Professional Documents

Culture Documents

Alignment of Pipe

Uploaded by

hoangcokhiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Alignment of Pipe

Uploaded by

hoangcokhiCopyright:

Available Formats

148

ALIGNMENT OF PIPE

Proper alignment is important if a piping system is to be correctly

fabricated.

Poor alignment may result in welding difficulties and a system that does

not function properly.

Welding rings may be employed to assure proper alignment as well as the

correct welding gap. In addition to using welding rings, some simple

procedures can be followed to assist the pipe fitter. Below and on the

following page are alignment procedures commonly used by todays

craftsmen.

PIPETOPIPE

1. Level one length of pipe

using spirit level

2. Bring lengths together leaving

only small welding gap

3. Place spirit level over both pipes as shown and maneuver unpositioned

length until both are level

4. Tack weld top and bottom

5. Rotate pipe 90

6. Repeat procedure

45 ELBOW-TO-PIPE

1. Level pipe using spirit level

2. Place fitting to pipe leaving small

welding gap

3. Place 45" spirit level on face of elbow

and maneuver elbow until bubble is centered

4. Tack weld in place

90 ELBOW.TO-PIPE

1. Level pipe using spirit level

2. Place fitting to pipe leaving small

welding gap

3. Place spirit level on face of elbow and maneuver elbow until level

4. Tack weld in place

149

ALIGNMENT OF PIPE

TEE-TO-PIPE

1. Level pipe using spirit level

2. Place tee to pipe leaving small

welding gap

3. Place spirit level on face of tee and

maneuver tee until level

4. Tack weld in place

FLANGE-TO-PIPE

1. Bring flange to pipe end leaving small

welding gop

2. Align toptwo holes of flange with spirit level

3. Tack weld in place

4. Center square on face of flange as

shown

5. Tack weld in place

6. Check sides in same way

JIG FOR SMALL DIAMETER PIPING

The jig is made from channel iron 3' 9" long.

Use

1

8" x 1

1

2" for pipe sizes 1

1

4" thru 3";

1

8" x

3

4" for Sizes 1" or smaller.

1. Cut out 90 notches about 9" from end.

2. Heat bottom of notch with torch.

3. Bend channel iron to 90 angle and weld sides.

4. Place elbow in jig and saw half thru sides

of channel iron as shown. Repeat this

step with several elbows so jig may be used

for different operations.

5. A used hack saw blade placed in notch as shown will provide proper

welding gap.

Cut Notch,

Heat & Bend

Weld

Sides

Weld

Sides

Cut Slots Using

Fitting as Guide

Weld

Sides

Cut Slots Using

Fitting as Guide

You might also like

- Pipe-To-Pipe: Lignment OF IPEDocument2 pagesPipe-To-Pipe: Lignment OF IPEMunir KadernaniNo ratings yet

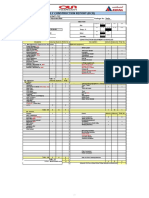

- Bill of Material For Mechnical & Structure For Hot Water Skid Rev.0 - 3Document5 pagesBill of Material For Mechnical & Structure For Hot Water Skid Rev.0 - 3Vu TranNo ratings yet

- Inspection Punch ListDocument2 pagesInspection Punch Listjrod915No ratings yet

- Mto Valve: CHKD Appd Appd Date DEC DSP/PPN REV Date Description BYDocument4 pagesMto Valve: CHKD Appd Appd Date DEC DSP/PPN REV Date Description BYAnonymous 6S9tcbhNo ratings yet

- Ipex FlangeDocument1 pageIpex FlangeNabil RamehNo ratings yet

- Instalasi Pipa SteamDocument140 pagesInstalasi Pipa SteamYudi KurniawanNo ratings yet

- Tech SpecDocument16 pagesTech SpecKingston RivingtonNo ratings yet

- PIPE SUPPORT-STR - Welding Inspection ReportDocument1 pagePIPE SUPPORT-STR - Welding Inspection ReportBWQNo ratings yet

- Detailed Engineering of Air Seperation Unit - SATORPDocument1 pageDetailed Engineering of Air Seperation Unit - SATORPfarhan yazdaniNo ratings yet

- Copia de EPCDocument32 pagesCopia de EPCPeter RodriguezNo ratings yet

- Pipe GuideDocument231 pagesPipe GuidegeorgD2010100% (1)

- Steel Pipe VesselDocument259 pagesSteel Pipe VesselJuragan TanjungNo ratings yet

- Minimum Length and Spacing For Welded Nozzles PDFDocument7 pagesMinimum Length and Spacing For Welded Nozzles PDFSoniNo ratings yet

- Standard Groove SpecificationsDocument5 pagesStandard Groove SpecificationsDavid SalgueroNo ratings yet

- How To Do A Tie-InDocument2 pagesHow To Do A Tie-Inrenjithv_4100% (1)

- API - Introduction - StandardsDocument29 pagesAPI - Introduction - Standardsrafael0j0moreno0r100% (1)

- 30 1 Static Equipment Horizontal ErectionDocument2 pages30 1 Static Equipment Horizontal Erectionpunitg_2No ratings yet

- Daily Report - XLSX 01Document1 pageDaily Report - XLSX 01kishoryawaleNo ratings yet

- How To Write A Welding Procedure Specification (WPS)Document5 pagesHow To Write A Welding Procedure Specification (WPS)Mohamed Atef100% (1)

- Made in Italy - EuropeDocument8 pagesMade in Italy - EuropeenenickNo ratings yet

- Procedure For DYE PENETRANT TestingDocument10 pagesProcedure For DYE PENETRANT TestingKarrar Talib100% (1)

- Form Welding SchematicDocument1 pageForm Welding SchematicZainudinNo ratings yet

- Itp PWHTDocument1 pageItp PWHTTridib DeyNo ratings yet

- M-2006 Weld KGDocument8 pagesM-2006 Weld KGDinesh ShahNo ratings yet

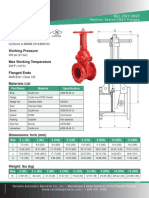

- OS&Y Gate Valve PDFDocument1 pageOS&Y Gate Valve PDFAhmed Mohamed Abd Elhakam100% (1)

- Table of Content: Elbow Trimming ProcedureDocument5 pagesTable of Content: Elbow Trimming ProcedureMechanical Static WRKNo ratings yet

- Daily Construction Report (DCR) : Project ManagerDocument5 pagesDaily Construction Report (DCR) : Project ManagerMoath AlhajiriNo ratings yet

- Saudi Arabian Oil Company: Instrument Specification Sheet Differential Type Level InstrumentsDocument1 pageSaudi Arabian Oil Company: Instrument Specification Sheet Differential Type Level Instrumentsgayu87No ratings yet

- Client: Job No.: Job Title: Client's Job No.:: Company NameDocument13 pagesClient: Job No.: Job Title: Client's Job No.:: Company NamejorgekarlosprNo ratings yet

- 1847 A Duplex Piston Pump Mud PumpDocument2 pages1847 A Duplex Piston Pump Mud PumpÆmanuel J SilvaNo ratings yet

- Katalog TSP PTDocument24 pagesKatalog TSP PTendroNo ratings yet

- NDT Request Form (Piping) : Wara Pressure Maintenance ProjectDocument7 pagesNDT Request Form (Piping) : Wara Pressure Maintenance ProjectVimin PrakashNo ratings yet

- CS 5200 SC01 Ope PRC 253007 - A - C2Document78 pagesCS 5200 SC01 Ope PRC 253007 - A - C2chancele nguepdjopNo ratings yet

- WP 11 Corrosion Protection Tape CoatingDocument3 pagesWP 11 Corrosion Protection Tape CoatingKarthikNo ratings yet

- WPQ FormDocument1 pageWPQ Formudaysrp100% (1)

- LT26G PDFDocument4 pagesLT26G PDFraul gonzalezNo ratings yet

- Trepanning Positioning Welding ManualDocument14 pagesTrepanning Positioning Welding ManualGovindan PerumalNo ratings yet

- Daftar Harga Fire Hydrant AppronDocument2 pagesDaftar Harga Fire Hydrant AppronWeri IsvebriantiNo ratings yet

- Test Pack Clearance FormatDocument2 pagesTest Pack Clearance FormatKarthikNo ratings yet

- Nozzle Dim 12th EdnDocument16 pagesNozzle Dim 12th EdnBTENo ratings yet

- Procedure Welding Consumible ProcedureDocument11 pagesProcedure Welding Consumible ProcedureCilobong Kubuk KubingNo ratings yet

- Fabrication PlanDocument1 pageFabrication PlanVũ GiangNo ratings yet

- Pengantar Dfki Pipa: Ediman Hotman Ir. MMBAT., DPL - SMDocument15 pagesPengantar Dfki Pipa: Ediman Hotman Ir. MMBAT., DPL - SMMulYadi100% (1)

- Layout Explained - PIPING GUIDEDocument14 pagesLayout Explained - PIPING GUIDEMir Mustafa Ali100% (1)

- Hot Tapping On Operating LinesDocument20 pagesHot Tapping On Operating LinesCelestine Ozokechi100% (1)

- Flushing Air Conditioner ProcedureDocument3 pagesFlushing Air Conditioner Proceduredimchien100% (1)

- Punch List FormatDocument27 pagesPunch List FormatChristoberNo ratings yet

- Electrofusion WeldingDocument11 pagesElectrofusion WeldingZuberYousufNo ratings yet

- Pipe Hangers, Pipe Supports, Variable and Constant Spring HangersDocument2 pagesPipe Hangers, Pipe Supports, Variable and Constant Spring Hangerskaiju85No ratings yet

- Fluxi 2000 TZ EN-03 - 18Document4 pagesFluxi 2000 TZ EN-03 - 18Praveen KumarNo ratings yet

- Step 7 De-Watering & DryingDocument1 pageStep 7 De-Watering & Dryingmansih457No ratings yet

- A 1 KDocument5 pagesA 1 KSumantrra ChattopadhyayNo ratings yet

- SikaBit W-15 Page 1 - 39Document52 pagesSikaBit W-15 Page 1 - 39Keesh RonoloNo ratings yet

- S o P-PipingDocument17 pagesS o P-PipingPrakash TiwariNo ratings yet

- VGK Structure Detailed ScheduleDocument2 pagesVGK Structure Detailed ScheduleHaytham SamirNo ratings yet

- Socket Weld X Threaded CouplingDocument1 pageSocket Weld X Threaded Couplingmatthewwalls4386No ratings yet

- Pipe WeldingDocument3 pagesPipe WeldingDoğan OrhangaziNo ratings yet

- Method Work Statement Pipe Welding WorksDocument17 pagesMethod Work Statement Pipe Welding WorksSanjana AhujaNo ratings yet

- Method Statement For Fab of Pipework and FittingsDocument13 pagesMethod Statement For Fab of Pipework and FittingsAllan EscobarNo ratings yet

- Q1W3 Install Metallic NonmetallicDocument12 pagesQ1W3 Install Metallic NonmetallicCloud DullasNo ratings yet

- Assembly and Installation PVC To MEtal PipeDocument11 pagesAssembly and Installation PVC To MEtal PipevuongNo ratings yet

- Selection of An NDT Method and The Extent of TestingDocument8 pagesSelection of An NDT Method and The Extent of TestingvuongNo ratings yet

- ++++u30000 - Us Motor NameplateDocument2 pages++++u30000 - Us Motor NameplatevuongNo ratings yet

- +++IOM - NETZSCH PUMP Pump General DatasheetDocument12 pages+++IOM - NETZSCH PUMP Pump General DatasheetvuongNo ratings yet

- ++++u30000 - Us Wiring DiagrDocument2 pages++++u30000 - Us Wiring DiagrvuongNo ratings yet

- ++++u30000 - Us Motor Ac Part ListDocument1 page++++u30000 - Us Motor Ac Part ListvuongNo ratings yet

- PC - 50APVS-5.75-1 m3 HR 1 BarDocument1 pagePC - 50APVS-5.75-1 m3 HR 1 BarvuongNo ratings yet

- TI 800 01 Design CritereaDocument459 pagesTI 800 01 Design CritereaAtifah Ahmad100% (1)

- Waste Water Collection, Treatment and StorageDocument46 pagesWaste Water Collection, Treatment and StoragevuongNo ratings yet

- PC - 80APVS-51.5-4 m3 HR 1.5 BarDocument1 pagePC - 80APVS-51.5-4 m3 HR 1.5 BarvuongNo ratings yet

- Drawing: Thai Binh 2 Thermal Power Plant ProjectDocument1 pageDrawing: Thai Binh 2 Thermal Power Plant ProjectvuongNo ratings yet

- Kök Paso HaynesDocument11 pagesKök Paso HaynesSuphi YükselNo ratings yet

- Chemcad Oil GasDocument3 pagesChemcad Oil GasleakNo ratings yet

- T2364 BOQ - Closed Sampling SystemDocument1 pageT2364 BOQ - Closed Sampling SystemvuongNo ratings yet

- Aljac Catg On Closed SamplerDocument2 pagesAljac Catg On Closed SamplervuongNo ratings yet

- SMWWTPGLDocument161 pagesSMWWTPGLPremasiri KarunarathnaNo ratings yet

- Water and Wastewater Calculations Manual 2nd EdDocument18 pagesWater and Wastewater Calculations Manual 2nd Edvuong0% (1)

- Technical Datasheet For Monorail With Chain HoistDocument5 pagesTechnical Datasheet For Monorail With Chain HoistvuongNo ratings yet

- Spec For Closed Sampling SystemDocument2 pagesSpec For Closed Sampling SystemvuongNo ratings yet

- RRRSDP Final PPMDocument176 pagesRRRSDP Final PPMDipankar SahaNo ratings yet

- Shielded Metal Arc Welding SMAW Vertical Down and Vertical Up Welding of PipelinesDocument48 pagesShielded Metal Arc Welding SMAW Vertical Down and Vertical Up Welding of PipelinesspahicdaniloNo ratings yet

- Monorail Electric HoistsDocument5 pagesMonorail Electric Hoistsvuong0% (1)

- Fess Procedure ManualDocument116 pagesFess Procedure ManualvuongNo ratings yet

- July 2013 - Iso 14001 Ems & Osha's 18001 Oh&s Program SlidesDocument39 pagesJuly 2013 - Iso 14001 Ems & Osha's 18001 Oh&s Program SlidesvuongNo ratings yet

- Process System Engineers (India) Pvt. LTD.: Marketing, Distribution & System Building ByDocument13 pagesProcess System Engineers (India) Pvt. LTD.: Marketing, Distribution & System Building ByvuongNo ratings yet

- DPW Des Dev Process FlowchartDocument1 pageDPW Des Dev Process FlowchartvuongNo ratings yet

- "Simplified Crane Data Sheet" - Api 2C 7'Th Edition - Fixed PlatformDocument1 page"Simplified Crane Data Sheet" - Api 2C 7'Th Edition - Fixed PlatformvuongNo ratings yet

- Weld Strengths To BS5950 01.01.03Document1 pageWeld Strengths To BS5950 01.01.03Pallavi DalviNo ratings yet

- Design of Crane Steel BeamsDocument134 pagesDesign of Crane Steel Beamsshak54383% (6)

- 22 TTG Heavy Oil ExxonmobilDocument56 pages22 TTG Heavy Oil ExxonmobilvuongNo ratings yet

- Classic Petrol 35 SDocument10 pagesClassic Petrol 35 S5432167890OOOONo ratings yet

- Lecture-14 Sheet Metal Forming ProcessesDocument34 pagesLecture-14 Sheet Metal Forming ProcessesDida KhalingNo ratings yet

- What Is The Best Way To Adjust or Get Rid of Negative Float in Primavera P6Document2 pagesWhat Is The Best Way To Adjust or Get Rid of Negative Float in Primavera P6Mohammed AmjadNo ratings yet

- Common Gain StageDocument37 pagesCommon Gain StageVincent ClaesNo ratings yet

- Digital Timer Modulator With Diagnostic Readout: Operating Instructions (701 10 Series)Document4 pagesDigital Timer Modulator With Diagnostic Readout: Operating Instructions (701 10 Series)Alex ConstantinescuNo ratings yet

- Topic 1:: Preliminary EstimatesDocument22 pagesTopic 1:: Preliminary EstimatesRajan RanjanNo ratings yet

- Birla Institute of Technology & Science, Pilani Practice School Division Session 2018 PSI Assignment HandoutDocument3 pagesBirla Institute of Technology & Science, Pilani Practice School Division Session 2018 PSI Assignment Handouttarun chauhanNo ratings yet

- Modelling Microstructures With OOF2: Andrew C.E. ReidDocument13 pagesModelling Microstructures With OOF2: Andrew C.E. ReidKaram JaradatNo ratings yet

- Team I Project Report: Biologically Inspired Alligator RobotDocument12 pagesTeam I Project Report: Biologically Inspired Alligator Robotapi-286147226No ratings yet

- Com Profinet-Io 7UM62 UsDocument36 pagesCom Profinet-Io 7UM62 Usmirage1977No ratings yet

- MT6592 Android ScatterDocument7 pagesMT6592 Android ScatterÁlvaro López VillegasNo ratings yet

- E-RAB Abnormal Release Causes: Huawei Technologies Co., LTDDocument14 pagesE-RAB Abnormal Release Causes: Huawei Technologies Co., LTDMShabbar Syed0% (1)

- SH5002-7J S EnuDocument304 pagesSH5002-7J S Enu19848096No ratings yet

- RFID Based Vending MachineDocument3 pagesRFID Based Vending MachineEditor IJTSRDNo ratings yet

- Peugeot 206Document1 pagePeugeot 206Sergio Hernandez0% (1)

- 3674aclio1 PDFDocument81 pages3674aclio1 PDFmattathiaNo ratings yet

- OSEIA Solar Safety 12-06Document112 pagesOSEIA Solar Safety 12-06srujanyeleti100% (1)

- Design of Seismic Force On BuildingDocument12 pagesDesign of Seismic Force On BuildingAjay DalviNo ratings yet

- Ips e PR 850 PDFDocument73 pagesIps e PR 850 PDFdeyanshu7No ratings yet

- On Windows Syscall Mechanism and Syscall Numbers Extraction MethodsDocument26 pagesOn Windows Syscall Mechanism and Syscall Numbers Extraction MethodsqdwqdNo ratings yet

- Bmaxx 4400 JindalDocument76 pagesBmaxx 4400 JindalRakesh Karan Singh0% (1)

- Sue's Rendezvous Illegal Certificate of OccupancyDocument3 pagesSue's Rendezvous Illegal Certificate of OccupancySamuel L. RiversNo ratings yet

- Low Density Parity Check CodesDocument21 pagesLow Density Parity Check CodesPrithvi Raj0% (1)

- GA-I (H) D 1000 Series ROBOTDocument1 pageGA-I (H) D 1000 Series ROBOTmfarrukhkNo ratings yet

- RGF 1Document4 pagesRGF 1mickymausNo ratings yet

- Design Simulation Manufacture and Testingof A Free-Piston Stirling Engine - Ivan Niell Deetlefs PDFDocument138 pagesDesign Simulation Manufacture and Testingof A Free-Piston Stirling Engine - Ivan Niell Deetlefs PDFJorge ValianteNo ratings yet

- Technical Sheet of EI2 60 Handed DoorDocument1 pageTechnical Sheet of EI2 60 Handed DoorTaoufikAzarkanNo ratings yet

- Simpson Anchors Anchoring and Fastening Systems 1461056Document236 pagesSimpson Anchors Anchoring and Fastening Systems 1461056Foisul AlamNo ratings yet

- P357 With Fanuc 04PC User Pre-Installation Guide Rev 4 - 0 PDFDocument35 pagesP357 With Fanuc 04PC User Pre-Installation Guide Rev 4 - 0 PDFParvezNo ratings yet