Professional Documents

Culture Documents

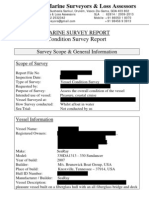

Ground Storage Spec Rev 093011

Uploaded by

Utari Prayetno0 ratings0% found this document useful (0 votes)

11 views7 pagesgygyg

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentgygyg

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views7 pagesGround Storage Spec Rev 093011

Uploaded by

Utari Prayetnogygyg

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 7

SECTION ________ - GROUND-SUPPORTED

FLAT-BOTTOM WATER STORAGE TANK

1. GENERAL REQUIREMENTS

1.1. Scope

The Contractor shall be responsible for all labor, materials and equipment necessary

for the design, fabrication, construction, painting, disinfection and testing of a welded

carbon steel water storage tank built at grade level on a concrete foundation. Design

and construction of the Water torage Tank shall conform to all requirements of

!WW! D1"" tandard for Welded Carbon teel Tanks for Water torage, e#cept as

modified by the requirements of these contract documents. The Contractor may use

ection 1$ of the !WW! D1"" as a part of the design. Tanks designed on this basis

must incorporate all the provisions of this section. The requirements of ection % of

the !WW! D1"" are superseded by any differing requirements of ection 1$.

1.&. Qualiica!io" o Ma"uac!u#e#

The design and construction of the 'round(upported )lat(*ottom Water torage

Tank shall only be undertaken by a Contractor with a minimum of five years e#perience

with tank construction. The Contractor must be able to demonstrate e#perience

through the design and construction of at least five 'round(upported )lat(*ottom

Water torage Tanks. The Contractor shall not subcontract the design or erection of

the steel tank.

1.%. Su$%i!!al&

+o bid will be considered unless this information is provided with the proposal.

1.%.1. ! list of five 'round(upported )lat(*ottom Water torage Tanks constructed

within the last five years, including the ,wner, tank capacity and the -ngineer.

1.%.&. ! preliminary drawing of the tank showing ma.or dimensions and plate thickness

upon which the bid is based, tank diameter, the high water level and the

dimensions of the supporting foundation.

1.%.%. ! foundation design drawing showing preliminary dimensions and appro#imate

quantities of concrete and reinforcing steel.

1.$. S!a"'a#' Speciica!io"&

!ll work on the water storage tank shall fully conform to the requirements of the latest

published editions of the following tandard pecifications/

1.$.1. !WW! 0!merican Water Works !ssociation1 D1"" tandard for Welded Carbon

teel Tanks for Water torage.

1.$.&. !WW! D1"& ( tandard for 2ainting teel Water torage Tanks.

1.$.%. !WW! C34& ( tandard for Disinfection of Water torage )acilities.

1.$.$. !W 0!merican Welding ociety1 D1.1

1.$.4. +) 0+ational anitation )oundation1 31 ( 5aterials in contact with 2otable

Water.

1.$.3. teel tructures 2ainting Council 5anual ( 6olume 1 ( 'ood 2ainting 2ractice,

1 7ev. 1"811

1.$.9. teel tructures 2ainting Council 5anual ( 6olume & ( ystems and

pecifications.

1.$.:. !C; %1: ( *uilding Code 7equirements for 7einforced Concrete

1.$.<. !C; %"1 =pecifications for tructural Concrete

1.4. Ta"( De!ail&

The tank shall be all(welded construction of the most economical design. !ll members

of structural steel or of reinforced concrete shall be designed to safely withstand the

ma#imum stresses to which they may be sub.ected during erection and operation.

1.4.1. The minimum operating capacity of the storage tank will be >>>>>> ? gallons.

1.4.&. The tank diameter will be >>>>>feet.

1.4.%. The height of the tank, top of foundation to @igh Water Aevel, shall be >>>>>

feet.

1.4.$. Top of foundation elevation shall be >>>>>>.

1.4.4. The e#isting ground elevation is >>>>>>.

1.4.3. The finished ground elevation shall be >>>>>>>>.

1.3. Pe#%i!&) Ea&e%e"!&) Elec!#ical Li"e& a"' U!ili!ie&

2ermits, licenses, airspace authority approval and easements required for the

construction of the tank and associated work shall be provided by the ,wner.

The site plan or specifications shall clearly indicate the appro#imate location of all

overhead or underground electrical lines and other utilities and piping. The ,wner is

responsible for relocating or de(energiBing any electrical or utility lines that may

interfere with the safe construction of the foundation or structure0s1. ;n general, no

overhead lines, or supports, shall pass or be located within 4" feet of any part of the

structure or the footprint of the tank. ! minimum vertical clearance of 14 feet shall be

provided along any access routes.

1.9. Wo#(i"* D#a+i"*&

!fter contract award and prior to construction, the Contractor shall provide engineering

drawings and design calculations for the steel tank and the foundation. Drawings shall

show the siBe and location of all structural components and the foundations along with

reinforcement details, the required strength and grade of all materials and the siBe and

arrangement of principle piping and equipment. The drawings and calculations shall

bear the certification of a professional -ngineer licensed in the tate of

>>>>>>>>>>>>. The design coefficients and resultant loads for snow, wind and seismic

forces, and the methods of analysis shall be documented.

2. DESIGN

&.1. Ge"e#al

The structural design of the storage tank shall conform to the following design

standards e#cept as modified or clarified as follows/

&.1.1. )oundations = !WW! D1"" and !C; %1: = *uilding Code 7equirements for

7einforced Concrete.

&.1.&. teel Tank ( !WW! D1""

& 7ev. 1"811

&.1.%. The Contractor may use ection 1$ of the !WW! D1"" as a part of the design.

Tanks designed on this basis must incorporate all the provisions of this section.

The requirements of ection % of the !WW! D1"" are superseded by any

differing requirements of ection 1$.

&.1.$. teel Tank 2ainting = !WW! D1"&

&.&. -nvironmental Aoads = !WW! D1"" and !C- 9

&.&.1. Wind Aoad = Wind pressure shall be determined in accordance with !WW!

D1"", ection %.1.$. *asic wind speed used in the Wind 2ressure formula shall

be determined using the mapped site location and )igure 1 of !WW! D1"".

)or tanks located in coastal regions, the ,wnerCs -ngineer shall consider the

use of an increased basic wind speed as appropriate.

*asic Wind peed 0*W1 D>>>>>>>> 52@

&.&.&. eismic Aoad = eismic loads shall be determined in accordance with !WW!

D1"", ection 1%.

&.&.&.1.1. 7egion Dependent Transition 2eriod 0TA1 D>>>>>>>> 0)ig. 1<1

&.&.&.1.&. ite Class >>>>>>>> 0Table &41

&.&.&.1.%. 5C- pectral 7esponse !cceleration at ".&sec 01 and 1sec 011

0)igCs. 4(1:1

D>>>>>>>>

1 D>>>>>>>>

Aongitude D>>>>>>>> 0at tank center1

Aatitude D>>>>>>>> 0at tank center1

&.&.&.1.$. ;mportance )actor 0;-1 D>>>>>>>> 0Table &$1

&.&.%. now Aoad = now load shall be determined in accordance with !WW! D1"",

ection %.1.%.1.

&.%. Fou"'a!io"

! 'eotechnical investigation has been carried out at the site and a copy of the report

is included with the Contract Documents. 7ecommendations for the foundation and

allowable bearing capacities are defined in this report. The ,wner shall retain the

services of the 'eotechnical consultant to verify the adequacy of the bearing stratum

after the Contractor has carried out the e#cavation and before any concrete or

reinforcement is placed. The concrete foundation shall be designed and constructed

by the Contractor based upon the recommendations contained in the 'eotechnical

report. The report must provide the allowable soil bearing pressure with appropriate

factors of safety, the active and passive earth pressure coefficients, the angle of soil

internal friction, its cohesion, unit weight and recommendations for bearing depth and

backfill requirements.

&.$. S!eel Ta"(

&.$.1. Ge"e#al

The materials, design, fabrication, erection, welding, testing and inspection of

the steel tank shall be in accordance with the applicable sections of !WW!

D1"" e#cept as modified in this document.

% 7ev. 1"811

&.$.&. Mi"i%u% Pla!e T,ic("e&&

The minimum thickness for any part of the structure shall be %813 inch for parts

not in contact with water and 18$ inch for parts in contact with water.

&.$.%. Ta"( Roo

The tank roof shall be designed as per the pro.ect drawings. !ll interior lap

.oints will be sealed by means of caulking or continuous seal welding. The

interior lap .oints shall be defined to include roof plate laps. ;f roof is supported

by rafters, the rafter shall be welded to the roof plates as required structurally.

!ny unwelded rafter to plate .oints shall be sealed by caulking. The minimum

thickness for roof plates not in contact with water will be %813E.

3. CONSTRUCTION

%.1. Co"c#e!e Fou"'a!io"

The foundation shall be designed and constructed to safely and permanently support

the structure. The basis of the foundation construction shall be consistent with the

soils investigation data included herein at the end of these specifications. !ppropriate

changes to construction schedule and price will be negotiated if, during e#cavation,

soil conditions are encountered which differ from those described in geotechnical

report. The concrete foundation shall be constructed in accordance with !C; %"1.

5inimum concrete compressive strength shall be as specified in ection >>>>>>,

FCast(;n(2lace ConcreteE.

%.&. S!eel Ta"( Co"&!#uc!io"

%.&.1. Ge"e#al

The erection of the steel tank shall comply with the requirements of ection 1"

of !WW! D1"" e#cept as modified by these documents.

%.&.&. Wel'i"*

!ll field welding shall conform to !W and ection 1", !WW! D1"". The

contractor shall ensure welders or welding operators are qualified in accordance

with !5- ection ;G or !+;8!W *&.1.

%.&.%. Fa$#ica!io"

!ll fabrication and shop assembly shall conform to the requirements of !WW!

D1"", ection <, hop )abrication.

%.&.$. E#ec!io"

3.2.4.1. 2lates sub.ected to stress by the weight or pressure of the contained liquid

shall be assembled and welded in such a manner that the proper

curvature of the plates in both directions is maintained. 2lates shall be

assembled and welded together by a procedure that will result in a

minimum of distortion from weld shrinkage.

3.2.4.2. Hoints in bottom of tank shall be continuously lap welded on top side only.

The bottom ring of the tank wall shall be continuously welded to the floor

plate both inside and outside.

$ 7ev. 1"811

%.&.4. I"&pec!io" a"' Te&!i"*

;nspection of shop and field welds shall be in accordance with !WW! D1"",

ection 11, ;nspection and Testing. !ll inspection shall be performed prior to

interior and e#terior field painting. 7adiographic inspection shall be performed

by an independent testing agency with all cost included in the ContractorCs bid

and paid by the Contractor.

%.&.3. Pai"!i"* a"' Di&i"ec!io"

urface preparation and coating of all steel surfaces shall be in accordance with

ection >>>>>> FCoating ystem for teel Water torage TanksE.

4. ACCESSORIES

$.1. Ge"e#al

The following accessories shall be provided in accordance with these specifications.

!ll items shall be in full conformity with the current applicable ,@! safety regulations

and the operating requirements of the structure.

$.&. La''e#&

$.&.1. !n e#terior tank ladder shall be attached to the tank shell e#tending from

appro#imately :C above top of foundation to the top of the shell.

$.&.&. Aadder side rails shall be a minimum %8: inch by & inches with a 13 inch clear

spacing. 7ungs shall be not less than %8$ inch, round or square, spaced at 1&

inch centers. The surface of the rungs shall be knurled, dimpled or otherwise

treated to minimiBe slipping. Aadders shall be secured to the tank by brackets

located at intervals not e#ceeding 1" feet. *rackets shall be of sufficient length

to provide a minimum distance of 9 inches from the center of the rung to the

nearest permanent ob.ect behind the ladder.

$.%. Fall P#o!ec!io"

Aadders shall be equipped with a fall arrest system meeting ,@! regulations. The

system shall be supplied complete with safety harnesses, locking mechanisms,

lanyards and accessories for two persons.

$.$. Ope"i"*&

$.$.1. Roo -a!c,e&

2rovide two access hatches on the roof of the tank. ,ne hatch shall be %" inch

diameter and allow access from the roof to the interior of the tank. The hatch

will be hinged and equipped with a hasp for locking. The hatch cover shall have

a & inch downward edge. The second hatch will be &$ inch diameter and

flanged with a removable cover so constructed that an e#haust fan may be

connected for ventilation during painting operations. The openings shall have a

minimum $ inch curb.

$.$.&. Ta"( .e"!

The tank vent shall be centrally located on the tank roof above the ma#imum

weir crest elevation. The tank vent shall have an intake and relief capacity

sufficiently large that e#cessive pressure or vacuum will not develop during

4 7ev. 1"811

ma#imum flow rate. The vent shall be designed, constructed and screened so

as to prevent the ingress of wind driven debris, insects, birds and animals. The

vent shall be designed to operate when frosted over or otherwise clogged. The

screens or relief material shall not be damaged by the occurrence and shall

return automatically to operating position after thepressure or vacuum is

relieved.

$.$.%. S,ell Acce&& Ma",ole

,ne %" inch diameter and one &$ inch diameter shell manhole shall be provided

near grade level to allow access to the tank interior. The manholes are to be

located 1:" degrees apart. The manhole lid shall be hinged or otherwise self(

supported and open outward.

$.4. Ri**i"*

! painterCs rail attached to the roof, pipe couplings with plugs in the roof or other

attachments that provide complete access for painting shall be furnished.

$.3. Pipi"*

$.3.1. I"le!/Ou!le! Pipi"*

The vertical inlet8outlet pipe connection to the bottom of the tank shall be a

>>>>inch standard weight carbon steel pipe with appropriate transition to a base

elbow of the same diameter. The vertical pipe shall be attached through the

bottom of the tank as near to the shell wall as feasible. The connection from the

piping to the tank floor shall be a watertight connection.

$.3.&. O0e#lo+

The overflow pipe shall be designed to carry the ma#imum design flow rate of

>>>>>>'25. The >>>> inch steel overflow pipe shall have a minimum wall

thickness of IE. ! suitable weir shall be provided inside the tank with the crest

located at @igh Water Aevel. The overflow pipe shall e#tend from the weir and

down the e#terior of the tank terminating appro#imately 1 to & feet above grade

and discharge onto a concrete splash pad. The point of discharge shall have a

$4 degree bend and be equipped with a stainless steel screen.

$.9. I'e"!iica!io" Pla!e

! tank identification plate shall be mounted above a shell manhole. The identification

plate shall be corrosion resistant and contain the following information.

$.9.1. Tank Contractor

$.9.&. ContractorCs pro.ect or file number

$.9.%. Tank capacity

$.9.$. Tank diameter and height to @igh Water Aevel

$.9.4. Date erected

5. Gua#a"!ee

4.1. The tank Contractor shall guarantee its work for a period of one year from the

completion date defined in the contract documents to the e#tent that it will repair any

defects caused by faulty design, workmanship or material furnished under the

specifications. ;f Contractor is not advised of any defects within %" days of end of

3 7ev. 1"811

guarantee period, guarantee shall be considered fulfilled and complete. Defects

caused by damaging service conditions such as electrolytic, chemical, abrasive or

other damaging service conditions are not covered by this guarantee.

4.&. !ll guarantees obtained by the tank Contractor from the manufacturer or installer of

paint, equipment or accessories not manufactured by tank Contractor shall be

obtained for the benefit of the 2urchaser.

9 7ev. 1"811

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Idriss I. M., Soil Liquefaction During Earthquakes, 2008 PDFDocument264 pagesIdriss I. M., Soil Liquefaction During Earthquakes, 2008 PDFalsafi118424No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Wall Panel SystemDocument27 pagesWall Panel SystemLiezel GasparNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Butterfly Valve CatalogueDocument6 pagesButterfly Valve CatalogueromeshmoreyNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- 20 - IWCF Practice Exam Booklet - 05mar13 PDFDocument127 pages20 - IWCF Practice Exam Booklet - 05mar13 PDFAdolfo AnguloNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Location: Capacity: Architect: Mr. Anil Yadav: Qutub Institutional Area 150 PatientsDocument18 pagesLocation: Capacity: Architect: Mr. Anil Yadav: Qutub Institutional Area 150 PatientsManishaDhimanNo ratings yet

- Squares Urban Spaces in Europe PDFDocument312 pagesSquares Urban Spaces in Europe PDFBianca ElenaNo ratings yet

- SAF-03 Plant BuildingsDocument19 pagesSAF-03 Plant Buildingsluke100% (2)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Ship LaddersDocument5 pagesShip LaddersPatrick GuoNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Final Indian Highways May - 2017Document64 pagesFinal Indian Highways May - 2017Manmatha SahooNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Special Tool For Peeling Wire Ends, Cutting WoodenDocument2 pagesA Special Tool For Peeling Wire Ends, Cutting WoodenRamos LeonaNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Searay 330 Sundancer-ReportDocument11 pagesSearay 330 Sundancer-ReportAshok KamathNo ratings yet

- AP - SPEC - Metro - ViaductDocument103 pagesAP - SPEC - Metro - Viaductvishal18mNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- OUGE Brand Double Protection LED Proudcts CatalogueDocument71 pagesOUGE Brand Double Protection LED Proudcts CatalogueFebry ArdiantoNo ratings yet

- Inline Slide ValveDocument1 pageInline Slide ValveBiswanath LenkaNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Indeterminate StrussDocument44 pagesIndeterminate StrussMohan NaikNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Fire Wall DesignDocument4 pagesFire Wall DesignIrshad KhanNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Piled Foundation ReportDocument7 pagesPiled Foundation ReportDijo Mathews100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Do 041 S2012 PDFDocument16 pagesDo 041 S2012 PDFJahRed FronterasNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- BS en 12970-2000 - (2020-08-27 - 08-49-38 Am) PDFDocument20 pagesBS en 12970-2000 - (2020-08-27 - 08-49-38 Am) PDF梁山伯No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- MOS For Construction of Bridge - 042 Updated at PIC-I-T - 7062Document27 pagesMOS For Construction of Bridge - 042 Updated at PIC-I-T - 7062Najmul QamarNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Tensile Deformation - John HollomonDocument23 pagesTensile Deformation - John Hollomonkelsiu1100% (7)

- Daniel LibeskindDocument9 pagesDaniel LibeskindSanjanaPrakashNo ratings yet

- Multiline-Stone Coated Roofing Balinese ShakesDocument2 pagesMultiline-Stone Coated Roofing Balinese ShakesjbonvierNo ratings yet

- 04 FORM Personal Daily Report HSEDocument4 pages04 FORM Personal Daily Report HSEArga Sakti YusnandarNo ratings yet

- Tensile Tests and Failure Analysis of Concrete: J. Struct. Eng., 1986, 112 (11) : 2462-2477Document16 pagesTensile Tests and Failure Analysis of Concrete: J. Struct. Eng., 1986, 112 (11) : 2462-2477angelNo ratings yet

- Engine PartsDocument28 pagesEngine PartsBrandiece 'Dee Dee' Berry100% (1)

- Squatting WC Pan: Special FeaturesDocument2 pagesSquatting WC Pan: Special FeaturesRushan LakdimuthuNo ratings yet

- Tablas de Esfuerzos PDFDocument729 pagesTablas de Esfuerzos PDFSamuel PohezNo ratings yet

- FORUM Case Study FinalDocument11 pagesFORUM Case Study FinalShaili78% (9)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- 9 BOQ Street Lights FINALDocument3 pages9 BOQ Street Lights FINALmooorthuNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)