Professional Documents

Culture Documents

FYP Report

Uploaded by

ahmed143_leoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FYP Report

Uploaded by

ahmed143_leoCopyright:

Available Formats

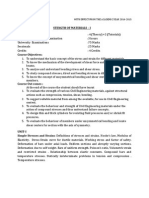

DE 28 (MTS)

PROJECT REPORT

STRATEGIC MONITORING USING RFID & REAL-TIME

TARGET TRACKING

Submitted to the Department of Mechatronics Engineering in partial fulfillment of the

requirements for the degree of

Bachelor of Engineering

in

Mechatronics

2010

Sponsoring DS: Submitted By:

Gp. Capt Arif Ejaz Adnan Munawer

Dr. Khurram Kamal Areeb Qaisar

Ahmed Mateen

M. Qasim Zia

ACKNOWLEDGMENTS

Allah, the most beneficial and the most magnificent, was of course the largest source

of support in this project. We are very thankful to God for granting us the will and ability to

surmount the difficulties in this project and gracing us with the honor of completing our Final

Year Project.

We would like to thank our Project Supervisors Gp Capt (R) Arif Ejaz & Dr.

Khurram Kamal for their support and help during the project. We are especially thankful to

Maj Dr Kunwar Faraz for helping us throughout the project whenever we needed it. We

would specially like to mention the help and support offered to us by our degree mates Khalid

Ahmed, Jazel Ashraf, Umer Ilyas, Ghayur Ahmed, Abdul Haseeb who contributed with

valuable advice and suggestions during the various design & development stages of

SMARTrax.

We are all thankful to our Parents who have been a source of great support and inspiration

in pursuing our work. This project would not have been completed without their prayers and

support.

ABSTRACT

Computing optical flow in low level computer vision is a handy problem since a

compromise has to be made at the end of accuracy and speed of tracking. In our work we

required both accuracy as well as speed for the tracking of intruder object. Two pan tilt

assemblies had to be controlled. One used for the camera and the other for the weapon. The

locked objects coordinates had to be scaled for the weapons pan tilt assembly after which two

separate control system made the two pan tilts follow the target. The camera had a broader

field of view so it had a relatively easier and slower movement while the weapons pan tilt had

to strictly follow the coordinates predicted by the tracking algorithm. Therefore both speed

and accuracy were required at both the tracking algorithms end as well as the pan tilts control

system.

TABLE OF CONTENTS:

Title Page No.

Acknowledgments i

Abstract ii

1 - Introduction 1

1.1 - Background 1

1.2 - Project Goals & Objectives 2

1.3 - Anticipated Benefits 2

1.4 - Project Plan 2

1.5 Work Distribution 3

2 - Literature Review 5

2.1 - Flowchart of System Architecture 5

2.2 Features of Electronics Control Box 6

2.3 Image Capturing Devices 7

2.3.1 USB Webcam 7

2.3.2 CCD Camera 7

2.4 Image Acquisition & Processing 8

2.4.1 Open CV Library on MS Visual Studio 08 8

2.4.2 Image Processing Toolbox on MATLAB v09 9

2.4.3 A comparison of OpenCV & Image processing Toolbox 9

2.5 Graphical User Interface (GUI) 10

2.6 Authorization of Target 12

2.7 AVR Microcontroller & Comm. Protocols 12

2.7.1 The AVR Microcontroller 12

2.7.2 User Defined Protocols 13

2.7.3 Communication Protocols 13

3 - Target Tracking using Real-time Digital Image Processing 14

3.1 Connected Component Labeling Algorithm 15

3.1.1 Difference Image 15

3.1.2 Median Filter 15

3.1.3 Thresholding 16

3.1.4 Distinguishing Features 16

3.1.5 Noise Elimination 17

3.1.6 Marking the Boundary 17

3.2 Segmented Correlation Tracking Algorithm 18

3.2.1 Distinguishing Features 19

3.2.2 Differences between two methods of Static Camera Tracking 20

3.3 Lucas Kanade Flow Algorithm 21

4 - Mean-Shift Tracking Algorithm 23

4.1 Object Model Histogram 24

4.2 Object Candidates Histogram 24

4.3 Measure of Similarity 25

4.4 Selection of Kernel 26

4.4.1 The Epanechnikov Kernel 26

4.4.2 The Gaussian Kernel 27

4.4.3 The Flat Kernel 27

5 Embedded Electronics System for Control 28

5.1 - Overview 28

5.2 Power Supply Unit 29

5.3 AC/DC Motor Drives 30

5.4 Ground Isolation 30

5.5 - Logic Circuitry & Manual Control 30

5.6 RFID Control Unit 31

5.7 Communication Standards 31

6 - Control System Design 32

6.1 Pan-Tilt Control System for the Gun 32

6.2 Proportional Integral Derivative Control 33

6.3 PID Parameters 34

6.3.1 The Proportional Error 34

6.3.2 The Integral Error 35

6.3.3 The Derivative Error 36

6.3.4 Summary 37

7 - Radio Frequency Identification 38

7.1 Introduction to RFID 38

7.2 Why we chose RFID? 38

7.3 Comparison of RFID with Bar-Code Technology 38

7.4 Active & Passive RFID Tags 39

7.5 RFID Frequencies 39

7.6 RFID Building Blocks 40

8 - Design of Pan-Tilt Gun Mount 41

8.1 - Introduction 41

8.2 Commercial Availability 41

8.3 Camera Pan Tilt 41

8.4 Gun Pan Tilt 42

8.5 The Design 42

8.5.1 Design 1 42

8.5.2 Design 2 43

8.6 Position Control & Gear Ratio 44

8.7 - Motors 44

8.8 Stress Analysis 45

Operating Instructions 46

Results 47

Summary 48

Future Work 49

List of Soft wares used 50

References 51

Annex A 52

Annex B 54

Annex C 78

Annex D 79

Annex E 81

LIST OF FIGURES:

Figure

No

Title Page No.

1 Project Timeline 2

2 Resource Allocation 3

3 Flowchart of System Architecture 5

4

C

Control Box Snapshots 6

5 Control Box Snapshots 7

6 CCD Camera with Pan Tilt 8

7 Graphical User Interface (GUI) 11

8 Effect of Median Filter 16

9 Histogram before & after applying Median Filter 17

10 The Epanechnikov Kernel 26

11 The Gaussian Kernel 27

12 Flowchart of Embedded System Electronics 28

13 The Electronics Control Box 29

14 Block diagram of Power Supply Unit 29

15 Block Diagram of AC/DC Motor Drives 30

16 RFID Control Unit 31

17 The Control Loop 32

18 The Vector Field 33

19 Gradient of Vector Field 33

20 The PID Control Loop 34

21 The Effect of Proportional constant 35

22 The Effect of Integral Constant 36

23 The Effect of Derivative Constant 37

24 First Design 43

25 Second Design 43

26 The Fabricated Pan Tilt for Gun 44

LIST OF TABLES:

Table No. Title Page No.

1 Work Distribution 3

2 A Comparison of Speed between MATLAB & OpenCV Library 10

3 A Comparison between the two Approaches of Segmentation 19

4 A Comparison between the two Approaches OF Static Camera

Tracking

20

5 A Comparison between RFID & Bar-Code Technology 38

6 Primary Differences between Passive and Active Tags 39

7 RFID Frequencies 39

Report: Strategic Monitoring using RFID & Real-time Target Tracking

2010

1

CHAPTER 1 INTRODUCTION

1.1: Background:

In the present era the need for automating many tasks previously done by man has

become a very popular field of interest. The reasons for automation are mostly to provide a

better task to be done at the ease of human labor and at the expense of machine and computer

intelligence. The need for this Project arose due to the recent security issues in the country,

e.g. Suicide Bombing. The current task is another dimension of automation, the automation

that will be provided is not only to provide ease to humans but is a very essential tool in

handling the security of almost every site being military, private, government etc.

The project being done is a security system that identifies the subject i.e. personnel

and then depending upon the security level takes necessary action to ensure the security of the

site. The identification is provided by the popular RFID (Radio Frequency Identification).

The subject is observed by a camera and tracked using computer vision. In addition, a weapon

is mounted to track and eliminate the unauthorized subject in case of the extreme security

level. For the current project we have used a high power water gun and a laser beam to do the

work of targeting.

The project when done would be a great relief for the security guards and companies

willing to adapt it, since it would do the work of a watchman and prevent loss of friendly

lives in case of an encounter or a terrorist attack. The camera and weapon are assembled on a

pan-tilt assembly.

1.2: Project Goals & Objectives:

1) To design a low-cost, versatile, indigenous security system.

2) Auto-Focus and Target Locking

3) Efficient and more precise than humanly operated weapons.

4) Works at night as well.

5) This technology will take over the work of security guards, and manned inspection;

hence the fear of loss of friendly lives can be minimized.

6) Ability to read data from individual RFID tags.

7) Complete information about the persons arrival and departure from observation site.

Chapter 1: Introduction

2010

2

1.3: Anticipated Benefits:

1) It will minimize the man-power required to maintain a given security system.

2) It will also reduce the chances of loss of life due to suicidal bombing and vulnerability

to open encounter.

3) It would be utilized to differentiate authorized personnel from unauthorized ones.

1.4: Project Plan:

This project was planned and monitored using Microsoft Office Project Professional

v2007. A snapshot of the Project plan and Timeline, which was implemented successfully is

shown in Figure 1.

Figure 1: Project Timeline (Microsoft Project)

Report: Strategic Monitoring using RFID & Real-time Target Tracking

2010

3

Figure 2 Resource Allocation

1.5: Work Distribution:

Table 1: Work Distribution

Tasks Responsible person(s)

1. Project proposal Adnan Munawar / Areeb Qaisar / Ahmed

Mateen

2. Working out strategy Adnan Munawar / Areeb Qaisar / Ahmed

Mateen

/Qasim Zia

3. Research work on the RFID module Ahmed Mateen

4. Research work on Digital Image

Processing

Adnan Munawar

5. Studying Visual Studio with reference

to

Open CV

Areeb Qaisar

6. Implementation of Back ground

subtraction algorithm in MATLAB

Areeb Qaisar

7. Implementation of Segmented

Correlation Algorithm in MATLAB

Areeb Qaisar / Adnan Munawar

8. Implementation of the Lucas

Kanade Algorithm in MATLAB

Adnan Munawar

9. Implementation of the Mean Shift

Algorithm in MATLAB

Adnan Munawar

10. Design of the electronics Areeb Qaisar

11. Design of power unit for the control Areeb Qaisar

Chapter 1: Introduction

2010

4

system

12. Design and implementation of the

safety

unit of the control box

Adnan Munawar / Areeb Qaisar

13. Survey of electronic components /

connector / special ICs

Areeb Qaisar / Ahmed Mateen

14. Procurement of electronic components Ahmed Mateen / Areeb Qaisar

15. Fabrication of electronics Adnan Munawar / Areeb Qaisar / Qasim Zia

/ Ahmed Mateen

16. Development of the control box Adnan Munawar / Areeb Qaisar / Ahmed

Mateen

/Qasim Zia

17. First mechanical design of the Pan Tilt

in PRO-E

Adnan Munawar / Ahmed Mateen

18. Second mechanical design of the Pan

Tilt in PRO-E

Qasim Zia

19. Supervision of the Fabrication of the

Pan Tilt

Qasim Zia / Ahmed Mateen

20. Mathematical modeling of the Pan Tilt Adnan Munawar

21. Control of both the Pan Tilts Adnan Munawar

22. Development of the communication

protocol

Adnan Munawar / Ahmed Mateen

23. Programming of AVR 1 (Master

Controller)

Adnan Munawar

24. Programming of AVR 2 (G-LCD and

A-LCD, Bridge for RFID data)

Adnan Munawar

25. Programming of AVR 3 (Manual

Control / Analog Control)

Ahmed Mateen

26. Programming of AVR 4 Ahmed Mateen

27. Responsibility of RFID modules

trouble shooting

Ahmed Mateen

28. Development of the 1

st

GUI

in MFC

Areeb Qaisar

29. Development of second GUI in

MFC with CDHTMLDialog Classes

Areeb Qaisar

30. Development of the segmented

correlation algorithm in Visual C++

Areeb Qaisar

31. Development of the Mean Shift

Algorithm in Visual C++

Areeb Qaisar

32. Application development in Visual

C++

Areeb Qaisar

33. Design of the Poster Ahmed Mateen

34. Documentation / Paper work Ahmed Mateen / Areeb Qaisar

35. Formulating Research Paper Adnan Munawar

36. Linking the modules Adnan Munawar/Areeb Qaisar

Report: Strategic Monitoring using RFID & Real-time Target Tracking

2010

5

CHAPTER 2 LITERATURE REVIEW

A handsome amount of literature concerning different methods for image acquisition

and processing, Target Authorization using Radio Frequency Identification etc was studied.

Initially a flowchart of the System Architecture was planned and work was assigned to

different Group Members. The overall flowchart of System Architecture and details of

literature are explained below:

2.1: Flowchart of System Architecture:

Figure 3: Flowchart of System Architecture

CAMERA AND WEAPON

ON PAN-TILT

CONTROL UNIT

RFID MODULE

DETECTION OF INCOMING

ENTITY BY CAMERA

ALLOW THE

ENTITY TO PASS

LOCK THE ENTITY

AND KEEP TRACKING

CHECK FOR

AUTHORIZATION TO

ENTER

AUTHORIZED UNAUTHORIZED

WARN THE ENTITY TO

LEAVE PREMESIS

TRIGGER THE ALARMS

AND INFORM CONTROL

ROOM

AIM THE TARGET AND

ELIMINATE

Chapter 2: Literature Review

2010

6

2.2: Features of Electronics Control Box:

Following are the main features of the electronics control box unit;

1) We have tried our best to give SMARTrax a professional form. A complete embedded

system was designed and developed for the electronics of SMARTrax. The electronics

control box is made of dark transparent acrylic with numerous button and slots for

different purposes.

2) Safety / Protection: Safety purposes all incoming & outgoing signals are rerouted at

the side of the control box. Appropriate fuses have been placed throughout the system.

3) Manual Control for initial positioning: Buttons for manual control have been added at

the front side to adjust the initial position of the system before startup. This applies for

both camera & gun pan tilt.

4) Status Display: A 128*64 Graphical LCD is installed at the front side to show the

status of the different electronic components and microcontrollers. It also shows the

direction of motion when manual control using the gamepad is implemented. An

alphanumeric LCD is also used to assist the Graphical LCD in showing the status of

SMARTrax.

5) Independent Power Supply: To make SMARTrax a professional product an

independent power supply is designed and included in the electronics control box so

that it can be used anywhere without the need for special power supplies, a simple

220V 60 Hz from a normal wall socket will suffice.

Figure 4 Control Box snapshots

Report: Strategic Monitoring using RFID & Real-time Target Tracking

2010

7

Figure 5 Control Box Snapshots

2.3: Image Capturing Device:

We had two options for the selection of an Image Capturing Device, a USB Webcam

and CCD Camera. We opted for a CCD Camera as explained in article 2.2.2.

2.3.1: USB Webcam:

A USB Webcam is a video capture device connected to a computer using a

USB (Universal Serial Bus) port. Webcams are known for low manufacturing costs and

flexibility. USB Webcams typically include a lens, an image sensor, and some support

electronics. They usually have fixed focus lenses, which have no provision for adjustment.

Most consumer webcams are capable of providing VGA-resolution video at a frame rate

of 25 frames per second. A USB Webcam is slow, and its frame rate varies drastically

depending on the intensity of light. It is slow in Dim lights and fast in bright light. Most

Webcams do not need any extra Drivers are supported by common operating Systems

such as various versions of Linux and Microsoft Windows.

2.3.2: CCD Camera:

A charge-coupled device (CCD) Camera is a single IC device, which consists

of an array of photosensitive cells. Its each cell produces an electric current dependent on

the incident light falling on it. It has a video signal output and has less geometric

distortion and more linear video output. A CCD Camera is fast, and its result is

independent of the amount of light. The CCD Camera that we are using is capable of

Chapter 2: Literature Review

2010

8

providing a Frame rate of 52, and can even provide a low-quality video in extremely dark

conditions. The drawback is that there is constant salt-and-pepper noise, which was

modeled in our system to remove this noisy effect. Moreover, a TV Card is required to

convert the analog video into the Digital video, and some extra drivers are needed to

interface a CCD Camera with a Computer. We opted for a CCD Camera, because of its

fast result, and because it is independent to lightening conditions.

Figure 6 CCD Camera with Pan Tilt

2.4: Image Acquisition & Processing:

Image Acquisition is the pre-requisite step for the any Image Processing Operation.

Once an image is available, it can be digitally processed and relevant information can be

extracted. We used the following two libraries for Image Acquisition & Processing.

2.4.1: OpenCV Library on Microsoft Visual Studio v2008:

OpenCV (Open Source Computer Vision) is a library of programming

functions for real time computer vision. Originally developed by Intel, it is a cross-

Report: Strategic Monitoring using RFID & Real-time Target Tracking

2010

9

platform library supported by many Operating Systems, and free for Commercial and

Research use. It focuses mainly on Real-time Image processing, as such, if it finds Intel's

Integrated Performance Primitives on the system, it will use these commercial optimized

routines to accelerate itself. We used this library in conjunction with Microsoft Visual

Studio v2008 to develop our application.

2.4.2: Image Processing Toolbox on MATLAB v2009:

Image Acquisition Toolbox allows acquiring of images and video directly into

MATLAB and Simulink from PC-compatible imaging hardware. Image Processing

Toolbox software provides a comprehensive set of reference-standard algorithms and

graphical tools for image processing, analysis, visualization, and algorithm development.

You can restore noisy or degraded images, enhance images for improved intelligibility,

extract features, analyze shapes and textures, and register two images. Image Acquisition

& Image Processing Toolboxes were used while developing the Target Tracking

Algorithms using MATLAB.

2.4.3: A Comparison of OpenCV & Image Processing Toolbox:

Image Processing Toolbox works with MATLAB, and we used it for algorithm

development. However, MATLAB is slow, and the developed application is not portable

i.e. it can only run on a system where MATLAB is installed. However, applications

developed in Microsoft Visual Studio, are fast and portable (Pack-and-Go installation).

Therefore, we mainly used MATLAB for algorithm development, and used Visual Studio

for our application development. The following Table shows the comparison between

application developed in MATLAB and Visual Studio using Mean-Shift Tracking

Algorithm and a CCD Camera.

Chapter 2: Literature Review

2010

10

Table 2: A Comparison of Speed between MATLAB & OpenCV Library

MATLAB OpenCV

Frames per Sec: 24.13 Frames per Sec: 48.83

Mean Time per Frame: 0.0414 s Mean Time per Frame: 0.0205 s

Standard Deviation: 0.0054 s Standard Deviation: 0.0025 s

2. 5: Graphical User Interface (GUI):

A Graphical User Interface is necessary for an End-user, allowing him to give full

access to the controls of the system. Our complete application including the Image Processing

Algorithms, and its interaction with the Control Box via Serial Communication was designed

using Microsoft Visual Studio 9 v2008 using the OpenCV Library and Microsoft Foundation

Classes (MFC) with a DHTML (Dynamic Hyper-Text mark-up Language) Dialog support.

The use of DHTML Dialogs was made, because interactive and dynamic Graphical user

Interfaces can be designed using the CDHTMLDialog Classes. Image Acquisition is the pre-

requisite step for the any Image Processing Operation. Figure 2 shows our Graphical User

Interface.

Report: Strategic Monitoring using RFID & Real-time Target Tracking

2010

11

Figure 7 : Graphical User Interface for SMARTrax

Our GUI consists of the following:

1) Control Icons: A Set of Buttons, allowing a user to zoom, start or stop the system,

add RFID Record, manually select a target etc.

2) Target Selection: Along with the automatic selection of target, the application also

allows manual selection of target using the panel on the left side.

3) Tracking Area: The Centre portion shows the Real-time tracking video, of an

autonomously selected or manually selected target.

4) RFID Database: The Right Side contains the RFID Database of authorized users.

5) Information Panel: The Bottom layer shows miscellaneous information related to

Color Histograms, Frame Rate, Model etc.

6) Status Panel: On the center bottom a status panel is created. This panel shows the

status of the hardware in the electronics control box.

7) Histogram Panel: Just besides the status panel a histogram panel is added which

shows the color histogram of the targeting area.

Chapter 2: Literature Review

2010

12

8) Velocity Profile: A velocity profile is added which shows the velocity of the target

if it moves.

9) RFID Detail: Below the RFID database a small panel is added to show the details

corresponding to a RFID code eg picture, contact details etc.

2.6: Authorization of Target:

We needed a way to check whether the incoming entity is authorized or not. Several

technologies were available for this, including the Bar-Code Identification, Radio Frequency

Identification, and some advanced techniques like Retina Scans, Finger Print Identification

etc. We opted for Radio Frequency Identification, keeping in mind the project cost and the

range provided by RFID Technology.

2.7: AVR Microcontroller & Communication Protocols:

We had two choices of microcontrollers for our project: AVR ATMEGA Series and

PIC18F Series. Both these microcontrollers fulfilled our requirements of PWM Channels and

ADC Channels. We opted for AVR ATMEGA Series, because of its low cost.

2.7.1: The AVR Microcontroller

The AVR ATMEGA family of microcontrollers are feature rich yet not expensive,

which naturally became our first choice for use in the project. The 8-bit advanced RISC

architecture provided tremendous computing power (for a microcontroller) which enabled

us to implement PIDs on the actuators using Position Feedback from Potentiometers. The

main features which made us choose AVR ATMEGA16 were its high endurance non-

volatile memory, four PWM channels, 8 channel 10 bit ADC and numerous

communication modes (Programmable Serial USART Master/Slave SPI & Serial

Interface, Programmable Watchdog Timer with Separate On-chip Oscillator) etc. We

needed a microcontroller with ADC Channels and an alternative was PIC18F Series. We

opted for AVR because of its low-cost. Some brief details about the chosen

microcontroller are attached as Annexure A.

2.7.2: User Defined Protocols

Report: Strategic Monitoring using RFID & Real-time Target Tracking

2010

13

The Computer, RFID Module and all the microcontrollers are communicating with

each other for different purposes. To keep every communicator coordinated and to avoid

misunderstandings some sort of order or protocol had to be developed. For this purpose a

custom user defined protocol was defined by us, a copy of which is attached in the

annexure B. A specific range of hex numbers was selected for the protocol where each

hex number represents a specific purpose or code.

2.7.3: Communication Protocols

The Serial Communication Protocols used in this project are RS485 for its long

range (1000m), RS232 for communication with Computer and RFID, and SPI (Serial

Peripheral Interface) for communication between the microcontrollers. The details of all

these Communication Protocols are given in article 5.7.

Chapter 3: Target Tracking using Real-time Digital Image Processing

2010

14

CHAPTER 3 TARGET TRACKING USING REAL-TIME DIGITAL

IMAGE PROCESSING

Real-time object tracking as a key technique in computer vision study has many

potential applications in the field of intelligent robot navigation, monitoring and surveillance,

human computer interfaces, smart rooms, vehicle tracking, Biomedical image analysis, Video

compression & Precise strike. Numerous algorithms have been proposed to track moving

objects in image sequences, such as the Kalman filter, the extended Kalman filter, the particle

filter, Algorithms based on Background Subtraction, Adaptive centroid tracking algorithm,

correlation tracking algorithm and matching tracking algorithm.

We used four different methods for object tracking and came up with some novel

ideas in these Target Tracking Techniques, and identified the pros and cons of each method.

We started our work with background extraction using Connected Component Labeling

Algorithm. It was slow but accurate, and marked the exact boundary of the object which was

NOT the primary requirement of our Project. Later we moved on to the segmented correlation

method which was both fast and accurate but it was prone to inherent uncertainty since it

assumed a constant background which was quite unrealistic assumption. Moreover, both of

these methods worked for a Static Camera, and our requirement was Tracking Algorithm

applicable to a movable Camera. Lucas Kanade algorithm was then adopted just for a study

point of view, it proved to be good for tracking rigid objects but since our targets were mostly

humans therefore we required an algorithm that tracked non-rigid objects. This led us to study

the mean shift algorithm which was first presented in 1975 by Fukunaga. Later a color based

mean shift tracking algorithm was proposed by Bradski. Commaniciu followed up and

proposed the first moving object tracking algorithm based on mean shift. The traditional mean

shift algorithm proposed by Commaniciu was a good tracking algorithm and was able to track

objects at a low computational cost providing real time tracking.

The following Tracking Algorithms were used:

1. Connected Component Labeling Algorithm.

2. Segmented-Correlation tracking Algorithm.

3. Lucas-Kanade Optical Flow Algorithm.

4. Mean-Shift Tracking Algorithm for Image Sequences.

Report: Strategic Monitoring using RFID & Real-time Target Tracking

2010

15

3.1: Connected-Component Labeling Algorithm:

This method makes use of conventional Image Processing Operations to mark the

boundary of the object. This method is slow, but under various circumstances, it marks the

exact boundary of the Object.

The method involves the following steps:

1. Gray-Scale Reference Image & Gray-Scale Image to be operated.

2. Taking the Difference Image.

3. Apply the Median Filter.

4. Thresholding.

5. Noise Elimination.

6. Marking the Boundary

At the Startup, a reference image is taken, and then the Difference Image is taken

repeatedly. If the number of pixels in which the change of intensity is observed, exceeds a

certain threshold, we continue to process the Image, else we take the next snapshot and repeat

the process. The reference Image is updated after a fixed interval of time say one hour just to

ensure that the effect of lights is minimized.

3.1.1: Difference Image:

Images are converted to Gray-Scale before processing. If I1 is the reference Image

and I2 is the image to be processed than the Difference Image I3 is given by the absolute

Image Subtraction of the intensities of the corresponding pixels.

3.1.2: Median Filter:

Applying the Median Filter reduces the overall gray-level of the noisy images but

the number of noise-pixels increases. The importance of this step is discussed later.

Chapter 3: Target Tracking using Real-time Digital Image Processing

2010

16

Figure 8: Effect of a Median Filter

3.1.3: Thresholding:

In Thresholding, we convert a gray-level image to a binary image. The pixels

above a certain Threshold are assigned a value 1 and those below the threshold are

assigned a value of 0. The computation of the threshold value is an important calculation

and this value of threshold varies with the overall image intensity. So the value of

threshold will vary depending upon the lightening conditions.

3.1.4: Distinguishing Features:

Our first distinguishing feature is that we compute a global threshold level that is a

normalized intensity value that lies in the range (0-255). We use Otsus method to find the

Threshold to minimize the interclass variance of the black and white pixels. With this we

also get an effectiveness metric ranging from 0 to 1 which indicates the effectiveness of

the thresholding process. By trial and error, it was observed that for effectiveness metric =

0.8 and above, good results were obtained. If during this process, we get a value lower

than 0.8, than we increase or decrease our threshold, and re-compute the effectiveness

metric. We repeat the iterations until we get a threshold for which our effectiveness metric

increases a value of 0.8.

The second distinguishing feature is that we apply a Median Filter before the

thresholding process. However, in most Digital Image Processing Techniques, the

difference Image is immediately thresholded. The advantage of this step is explained

below:

Report: Strategic Monitoring using RFID & Real-time Target Tracking

2010

17

The noise is usually distributed in such a way that it occupies large intensity

values close to those of the object, and normally occupies a small number of pixels. If we

set a Threshold, say, x, than the noise will also be considered as an object in the

obtained binary image. To resolve this problem, we apply a median Filter, which reduces

the overall intensity of the noisy pixels, but the number of noisy pixels increases. Now we

have a noticeable difference, between the intensity of the Noisy Pixels and the Intensity of

the Object Pixels. Now we set a Threshold, which will have an intermediate value

between the two intensities.

Fig 9: Histograms before and after applying the Median Filter.

We can deduce this result from the Image Histograms. Before applying the

Median Filter, only 15,000 pixels were in the extreme dark range, whereas after applying

Median Filter, the number of pixels in the extreme dark range increases to 18,000.

3.1.5: Noise Elimination:

Since we applied the median filter before the thresholding process, we are left with

very low noise. To remove this noise, any object which contained less than the specified

number of pixels connected by the definition of N8 neighbours are eliminated.

3.1.6: Marking the Boundary:

Now we are left with a binary image, where 1 denotes an object and a 0

denotes the background. By scanning the image from left-to-right and from top-to-bottom,

we use Connected Component Labeling Algorithm to mark the pixels where a transition

from a 1 to 0 or a transition from 0 to 1 is observed. This way we get the boundary

of the object.

Chapter 3: Target Tracking using Real-time Digital Image Processing

2010

18

3.2: Segmented Correlation Tracking Algorithm:

The second method makes use of the Normalized Correlation Coefficient. The

Normalized Correlation Coefficient of two Images A & B is defined as:

The basic phenomenon is that, for two similar images, the value of the Correlation

Coefficient is equal to 1. In case of different images, this value is less than 1. We know that

the same image captured by a camera at two different intervals doesnt yield the same result.

There are minor fluctuations in the intensity values depending on the lightening conditions.

Therefore the Correlation Coefficient of the same image captured at two different intervals is

not 1. However, a Normalized Correlation Coefficient in the range 0.9<r1 is a reasonable

assumption; it represents the same image, keeping in mind the lightening issue.

Just like the first method, we capture a Background Image, which is updated after

regular intervals of time to minimize the effect of lightening. As soon as the new image is

captured, we split both the images into equal number of vertical segments. The Correlation

Coefficient of each vertical segment is computed with the corresponding segment of the

Background Image. If we dont get a value less than 0.9 for any of the segment, than we

assume that no object is detected. If one or more segments contain a value less than 0.9, than

we compute the mean of all the correlation values, and all those segments where the value of

correlation coefficient is less than mean are assumed to contain the object. The Required

Vertical Segments are than added, to compute the absolute Vertical Coordinates of the

Object.

Once we know the location of the Vertical Segments in which the object is located, we

further split those verticals segments in the horizontal direction and compute the correlation

coefficient and then the mean. All those horizontal Segments where the Correlation

Coefficient is less than the Mean, we assume that the Object is located in those Horizontal

Segments.

Report: Strategic Monitoring using RFID & Real-time Target Tracking

2010

19

3.2.1: Distinguishing Features:

The first distinguishing feature is that in most of the Correlation Tracking

Algorithms, Image is segmented in horizontal and vertical directions which take

considerable amount of time to process the Image. For Instance, if we split the image in

20 Vertical and 20 Horizontal segments, we need to compute 400 Correlation

Coefficients. However in our case we only compute 40 Correlation Coefficients.

The Table 2 shows the result. First Figure shows the progress when image is

processed by segmenting in equal horizontal & vertical strips and second figure shows the

result of our approach. In the first case, effective Frame rate is 17.2 and in the second case

it is 25.3. These results are from MATLAB.

The second distinguishing feature is that for the second time we dont start the

procedure the way it was done for the first time. Once we identify that object is in a

specified vertical segment, we start observing the object in the adjacent segments. This

saves computational time.

Table 3: A Comparison between the two Approaches of Segmentation

CONVENTIONAL APPROACH OUR APPROACH

Frames per Sec: 17.155 Frames per Sec: 25.294

Mean Time per Frame: 0.0583 s Mean Time per Frame: 0.0395 s

Standard Deviation: 0.0192 s Standard Deviation: 0.0095 s

Chapter 3: Target Tracking using Real-time Digital Image Processing

2010

20

3.2.2: Differences between two methods of Static Camera Tracking:

Table 4 shows the comparison between the two Methods of Static Camera

Tracking, as processed by MATLAB.

Table 4: A Comparison between the two Approaches OF Static Camera Tracking

METHOD 1 METHOD 2

Frames per Sec: 12.6422 Frames per Sec: 25.294

Mean Time per Frame: 0.0791 s Mean Time per Frame: 0.0395 s s

Standard Deviation: 0.0344 s Standard Deviation: 0.0095 s

Advantages:

1) Marks the exact boundary of the Objects, but

this is not the exact requirement of our project.

Disadvantages:

1) Slow Method (12.6 FPS)

Works only when there is a noticeable difference

between the objects color and the backgrounds color.

Advantages:

1) Marks a bounding Box for objects, which can be

used to point the weapon to the target.

2) Pretty fast (25.3 FPS) in Matlab and 52 FPS in

Visual C++ using OpenCV Library.

Disadvantages:

It cannot tag the identity of the object. Method# 3 and

Method#4 solves this problem.

Report: Strategic Monitoring using RFID & Real-time Target Tracking

2010

21

3.3: Lucas-Kanade Optical Flow Algorithm:

The Lucas-Kanade algorithm was proposed in 1981 and since then has evolved a great

deal. It is effectively used for image alignment, mosaic-ing, optical flow, layered tracking etc.

It is basically derived from the sum squared difference error that is computed between two

image patches of the same size.

[ ]

It is this equation that formed the basis of the Lucas Kanade algorithm. This equation is

expanded according to the second order Taylor series expression. First order Taylor series

function is as follows.

The second order Taylor series function takes the form.

]

Only the first order terms are taken.

Applying the same to equation [] results in.

[ ]

Taking partial derivates of equation [] and setting them to zero.

Chapter 3: Target Tracking using Real-time Digital Image Processing

2010

22

Rearranging the equations and form a matrix form results in.

[

] [

] [

]

This equation is solved by the method of least squares.

Report: Strategic Monitoring using RFID & Real-time Target Tracking

2010

23

CHAPTER 4 MEAN-SHIFT TRACKING ALGORITHM

The mean shift algorithm is basically a non parametric statistical method. It was

derived from the Parzen window estimation method and the second order Taylor series

expansion of the Bhattacharyya coefficient. The parzen window estimation technique uses a

kernel to estimate the density of a set of data samples. By convoluting the kernel at all the

data points a density estimate is obtained. This is also called kernel density estimation (KDE).

The following equation denotes the parzen window estimation.

In this equation n denotes the number of data points that are being sampled by the

kernel K. P(x) denotes the estimated probability density of those set of data points. The kernel

K must have the following properties:

i. Normalized

ii. Symmetric

iii. Should have exponential weight decay

Estimating the density is done by this kernel density estimation technique but we need a way

of finding the modes in the set of data samples. Thus instead of the kernel density estimation

we use the gradient of kernel density estimate. This provides us a way of climbing up a

contour and finding the modes. Thus the equation that follows is as under.

For this we use the kernel of the form.

Chapter 4: Mean Shift Tracking Algorithm

2010

24

)

Where k another KDE and h is the bandwidth. The final form that results is.

] [

The kernel g is simply.

4.1: Object Model Histogram:

We used quantized color space as the objects representation feature. A weighted color

histogram is formed from the parzen window estimation technique with the difference that in

this probability distribution the set of data points, that are the images pixels are located at

uniform spatial distance so original parzen window estimation has a meaningless probability

estimate. Thus to estimate a suitable density for these pixels a corresponding weight is

assigned to each pixel which corresponds to the intensity of the pixel and its distance from the

centre pixel when convoluted with the mean shift kernel. Thus the objects model histogram is

formed from the following equation.

]

Where u = 1, 2m. m is the number of quantized binary levels chosen for the color space. C

is the normalization constant,

is the color binary index of pixel

, where i = 1, 2 . n.

is the kronecker delta function. (0) = 1and for all the other values of a other

than 0.

is the initial position where the kernel K is centered. It is normally taken as zero.

is the bandwidth matrix.

4.2: Object Candidates Histogram:

After the object models histogram has been calculated, an initial estimate of the

targets location

is given over which the kernel K is convoluted according to the parzen

Report: Strategic Monitoring using RFID & Real-time Target Tracking

2010

25

window estimation technique and the candidates histogram is computed by the following

equation.

]

Here again

is the normalization constant. It should be noted that both the probability

distributions are normalized i.e.

and

.

4.3: Measure of Similarity:

Commaniciu used the Bhattacharyya coefficient as the measure of absolute similarity

between two histograms. The Bhattacharyya coefficient produces a scalar value denoting the

amount of match between two probability distributions resulting in a larger value for a better

match. Thus the goal is to maximize its value in the vicinity of the region of interest. The

expression is as follows.

This expression is expanded according to the second order Taylor series which results in the

expression.

The term

in the above equation is called the weight term. It is expressed as.

]

The first term in equation [ ] does not depend upon y so only the second term in equation [ ]

has to be maximized. Thus the mode of the second term is found by the mean shift iterations.

The expression that results is as follows.

Chapter 4: Mean Shift Tracking Algorithm

2010

26

In the equation above (

) is another kernel and is related to the kernel k by the

expression.

This justifies why the kernel k had to be differentiable. From expression [ ] a new value of

is obtained. The previous value of y is updated by this new value and the iterations are

continued until either one or both of the following conditions are satisfied.

4.4: Selection of the Kernel:

The selection of the right kernel is an important task in the result of the mean shift

algorithm since computational cost, accuracy and complexity of the algorithm depends

somewhat on the selection of the kernel itself. Following are the three kernels that are

generally used.

4.4.1: The Epanechnikov Kernel:

The epanechnikov kernel is a

symmetric, differentiable normalized

kernel and is represented by the

following equation.

{

Fig 10: The Epanechnikov Kernal.

Report: Strategic Monitoring using RFID & Real-time Target Tracking

2010

27

It can be seen that the data points at the centre of the kernel are given the

maximum weight age while the distant data points are given minor weight age. The

periphery pixels are given 0 weight age. The main idea is to give higher weight age to the

objects pixels while the pixels at the kernels edges are normally the background pixel so a

lower weight age is given to them. Epanechnikov kernel minimizes the AMISE

(asymptotic mean integrated squared error) and therefore an optimum solution. The

efficiency of this kernel is one and the efficiency of all the other kernels is compared to

the epanechnikov kernel.

4.4.2: The Gaussian Kernel:

The Gaussian kernel is a normalized kernel represented by the following equation:

{

Fig 11: The Gaussian Kernel.

As can viewed from the equation the image pixel that fall inside the kernel are

given an exponential weight age with the maximum weight at the centre. This provides a

more preference to the objects pixels and reducing the effect of the background pixels.

4.4.3: The Flat Kernel:

The flat kernel is represented by the following equation. This assigns equal

weights to all the pixels inside the kernel window.

{

Chapter 5: Embedded Electronics System for the Control

2010

28

CHAPTER 5 EMBEDDED ELECTRONICS SYSTEM FOR THE

CONTROL

5.1: Overview:

A handsome amount of electronics is involved in this project which includes an

independent power supply, H-bridges, Microcontrollers, Gamepad, ISP Burner and Serial

communication modules etc all of which have to coordinate with each other without any error

to ensure successful operation of SMARTRAX. To achieve successful operation we designed

an embedded system that could be used in readymade product form or in other words plug

and play. An acrylic box was made to adjust all the electronics and to give it a product form.

At the side of the box a small panel was made to accommodate all incoming and outgoing

signals, and on the front side of the box numerous buttons are attached for secondary manual

control. Given below is chart of the electronics of the embedded system:

Fig 12 Flowchart OF Embedded Electronics system.

Report: Strategic Monitoring using RFID & Real-time Target Tracking

2010

29

Figure 13 The Electronics Control Box

5.2: Power Supply Unit:

A handsome amount of electronics is involved in this project which includes an

independent an independent power supply unit was developed for SMARTRAX, the input

being the standard 60Hz AC from any wall socket. The power supply unit consists of two step

down transformers, the reason we used two transformers was to keep the logic and motor

drives isolated from each other. After step down the voltage is fed into bridge rectifiers which

create a DC signal with ripples. To cater the ripples filtering capacitors were used which

resulted in a smooth DC voltage, separate for logic and motor drives. Given below is an

outline of the power supply unit integrated in the embedded system.

Fig 14: Block Diagram of Power Supply Unit.

220VAC

60Hz

220VAC

60Hz

Transformer,

Stepdown to 16VAC

for motor drives

Transformer,

Stepdown to 20VAC

for Logic

Bridge Rectifiers

Bridge Rectifiers

Filtering Capacitors to

remove ripples.

Output 20VDC

Filtering Capacitors

to remove ripples.

Output 28VDC

Chapter 5: Embedded Electronics System for the Control

2010

30

5.3: AC / DC Motor Drives:

The control signals for the DC motors come from AVR 1 into the optocouplers and

from the optocouplers to the H-Bridges and then finally into the respective motors. The h

bridges used are LMD 18201. The control signals for the AC motors also generate from AVR

1, they go into the optocouplers then into relays and then to the AC motors. The control

signals for the motors are namely brake, direction & PWM.

Fig 15: Block Diagram of AC / DC Drives.

5.4: Ground Isolation:

Large current spikes are sometimes generated in the power supply unit, such

unexpected current spikes cause anomalies in logical operations. To avoid all this we have to

separate the logics voltage and the motor drive voltage, thats why we used two transformers

in the power supply unit to generate separate voltages for the logic and motor drive circuits,

and secondly we used optocouplers between control signals of motors and the drive voltage of

the motors.

5.5: Logic Circuitry & Manual Control:

The logical circuitry consists of three AVR ATMEGA16 and one ATMEGA168

micro controllers. AVR1 is used for communication with PC and SPI with AVR2,

additionally its the only micro controller responsible for driving all the motors and

implementing PID on them. AVR 2 controls two LCDs used for displaying data and

Optocoupl

ers

Optocoupl

ers

H-Bridge,

LMD

1829

Relays

DC Motors

Gun pan, tilt &

Trigger

AC Motors

Camera pan &

tilt

Signal

Signal

Report: Strategic Monitoring using RFID & Real-time Target Tracking

2010

31

receiving the data sent from the RFID end. A gamepad is also interfaced using AVR 3 for

manual control of the gun & camera as well.

5.6: RFID Control Unit

The RFID module used in SMARTrax is a system 3000 model purchased from a local

vendor CNS (Computer Networking & Systems). Whenever a card is brought into the vicinity

of the reader, it reads data from it and sends it to AVR 4 via RS 232 at 9600bps. AVR 4 then

extracts the relevant data and sends it to AVR 2 via RS 485. AVR 2 communicates the newly

received data to AVR 1 via SPI. The AVR 1 sends it to the control PC where it is processed

upon to check the authenticity of the user. Given below is block diagram of this process;

Fig 16:RFID Control Unit.

5.7: Communication Standards

Numerous communication standards have been adopted in this project. Since the PC

has a serial port which communicates using RS 232 standard, AVR 1 communicates with the

PC via RS 232. SPI (serial peripheral interface) is a high speed communication mode for

micro controllers, AVR 1 and AVR 2 communicate with each other via SPI. RS 485 is an

enhanced version of serial communication with the advantage of communication over long

distances (up to 1000meters), AVR 4 and AVR 2 communicate with each other using RS 485.

The RFID module which we utilized in this project communicates using RS 232, hence RS

232 is implemented between the RFID module and AVR 4. AVR 3 which is used for

interfacing the gamepad communicates with AVR 1 using RS 232 standards.

RFID

Module

AVR 4 AVR 2 AVR 1 Control

PC

RS 232 RS 485 SPI RS 232

Chapter 6: Control System Design

2010

32

CHAPTER 6 CONTROL SYSTEM DESIGN

The equipment that consisted of the two pan tilts had to be controlled. Since both the

pan tilts had separate movement thus two separate control systems had to be designed. The

problem at hand was the accurate and efficient following of the target by the guns pan tilt.

The guns aim was supposed to lock on the target. This was being handled in a two way

indirect process.

Fig 17: The Control Loop.

Thus there was no direct connection between the guns pan tilt and the camera. Only an

indirect connection existed via cameras input and dip algorithms targets coordinates

estimation. This called for a more complex control system since it formed a non linear

system.

6.1: Pan-Tilt Control System for the Gun:

The guns movement can be denoted by a vector field that denoted the destination of

the guns nozzle. This vector field shown the path to be followed and the magnitude of the

acceleration followed by the velocity required to reach its apex or maximum. The vector field

forms a surface that looks like a hill. The required position that is always the tip of the hill can

be mathematically achieved by the gradient of the vector field.

SCALING OF THESE

COORDINATES

THEN FOLLOWING

THEM BY THE GUNS

PAN-TILT

FEEDBACK

TARGET TRACKING

AND COORDINATES

ESTIMATION BY THE

CAMERA

Report: Strategic Monitoring using RFID & Real-time Target Tracking

2010

33

This shows the two dimensional nature of the vector field. The vector field is shown

below.

Fig 18: The Vector Feild.

The length of the arrows is proportional to the magnitude of the pan tilts input. The

gradient of this vector field is shown below.

Fig 19: The Gradient of the Vector Feild.

6.2: Proportional-Integral-Derivative Control:

The selection of the right control system was of great importance in view of the

problems presented above. The PID control system was finally chosen for the guns pan tilt. A

proportionalintegralderivative controller (PID controller) is a generic control loop feedback

mechanism (controller) widely used in industrial control systems a PID is the most

commonly used feedback controller. A PID controller calculates an "error" value as the

difference between a measured process variable and a desired set point. The controller

attempts to minimize the error by adjusting the process control inputs. In the absence of

knowledge of the underlying process, a PID controller is the optimal controller. However, for

Chapter 6: Control System Design

2010

34

best performance, the PID parameters used in the calculation must be tuned according to the

nature of the system while the design is generic, the parameters depend on the specific

system.

Fig 20: The PID Control Loop.

6.3: PID Parameters:

The PID controller calculation (algorithm) involves three separate parameters, and is

accordingly sometimes called three-term control: the proportional, the integral and derivative

values, denoted P, I, and D. The proportional value determines the reaction to the current

error, the integral value determines the reaction based on the sum of recent errors, and the

derivative value determines the reaction based on the rate at which the error has been

changing. The weighted sum of these three actions is used to adjust the guns position control

element. Heuristically, these values can be interpreted in terms of time: P depends on the

present error, I on the accumulation of past errors, and D is a prediction of future errors, based

on current rate of change.

By tuning the three constants in the PID controller algorithm, the controller provides

control action designed for the guns accurate target locking. The response of the controller

can be described in terms of the responsiveness of the controller to an error, the degree to

which the controller overshoots the set point and the degree of system oscillation.

6.3.1: The Proportional Error:

The proportional term (sometimes called gain) makes a change to the output that is

proportional to the current error value. The proportional response can be adjusted by

Report: Strategic Monitoring using RFID & Real-time Target Tracking

2010

35

multiplying the error by a constant K

p

, called the proportional gain. The proportional term

is given by:

Where

denotes the proportional output generated in time,

is the

proportional constant and is the percentage error. This error is equal the percentage

difference between the required output to the current output.

A high proportional gain results in a large change in the output for a given change

in the error. If the proportional gain is too high, the system can become unstable. In

contrast, a small gain results in a small output response to a large input error, and a less

responsive (or sensitive) controller. If the proportional gain is too low, the control action

may be too small when responding to system disturbances.

Fig 21: The Effect of Proportional Constant.

6.3.2: The Integral Error:

The contribution from the integral term is proportional to both the magnitude of

the error and the duration of the error. Summing the instantaneous error over time

(integrating the error) gives the accumulated offset that should have been corrected

previously. The accumulated error is then multiplied by the integral gain and added to the

controller output. The magnitude of the contribution of the integral term to the overall

control action is determined by the integral gain, K

i

. The integral term is given by.

Chapter 6: Control System Design

2010

36

Where

denotes the integral output generated in time,

is the integral

constant and is the percentage error. The integral term (when added to the

proportional term) accelerates the movement of the process towards set point and

eliminates the residual steady-state error that occurs with a proportional only controller.

However, since the integral term is responding to accumulated errors from the past, it can

cause the present value to overshoot the set point value (cross over the set point and then

create a deviation in the other direction).

Fig 22: The Effect of Integral Constant.

6.3.3: The Derivative Error:

The rate of change of the process error is calculated by determining the slope of

the error over time and multiplying this rate of change by the derivative gain K

d

. The

magnitude of the contribution of the derivative term to the overall control action is termed

the derivative gain, K

d

. The derivate term is given by.

The derivative term slows the rate of change of the controller output and this effect

is most noticeable close to the controller set point. Hence, derivative control is used to

reduce the magnitude of the overshoot produced by the integral component and improve

Report: Strategic Monitoring using RFID & Real-time Target Tracking

2010

37

the combined controller-process stability. However, differentiation of a signal amplifies

noise and thus this term in the controller is highly sensitive to noise in the error term, and

can cause a process to become unstable if the noise and the derivative gain are sufficiently

large. Hence an approximation to a differentiator with a limited bandwidth is more

commonly used. Such a circuit is known as a Phase-Lead compensator.

Fig 23: The Effect of Derivative Constant.

6.3.4: Summary:

The proportional, integral, and derivative terms are summed to calculate the output

of the PID controller. Defining u(t) as the controller output, the final form of the PID

algorithm is:

Chapter 7: Radio Frequency Identification

2010

38

CHAPTER 7 RADIO FREQUENCY IDENTIFICATION

7.1: Introduction to RFID:

RFID, short for Radio Frequency Identification, is a technology that enables

identification of a tag (that is normally attached with an entity) by using electromagnetic

waves. The function served by RFID is similar to bar code identification, but line of sight

signals are not required for operation of RFID. Important components of an RFID system are:

1) An RFID reader (also called transceiver) with an antenna and a transceiver,

2) A transponder (Also called a tag) that includes an antenna and a chip)

7.2: Why we chose RFID:

We choose RFID over the many of the technologies in use today because of several

reasons; the user doesnt has to particularly swipe the card or make any log entry of some

sort, the RFID automatically takes care of that. One of the main reasons we chose RFID was

because of cheap maintenance & implementation cost, convenience for people, time saving,

to save operating costs (i.e. no requirements for hiring of staff just to keep log of entry &

exit). Thirdly RFID is being inoculated into our daily lives in many different ways (use of

RFID in stores, inventory of products, livestock, e-passports etc), by choosing RFID we are

giving SMARTrax the ability to integrate in new environments and most importantly future

proofing for longer life of the product.

7.3: Comparison of RFID with Bar-Code Technology:

Table 5: A Comparison between RFID & Bar-Code Technology

Parameter Bar Code RFID

Frequencies used

for tag reading

Optical frequencies Radio frequencies

Type of

communication

Line of sight communication Non-line of sight communication

Data Volume Physical limitation exists. It is

very difficult to read a very long

barcode.

Can carry relatively large volume

of data.

Range of data

readability

Very limited range, less than a

feet or two.

Can be read up to several feet.

Cost Cheap Expensive, but likely to cost less

as more industries adopt the

technology.

Report: Strategic Monitoring using RFID & Real-time Target Tracking

2010

39

7.4: Active and Passive RFID Tags:

There are primarily two types of RFID tags. One is active and the other is passive. An

active tag is powered using internal battery, where a passive tag gets energized using the

power from a tag reader. A passive RFID tag will not have a battery or any kind of power

source by itself. It extracts the required energy from a reader. Hence, a passive RFID tag

reader must be able to emit stronger electromagnetic signals, and in return, identify very weak

signals from the passive RFID tag.

Given below are the primary differences between a Passive and Active RFID tags:

Table 6: Primary Differences between Passive and Active Tags

Parameter Passive Tags Active Tags

Power Source External (Reader provided) Internal (Battery)

Tag Readability

Only within the area covered by the reader,

typically up to 3 meters.

Can provide signals over an extended

range, typically up to 100 meters..

Energization

A passive tag is energized only when there is a

reader present.

An active tag is always energized.

Magnetic Field Strength

High, since the tag draws power from the

electromagnetic field provided by the reader.

Low, since the tag emits signals

using internal battery source.

Shelf Life

Very high, ideally does not expire over a life

time.

Limited to about 5 years, the life of a

battery.

Data storage Limited data storage, typically 128 bytes. Can store larger amounts of data.

Cost Cheap Expensive

Size Smaller Slightly bulky (due to battery)

7.5: RFID Frequencies:

There are several frequencies that are used for RFID. These include LF, HF, UHF, and

Microwave frequencies. The exact frequencies may vary depending on the country where it is

used.

Table 7: RFID Frequencies

Frequency Description Typical Applications

<135KHz Low Frequency, Inductive coupling

Access Control & Security

Widgets identification through manufacturing

processes

Chapter 7: Radio Frequency Identification

2010

40

Ranch animal identification

OEM applications

13.56 MHz High Frequency, Inductive coupling

Access Control

Library books

Laundry identification

OEM applications

868 to 870 MHz

902 to 928 MHz

Ultra High Frequencies (UHF),

Backscatter coupling

Supply chain tracking

2.400 to 2.483 GHz SHF, Backscatter coupling

Asset tracking

Highway toll tags

Vehicle tracking

7.6: RFID Building Blocks:

Tags:

A tag is the data carrier and normally contains the ID number, and unique EPC code

programmed into the Tag.

Tag Antenna:

The tag antenna is connected to the chip in tag. It could be wire or printed using conductive

ink.

Reader Antenna:

It is a coil included in plastic or similar case, and normally measures 12 -18 inches square

Reader:

A reader captures the data provided by the tag within the detectable area of the Reader. There

can be one or more tags within the capture area. A reader is typically capable of reading

multiple tags simultaneously.

Savant:

This is normally a middleware that interacts with the readers, and communicate with

External database

Report: Strategic Monitoring using RFID & Real-time Target Tracking

2010

41

CHAPTER 8 MECHANICAL DESIGN OF PAN-TILT FOR GUN

8.1: Introduction:

The basic concept of a pan tilt mechanism is to design a mechanism that has two degrees

of freedom. Both are rotation one along the x-axis, giving the pan motion and the other is

along the y-axis giving it the tilt motion. To make SMARTrax both efficient and cost

effective the main task in mechanical area was to come up with a light weight yet strong pan

tilt for mounting the gun. Since there arent many commercial pan tilt designs for gun

mounting available we had to study the commercially available pan tilt mechanism for

cameras. After going through a number of Pan Tilt Camera Mount designs that are

commercially available, the conclusion drawn was to rethink the whole mechanism to cater

for two main tasks light weight and strength. The pan tilt mechanism for the gun mounting

was designed in Pro E Wildfire 4.0.

8.2 : Commercial Availability:

There are many sorts of pan tilt mechanisms commercially available but there are a few

draw backs. Some of them are:

1. They are fitted with AC motors.

2. It is hard to control.

3. Speed is normally very slow.

4. They are unable to handle large amount of weight.

5. Fitting for the gun is not available.

8.3 : Camera Pan Tilt:

For the camera high speed and agile motion was not required. Since limited pan and tilt

motion gives us a wide enough field of view. So to keep SMARTrax cost effective it was

decided to purchase a commercially available pan tilt. The purchased pan tilt has the

following specifications,

1. Its fitted with AC motors.

2. The speed of pan motion is 2 degrees per second.

3. The speed of tilt motion is 4 degrees per second.

4. Camera fitting assembly was already present so no modifications were required.

Chapter 8 Pan Tilt for Gun

2010

42

8.4 : Gun Pan Tilt:

For the gun mechanism the basic requirements were;

1. A low weight assembly that can undergo swift & agile motion.

2. The weight of the gun was assumed to be 7Kg. so the pan-tilt capable of handling

that much weight and maintaining the agility was required

Since pan tilt mechanisms are generally not available in the market, at least not at cheap

rates. So we decided to design and build one ourselves.

8.5 : The Design

It was a top priority to make the mechanism as light weight, stable and as fast as possible and

also keeping it under control at all times. The software used to design the mechanical

assembly was ProE, which is the top end software as far as the mechanical designing is

concerned. A stress analysis was also performed on the mechanism to evaluate the strength of

the mechanism at critical points and to reduce the chances of failure. Two designs were made

and finally one was selected after serious consideration.

8.5.1: Design 1

The first design as shown in the figure was very simple and was capable of serving our

purpose well but it had one very big disadvantage it made the size of the entire assembly

large. Since we were interested in using the water gun as a test weapon and it had a water tank

attached with the gun so it was important to keep the size under control. Also the connecting

shaft was not strong enough to hold large amounts of weight. In order to counter these issues

we moved to a second design.

Report: Strategic Monitoring using RFID & Real-time Target Tracking

2010

43

Figure 24. First Design

8.5.2: Design 2

In the second design these problems were resolved by tackling the problem with a completely

different approach instead of keeping the bottle attached with the gun at all the times it was

decided to use the disc as a base to support the bottle it has two advantages one is that it

reduced the weight of the disc also it provided sufficient space for the gun while keeping the

mechanism small. Finally the pressure on the gun increased due to gravity giving water gun a

flat range of above 6m.

Figure 25. Second Design

Chapter 8 Pan Tilt for Gun

2010

44

Figure 26 The Fabricated Pan Tilt for Gun

8.6: Position control & Gear Ratio

One of the most important parts of the project was to control the direction of the gun. In order

to achieve the position control of the assembly potentiometers were employed with the shift

of both the pan and tilt part. The gear ratio for the pan part was maintained to 8:1 and for the

tilt it was 1:2. We added some potentiometers in the gun pan tilt mechanism for feedback

purposes. Adding a gear train provided us with a reasonable reading from the potentiometers

upon any change.

8.7: Motors

The motors selection was a crucial part of the assembly design. We required the motors small

in size yet powerful enough to carry the weight of the gun with it. It was decided to use the

motor D23232343. For the pan part which was strong enough to provide us with the torque of

0.8Nm. for the tilt part we have used the motors L34kjfdk which provides us with 1.8Nm of

torque, sufficient enough to lift the load of 7Kgs.

Report: Strategic Monitoring using RFID & Real-time Target Tracking

2010

45

8.8: Stress Analysis

Stress analysis was performed on the crucial parts of the mechanism first of all there were two

assumptions

Conditions:

No external Forces on complete assembly

Only its weight acting in downward direction

The entire assembly was constrained and it was supposed that no external force except the

stress was being applied on the assembly.

2010

46

Operating Instructions:

Operating instructions for SMARTrax are given below;

1) There is no need for any special power supply, a simple output from a standard wall

socket 220VAC 60Hz will suffice.

2) Currently SMARTrax is effective for a range of 20 meters. For optimum performance

SMARTrax should be installed at places with a relatively narrow or small entrance.

3) Shocks of any kind should be avoided to SMARTrax as it may interfere with the input

from the camera. Sudden changes or jerky image input can affect the digital image

processing at the computer end.

4) The range for the RFID reader to detect cards is small. The user has to bring the card

in proximity of about 4 inches in any direction around the RFID reader.

5) In free video mode the operator has to manually select the target using the control

panel in GUI otherwise the system wont track the target in manual mode. Once a

target is selected in free video running mode it will be tracked via Mean Shift

Tracking Mode.

6) When operating the manual target tracking the buttons on the gamepad have been

designated different tasks. The Start button initiates the manual tracking mode. The

analog button shifts the control to the two analog sticks present on the gamepad. The

turbo button increases the speed of the motors on the pan tilt mechanisms. The Select

button terminates the manual tracking mode and the system moves back into one of

the automatic modes.

7) In Segmented Correlation Tracking Mode the system first analyses the background

environment and then tracks any target depending upon the change in environment

compared with the initial environment analyzed. This mode is effective for narrow

entrance places and where there is no movement of the camera.

Report: Strategic Monitoring using RFID & Real-time Target Tracking

2010

47

Results:

1) All the objectives proposed upon undertaking this project have been achieved

successfully.

2) SMARTrax comprises of different fields which gave us the chance of research work

as well as implementing the research done.

3) During the development of SMARTrax we developed and implemented four different

algorithms for image processing for tracking the target.

4) This project made us realize the necessity & advantages of embedded systems in

engineering applications. We tried our best to produce a professional level product out

of SMARTrax in which we have succeeded.

5) SMARTrax was designed keeping portability in mind thats why we have tried our

best to make the electronics control box more like a plug and play device.

6) We had to develop an indigenous protocol for successful communication between the

microcontrollers, RFID reader and the control PC.

7) With the addition of the future work (mentioned in the Future Work section)

SMARTrax will get its final form, a complete professional level product from cradle

to grave.

2010

48

Summary / Conclusion:

The idea of SMARTrax originated during the numerous security related incidents in Pakistan

in 09. For any country securing its borders is a crucial and important task which demands a

lot of time and resources. However with the advancement in technology steps are being taken

towards making such tasks easy, SMARTrax being one of them. SMARTrax can also be

added to unmanned vehicles for reconnaissance & other purposes. This project still holds a lot

of room for further research work & innovation. The low cost of SMARTrax makes it ideal

for utilization in local vicinities which require a higher security level. The low cost,

convenience & versatility of RFID make it a technology which is being inculcated into daily

lives at quite a fast rate. The low cost & user friendliness make SMARTrax an efficient

security product.

Report: Strategic Monitoring using RFID & Real-time Target Tracking

2010

49

Future Work:

Following are the main areas of future work in this project;

1) Implementation of Stereoscopic vision using two cameras to track target in pan

motion. Stereoscopic vision will be helpful to determine the actual position of the

target using only Digital Image Processing, further more it will also be helpful when

the target moves quite far away from the camera & gun.

2) Design & development of mounting for actual gun on pan tilt with proper mechanical

analysis & calculations keeping gun recoil & ammunition reloading in mind. The

system should be designed in such a way to keep the mechanical vibrations to a

minimum.

References

2010

50

LIST OF SOFTWARES USED:

1) Matlab v2008

a. For the Image Processing Algorithm Development.

2) Microsoft Visual Studio v2008

a. Complete Standalone Application Development using MFC & OpenCV

Library, incorporating all the requirements of the Project such as Graphical

User Interface, Serial Communication, Image Processing and RFID Database.

3) Open Computer Vision Library v2.0

a. OpenCV Library is a Computer Vision Library

4) ProEngineer Wildfire

a. Mechanical Design by Qasim Zia

5) AVR Studio 4

6) WinAVR

7) Proteus v7.6

8) Adobe Photoshop CS4 Extended

a. For the Design of Poster and Graphical User Interface of the Application

9) Pixel View Station

a. Software for Interfacing Camera with the Computer

10) Realterm Serial Capture Program v2.0

11) Novarm DipTrace

Report: Strategic Monitoring using RFID & Real-time Target Tracking

2010

51

References:

[1] FAST OBJECT TRACKING IN DIGITAL VIDEO, Dong Kwon Park, Ho Seok Yoon, and

Chee Sun Won, Dep. of Electronic Engineering, Dongguk University, Seoul, 100-7 15, KOREA.

cswon@dgu.ac.kr

[2] High Speed and Wide Range Object Tracking System Using Pan-Tilt Cameras and Arm

Robot, Hiroyuki Ukida, Department of Mechanical Engineering, University of Tokushima, Via 21

Minamijosanjima-cho, Tokushima, Japan. ukida@me.tokushima-u.ac.jp

[3] Multi-Strategy Object Tracking in Complex Situation for Video Surveillance,

Ruijiang Luo, Liyuan Li, Weimin Huang, Qibin Sun

Institute for Infocomm Research, 21 Heng Mui Keng Terrace, Singapore