Professional Documents

Culture Documents

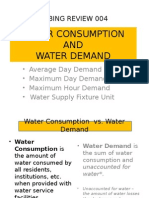

Sizing Water Supply System

Uploaded by

Arnel AlvarezOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sizing Water Supply System

Uploaded by

Arnel AlvarezCopyright:

Available Formats

UNIFORM PLUMBING CODE

158

P

r

e

s

s

u

r

e

L

o

s

s

-

L

b

s

.

/

S

q

.

I

n

.

0

.

2

5

0

.

3

2

0

.

3

8

0

.

5

0

0

.

5

7

0

.

6

3

1

.

3

1

.

9

2

.

5

3

.

2

5

.

0

1

2

.

6

1

8

.

9

2

5

.

2

3

7

.

8

5

0

.

4

6

.

3

0

.

4

4

P

r

e

s

s

u

r

e

L

o

s

s

-

k

P

a

APPENDIX A

RECOMMENDED RULES FOR SIZING THE WATER SUPPLY SYSTEM

Because of the variable conditions encountered, it is

impractical to lay down definite detailed rules of

procedure for determining the sizes of water supply

pipes in an appendix which must necessarily be

limited in length. For a more adequate

understanding of the problems involved, refer to

Water-Distributing Systems for Buildings, Report

BMS 79 of the National Bureau of Standards; and

Plumbing Manual, Report BMS 66, also published by

the National Bureau of Standards.

The following is a suggested order of

procedure for sizing the water supply system.

A 1 Preliminary Information

A 1.1 Obtain the necessary information

regarding the minimum daily service pressure in the

area where the building is to be located.

A 1.2 If the building supply is to be metered,

obtain information regarding friction loss relative to

the rate of flow for meters in the range of sizes likely

to be used. Friction-loss data can be obtained from

CHART A-1

Friction Losses for Disk Type Water Meters

20

16

10

9

8

7

6

5

4

3

2

1

4 5 6 78910 20 30 40 5060 80100 200 300 400 600 8001000

Flow - Gallons per Minute

CHART A-1 (Metric)

Friction Losses for Disk Type Water Meters

137.8

110.2

68.9

62.0

55.1

48.2

41.3

34.5

27.6

20.7

13.8

6.9

Flow - Liters per Second

161

Appendix A UNIFORM PLUMBING CODE

Inch mm

TABLE A-2

1/2 15

Water Supply Fixture Units (WSFU) and Minimum Fixture Branch Pipe Sizes

3

3/4 20

1 25 Minimum

Fixture Branch Private Public Assembly

5

Appliances, Appurtenances or Fixtures

2

Pipe Size

1,4

Bathtub or Combination Bath/Shower (fill) .................................... 1/2" 4.0 4.0

3/4 Bathtub Fill Valve ........................................................... 3/4 10.0 10.0

Bidet ............................................................................................ 1/2" 1.0

Clotheswasher............................................................................. 1/2" 4.0 4.0

Dental Unit, cuspidor .................................................................... 1/2" 1.0

Dishwasher, domestic .................................................................. 1/2" 1.5 1.5

Drinking Fountain or Watercooler ................................................. 1/2" 0.5 0.5 0.75

Hose Bibb .................................................................................... 1/2" 2.5 2.5

Hose Bibb, each additional

7 ...........................................................................

1/2" 1.0 1.0

Lavatory ...................................................................................... 1/2" 1.0 1.0 1.0

Lawn Sprinkler, each head

5............................................................................

1.0 1.0

Mobile Home, each (minimum) .................................................... 12.0

Sinks

Bar ........................................................................................... 1/2" 1.0 2.0

Clinic Faucet............................................................................. 1/2 3.0

Clinic Flushometer Valve ..........................................................

with or without faucet ............................................................ 1 8.0

Kitchen, domestic ..................................................................... 1/2" 1.5 1.5

Laundry .................................................................................... 1/2" 1.5 1.5

Service or Mop Basin ................................................................ 1/2" 1.5 3.0

Washup, each set of faucets ..................................................... 1/2" 2.0

Shower ........................................................................................ 1/2" 2.0 2.0

Urinal, 1.0 GPF ............................................................................ 3/4" 3.0 4.0 5.0

Urinal, greater than 1.0 GPF ........................................................ 3/4" 4.0 5.0 6.0

Urinal, flush tank .......................................................................... 1/2" 2.0 2.0 3.0

Washfountain, circular spray ........................................................ 3/4" 4.0

Water Closet, 1.6 GPF Gravity Tank ............................................ 1/2" 2.5 2.5 3.5

Water Closet, 1.6 GPF Flushometer Tank .................................... 1/2" 2.5 2.5 3.5

Water Closet, 1.6 GPF Flushometer Valve ................................... 1" 5.0 5.0 6.0

Water Closet, greater than 1.6 GPF Gravity Tank ........................ 1/2" 3.0 5.5 7.0

Water Closet, greater than 1.6 GPF Flushometer Valve ............... 1" 7.0 8.0 10.0

Notes:

1. Size of the cold branch outlet pipe, or both the hot and cold branch outlet pipes.

2. Appliances, Appurtenances or Fixtures not included in this Table may be sized by reference to fixtures having a similar flow rate

and frequency of use.

3. The listed fixture unit values represent their total load on the cold water service. The separate cold water and hot water fixture unit

value for fixtures having both cold and hot water connections shall each be taken as three-quarters (3/4) of the listed total value of

the fixture.

4. The listed minimum supply branch pipe sizes for individual fixtures are the nominal (I.D.) pipe size.

5. For fixtures or supply connections likely to impose continuous flow demands, determine the required flow in gallons per minute

(GPM) and add it separately to the demand (in GPM) for the distribution system or portions thereof.

6. Assembly [Public Use (See Table 4-1)].

7. Reduced fixture unit loading for additional hose bibbs as used is to be used only when sizing total building demand and for pipe

sizing when more than one hose bibb is supplied by a segment of water distributing pipe. The fixture branch to each hose bibb

shall be sized on the basis of 2.5 fixture units.

162

SIZING WATER SYSTEMS

most manufacturers of water meters. Friction losses

for disk type meters may be obtained from Chart A-1.

A 1.3 Obtain all available local information

regarding the use of different kinds of pipe with

respect both to durability and to decrease in capacity

with length of service in the particular water supply.

A 2 Demand Load

A 2.1 Estimate the supply demand for the

building main and the principal branches and risers

of the system by totaling the fixture units on each,

Table A-2, and then by reading the corresponding

ordinate from Chart A-2 or A-3, whichever is

applicable.

A 2.2 Estimate continuous supply demands in

gallons per minute (liters per second) for lawn

sprinklers, air conditioners, etc., and add the sum to

the total demand for fixtures. The result is the

estimated supply demand of the building supply.

A 3 Permissible Friction Loss

A 3.1 Decide what is the desirable minimum

residual pressure that shall be maintained at the

highest fixture in the supply system. If the highest

group of fixtures contains flushometer valves, the

residual pressure for the group shall not be less than

fifteen (15) psi (103 kPa). For flush tank supplies, the

available residual pressure shall not be less than

eight (8) psi (55 kPa).

Appendix A

A 3.2 Determine the elevation of the highest

fixture or group of fixtures above the water (street)

main. Multiply this difference in elevation by forty-

three hundredths (0.43). The result is the loss in static

pressure in psi (pounds per square inch) (kPa).

A 3.3 Subtract the sum of loss in static

pressure and the residual pressure to be maintained

at the highest fixture from the average minimum

daily service pressure. The result will be the pressure

available for friction loss in the supply pipes, if no

water meter is used. If a meter is to be installed, the

friction loss in the meter for the estimated maximum

demand should also be subtracted from the service

pressure to determine the pressure loss available for

friction loss in the supply pipes.

A 3.4 Determine the developed length of pipe

from the water (street) main to the highest fixture. If

close estimates are desired, compute with the aid of

Table A-3 the equivalent length of pipe for all fittings

in the line from the water (street) main to the highest

fixture and add the sum to the developed length. The

pressure available for friction loss in pounds per

square inch (kPa), divided by the developed lengths

of pipe from the water (street) main to the highest

fixture, times one hundred (100), will be the average

permissible friction loss per one hundred (100) foot

(30480 mm) length of pipe.

A 4 Size of Building Supply

A 4.1 Knowing the permissible friction loss

TABLE A-3

Allowance in equivalent length of pipe for friction loss

in valves and threaded fittings.*

Equivalent Length of Pipe for Various Fittings

90 45 Coupling or

Diameter Standard Standard Standard Straight Gate Globe Angle

of fitting Elbow Elbow Tee 90 Run of Tee Valve Valve Valve

Inches Feet Feet Feet Feet Feet Feet Feet

3/8 1.0 0.6 1.5 0.3 0.2 8 4

1/2 2.0 1.2 3.0 0.6 0.4 15 8

3/4 2.5 1.5 4.0 0.8 0.5 20 12

1 3.0 1.8 5.0 0.9 0.6 25 15

1-1/4 4.0 2.4 6.0 1.2 0.8 35 18

1-1/2 5.0 3.0 7.0 1.5 1.0 45 22

2 7.0 4.0 10.0 2.0 1.3 55 28

2-1/2 8.0 5.0 12.0 2.5 1.6 65 34

3 10.0 6.0 15.0 3.0 2.0 80 40

4 14.0 8.0 21.0 4.0 2.7 125 55

5 17.0 10.0 25.0 5.0 3.3 140 70

6 20.0 12.0 30.0 6.0 4.0 165 80

163

Appendix A UNIFORM PLUMBING CODE

TABLE A-3 (Metric)

Equivalent Length of Pipe for Various Fittings

90 45 Coupling or

Diameter Standard Standard Standard Straight Gate Globe Angle

of fitting Elbow Elbow Tee 90 Run of Tee Valve Valve Valve

mm mm mm mm mm mm mm mm

10 305 183 457 91 61 2438 1219

15 610 366 914 183 122 4572 2438

20 762 457 1219 244 152 6096 3658

25 914 549 1524 274 183 7620 4572

32 1219 732 1829 366 244 10668 5486

40 1524 914 2134 457 305 13716 6706

50 2134 1219 3048 610 396 16764 8534

65 2438 1524 3658 762 488 19812 10363

80 3048 1829 4572 914 610 24384 12192

100 4267 2438 6401 1219 823 38100 16764

125 5182 3048 7620 1524 1006 42672 21336

150 6096 3658 9144 1829 1219 50292 24384

*Allowances are based on non-recessed threaded fittings. Use one-half (1/2) the allowances for recessed threaded

fittings or streamline solder fittings.

per one hundred (100) feet (30480 mm) of pipe and

the total demand, the diameter of the building

supply pipe may be obtained from Charts A-4, A-5,

A-6, or A-7, whichever is applicable. The diameter of

pipe on or next above the coordinate point

corresponding to the estimated total demand and the

permissible friction loss will be the size needed up to

the first branch from the building supply pipe.

A 4.2 If copper tubing or brass pipe is to be

used for the supply piping, and if the character of the

water is such that only slight changes in the

hydraulic characteristics may be expected, Chart A-4

may be used.

A 4.3 Chart A-5 should be used for ferrous

pipe with only the most favorable water supply as

regards corrosion and caking. If the water is hard or

corrosive, Charts A-6 or A-7 will be applicable. For

extremely hard water, it will be advisable to make

additional allowances for the reduction of capacity of

hot water lines in service.

A 5 Size of Principal Branches and Risers

A 5.1 The required size of branches and risers

may be obtained in the same manner as the building

supply by obtaining the demand load on each

branch or riser and using the permissible friction loss

computed in SectionA 3.

164

A 5.2 Fixture branches to the building supply,

if they are sized for the same permissible friction loss

per one hundred (100) feet (30480 mm) of pipe as the

branches and risers to the highest level in the

building, may lead to inadequate water supply to the

upper floor of a building. This may be controlled by:

(1) selecting the sizes of pipe for the different

branches so that the total friction loss in each lower

branch is approximately equal to the total loss in the

riser, including both friction loss and loss in static

pressure; (2) throttling each such branch by means of

a valve until the preceding balance is obtained; (3)

increasing the size of the building supply and risers

above the minimum required to meet the maximum

permissible friction loss.

A 5.3 The size of branches and mains serving

flushometer tanks shall be consistent with sizing

procedures for flush tank water closets.

A 6 General

A 6.1 Velocities shall not exceed 10

feet/second (3.0 m/sec.) or the maximum values

given in the appropriate Installation Standard,

except as otherwise approved by the Administrative

Authority.

A 6.2 If a pressure reducing valve is used in

the building supply, the developed length of supply

SIZING WATER SYSTEMS Appendix A

Example

Fixture Units and Estimated Demands

Building Supply Demand Branch to Hot Water System

Building Supply Demand

Demand Fixture Unit in gallons

Kind of No. of Fixture Unit Total in gpm No. of Demand per minute

Fixtures Fixtures Demand Units (L per sec) Fixtures Calculation (L per sec)

Water Closets 130 8.0 1040 - - - -

Urinals 30 4.0 120 - - - -

Shower Heads 12 2.0 24 - 12 12 x 2 x 3/4 = 18 -

Lavatories 100 1.0 100 - 100 100 x 1 x 3/4 = 75 -

Service Sinks 27 3.0 81 - 27 27 x 3 x 3/4 = 61 -

Total 1365 252 gpm (15.8 L/s) 154 55 gpm (3.4 L/s)

Allowing for 15 psi (103.4 kPa) at the highest fixture under the maximum demand of 252 gallons per minute (15.8

L/sec.), the pressure available for friction loss is found by the following:

55 - [15 + (45 x 0.43)] = 20.65 psi

Metric: 379 - [103.4 + (13.7 x 9.8)] = 142.3 kPa

The allowable friction loss per 100 feet (30.4 m) of pipe is therefore:

100 x 20.65 200 = 10.32 psi

Metric: 30.4 x 142.3 60.8 = 71.1 kPa

piping and the permissible friction loss should be

computed from the building side of the valve.

A 6.3 The allowances in Table A-3 for fittings

are based on non-recessed threaded fittings. For

recessed threaded fittings and streamlined soldered

fittings, one-half (1/2) the allowances given in the

table will be ample.

A 7 Example

A 7.1 Assume an office building of four (4)

stories and basement; pressure on the building side

of the pressure reducing valve of fifty-five (55) psi

(379 kPa) (after an allowance for reduced pressure

fall off at peak demand); an elevation of highest

fixture above the pressure reducing valve of forty-

five (45) feet (13716 mm); a developed length of pipe

from the pressure reducing valve to the most distant

fixture of two hundred (200) feet (60960 mm); and

fixtures to be installed with flush valves for water

closets and stall urinals as follows:

If the pipe material and water supply are such that

Chart A-5 applies, the required diameter of the

building supply is three (3) inches (80 mm), and the

required diameter of the branch to the hot water

heater is one and one half (1-1/2) inch (40 mm).

The sizes of the various branches and risers may be

determined in the same manner as the size of the

building supply or the branch to the hot water

system by estimating the demand for the riser or

branch from Charts A-2 or A-3, and applying the

total demand estimate from the branch, riser or

section thereof, to the appropriate flow

165

D

e

m

a

n

d

-

G

.

P

.

M

.

D

e

m

a

n

d

-

L

i

t

e

r

s

/

S

e

c

o

n

d

Appendix A UNIFORM PLUMBING CODE

CHART A-2

Estimate Curves for Demand Load

500

400

300

200

1

100

2

No. 1 for system predominantly for flushometer valves

No. 2 for system predominantly for flush tanks

0 500 1000 1500 2000 2500 3000

Fixture Units

CHART A-2 (Metric)

Estimate Curves for Demand Load

31.5

25.4

18.9

12.6

1

No. 1 for system predominantly for flushometer valves

6.3 2

No. 2 for system predominantly for flush tanks

0 500 1000 1500 2000 2500 3000

Fixture Units

166

D

e

m

a

n

d

-

G

.

P

.

M

.

D

e

m

a

n

d

-

L

i

t

e

r

s

/

S

e

c

o

n

d

SIZING WATER SYSTEMS

100

80

60

40

Appendix A

CHART A-3

Enlarged Scale Demand Load

1

20

2

0 20 40 60 80 100 120 140 160 180 200 220 240

Fixture Units

CHART A-3 (Metric)

Enlarged Scale Demand Load

6.3

5.0

3.8

2.5

1.3

1

2

0 20 40 60 80 100 120 140 160 180 200 220 240

Fixture Units

167

F

l

o

w

i

n

G

a

l

l

o

n

s

p

e

r

M

i

n

u

t

e

Appendix A

CHART A-4

Copper Tubing

Smooth Pipe

Type M

Type L

Type K

0.1 0.2 0.3 0.4 0.60.8 1 2 3 4 5 6 8 10 20 30 405060

Friction Loss - Lbs. per Square Inch Head per 100 Foot Length

168

UNIFORM PLUMBING CODE

10,000

8000

6000

5000

4000

3000

2000

1000

800

600

500

400

300

200

100

80

60

50

40

30

20

10

8

6

5

4

3

2

1

80100

F

l

o

w

i

n

L

i

t

e

r

s

p

e

r

S

e

c

o

n

d

3

.

0

6

.

6

9

.

9

1

3

.

2

1

6

.

4

1

9

.

7

2

6

.

3

3

2

.

9

6

5

.

8

9

8

.

7

1

3

1

.

6

1

6

4

.

5

1

9

7

.

4

2

6

3

.

2

3

2

9

.

0

6

5

7

.

9

9

8

6

.

8

1

3

1

5

.

8

1

6

4

4

.

7

1

9

7

3

.

7

2

6

3

1

.

6

3

2

8

9

.

5

SIZING WATER SYSTEMS

Copper Tubing

Smooth Pipe

Type M

Type L

Type K

CHART A-4 (Metric)

Friction Loss - 32.9 Pa/m

Appendix A

630.0

504.0

378.0

315.0

252.0

189.0

126.0

63.0

50.4

37.8

31.5

25.2

18.9

12.6

6.3

5.0

3.8

3.2

2.5

1.9

1.3

0.6

0.5

0.4

0.4

0.3

0.3

0.2

0.1

169

F

l

o

w

i

n

G

a

l

l

o

n

s

p

e

r

M

i

n

u

t

e

Appendix A

CHART A-5

Fairly Smooth

0.1 0.2 0.3 0.4 0.6 0.81 2 3 4 5 6 8 10 20 30 405060

Friction Loss - Lbs. per Square Inch Head per 100 Foot Length

170

UNIFORM PLUMBING CODE

10,000

8000

6000

5000

4000

3000

2000

1000

800

600

500

400

300

200

100

80

60

50

40

30

20

10

8

6

5

4

3

2

1

80100

F

l

o

w

i

n

L

i

t

e

r

s

p

e

r

S

e

c

o

n

d

3

.

0

6

.

6

9

.

9

1

3

.

2

1

6

.

4

1

9

.

7

2

6

.

3

3

2

.

9

6

5

.

8

9

8

.

7

1

3

1

.

6

1

6

4

.

5

1

9

7

.

4

2

6

3

.

2

3

2

9

.

0

6

5

7

.

9

9

8

6

.

8

1

3

1

5

.

8

1

6

4

4

.

7

1

9

7

3

.

7

2

6

3

1

.

6

3

2

8

9

.

5

SIZING WATER SYSTEMS Appendix A

CHART A-5 (Metric)

630.0

504.0

Fairly Smooth 378.0

315.0

252.0

189.0

126.0

63.0

50.4

37.8

31.5

25.2

18.9

12.6

6.3

5.0

3.8

3.2

2.5

1.9

1.3

0.6

0.5

0.4

0.4

0.3

0.3

0.2

0.1

Friction Loss - 32.9 Pa/m

171

F

l

o

w

i

n

G

a

l

l

o

n

s

p

e

r

M

i

n

u

t

e

Appendix A UNIFORM PLUMBING CODE

CHART A-6

10,000

8000

Fairly Rough 6000

5000

4000

3000

2000

1000

800

600

500

400

300

200

100

80

60

50

40

30

20

10

8

6

5

4

3

2

1

0.1 0.2 0.30.4 0.60.8 1 2 3 4 5 6 8 10 20 30 405060 80100

Friction Loss - Lbs. per Square Inch Head per 100 Foot Length

172

3

.

0

6

.

6

9

.

9

1

3

.

2

1

6

.

4

1

9

.

7

2

6

.

3

3

2

9

.

0

6

5

.

8

9

8

.

7

1

3

1

.

6

1

6

4

.

5

1

9

7

.

4

2

6

3

.

2

6

5

7

.

9

9

8

6

.

8

1

3

1

5

.

8

1

6

4

4

.

7

1

9

7

3

.

7

2

6

3

1

.

6

3

2

8

9

.

5

3

2

.

9

F

l

o

w

i

n

L

i

t

e

r

s

p

e

r

S

e

c

o

n

d

SIZING WATER SYSTEMS Appendix A

CHART A-6 (Metric)

630.0

504.0

Fairly Rough 378.0

315.0

252.0

189.0

126.0

63.0

50.4

37.8

31.5

25.2

18.9

12.6

6.3

5.0

3.8

3.2

2.5

1.9

1.3

0.6

0.5

0.4

0.4

0.3

0.3

0.2

0.1

Friction Loss - 32.9 Pa/m

173

F

l

o

w

i

n

G

a

l

l

o

n

s

p

e

r

M

i

n

u

t

e

Appendix A UNIFORM PLUMBING CODE

CHART A-7

10,000

8000

Rough 6000

5000

4000

3000

2000

1000

800

600

500

400

300

200

100

80

60

50

40

30

20

10

8

6

5

4

3

2

1

0.1 0.2 0.3 0.4 0.60.8 1 2 3 4 56 8 10 20 30 405060 80100

Friction Loss - Lbs. per Square Inch Head per 100 Foot Length

174

F

l

o

w

i

n

L

i

t

e

r

s

p

e

r

S

e

c

o

n

d

3

.

0

6

.

6

9

.

9

1

3

.

2

1

6

.

4

1

9

.

7

2

6

.

3

3

2

9

.

0

6

5

.

8

9

8

.

7

1

3

1

.

6

1

6

4

.

5

1

9

7

.

4

2

6

3

.

2

6

5

7

.

9

9

8

6

.

8

1

3

1

5

.

8

1

6

4

4

.

7

1

9

7

3

.

7

2

6

3

1

.

6

3

2

8

9

.

5

3

2

.

9

SIZING WATER SYSTEMS Appendix A

CHART A-7 (Metric)

630.0

504.0

Rough 378.0

315.0

252.0

189.0

126.0

63.0

50.4

37.8

31.5

25.2

18.9

12.6

6.3

5.0

3.8

3.2

2.5

1.9

1.3

0.6

0.5

0.4

0.4

0.3

0.3

0.2

0.1

Friction Loss - 32.9 Pa/m

175

You might also like

- Revised National Plumbing Code of The PhilippinesDocument225 pagesRevised National Plumbing Code of The PhilippinesGizelle Ambasan91% (85)

- Revised National Plumbing Code of The PhilippinesDocument225 pagesRevised National Plumbing Code of The PhilippinesGizelle Ambasan91% (85)

- Revised National Plumbing Code of The PhilippinesDocument225 pagesRevised National Plumbing Code of The PhilippinesGizelle Ambasan91% (85)

- Revised National Plumbing Code of The PhilippinesDocument225 pagesRevised National Plumbing Code of The PhilippinesGizelle Ambasan91% (85)

- Motor Protection: Module #2Document32 pagesMotor Protection: Module #2Reymart Manablug50% (2)

- ASPE Sump Pump SizingDocument60 pagesASPE Sump Pump Sizingzaqhusanz100% (5)

- Plumbing Systems 5-Storm Water Drainage SystemDocument27 pagesPlumbing Systems 5-Storm Water Drainage SystemArnel Alvarez100% (1)

- Water Supply and Distribution SystemDocument33 pagesWater Supply and Distribution SystemLeera Lee Adorablé100% (2)

- New Plumbing Calculation SheetDocument15 pagesNew Plumbing Calculation SheetRamadan Rashad100% (1)

- 1 VentsDocument4 pages1 VentsEugene MicarandayoNo ratings yet

- Two Storey Structural DesignDocument9 pagesTwo Storey Structural Designking taugNo ratings yet

- A-Z in Plumbing and Fire Fighting DesignDocument63 pagesA-Z in Plumbing and Fire Fighting DesignArnel Alvarez92% (13)

- Methods of Collecting DataDocument26 pagesMethods of Collecting DataLolol LololNo ratings yet

- Basics of AFSS DesignDocument59 pagesBasics of AFSS DesignJoseph Ryan Manandeg100% (2)

- 005a - Plumbing ToolsDocument159 pages005a - Plumbing ToolsdinoNo ratings yet

- Risk Assessment of Ship Platform ColissionDocument6 pagesRisk Assessment of Ship Platform Colission123habib123fikriNo ratings yet

- Plumbing Fixtures Pipes and FittingsDocument4 pagesPlumbing Fixtures Pipes and FittingsNicole RodilNo ratings yet

- Rainfall-Runoff RelationDocument58 pagesRainfall-Runoff RelationEam100% (2)

- Lecture 2 Sanitary Pipe SizingDocument52 pagesLecture 2 Sanitary Pipe SizingAlchea Aldeguer100% (1)

- MODULE 8. Sizing of Water LinesDocument4 pagesMODULE 8. Sizing of Water LinesFernando PascualNo ratings yet

- 2014 - 0011b Pipe Sizing For Water Supply and DistributionDocument34 pages2014 - 0011b Pipe Sizing For Water Supply and Distributiondino100% (1)

- Maya Dynamics Basics:: MEL and ExpressionDocument33 pagesMaya Dynamics Basics:: MEL and ExpressionNguyễn HuỳnhNo ratings yet

- Plumbing ReferencesDocument5 pagesPlumbing ReferencesEddito CachoNo ratings yet

- Airfield Pavement2Document12 pagesAirfield Pavement2molgarNo ratings yet

- Sanitary EngineeringDocument9 pagesSanitary EngineeringaulaNo ratings yet

- Max FajardoDocument15 pagesMax FajardoJomari Pecson0% (1)

- ARMY Plumbing III - Waste Systems EN5112 102 PagesDocument102 pagesARMY Plumbing III - Waste Systems EN5112 102 PagesStevenNo ratings yet

- Unit 3 - Losses From Precipitation (Evaporation)Document51 pagesUnit 3 - Losses From Precipitation (Evaporation)Theeva RajNo ratings yet

- Building Plumbing Systems Design - (Lecture 01-Introduction)Document30 pagesBuilding Plumbing Systems Design - (Lecture 01-Introduction)محمد إسلام عبابنه100% (3)

- Quiz No. 01 Plumbing Arithmetic (10%)Document28 pagesQuiz No. 01 Plumbing Arithmetic (10%)Shadow100% (1)

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- Gear Manufacturing ProcessDocument30 pagesGear Manufacturing ProcessSanjay MehrishiNo ratings yet

- Water Consumption AND Water DemandDocument40 pagesWater Consumption AND Water DemandGerlie DimayugaNo ratings yet

- Building Svs - Plumbing and Sanitary ServicesDocument84 pagesBuilding Svs - Plumbing and Sanitary ServicesArnel Alvarez0% (1)

- Module 12-Private STPDocument89 pagesModule 12-Private STPPhel FloresNo ratings yet

- Plumbing Specs SampleDocument7 pagesPlumbing Specs SampleRichmond SyNo ratings yet

- Master Plumber QuestionnaireDocument131 pagesMaster Plumber QuestionnaireJana Kashim100% (1)

- On-Site Sewage Treatment HandoutDocument14 pagesOn-Site Sewage Treatment HandoutJhyneJazarenoAtutuboNo ratings yet

- Vents, Joints, TrapsDocument9 pagesVents, Joints, TrapsKevinNavidadNo ratings yet

- Master Plumbers Reviewers 06-10-19Document4 pagesMaster Plumbers Reviewers 06-10-19kenneth0% (1)

- Pipe Size Calculation-ResidentialDocument34 pagesPipe Size Calculation-ResidentialSedfrey Pekitpekit100% (1)

- History of Plumbing Practice of The PhilippinesDocument40 pagesHistory of Plumbing Practice of The PhilippinesArnel Alvarez79% (19)

- Senate Bill No. 2008 - Plumbing Engineering LawDocument15 pagesSenate Bill No. 2008 - Plumbing Engineering LawJhobs Besmonte100% (1)

- July 2015 Master Plumber Terms IncludedDocument5 pagesJuly 2015 Master Plumber Terms Includedzenzen1100% (1)

- Storm Drainage System: By: Niel John C. SalgadoDocument18 pagesStorm Drainage System: By: Niel John C. SalgadoCharles Dominic Reyes TapnioNo ratings yet

- Understanding STP StagesDocument25 pagesUnderstanding STP StagesArnel AlvarezNo ratings yet

- Module 4elementsofplumbingDocument44 pagesModule 4elementsofplumbingMarvin Pavo100% (1)

- Baguio Water District (BAWADI) : SourcesDocument4 pagesBaguio Water District (BAWADI) : SourcesDom Vincent LasMarias SabasNo ratings yet

- 4 Water Consumption & Water DemandDocument22 pages4 Water Consumption & Water DemandLeera Lee AdorabléNo ratings yet

- Water Pressure ConsiderationsDocument18 pagesWater Pressure ConsiderationsEnha EnhaNo ratings yet

- Equivalent Water Supply Fixture UnitsDocument1 pageEquivalent Water Supply Fixture UnitsJoey MelencionNo ratings yet

- Plumbing Arithmetic 10-20Document2 pagesPlumbing Arithmetic 10-20Philip JohnNo ratings yet

- 9 HYDRAULICALLY Plumbing System - ShopDocument5 pages9 HYDRAULICALLY Plumbing System - Shopjurhym doteNo ratings yet

- Revised National Plumbing Code of The PhilippinesDocument24 pagesRevised National Plumbing Code of The PhilippinesJohn michael Del rosarioNo ratings yet

- Computations: Table 9-1 Size of Storm Drain Table 9-2 Size of Roof Gutter and Roof LeaderDocument12 pagesComputations: Table 9-1 Size of Storm Drain Table 9-2 Size of Roof Gutter and Roof LeaderZedrickTrinidadNo ratings yet

- National Plumbing Code of The Philippines - Architecture Is Fun! PDFDocument5 pagesNational Plumbing Code of The Philippines - Architecture Is Fun! PDFJayson Jedidiah UdangNo ratings yet

- Refresher Arithmetic 101-200Document6 pagesRefresher Arithmetic 101-200Dash SmthNo ratings yet

- Anghel A Open ChannelsDocument32 pagesAnghel A Open ChannelsJovan Bucol100% (1)

- PIPES ParallelDocument27 pagesPIPES ParallelSalman100% (1)

- Ra 1378Document22 pagesRa 1378kayrellenormaeNo ratings yet

- Plumbing Arithmetic 20-30Document2 pagesPlumbing Arithmetic 20-30Philip JohnNo ratings yet

- Sanitary and Plumbing Systems and EquipmentDocument117 pagesSanitary and Plumbing Systems and EquipmentJustine Policarpio Fabian100% (5)

- ASPE PSD - Storm Drainage ComponentsDocument2 pagesASPE PSD - Storm Drainage ComponentsNiong DavidNo ratings yet

- Private Sewage Disposal Sys.Document3 pagesPrivate Sewage Disposal Sys.KevinNavidad50% (2)

- Research Work 3Document11 pagesResearch Work 3Fer MaeNo ratings yet

- BDBDBDBD 1Document51 pagesBDBDBDBD 1artemio john clave100% (1)

- Design of Beam Using Ultimate Strength Design (Usd) Method Based On The Nscp2015 Singly Reinforced Rectangular BeamsDocument20 pagesDesign of Beam Using Ultimate Strength Design (Usd) Method Based On The Nscp2015 Singly Reinforced Rectangular BeamsWalter CatapangNo ratings yet

- Rainfall Analysis (1) : HydrologyDocument64 pagesRainfall Analysis (1) : Hydrologymrs_minalNo ratings yet

- Irrigation Implements and Structures WaterxzxDocument8 pagesIrrigation Implements and Structures Waterxzxlyka g100% (1)

- Sanitary EnggDocument8 pagesSanitary EnggAdNo ratings yet

- Types of Water Closet: Siphon-VortexDocument2 pagesTypes of Water Closet: Siphon-VortexMherlieNo ratings yet

- Sanitary Design & Lay-OutingDocument29 pagesSanitary Design & Lay-OutingJeco BildNo ratings yet

- River NavigationDocument7 pagesRiver NavigationIntan MadiaaNo ratings yet

- (Excerpts From The National Plumbing Code (1993-1994 Revision)Document51 pages(Excerpts From The National Plumbing Code (1993-1994 Revision)Dave MarkNo ratings yet

- Electrical-Communication-Security-Fire-Building Service SystemsDocument2 pagesElectrical-Communication-Security-Fire-Building Service SystemsPrincess Morales TyNo ratings yet

- Appendices: Recommended Rules For Sizing The Water Supply SystemDocument21 pagesAppendices: Recommended Rules For Sizing The Water Supply Systemrex tanongNo ratings yet

- 006 Chapter 3-General Regulations PDFDocument8 pages006 Chapter 3-General Regulations PDFArnel AlvarezNo ratings yet

- 009a Water Supply & Distribution Upc PDFDocument15 pages009a Water Supply & Distribution Upc PDFArnel AlvarezNo ratings yet

- 001 History of Plumbing Practice PDFDocument3 pages001 History of Plumbing Practice PDFArnel AlvarezNo ratings yet

- 003 Master Plumber Code of Ethics PDFDocument1 page003 Master Plumber Code of Ethics PDFArnel AlvarezNo ratings yet

- 009 Chapter 6-Water Supply and DistributionDocument22 pages009 Chapter 6-Water Supply and DistributionArnel AlvarezNo ratings yet

- 136-143 House Drains and House SewersDocument8 pages136-143 House Drains and House SewersArnel AlvarezNo ratings yet

- 004 Chapter 1-Administration PDFDocument7 pages004 Chapter 1-Administration PDFArnel AlvarezNo ratings yet

- 171-184 Appendix A-Recommended Rules For Sizing The Water Supply SystemDocument14 pages171-184 Appendix A-Recommended Rules For Sizing The Water Supply SystemArnel AlvarezNo ratings yet

- 108-112 Vents and VentingDocument5 pages108-112 Vents and VentingArnel AlvarezNo ratings yet

- 005a Definitions Upc PDFDocument8 pages005a Definitions Upc PDFArnel AlvarezNo ratings yet

- Barry Construction of Buildings Volume 1Document287 pagesBarry Construction of Buildings Volume 1nourhan97% (33)

- 001design Tables of Reinforced Concrete MembersDocument21 pages001design Tables of Reinforced Concrete MembersjoeycolerangleNo ratings yet

- Water Corp Plumbing HandbookDocument48 pagesWater Corp Plumbing HandbookSarah Pancevska100% (1)

- Compendium of Sanitation Systems and TechnologiesDocument158 pagesCompendium of Sanitation Systems and TechnologiesSpaceTurtleNo ratings yet

- PC-Traps, Cleanouts and ValvesDocument16 pagesPC-Traps, Cleanouts and ValvesArnel AlvarezNo ratings yet

- Plumbing Systems 1-Plumbing FixturesDocument54 pagesPlumbing Systems 1-Plumbing FixturesArnel AlvarezNo ratings yet

- Apparent Calling CardDocument1 pageApparent Calling CardArnel AlvarezNo ratings yet

- PC Apendix DDocument6 pagesPC Apendix DArnel AlvarezNo ratings yet

- Spesifikasi Teknis Genset Dan AtsDocument2 pagesSpesifikasi Teknis Genset Dan AtsRamadan yusuf afifNo ratings yet

- Supply Installation Commissioning of Worlld Largest MillDocument12 pagesSupply Installation Commissioning of Worlld Largest MillAbe ArdiNo ratings yet

- Wea Met Aws310 Brochure 210x280 B211290en C Low v2Document4 pagesWea Met Aws310 Brochure 210x280 B211290en C Low v2Anonymous rpSGuQPNo ratings yet

- Basics, Maintenance, and Diagnostics 19Document1 pageBasics, Maintenance, and Diagnostics 19imcoolmailme2No ratings yet

- Tablet Processing Problems and Their Remedies: Baharul IslamDocument16 pagesTablet Processing Problems and Their Remedies: Baharul IslamEspañola EloiseNo ratings yet

- Eaton Fuller - Autoshift 16 Service Manual (T20891)Document81 pagesEaton Fuller - Autoshift 16 Service Manual (T20891)Miller Andres ArocaNo ratings yet

- C & Embedded QuestionsDocument109 pagesC & Embedded QuestionskalkikaliNo ratings yet

- Wos 2 Pajek 07Document36 pagesWos 2 Pajek 07Omar SitoNo ratings yet

- Mahesh - Informatica DeveloperDocument5 pagesMahesh - Informatica DeveloperMadhav GarikapatiNo ratings yet

- Why Might Some People Regard Science As The Supreme Form of All KnowledgeDocument4 pagesWhy Might Some People Regard Science As The Supreme Form of All KnowledgexxxsyedxxNo ratings yet

- Lista Ejercicios 3 PPEDocument25 pagesLista Ejercicios 3 PPEKarla HermorNo ratings yet

- Switching Theory and Logic DesignDocument89 pagesSwitching Theory and Logic DesignUppalaguptam Hari Satya PriyaNo ratings yet

- Aqa Byb1 W QP Jun07Document12 pagesAqa Byb1 W QP Jun07李超然No ratings yet

- PRINCIPLES OF SURGERY (James R. Hupp Chapter 3 Notes) : 1. Develop A Surgical DiagnosisDocument5 pagesPRINCIPLES OF SURGERY (James R. Hupp Chapter 3 Notes) : 1. Develop A Surgical DiagnosisSonia LeeNo ratings yet

- Lesson 5 Appraising Diagnostic Research StudiesDocument23 pagesLesson 5 Appraising Diagnostic Research StudiesProject MedbooksNo ratings yet

- Understand Concept of Multi-Rate Signal Processing: (Autonomous College Affiliated To University of Mumbai)Document2 pagesUnderstand Concept of Multi-Rate Signal Processing: (Autonomous College Affiliated To University of Mumbai)nicO neeNo ratings yet

- BUshed Pin TypeDocument48 pagesBUshed Pin TypeAkshayNo ratings yet

- DLP in Law of SineDocument4 pagesDLP in Law of SineRed DeverraNo ratings yet

- Bacillariophyceae (Heterokontophyta)Document11 pagesBacillariophyceae (Heterokontophyta)Anjali OjhaNo ratings yet

- 17.alekhya Research ArticleDocument8 pages17.alekhya Research ArticleBaru Chandrasekhar RaoNo ratings yet

- Method Comparison Study Report For The ISO 16140-2:2016 Validation of Compact Dry EC, For The Enumeration of ColiformsDocument24 pagesMethod Comparison Study Report For The ISO 16140-2:2016 Validation of Compact Dry EC, For The Enumeration of ColiformsKAREEMNo ratings yet

- Math Iv Chapter 3Document60 pagesMath Iv Chapter 3Benjamin AkingeneyeNo ratings yet

- Quadratic Equation - MATH IS FUNDocument8 pagesQuadratic Equation - MATH IS FUNChanchan LebumfacilNo ratings yet

- Assigment Sheet Tast 2 Aina MardianaDocument10 pagesAssigment Sheet Tast 2 Aina MardianaAina MardianaNo ratings yet