Professional Documents

Culture Documents

Function and Composition of A Surface Layer

Uploaded by

Sandeep Vaishnav0 ratings0% found this document useful (0 votes)

39 views2 pagesFunction and composition of a surface layer

Original Title

Function and Composition of a Surface Layer

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFunction and composition of a surface layer

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

39 views2 pagesFunction and Composition of A Surface Layer

Uploaded by

Sandeep VaishnavFunction and composition of a surface layer

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Function and composition of a surface layer

LEARNING ELEMENT OBJECTIVES

After you have learned this element you should be able to:

- explain the function of a surface layer;

- describe when a soil is suitable to be used as surfacing material;

- describe the functions and desirable quantities of the various fractions in a surface layer soil.

A road can be built up of a number of different layers: and weakening the base and subgrade, subgrade, sub-base, base and surface

layer. Roads which are built for traffic by a few light vehicles or on very good soils do not need all these different layers; it is usually

sufficient to put on a good surface layer. Sometimes even the natural soil is strong enough to carry the projected number of

vehicles. Surface layers serve to spread the traffic load (usually through a base), so that the subgrade (natural) soil is protected

from overloading and deformation. Bituminous surface layers also seal the surface and prevent surface water (rain) from

penetrating and weakening the base and subgrade.

In the case of a gravelled road this function is carried out partly by the gravel layer and partly by the camber of the road.

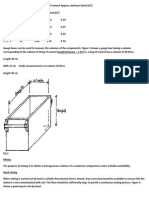

Fig 6

The type (bitumen, gravel, stabilised soil or natural soil) and thickness of the surface layer should ideally be determined by the

expected traffic density and the type of the natural soil. However, usually other factors, such as available funds, the location of the

road and the availability of suitable material in the area are more important when surface layers are designed.

The suitability of a soil for a surface layer depends on its behaviour in dry and wet weather. In dry weather a fairly high proportion

of clay is desirable to bind the particles together and to prevent corrugation. However, in wet weather the presence of a lot of clay

in the mixture is disadvantageous, because it makes the surface slippery and ruts are easily formed. Therefore, the specifications

for a soil to be used as a surface layer have to be a compromise between the ideal requirements for wet and dry weather.

As a rough guide, a mixture of 35-65 per cent stones, 20-40 per cent sand and 10-25 per cent clay will produce an optimum soil for

a surface layer. A higher proportion (up to 65 per cent) of suitably sized stones is preferable, as the strength and density of the hard

stones will provide a stronger surface. The gravel will behave better if the stones in the mixture are of various sizes well graded,

so that the voids in between the particles, are filled. Angular-shaped particles are preferable, because they will lock together

better than round particles.

Pure clay and silts, mixtures of silt and clay, and organic soils are generally unsuitable for surface layers.

The stony particles to be used in a surface layer should not be bigger than 3 cm in order to obtain a reasonably smooth finish.

Bigger particles should be crushed by hand or by roller.

Fig 7

A good surface layer should spread the traffic load evenly to the underlying base and prevent water from penetrating. It should also

be resistant to corrugation and provide a non-slippery and dust-free surface.

Although such surfaces can hardly be made with earth or gravel, fair results can be achieved by avoiding pure clays and silts,

mixtures of clays and silt, and organic soils.

A mixture of some 10-25 per cent clay and a good gravel (i.e. small stones of different sizes + sand) can provide a very good surface

material.

Sand/clay mixtures also provide reasonable surfaces, although the strength and durability are less than a mixture in which stones

(gravel) are present. Here again, not more than 25 per cent clay should be present in the mixture

You might also like

- Height of Colimation MethodDocument4 pagesHeight of Colimation MethodSandeep VaishnavNo ratings yet

- Routine Maintenance Activities For RoadDocument1 pageRoutine Maintenance Activities For RoadSandeep VaishnavNo ratings yet

- WTP Design 3.12 MLDDocument21 pagesWTP Design 3.12 MLDSandeep VaishnavNo ratings yet

- Manning Equation For Discharge & Rating Puna-1Document30 pagesManning Equation For Discharge & Rating Puna-1Sandeep VaishnavNo ratings yet

- Discharges of Punatsangchhu River Near Taksha Parameters Computed DischargesDocument2 pagesDischarges of Punatsangchhu River Near Taksha Parameters Computed DischargesSandeep VaishnavNo ratings yet

- Discharge KamechhuDocument1 pageDischarge KamechhuSandeep VaishnavNo ratings yet

- Final EmoDocument21 pagesFinal EmoSandeep VaishnavNo ratings yet

- LE-5 Placing, Compacting and Curing of Concrete - 2Document1 pageLE-5 Placing, Compacting and Curing of Concrete - 2Sandeep VaishnavNo ratings yet

- AggregateDocument1 pageAggregateSandeep VaishnavNo ratings yet

- LE-4 The Manufacture of Concrete (Part1)Document2 pagesLE-4 The Manufacture of Concrete (Part1)Sandeep VaishnavNo ratings yet

- LE-4 The Manufacture of Concrete (Part2)Document4 pagesLE-4 The Manufacture of Concrete (Part2)Sandeep VaishnavNo ratings yet

- LE-5 Placing, Compacting and Curing of Concrete - 1Document1 pageLE-5 Placing, Compacting and Curing of Concrete - 1Sandeep VaishnavNo ratings yet

- Simple Field Tests To Determine Soil PropertiesDocument2 pagesSimple Field Tests To Determine Soil PropertiesSandeep VaishnavNo ratings yet

- Improvement of Soils by Mechanical MeansDocument3 pagesImprovement of Soils by Mechanical MeansSandeep VaishnavNo ratings yet

- Catchwater Drains and Scour ChecksDocument3 pagesCatchwater Drains and Scour ChecksSandeep Vaishnav50% (2)

- Nature, Definition and of Soil Mechanics PDFDocument1 pageNature, Definition and of Soil Mechanics PDFSandeep VaishnavNo ratings yet

- Catchwater Drains and Scour ChecksDocument3 pagesCatchwater Drains and Scour ChecksSandeep Vaishnav50% (2)

- Gravel, Sand and Fine Particles in A Soil SampleDocument3 pagesGravel, Sand and Fine Particles in A Soil SampleSandeep VaishnavNo ratings yet

- Types of DrainageDocument2 pagesTypes of DrainageSandeep VaishnavNo ratings yet

- Catchwater Drains and Scour ChecksDocument3 pagesCatchwater Drains and Scour ChecksSandeep Vaishnav50% (2)

- Field Instruction For DrainageDocument4 pagesField Instruction For DrainageSandeep VaishnavNo ratings yet

- Side Drains and Mitre DrainsDocument3 pagesSide Drains and Mitre DrainsSandeep VaishnavNo ratings yet

- Types of DrainageDocument2 pagesTypes of DrainageSandeep VaishnavNo ratings yet

- LE 5 CulvertsDocument3 pagesLE 5 CulvertsSandeep VaishnavNo ratings yet

- 4 Bridge DesignDocument7 pages4 Bridge DesignSandeep VaishnavNo ratings yet

- Water Table DrainageDocument2 pagesWater Table DrainageSandeep VaishnavNo ratings yet

- Catchwater Drains and Scour ChecksDocument3 pagesCatchwater Drains and Scour ChecksSandeep Vaishnav50% (2)

- 3 Culvert DesignDocument5 pages3 Culvert DesignSandeep VaishnavNo ratings yet

- 2 - Cause Way DesignDocument7 pages2 - Cause Way DesignSandeep VaishnavNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Research in International Business and Finance: Huizheng Liu, Zhe Zong, Kate Hynes, Karolien de Bruyne TDocument13 pagesResearch in International Business and Finance: Huizheng Liu, Zhe Zong, Kate Hynes, Karolien de Bruyne TDessy ParamitaNo ratings yet

- BQ - Structural Works - CompressedDocument163 pagesBQ - Structural Works - CompressedLee YuxuanNo ratings yet

- Brochure - Actiwhite PWLS 9860.02012013Document12 pagesBrochure - Actiwhite PWLS 9860.02012013J C Torres FormalabNo ratings yet

- Chapter 3-CP For Armed Conflict SituationDocument23 pagesChapter 3-CP For Armed Conflict Situationisidro.ganadenNo ratings yet

- Manual de Utilizare HUMAX DIGI TV RDSDocument116 pagesManual de Utilizare HUMAX DIGI TV RDSenamicul50No ratings yet

- Case-Based Learning Guide (A)Document19 pagesCase-Based Learning Guide (A)pentagon 5No ratings yet

- Matrix CPP CombineDocument14 pagesMatrix CPP CombineAbhinav PipalNo ratings yet

- An Analysis of The Cloud Computing Security ProblemDocument6 pagesAn Analysis of The Cloud Computing Security Problemrmsaqib1No ratings yet

- N164.UCPE12B LANmark - OF - UC - 12x - Singlemode - 9 - 125 - OS2 - PE - BlackDocument2 pagesN164.UCPE12B LANmark - OF - UC - 12x - Singlemode - 9 - 125 - OS2 - PE - BlackRaniaTortueNo ratings yet

- La La Mei Seaside Resto BAR: Final PlateDocument4 pagesLa La Mei Seaside Resto BAR: Final PlateMichael Ken FurioNo ratings yet

- All About History History of Communism - 4th Edition 2022Document148 pagesAll About History History of Communism - 4th Edition 2022Duke100% (1)

- Corporate Members List Iei Mysore Local CentreDocument296 pagesCorporate Members List Iei Mysore Local CentreNagarjun GowdaNo ratings yet

- Electromyostimulation StudyDocument22 pagesElectromyostimulation StudyAgnes Sophia PenuliarNo ratings yet

- Industry GeneralDocument24 pagesIndustry GeneralilieoniciucNo ratings yet

- 3114 Entrance-Door-Sensor 10 18 18Document5 pages3114 Entrance-Door-Sensor 10 18 18Hamilton Amilcar MirandaNo ratings yet

- Cultural AnthropologyDocument12 pagesCultural AnthropologyTRISH BOCANo ratings yet

- Rfis On Formliners, Cover, and EmbedmentsDocument36 pagesRfis On Formliners, Cover, and Embedmentsali tahaNo ratings yet

- Enzymatic Hydrolysis, Analysis of Mucic Acid Crystals and Osazones, and Thin - Layer Chromatography of Carbohydrates From CassavaDocument8 pagesEnzymatic Hydrolysis, Analysis of Mucic Acid Crystals and Osazones, and Thin - Layer Chromatography of Carbohydrates From CassavaKimberly Mae MesinaNo ratings yet

- Infor Mashup DesignerDocument95 pagesInfor Mashup DesignerBalayogesh Alagesan100% (1)

- F. Moyra Allen: A Life in Nursing, 1921-1996: Meryn Stuart, R.N., PH.DDocument9 pagesF. Moyra Allen: A Life in Nursing, 1921-1996: Meryn Stuart, R.N., PH.DRose Nirwana HandayaniNo ratings yet

- 3 HVDC Converter Control PDFDocument78 pages3 HVDC Converter Control PDFJanaki BonigalaNo ratings yet

- Design and Analysis of DC-DC Boost Converter: September 2016Document5 pagesDesign and Analysis of DC-DC Boost Converter: September 2016Anonymous Vfp0ztNo ratings yet

- Pharmacy System Project PlanDocument8 pagesPharmacy System Project PlankkumarNo ratings yet

- Unix SapDocument4 pagesUnix SapsatyavaninaiduNo ratings yet

- Lab Activity 5Document5 pagesLab Activity 5Jasmin CeciliaNo ratings yet

- Comparison of Multi-Coil and Diaphragm Spring ClutchesDocument3 pagesComparison of Multi-Coil and Diaphragm Spring Clutchesmasb_994077No ratings yet

- MJDF Mcqs - Mixed - PDFDocument19 pagesMJDF Mcqs - Mixed - PDFAyesha Awan0% (3)

- Old Man and The SeaDocument10 pagesOld Man and The SeaXain RanaNo ratings yet

- 8A L31 Phiếu BTDocument7 pages8A L31 Phiếu BTviennhuNo ratings yet

- Matter Around Me: SC1 - Teaching Science in ElementaryDocument27 pagesMatter Around Me: SC1 - Teaching Science in ElementaryYanna Marie Porlucas Macaraeg50% (2)