for

= 100 and

= 250 .

C3.1 Using equations (2), (3), and (5), and any two

points from Table E3.3,

calculate and

of the machine, for

= 100 and

= 175 ; show all the

work. Report the results in Table C3.1. Then, compare this value of with the

value of you found in P1; calculate their difference as a percent of the latter.

Table C3.1:

and , for

= and

= .

() (/)

C3.2 Using the calculated value of from Table C3.1, and the armature currents from

Table E3.3, calculate the developed torque for each corresponding shaft speed.

Report the result in Table C3.2 below. Then, plot versus on Graph C3 (show

on the horizontal axis); label the curve as experimental . Use appropriate data

ranges and ticks for the axes, such that graphs space is efficiently utilized (for

example, should range from 0 to 2.5 , in steps of 0.1, etc.). Next, on the same

graph, plot the straight line that Equation (4) represents, and title it theoretical .

Again, assume the values of

and from Table C3.1.

Comment on the torque-speed characteristic of the motor and the disagreements

between the experimental and theoretical curves. State your reasons for the

discrepancies.

Table C3.2: Cal culated developed torque versus shaft speed, for

= and

= .

Dynamometers

reading from

Table E3.3

()

From Table E3.3

()

From Table E3.3

=

()

Take from Table C3.1

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

1.4

n (rpm)

T (N.m)

Graph C3: Theoretical and experimental torque-speed

curves for

= 100 and

= 175 .

C4 Using the data of Tables E1.4 and C1.2, calculate the motors output power (shaft

power) and efficiency, for each value of the shaft torque. Complete Table C4, and

plot the efficiency versus the output power of the motor on Graph C4. Comment on

the variations of efficiency as a function of the output power.

Table C4: Input power, output power, and efficiency, for

= and

= .

Dynamometers

reading

() (/)

()

= () =

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

1.4

%

Output Power

(W)

Graph C4: Efficiency versus shaft power, for

= 120 and

= 250 .

n (rpm)

T (N.m)

C5 Plot all the three theoretical curves of C1.2, C2.2, and C3.2 on Graph C5, and

comment on the effect of the following practices on the torque-speed characteristic of

a separately excited DC motor: (1) only armature voltage reduction, and (2) both

armature voltage reduction and field weakening.

Also, explain why in this experiment we did not weaken the field alone, but also

reduced the armature voltage along with it.

Graph C5: Theoretical torque-speed curves resulted from the experiments

E1, E2, and E3.

Blank Page

C6 Using the measurements of E1.3, E2.2, and E3.2, and the results of C1.1, C2.1, and

C3.1, calculate the motors rotational power loss and its associated torque, for each of

the three test conditions. Show all the work. Report the results in Table C6.

Table C6: Rotational power loss and torque, for the three test conditions.

Dynamometers

reading

() (/)

()

()

()

0

0

0

Last updated Sep 16, 2013AY

You might also like

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Ac Servo MotorDocument14 pagesAc Servo MotorJeyanthNo ratings yet

- Data Structures and Algorithms AssignmentDocument25 pagesData Structures and Algorithms Assignmentعلی احمد100% (1)

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetNo ratings yet

- Experiment No 5 The DC Series MotorDocument6 pagesExperiment No 5 The DC Series MotorMadel Roque50% (2)

- Study of Characteristics of Three Phase Induction MotorDocument32 pagesStudy of Characteristics of Three Phase Induction MotorMohamed Omer Al Hadi100% (2)

- A705F Schematic Circuit Diagram HALABTECHDocument11 pagesA705F Schematic Circuit Diagram HALABTECHbcscneg0% (1)

- Lab 3Document7 pagesLab 3jisteeleNo ratings yet

- Electrical Machines-I Lab ManualDocument24 pagesElectrical Machines-I Lab Manualankur_sharma_95No ratings yet

- Almugea or Proper FaceDocument5 pagesAlmugea or Proper FaceValentin BadeaNo ratings yet

- Blocked Rotor TestDocument11 pagesBlocked Rotor TestIjabi100% (1)

- Power Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlFrom EverandPower Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlRating: 5 out of 5 stars5/5 (1)

- Lab 3 Squirrel Cage Induction Machine-1Document8 pagesLab 3 Squirrel Cage Induction Machine-1max100% (1)

- Trend Management How To Effectively Use Trend-Knowledge in Your Company (Jörg Blechschmidt)Document121 pagesTrend Management How To Effectively Use Trend-Knowledge in Your Company (Jörg Blechschmidt)Antonio Gonzalez AriasNo ratings yet

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetRating: 2 out of 5 stars2/5 (1)

- BME634-Lab1 Separately Excited DC MotorDocument24 pagesBME634-Lab1 Separately Excited DC Motorc24bhrkk6pNo ratings yet

- De La Salle University Dasmarinas: Experiment No. 4 DC Shunt MotorDocument6 pagesDe La Salle University Dasmarinas: Experiment No. 4 DC Shunt MotorMizhar GerardoNo ratings yet

- Exp 7Document11 pagesExp 7John Renzel RiveraNo ratings yet

- Ac Servo Speed Torque Characteristics Measurement Unit - PREMIERDocument14 pagesAc Servo Speed Torque Characteristics Measurement Unit - PREMIERAAYUSH KUMARNo ratings yet

- ECCE4356 Lab Manual 2Document29 pagesECCE4356 Lab Manual 2Siva Bala KrishnanNo ratings yet

- Experiment 04Document7 pagesExperiment 04Zeynal Abidin ŞabaşNo ratings yet

- Lab # 7 - DC Machines Part 3 Separately Excited DC GeneratorDocument6 pagesLab # 7 - DC Machines Part 3 Separately Excited DC GeneratorAdeel SyedNo ratings yet

- Induction MatlabDocument12 pagesInduction Matlabgrido002No ratings yet

- Analysis of D.C. Electric Motors: EEEE 531 - Mechatronics Experiment #2Document8 pagesAnalysis of D.C. Electric Motors: EEEE 531 - Mechatronics Experiment #2kay_rolNo ratings yet

- Electrical and Electronics Lab Manual For Mechanical EngineeringDocument21 pagesElectrical and Electronics Lab Manual For Mechanical EngineeringSreerag Kunnathu SugathanNo ratings yet

- 2 Brake Test On DC Shunt MotorDocument12 pages2 Brake Test On DC Shunt MotorMahesh Patil100% (1)

- E M L - M: Lectrical Achines AB AnualDocument29 pagesE M L - M: Lectrical Achines AB AnualSuresh Kumar MunnurukapuNo ratings yet

- Control Material Module IIDocument15 pagesControl Material Module IIAbiodun MustaphaNo ratings yet

- Open Circuit Saturation Curve of An Alternator I. ObjectivesDocument4 pagesOpen Circuit Saturation Curve of An Alternator I. ObjectivesArnel Pamaos Lopiba MontañezNo ratings yet

- DC Motors: 2.0 ObjectivesDocument16 pagesDC Motors: 2.0 ObjectivesBelayet RonyNo ratings yet

- Experiment No.6 The DC Shunt Motor RatingDocument7 pagesExperiment No.6 The DC Shunt Motor RatingMounta1n DewNo ratings yet

- DC Shunt MotorDocument9 pagesDC Shunt MotorPeterNo ratings yet

- Ec221 Lab04 PDFDocument5 pagesEc221 Lab04 PDFishara karunarathnaNo ratings yet

- Control System Lab EE-324-FDocument45 pagesControl System Lab EE-324-FDheeraj KumarNo ratings yet

- Bersabal - Experiment 25 - Ee435alDocument8 pagesBersabal - Experiment 25 - Ee435alCegrow Ber BersabalNo ratings yet

- Lab Manual Load - Test - On - DC - Shunt - Motor PDFDocument8 pagesLab Manual Load - Test - On - DC - Shunt - Motor PDFfongNo ratings yet

- EXPERIMENT Induction MotorDocument10 pagesEXPERIMENT Induction MotorMohamed Meeran100% (1)

- Exp. 2 - OCC and Load Test On AlternatorDocument7 pagesExp. 2 - OCC and Load Test On AlternatorKailash Jagarwal100% (1)

- Chapter 5Document34 pagesChapter 5Jayshon Montemayor100% (1)

- DC Motors Speed Control - ModDocument9 pagesDC Motors Speed Control - ModAnuja VargheseNo ratings yet

- Lab9 - Shunt and Cumulative Compound DC GeneratorsDocument12 pagesLab9 - Shunt and Cumulative Compound DC GeneratorsMomal ARNo ratings yet

- Total 363 Lab ManualDocument67 pagesTotal 363 Lab ManualBisal Sarker JoyNo ratings yet

- Three-Phase Induction MotorDocument10 pagesThree-Phase Induction MotorMadarwi SarwaNo ratings yet

- Exp. 3 - Load Test and Equivalent Circuit Determination On Three Phase Squirrel Cage Induction Motor andDocument9 pagesExp. 3 - Load Test and Equivalent Circuit Determination On Three Phase Squirrel Cage Induction Motor andSanjay MeenaNo ratings yet

- Practical Activity 2 DC Shunt Motor PLMDocument9 pagesPractical Activity 2 DC Shunt Motor PLMMarc Jairro GajudoNo ratings yet

- Experiment 03Document8 pagesExperiment 03Zeynal Abidin ŞabaşNo ratings yet

- EE 448 Laboratory Experiment 4 Introduction To DC MotorsDocument10 pagesEE 448 Laboratory Experiment 4 Introduction To DC MotorsjegjegtNo ratings yet

- Lab 12 - Universal MotorDocument8 pagesLab 12 - Universal MotorSanjeev Kumar Jha50% (2)

- Electrical Machines Lab: Experiment 2ADocument9 pagesElectrical Machines Lab: Experiment 2AARTI RAWATNo ratings yet

- ASSIGNMENT Elektric q1-q3Document16 pagesASSIGNMENT Elektric q1-q3Nur Aisyah ZainuddinNo ratings yet

- ECEN 441-504: Electronic Motor Drive: Lab 3: Operating Characteristics of The Separately Excited DC MotorDocument6 pagesECEN 441-504: Electronic Motor Drive: Lab 3: Operating Characteristics of The Separately Excited DC Motorapi-241454978No ratings yet

- Control System Lab ManualDocument63 pagesControl System Lab ManualkrishnandrkNo ratings yet

- Experiment - No.10 Load Test On DC Shunt Motor: DATE:10/12/2021Document6 pagesExperiment - No.10 Load Test On DC Shunt Motor: DATE:10/12/2021Baba YagaNo ratings yet

- AC Motor - FormulasDocument10 pagesAC Motor - FormulasJay Mark Balane100% (1)

- Experiment 6: Alternator Characteristics ObjectDocument4 pagesExperiment 6: Alternator Characteristics ObjectarjayNo ratings yet

- Induction Motor Lab ManualDocument11 pagesInduction Motor Lab ManualRabah ZaimeddineNo ratings yet

- Engineering Lab 5 Machine Lab Lab 1 ReportDocument9 pagesEngineering Lab 5 Machine Lab Lab 1 Reportram010No ratings yet

- DC Shunt MotorDocument9 pagesDC Shunt MotorPeterNo ratings yet

- Injection of EMF in Rotor Circuit PDFDocument5 pagesInjection of EMF in Rotor Circuit PDFkhidirtay50% (2)

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Some Power Electronics Case Studies Using Matlab Simpowersystem BlocksetFrom EverandSome Power Electronics Case Studies Using Matlab Simpowersystem BlocksetNo ratings yet

- Pism Pub Line Up - Jul-Dec - 2022Document1 pagePism Pub Line Up - Jul-Dec - 2022Yus CeballosNo ratings yet

- AutoCAD 2006 Installing Network License Manager0Document12 pagesAutoCAD 2006 Installing Network License Manager0gurugovindanNo ratings yet

- Analysis and Design of Cantilever Slab Analysis and Design of Cantilever SlabDocument3 pagesAnalysis and Design of Cantilever Slab Analysis and Design of Cantilever SlabMesfinNo ratings yet

- Jurong Junior College: Preliminary Examination 2009Document16 pagesJurong Junior College: Preliminary Examination 2009cjcsucksNo ratings yet

- Loading and Hauling Dump Truck: DumperDocument2 pagesLoading and Hauling Dump Truck: DumperRJNo ratings yet

- Addis Ababa University Lecture NoteDocument65 pagesAddis Ababa University Lecture NoteTADY TUBE OWNER100% (9)

- Description: Super Thoroseal Is A Blend of PortlandDocument2 pagesDescription: Super Thoroseal Is A Blend of Portlandqwerty_conan100% (1)

- Imarest 2021 Warship Development 1997Document43 pagesImarest 2021 Warship Development 1997nugrohoNo ratings yet

- Lab Science of Materis ReportDocument22 pagesLab Science of Materis ReportKarl ToddNo ratings yet

- Adsa Ka SyllabusDocument3 pagesAdsa Ka SyllabusHacker RanjanNo ratings yet

- NAAC 10.12.1888888 NewDocument48 pagesNAAC 10.12.1888888 Newచిమ్ముల సందీప్ రెడ్డిNo ratings yet

- Employment Under Dubai Electricity & Water AuthorityDocument6 pagesEmployment Under Dubai Electricity & Water AuthorityMominur Rahman ShohagNo ratings yet

- Lifestyle Mentor. Sally & SusieDocument2 pagesLifestyle Mentor. Sally & SusieLIYAN SHENNo ratings yet

- Brochure - Mounted Telescopic Crane (S) - NOVEMBER - 2018Document2 pagesBrochure - Mounted Telescopic Crane (S) - NOVEMBER - 2018Fernanda RizaldoNo ratings yet

- ECON 304 Course ContentDocument2 pagesECON 304 Course ContentAanand JhaNo ratings yet

- Preview - ISO+8655 6 2022Document6 pagesPreview - ISO+8655 6 2022s7631040No ratings yet

- ACFrOgDVly789-6Z8jIbi7pBoLupubEgMyOp7PczEvUguHoW3uj oR2PKzDvuhRzzkIhacYjxXRrU6iA7sHt t6MhtpZFq0t uZL2pF5Ra NNZ kmcl5w7BCQeUegKhjRhNuou88XxLodzWwbsrDocument14 pagesACFrOgDVly789-6Z8jIbi7pBoLupubEgMyOp7PczEvUguHoW3uj oR2PKzDvuhRzzkIhacYjxXRrU6iA7sHt t6MhtpZFq0t uZL2pF5Ra NNZ kmcl5w7BCQeUegKhjRhNuou88XxLodzWwbsrJohn Steven LlorcaNo ratings yet

- A.O: Against Order: Desktop Hard Disk Laptop Hard Disk Scsi Hard Disk Adaptec Cards External Hard DiskDocument28 pagesA.O: Against Order: Desktop Hard Disk Laptop Hard Disk Scsi Hard Disk Adaptec Cards External Hard DiskArul brittoNo ratings yet

- Briefing Evaluation: Yes / No High / Low Yes / No High / Low Good / Inferior Yes / NoDocument4 pagesBriefing Evaluation: Yes / No High / Low Yes / No High / Low Good / Inferior Yes / NoAmmarah AzharNo ratings yet

- Understanding ISO 9001 Calibration RequirementsDocument6 pagesUnderstanding ISO 9001 Calibration RequirementsAldrin HernandezNo ratings yet

- s145 Series HMM 201902 PDFDocument73 pagess145 Series HMM 201902 PDFEuNo ratings yet

- Job No. 25800: Quebrada Blanca Fase 2Document1 pageJob No. 25800: Quebrada Blanca Fase 2Benjamín Muñoz MuñozNo ratings yet

- Leap Motion PDFDocument18 pagesLeap Motion PDFAnkiTwilightedNo ratings yet

- Question 1: As Shown in Figure 1. A 6-Pole, Long-Shunt Lap-Wound CompoundDocument4 pagesQuestion 1: As Shown in Figure 1. A 6-Pole, Long-Shunt Lap-Wound Compoundالموعظة الحسنه chanelNo ratings yet

- Dynamic Analysis of Synchronous Reluctance Motor Drives Based On Simulink and Finite Element ModelDocument5 pagesDynamic Analysis of Synchronous Reluctance Motor Drives Based On Simulink and Finite Element ModelenmnabilNo ratings yet

- Science 8: Learning Activity SheetDocument9 pagesScience 8: Learning Activity SheetVan Amiel CovitaNo ratings yet