Professional Documents

Culture Documents

Ultrasonicflowetersshort 120214132732 Phpapp02

Uploaded by

Larry SmithOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ultrasonicflowetersshort 120214132732 Phpapp02

Uploaded by

Larry SmithCopyright:

Available Formats

Ultrasonic Flow Measurement Principles & Introduction

Series PUX2

Series UXF2

Series UXF3

The materials included in this compilation are for the use of

Dwyer Instruments, Inc. potential customers and current

employees as a resource only. They may not be reproduced,

published, or transmitted electronically for commercial

purposes. Furthermore, the Companys name, likeness,

product names, and logos, included within these compilations

may not be used without specific, written prior permission

from Dwyer Instruments, Inc.

Copyright 2011 Dwyer Instruments, Inc.

Transit Time Measuring Principle

Clamp-on sensors

Transit-time difference system

Principle equation:

Q = D

2

/ 4 * * D/sin2

f

* 1/(T

0

-)

2

T

K

Q : Flow rate

D : Inner pipe diameter

K : Conversion factor

of average velocity

f

: Incident angle into liquid

T

1

, T

2

: Transit time

T

0

: Transit time between sensors

when flow is at rest

((T

1

+ T

2

)/2)

: Transit time in pipe walls and

sensors

T=T

2

T

1

(Note)

Ultrasonic waves are

carried with the motion of

fluid.

Upstream Sensor

Oscillator Wedge

Pipe

f

D

Q

/2 /2

T

1

T

2

Downstream

Sensor

Utilized in Model PUX2, UXF3

Digital sampling of received signals increases flow reading reliability

Synchronized summation of received signals :

- Normal propagation

- Interrupted propagation

Advanced ABM (Anti-bubble Measurement)

Received signal :

t

v

Received signal :

Digital data of

received signals :

t

v

In case of analog system no

signal, intermittent loss of

receive echo

Summed

128 or 256

times for

one output

flow

bubble

flow

bubble

t

v

Nothing!

Result of Bubble Immersion Test

(Note) The flowmeters indicate volumetric flow rate containing air volume.

Models PUX2, UXF3

Velocity [m/s]

P

e

r

m

i

s

s

i

b

l

e

A

i

r

V

o

l

u

m

e

[

v

o

l

.

%

]

12

12

10

8

6

4

2

1

Model UXF2

1.0 2.0 3.0 4.0 5.0

7.0

4.0

1.5

0.4

0.03

0.02

1.2

1.0

0.02

Patented sound velocity compensation all

models

Changing process conditions (temp/pressure)

change fluid sound velocity (changes results)

Changing temp/pressure can be ignored if sound

velocity is constantly measured and compensated

Sound velocity compensation system tracks and

adjusts and

Sound Velocity Measurement System

Upstream Sensor

Pipe

f

D

Q

/2 /2

T

1

T

2

Downstream

Sensor

Sound

Velocity C

f

Effect of temp./

pressure change

Successive calculation with sensors spacing having no change from the set value

Model Specifications & Applications

PUX2

UXF2

UXF3

0.5 235 diameter, up to 12% air/solids

Digital fine filter & correlation

12 hour battery, data logger, memory card &

printer (options)

0.5 235 diameter, up to 12% air/solids

Digital fine filter & correlation

Full featured, flexible I/O, IP65 enclosure

1 24 diameter, up to 1.5% air/solids

Advanced transit time technology

Full featured, flexible I/O, highly competitive

PUX2 Specifications

Dwyer Instruments PUX2

Measurement Method Transit Time

Pipe sizes 0.50 to 236 inch diameter

Number of Paths 1 path

Fluid temperature -40 to +80/100/200

Ambient temperature -10 to +55 (Printer 45)

Air bubble resistance 12 Vol% (at 1m/s)

Accuracy +/-1.0% of rate

Velocity range 0 to +/- 32m/s (105 fps)

Output Analog Output: 1point 4-20mA; Heat Transfer Rate Function

Input Analog Input: 1 point 4-20 mA

Serial communication USB Port (Mini type B, 500kbps)

Key 11 keys (ON, OFF, LEFT, RIGHT, UP, DOWN, ESC,

ENT, MENU, BACKLIGHT, PRINT)

Display 240 X 320 Color LCD

Language 6 languages (ENG, ESP, GER, FRA, JAP, CHI)

Power Supply Built-in battery or power adapter

Built-in battery: L-Ion battery, approximately 12 hours

Power adaptor: AC Power Adapter/Charger 90 to 264V

Dimensions H210 x W120 x D65mm (without printer)

H320 x W127 x D70mm (with printer)

Mass: 1.0 kg (without printer)

1.2 kg (with printer)

Type of Enclosure IP64 (Plastic)

UXF3 Specifications

Dwyer Instruments UXF3

Measurement Method Transit Time

Pipe sizes 0.50 to 235 inch diameter

Number of Paths 1 path

Fluid temperature -40 to +80/100/200

Ambient temperature -10 to +55

Air bubble resistance 12 Vol% (at 1m/s)

Accuracy +/-1.0% of rate

Velocity range 0 to +/- 32m/s (105 fps)

Output

Input: 1 digital input, 1 pt. - No Voltage

transistor switch; set zero/reset

totalizer

One 4 to 20mA DC current outputMax. load

resistance 1k

Digital status output: 2 points available - 30V DC,

0.1ATotal pulse, Flow switch, Over flow, Range

change-over, Flow direction, Range over

Mechanical relay: 1 pt available; 240VAC/30VDC-1 amp

Serial communication RS232C/Modbus RS485 option; Baud rate: 9600 to

39400 bps; Distance: 15m(RS232)/1000m(RS485) max.

Key 4 key keyboard; menu driven programming

Display LCD with back light, 16 x 2 lines

Language 5 languages (ENG, ESP, GER, FRA, JAP)

Power Supply 100 to 240V AC 50/60Hz, or 20 to 30V DC

Dimensions H170 x W142 x D70mm

Type of Enclosure IP66 (1.5 kg)

UXF2 Specifications

Dwyer Instruments UXF2

Measurement Method Transit Time

Pipe sizes 1 to 24 inch (plastic pipe); 2 to 24 inch (metal)

Number of Paths 1 path

Fluid temperature -40 to +80/100

Ambient temperature -20 to +50

Air bubble resistance 1.2 Vol% (at 1m/s)

Accuracy 2% of rate (>2m/s), 0.04m/s (<2m/s)

Velocity range 0 to +/- 10 m/s (33 fps)

Output 4 to 20mAdc, 1 point

Digital output: Relay & transistor, each 1 point (scaled

totalizer pulse, alarm, etc.)

Scaled pulse: 1pulse/day to 100pps for transistor output

1pulse/day to 1pps for relay output

Serial communication RS-232C equivalent / RS-485

Number of connectable units: one (RS-485)/

up to 31 (RS-485)

Cable length: up to 15m (RS-232C)/up to 1km (RS-485)

Key 4 key front panel keyboard; menu driven programming

Display LCD 2 lines 32 characters - backlight

Language 5 languages (incl. Spanish)

Power Supply 20 to 30Vdc, 100 to 120Vac or 200 to 240Vac, 50/60Hz

Dimensions Dimensions of converter: H140 x W137 x D68mm

Mass of converter: approx, 0.8 kg

Type of Enclosure IP65 (Plastic)

Type Model No. Pipe size Fluid temp.

Sensor Mount & UXF2 Sensor Selection

SX3-A

UXF2

1

(V-mount)

(V)

4 in -20 +100

2 9 in SX3-B

SX3-C (V) 2 12 in

-20 +100

-20

+80

SX3-D

-20 +80

12 24 in (Z)

V mount configuration

Typical setup; recommended for most cases

having sufficient return signal

Sensors mounted axially on the same side

Z mount configuration

Single reflection reduces signal attenuation

Effective at upper end of sensor diameter range or

specific circumstances to increase return signal

Type Model No. Pipe size Fluid temp.

Sensor Selection PUX2, UXF3

PSX2-B

PUX2

UXF3

1/2 (V-mount)

(V)

4 in -40 +100

2

PSX2-A

PSX2-HT

PSX2-D

SX1-A

SX2-B

(Z) 12 16 in

(V) 2 14 in

(V

)

2 14 in

(Z) 12 16 in

(Z)

12 16 in

(Z) 8 236 in

(V) 8 120 in

(Z)

8

(V)

2

120 in

-40

-40 +80

-40 +80

-40 +80

-40

+200

SX1-C

(V) 2 14 in

(Z)

12

16 in

-40

+200

PSX2-E -40 +80

12

2 16 in (V)

48 in (Z)

SX1-B

12

24 in (V)

48 in (Z)

-40 +80

SX2-A

4 in

(V-mount)

-40 +100

14 in

1/2

236 in

8

+100

PUX2

UXF3

PSX

SX1

SX2

1 to 32 m/s

0 to 1 m/s

12 in.to

24 in. +

1.0% of rate

0.01 m/s

2 to 32 m/s

0 to 2 m/s

2 in. to

12 in.

1.0% of rate

0.02 m/s

2 to 32 m/s

0 to 2 m/s

0.5 in.

to 2 in.

1.5% of rate

0.03 m/s

Pipe diameter Velocity Accuracy Converter Sensor

Accuracy PUX2 & UXF3

Rated accuracy PUX2, UXF3 :

Reference conditions :

1. Fluid temp : Clean water 4 to 40

2. Fluid pressure : Less than 1 MPa

3. Flow : Full-filled, axisymmetric & well

developed turbulent flow

4. Warm-up time : 30 mins.

+0.32

A

c

c

u

r

a

c

y

[

m

/

s

]

Velocity

+0.02

0 32

+0.01

-0.01

-0.02

-0.32

2 1

2 in.to

24 in

UXF2

SX3-A/B

SX3-C/D

2 to 10 m/s

0 to 2 m/s

2 in. to

24 in.

1.5% of rate

0.03 m/s

2 to 10 m/s

0 to 2 m/s

1 in.to

2 in.

2.5% of rate

0.05 m/s

Pipe diameter Velocity Accuracy Converter Sensor

Plastic pipe

Accuracy UXF2

UXF2

SX3-A/B

SX3-C/D

2 to 10 m/s

0 to 2 m/s

2% of rate

0.04 m/s

Pipe size Velocity Accuracy Converter Sensor

Metal pipe

UXF2 Rated Accuracy

Getting Started PUX2

Setting up

the model

PUX2

Overview of functions

PUX2 Display & Screen navigation

Interface divided among 6 selections

Default view = measure screen (below)

To enter the menu

screen anytime, press the

menu button

6 menu selections for

setup, configuration,

datalogger, printer, etc.

appear

Getting Started UXF3

Setting up the

model UXF3

Overview of functions

UXF3 Inside the cover, wiring

UXF3 Installation steps

4 key operation

Additional Installation steps

Install optional wiring

Analog output, totalizer, switch outputs

Program optional functions

AO range

Totalizer

Flow switch/alarms

Low flow cutoff

Damping

Record system parameters

Basic Installation steps

Install Transmitter wiring and power

Locate appropriate mounting location

Set Inch or metric units

Program piping parameters

Set main display preference & units

Install sensor set on pipe

Verify signal and reading

Green/Red LED indicator on front panel

Getting Started UXF1

Setting up the

model UXF2

Overview of functions

- 19 -

Getting Started UXF2

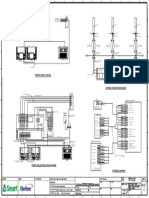

UXF2 Primary components - inside

Modular 2 or 3 boards design

Signal (bottom)

Power supply (left top)Install Transmitter

wiring and power

Serial comms (top right-optional)

Primary components & Functions

Key input via front panel

Front Panel LED

Red/Green LED provides signal Normal or

error condition

UXF2 Installation steps

Basic Installation steps

Install Transmitter wiring and power

Locate appropriate mounting location

Set Inch or metric units

Program piping parameters

Set main display preference & units

Install sensor set on pipe

Verify signal and reading

Recommend Hardcopy of Manual Pages 40-42

Additional Installation steps

Install optional wiring

Analog output, totalizer, switch outputs

Program optional functions

AO range

Totalizer

Flow switch/alarms

Low flow cutoff

Damping

Record system parameters

jumper

Markets & Applications

PUX2 and UXF3

Wastewater flow monitoring in wastewater treatment systems and plants

Water flow monitoring at water treatment plants

UXF2

Semiconductor water flow monitoring

Building Automation Systems

Hot and cold water flow from chillers and boilers

PUX2

Building Automation Systems

BTU Calculations

In general good for flow monitoring when selling on the advantage of not

having to cut open the pipe for installation and also for repair work

Markets & Applications PUX2 as an Energy Meter for BAS

Markets & Applications PUX2 Installation

Questions

To order a free catalog or for more information contact;

Dwyer Instruments, Inc., P.O. Box 373,

Michigan City, IN., 46361

Telephone: (800) 872-9141 or (219) 879-8000

Fax: (219) 872-9057

Internet address: www.dwyer-inst.com

E-mail: info@dwyer-inst.com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Pneumatic Comparators (Metrology)Document17 pagesPneumatic Comparators (Metrology)Larry Smith100% (2)

- Me 2204 - Fluid Mechanics and MachineryDocument3 pagesMe 2204 - Fluid Mechanics and MachineryKarthik SubramaniNo ratings yet

- Fluid Mechanics and Machinery Laboratory ManualDocument54 pagesFluid Mechanics and Machinery Laboratory ManualLarry SmithNo ratings yet

- Fluid Mechanics and Machinery (May2013)Document3 pagesFluid Mechanics and Machinery (May2013)Dmj Anbu RajNo ratings yet

- Fluid Mechanics and MachineryDocument10 pagesFluid Mechanics and Machinerysrajapraty50% (2)

- Fluid Mechanics and MachineryDocument2 pagesFluid Mechanics and MachineryNellai VprNo ratings yet

- Fluid Mechanics and Machinery (May2012)Document4 pagesFluid Mechanics and Machinery (May2012)Dmj Anbu RajNo ratings yet

- Fluid Mechanics and Machinery LabDocument43 pagesFluid Mechanics and Machinery LabLarry SmithNo ratings yet

- 20041709Document62 pages20041709Larry SmithNo ratings yet

- Me2034 QB PDFDocument2 pagesMe2034 QB PDFekanthamoorthyNo ratings yet

- NE May2013Document2 pagesNE May2013Larry SmithNo ratings yet

- NR-222101-Fluid Mechanics and MachineryDocument8 pagesNR-222101-Fluid Mechanics and MachinerySrinivasa Rao G100% (1)

- NE May2013Document2 pagesNE May2013Larry SmithNo ratings yet

- Me 1004 Nuclear ENGINEERING Questions Bank 2014: SubscribeDocument14 pagesMe 1004 Nuclear ENGINEERING Questions Bank 2014: SubscribeLarry SmithNo ratings yet

- Ansys PDFDocument2 pagesAnsys PDFLarry SmithNo ratings yet

- Group Technology AND Cellular Manufacturing: Submitted By: GROUP NO: 8 (ROLL NO 1111041 TO 1111045)Document30 pagesGroup Technology AND Cellular Manufacturing: Submitted By: GROUP NO: 8 (ROLL NO 1111041 TO 1111045)Larry SmithNo ratings yet

- Group Technology: Job Shop Production System Batch Production System Mass Production SystemDocument11 pagesGroup Technology: Job Shop Production System Batch Production System Mass Production SystemLarry SmithNo ratings yet

- ME 1004 NUCLEAR ENGINEERING Questions Bank 2014 Vidyarthiplus (V+) Blog - A Blog For StudentsDocument14 pagesME 1004 NUCLEAR ENGINEERING Questions Bank 2014 Vidyarthiplus (V+) Blog - A Blog For StudentsLarry SmithNo ratings yet

- Gtbylathu 101231003739 Phpapp01Document25 pagesGtbylathu 101231003739 Phpapp01Larry SmithNo ratings yet

- Group Technology PPT at Bec DomsDocument34 pagesGroup Technology PPT at Bec DomsBabasab Patil (Karrisatte)No ratings yet

- Group Technology AND Cellular Manufacturing: Submitted By: GROUP NO: 8 (ROLL NO 1111041 TO 1111045)Document30 pagesGroup Technology AND Cellular Manufacturing: Submitted By: GROUP NO: 8 (ROLL NO 1111041 TO 1111045)Larry SmithNo ratings yet

- Grouptechnology1 131203094018 Phpapp01Document9 pagesGrouptechnology1 131203094018 Phpapp01Larry SmithNo ratings yet

- Grouptechnology 140412022931 Phpapp01Document22 pagesGrouptechnology 140412022931 Phpapp01Larry SmithNo ratings yet

- Group Technology (GT)Document15 pagesGroup Technology (GT)Larry SmithNo ratings yet

- Gtbylathu 101231003739 Phpapp01Document25 pagesGtbylathu 101231003739 Phpapp01Larry SmithNo ratings yet

- Grouptechnology1 131203094018 Phpapp01Document9 pagesGrouptechnology1 131203094018 Phpapp01Larry SmithNo ratings yet

- Cellular Manufacturing & Group TechnologyDocument24 pagesCellular Manufacturing & Group TechnologyLarry SmithNo ratings yet

- Grouptechnology1 131203094018 Phpapp01Document9 pagesGrouptechnology1 131203094018 Phpapp01Larry SmithNo ratings yet

- Group Technology: Job Shop Production System Batch Production System Mass Production SystemDocument11 pagesGroup Technology: Job Shop Production System Batch Production System Mass Production SystemLarry SmithNo ratings yet

- Group Technology PPT at Bec DomsDocument34 pagesGroup Technology PPT at Bec DomsBabasab Patil (Karrisatte)No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- SPSC - Test MCQs - Sub Engineer Electrical (BPS-11) PDFDocument9 pagesSPSC - Test MCQs - Sub Engineer Electrical (BPS-11) PDFFunny Videos83% (6)

- NERC Standardized Component Model ManualDocument19 pagesNERC Standardized Component Model ManualNagy AbedNo ratings yet

- ch06 SolnDocument39 pagesch06 Soln陳怡萱No ratings yet

- ANGEN - En006 B Restricted Earth Fault ProtectionDocument5 pagesANGEN - En006 B Restricted Earth Fault ProtectionAlejandro Mira EstradaNo ratings yet

- Cinta Led SMD 5060 Interior RGB 30 Led M 12v 96w M 1m PDFDocument3 pagesCinta Led SMD 5060 Interior RGB 30 Led M 12v 96w M 1m PDFJacob MelladoNo ratings yet

- 10 CodesDocument4 pages10 CodesPerzi ValNo ratings yet

- Project AbbreviationsDocument4 pagesProject AbbreviationsLuis SabinoNo ratings yet

- C M ProjectDocument54 pagesC M ProjectCONVEX VENTURESNo ratings yet

- Newtec MCX7000 Multi Carrier Satellite Gateway r2.4 DatasheetDocument4 pagesNewtec MCX7000 Multi Carrier Satellite Gateway r2.4 DatasheetarzeszutNo ratings yet

- Keyence Infrared Temperature Sensors BrochureDocument14 pagesKeyence Infrared Temperature Sensors BrochureAlfin AhsanNo ratings yet

- Mrfud Description: Huawei Technologies Co., LTDDocument14 pagesMrfud Description: Huawei Technologies Co., LTDعلي عباسNo ratings yet

- Digital Timers: FeaturesDocument2 pagesDigital Timers: FeaturesLaban Menya - Power ControlsNo ratings yet

- Genesys Logic, Inc.: Revision 1.32 Jul. 15, 2011Document33 pagesGenesys Logic, Inc.: Revision 1.32 Jul. 15, 2011nqrcNo ratings yet

- PC Notebook Diagnostic Card: User's GuideDocument15 pagesPC Notebook Diagnostic Card: User's GuideAkash KumarNo ratings yet

- DF50 Auto Hematology Analyzer Operator's Manual-1Document225 pagesDF50 Auto Hematology Analyzer Operator's Manual-1faiz71% (7)

- Electronics IIDocument13 pagesElectronics IIDr. Neha KondalNo ratings yet

- Exhibitory Book FINAL Version 2Document100 pagesExhibitory Book FINAL Version 2Balakrishna Dora100% (1)

- Rbs/Bts Signal Cabling: DF PanelDocument1 pageRbs/Bts Signal Cabling: DF PanelMayuSalanggaNo ratings yet

- Static Timing Analysis and Timing Violations of Sequential CircuitsDocument7 pagesStatic Timing Analysis and Timing Violations of Sequential CircuitssunnygogineniNo ratings yet

- Lecture 2 - Modern Computer SystemsDocument44 pagesLecture 2 - Modern Computer SystemsKisarach PhilipsNo ratings yet

- Question Bank CAD CAMDocument7 pagesQuestion Bank CAD CAMAjay Kumar AgarwalNo ratings yet

- The Thermoelectric GeneratorDocument8 pagesThe Thermoelectric GeneratorSayed MesallamyNo ratings yet

- Flextec 350X ConnectDocument180 pagesFlextec 350X ConnectRigoberto Delgado100% (1)

- Testo 175 H1 INDocument2 pagesTesto 175 H1 INsundarNo ratings yet

- Smart CardDocument24 pagesSmart Carddrakshavali medidaNo ratings yet

- Stage 4 Technology Mandatory Digital Technologies: Crack The CodeDocument18 pagesStage 4 Technology Mandatory Digital Technologies: Crack The Codesnooze101No ratings yet

- Power Electronics and Motor Control PDFDocument563 pagesPower Electronics and Motor Control PDFAnonymous qdJOxst100% (3)

- Tapco Mix120 Service Manual Plastic Power JackDocument15 pagesTapco Mix120 Service Manual Plastic Power JackMontserrat AlvarezNo ratings yet

- PDFDocument2 pagesPDFgordomanotas100% (1)

- All Kinds of Faults in An Alternator and Their ProtectionDocument9 pagesAll Kinds of Faults in An Alternator and Their ProtectionFaisalNo ratings yet