Professional Documents

Culture Documents

Zerbst

Uploaded by

ramnadh803181Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Zerbst

Uploaded by

ramnadh803181Copyright:

Available Formats

Fracture and Crack Propagation in Weldments.

A Fracture Mechanics Perspective A Fracture Mechanics Perspective

Uwe Zerbst, BAM Berlin

Outline

Specific aspects of weldments

Determination of fracture toughness

Determination of the crack driving force

Shallow crack propagation and fatigue strength Shallow crack propagation and fatigue strength

Outline

Specific aspects of weldments

Determination of fracture toughness

Determination of the crack driving force

Shallow crack propagation and fatigue strength Shallow crack propagation and fatigue strength

Fracture mechanics of weldments: Specific aspects

Inhomogeneous

microstructure

Residual stresses

Misalignment

Strength mismatch

Susceptibility

to cracking

Misalignment

Fracture mechanics of weldments: Specific aspects

Susceptibility

to cracking

Weld imperfections

Figure according to Gagg, 2005

ISO 5817: Arc welded joints in steel - Guidance on quality levels

for imperfections

26 different types of weld imperfections

Can be assigned to distinct groups from the perspective of mechanical integrity Can be assigned to distinct groups from the perspective of mechanical integrity

(a) Cracks and crack-like imperfections

have to be avoided or if they occur are immediately subject to

fracture mechanics analysis

(b) Material imperfections which act as crack initiation sites

of paramount importance for fatigue strength and fatigue life analyses of paramount importance for fatigue strength and fatigue life analyses

(c) Geometric discontinuities

increase the local stresses, affect crack initiation, propagation and final failure

(d) Imperfections which probably are of no effect on fracture or fatigue life

Fracture mechanics of weldments: Specific aspects

Inhomogeneous

microstructure

Susceptibility

to Cracking

Material inhomogeneity

Reason: Inhomogeneous cooling & TTT behaviour

Figure according to Toyoda, 1998

HAZ regions

Consequence

Toughness scatter

Specific requirements

on toughness testing

identification of

specific micro-

structure

Figure according to Toyoda, 1998

number of test

specimens

Fracture mechanics of weldments: Specific aspects

Inhomogeneous

microstructure

Strength mismatch

Susceptibility

to cracking

Unintended and intended

mismatch

Usually in steel:

moderate overmatching

Strength mismatch

moderate overmatching

Cases of undermatching:

aluminium, high strength steels

Pronounced mismatching:

laser & electron beam welding

YW YB

M =

W = Weld metal

B = Base plate

Strength mismatch

Effect on crack driving force

Effect on crack path deviation

Figures: Dos Santos et al., Koak

UM

OM

Factors affecting the mismatch effect

Crack location (weld metal, fusion line etc.) Mismatch ratio (

YW

/

YB

)

Global constraint interdependency (W-a)/H

Residual stresses

Fracture mechanics of weldments: Specific aspects

Inhomogeneous

microstructure

Residual stresses

Strength mismatch

Susceptibility

to cracking

Welding residual stresses

Reason: inhomogeneous cooling

constrained shrinking

solid state phase transformations

External restraint

macro-residual stresses (residual stresses of the

first kind); vary within the cross section over a

distance much larger than grain size

Internal forces and moments are in equilibrium with

respect to any cross section and axis respectively

Figure according to

Leggatt, 2008

Welding residual stresses

Scatter and uncertainty in simulation and measurement

Figures according to

Bouchard, 2008

Welding residual stresses

Dependency on location along the weld

Further effect: Stop-start features

Figures according to Hosseinzadeh and Bouchard,

2011; (b) Bouchard, 2008

Welding residual stresses

Residual stress profiles

Individual determination

Compendia (upper bound curves

to literature data) to literature data)

Membrane stress (as-welded:

max. value: yield strength)

p r

Y

+

Post weld treatment:

Membrane stress (yield strength at

annealing temperature + correction

for ratio of E modules at room &

annealing temperatures

Mechanical post weld treatment

Fracture mechanics of weldments: Specific aspects

Inhomogeneous

microstructure

Residual stresses

Misalignment

Strength mismatch

Susceptibility

to cracking

Misalignment

Types of misalignment:

(a) Axial misalignment between flat plates

(b) Angular misalignment between flat plates

Welding residual stresses

(b) Angular misalignment between flat plates

(c) Angular misalignment in a fillet welded joint

Consequence:

Notch effect/local bending stress

Strong effect of fatigue life and

shallow crack propagation

Effect on long crack fatigue

propagation and (sometimes)

on failure load

Outline

Specific aspects of weldments

Determination of fracture toughness

Determination of the crack driving force

Shallow crack propagation and fatigue strength Shallow crack propagation and fatigue strength

Specimen geometries most appropriate

Fracture toughness determination

Modifications compared to testing of non-welded material

for weldments, e.g., shallow cracked

bend specimens

Weldment specific aspects of specimen

preparation such as the introduction of

the notch, minimisation of residual

stresses and misalignment

Generation of a straight crack front

ISO 15653

Validity criteria

Required number of test specimens

Strength mismatch effects for testing

in the net section yielding range

ISO 15653

Fracture toughness determination: Scheme

According to ISO 15653

Fracture toughness determination

Adapted testing

Perform test as much as possible representative with respect to the component

in service. Relevant factors and parameters are:

Welding process including filler material

Base plate composition

Joint thickness

Preheat and interpass temperatures

Heat input

Detailed welding procedure

Joint configuration

Restraint

Postweld treatment

Time between welding and testing

Environment

Test temperature

Hydrogen release heat treatment

prior to testing can be necessary

when the time between welding

and the beginning of service is

much longer than those between

welding and testing.

Fracture mechanics of weldments: Specific aspects

Inhomogeneous

microstructure

Susceptibility

to cracking

Fracture toughness determination

Specific features because of inhomogeneous

microstructure, metallography

HAZ testing: Pre and post test

metallographic examination

In steel: crack tip no more distant

than 0.5 mm from target microstructure

Crack front should sample either 15%

or at least 7 mm of the HAZ microstructure

Both within the central 75% of the specimen thickness

ISO 15653

Randomly distributed small regions of low toughness (weak links) across the ligament;

Fracture toughness determination

Specific features due to inhomogeneous

microstructure: Weakest link approach (1)

in weldments: HAZ brittle zones

During load increase, when stress peak is shifted into the ligament to the location of

the nearest weak link the whole specimen (or component) fails

Due to the random distribution of the weak links

in the ligament area the distance of the

first one from the crack tip varies from

specimen to specimen and so does the

work necessary to shift the stress peak work necessary to shift the stress peak

to the right position

fracture toughness scatter

The longer the crack front the higher the

probability of a weak link next to it

Fracture toughness determination

Specific features due to inhomogeneous

microstructure: Weakest link approach (2)

probability of a weak link next to it

Toughness scatter becomes smaller

for longer crack fronts but lower bound

remains constant

Same lower bound toughness can be

determined by using few specimens

with large crack fronts or by using

many specimens with short crack fronts

Usually: 3-Parameter Weibull distribution; e.g., Stage 2 and 3 Options of SINTAP Master

Curve approach

Fracture toughness determination

Specific features due to inhomogeneous

microstructure: Weakest link approach (3)

BS 7910: Minimum of 12 valid HAZ tests for ductile-to-brittle transition BS 7910: Minimum of 12 valid HAZ tests for ductile-to-brittle transition

Figures according to Toyoda, 1998

Fracture toughness determination

Pop-in behaviour

Pop-in: Discontinuity in the load versus displacement curve in the fracture mechanics test

displacement suddenly increases and

load decreases load decreases

Different reasons:

Limited cleavage fracture propagation + arrest

Out-of-plane slits

Other reasons

Criteria: > 4 (2) % of (W-a) crack propagartion

Fig.: Dos Santos

et al., 2001

Criteria: > 4 (2) % of (W-a) crack propagartion

Load drop more than x %

Increase in compliance

Problem: When is a pop-in event

component relevant?

Fracture mechanics of weldments: Specific aspects

Inhomogeneous

microstructure

Strength mismatch

Susceptibility

to cracking

Fracture toughness determination

Specific features because of strength mismatch

ISO 15653: Error in J integral or CTOD (standard equations) due to mismatch

less than 10% as long as

Weld metal testing:

CTOD tests:

J integral tests:

M > 1.5 or 1.25: overestimation of J or CTOD

M < 0.5 underestimation

< < 0.5 M 1.5

< < 0.5 M 1.25

HAZ testing: Error for J and -20% to +10% for CTOD as long as

Else mismatch specific

pl

function in

< < 0.7 M 2.5

5%

( )

= +

2

pl

K U

J

E B W a

Fracture toughness determination

pl

function for strength mismatch (EFAM , Schwalbe et al.)

Some additional solutions in the literature

Fracture toughness determination

Definition of weld width H for other than prismatic welds

Proposals:

(a) H = average of 2H

1

and 2H

2

(b) equivalent H, H

eq

, on the basis of

the shortest distance between the

crack tip and the fusion line along

the slip lines emanating from the

crack tip

However: Systematic investigation

still missing.

Fracture toughness determination

Effect of strength mismatch on constraint and toughness

According to Toyoda, 2002

According to Kim (Schwalbe et al., 1996)

Complex issue: Various constraint parameters

Damage mechanics simulation (e.g. GTN)

Fracture toughness determination

Effect of strength mismatch on toughness

and crack path deviation

Electron beam weld, steel

Kocak et al., 1999

Probability of crack path deviation

decreases with longer crack front

Laser beam weld, steel

Heerens & Hellmann, 2003

Stress-strain curves

Micro tensile tests

e.g., Kocak et al., 1998

BS 7448: Estimation from hardness

p0.2B

p0.2W

Base plate : R 3.28 HV 221 for 160 < HV < 495

Weld metal : R 3.15 HV 168 for 150 < HV < 300

=

=

Fracture mechanics of weldments: Specific aspects

Inhomogeneous

microstructure

Residual stresses

Strength mismatch

Susceptibility

to cracking

Fracture toughness determination

Specific features because of residual stresses

Considered at applied side

(crack driving force in component)

Specimen if possible residual Specimen if possible residual

stress free (but not realistic)

Specimen preparation

in order to generate

straight crack front

From left to right:

- Local compression - Local compression

- (Reverse

bending)

- High R ratio

test

Fracture mechanics of weldments: Specific aspects

Inhomogeneous

microstructure

Residual stresses

Misalignment

Strength mismatch

Susceptibility

to cracking

Misalignment

Fracture toughness determination

Specific features because of misalignment

Deformation of specimen wings in order to avoid bending Deformation of specimen wings in order to avoid bending

However, no plastic deformation within a distance B from weld

Outline

Specific aspects of weldments

Determination of fracture toughness

Determination of the crack driving force

Shallow crack propagation and fatigue strength Shallow crack propagation and fatigue strength

Fracture mechanics of weldments: Specific aspects

Inhomogeneous

microstructure

Strength mismatch

Susceptibility

to cracking

Crack path simulation by damage

mechanics methods, e.g., GTN model

Local parameters for at least base plate,

Crack driving force and

fracture assessment

Local parameters for at least base plate,

weld metal and HAZ

Negre et al., 2004

}

Conventional fracture mechanics

(finite element based and analytical)

Lower bound toughness or R curve

or probabilistic analysis

Effect of mismatch and residual stresses

}

Mismatch corrected limit load

on R curve or toughness scatter!

(crack path deviation)

Again: When are pop-in events component

relevant?

( )

-2

e r

J J f L ( =

( )

r r

K f L =

Crack driving force: R6 type assessment

FAD approach CDF approach

2

e

J K E =

r mat

K K K =

( )

( )

-1 2

2 6

r r r

f L 1 0.5 L 0.3 0.7 exp L

(

( = + +

r

0 L 1

( ) ( )

( ) N 1 2N

r r r

f L f L 1 L

= =

max

r r

1 L L

( )

max

r p0.2 m eL

L 0.5 R R R

(

= +

Example. Option 1B analysis (no Lders plateau)

r Y ref Y

L F F = =

( )

p0.2

0.001 E R

min

0.6

( )

p0.2 m

N 0.3 1 R R

(

=

( )

r p0.2 m eL

L 0.5 R R R

(

= +

Replace F

Y

by F

YM

Mismatch corrected limit load F

YM

Example

Conservative option:

F

YM

determined as F

Y

based on the lower yield

strength of base plate and weld metal

Individual determination

F

YM

solutions as functions of global geometry,

mismatch ratio M and (W-a)/H

Limit states:

long crack a and/or wide weld (large H) short crack and/or narrow weld (small H)

plastic zone mainly in weld metal plastic zone mainly in base plate

F

Y

based on

YW

gives good estimate F

Y

based on

YB

gives good estimate

(e.g. laser or electron beam weld)

Mismatch corrected limit load F

YM

Examples

UM OM

Fracture analyses including mismatch: Examples

F

c

= 569 kN

F

c

= 589 kN

M = 1.5

F

c

(homogenous) = 550 kN

Fracture mechanics of weldments: Specific aspects

Inhomogeneous

microstructure

Residual stresses

Strength mismatch

Susceptibility

to cracking

Primary stresses

p

:

Arise from the applied mechanical contribute to

load, including dead weight or plastic collapse

inertia effects

Primary and secondary stresses

Secondary stresses

s

:

Result from suppressed local do not contribute

distortions, e.g., during the to plastic collapse

welding process, or are due

to thermal gradients

Self-equilibrating across the

structure, i.e., net force and

K factor determination is based

on both primary and secondary

stresses but only the primary

structure, i.e., net force and

bending moment are zero

However: Secondary stresses can act like primary stresses in the crack carrying section

Treatment as primary conservativ

stresses but only the primary

stresses are taken into account

for the limit load F

Y

,

Crack driving force due to primary

and secondary stresses

Primary stresses only

n

a

K a f

(

| |

=

(

|

}

Primary + secondary stresses

n n

n

a

K a f

T

| |

=

(

|

\

(

( )

n

n

n

x

x

T

(

| |

=

(

|

\

(

}

Interaction factor V

Small scale yielding:

K = K

p

+ K

s

However: because of rather high

s

in as-welded structures

s

in as-welded structures

K > K

p

+ K

s

L

r

< 1

and because of stress relief

K < K

p

+ K

s

L

r

> 1

Although secondary stresses dont

contribute to plastic collapse they

contribute to ligament yielding

contribute to ligament yielding

p s

I I

r

mat

V K K

K

K

+

=

( )

2

p s

I I

r

K K 1

J

E f L

V

(

+

=

(

FAD approach:

CDF approach:

p s

K K K V = + = + = + = +

s

p

s

K

V

K

= = = =

Plasticity corrected

K factor for se-

condary stresses

Determination of V

s

V

K

= = = =

K factor for

secondary

stresses

Fit function to finite

element results

Different options for determining

s

p

K

( )

s p

p r

K K L 0 0.02 0.04

e.g., plastic zone corrected K:

p

( ) ( )

s s

p eff

K a a K a =

L

r

0

0.01

0.02

0.03

( )

2

s

eff

Y

K a 3 plane strain

1

a a =

2 1 plane stress

(

= +

(

Fracture analyses including residual stresses

Example: Residual stress profile

( )

2 3

T *

R Y

z z z

z t 1 0.917 14.533 83.115

t t t

( ( (

= +

( ( (

4 5 6

z z z

215.45 244.16 93.36

t t t

( ( (

+

( ( (

Transverse residual stresses (compendium)

Fracture analyses including residual stresses

Example: Critical load for stable crack initiation

Reduction in critical load: ca. 25%

Fracture analyses including residual stresses

Example: Fatigue crack propagation and residual lifetime

No effect on K

But on R = K

min

/K

max

Effect on crack closure behaviour

Reduction in

Effect on crack closure behaviour

Reduction in

residual lifetime:

ca. 25%

Simplified assumption:

R > 0.5 (BS 7910)

Fracture analyses including residual stresses

Ongoing discussion on

less conservative deter-

mination of V factor

This workshop

Including solutions

Without elastic follow-up Without elastic follow-up

Large elastic follow-up

for application to short crack propagation problems

Fracture mechanics of weldments: Specific aspects

Inhomogeneous

microstructure

Residual stresses

Misalignment

Strength mismatch

Susceptibility

to cracking

Misalignment

Example:

Angular distorsion

Butt weld

clamped

Fracture analyses including residual stresses

Misalignment

( ) ( )

s

m

tanh tanh

y

t t

= =

` `

) )

2 2

3 3

2 2 2

Solution for bending stress

s

refered to membrane stress

m

Alternativ: Finite element stress distribution

1 2

m

3 2

(rad!)

t E

(

=

(

Outline

Specific aspects of weldments

Determination of fracture toughness

Determination of the crack driving force

Shallow crack propagation and fatigue strength Shallow crack propagation and fatigue strength

Frequently: Inclusions at or

close to surface are

crack initiaton sites

Initial defects in engineering alloys

crack initiaton sites

Further crack initiation sites:

Primary phases

Pores/cavities

Corrosion pits

Crack initiation at inclusions in steel (42CrMoS4)

(Figs. Pyttel)

Surface roughness

(scratches)

Welding defects

Distinguish between geometrical dis-

continuities (considered at applied

side) and material defects

Weld discontinuities and defects

side) and material defects

Applied side Material

- Misalignment - Slag lines

- weldment geometry - Pores

- Undercuts - Lack of fusion

- Overlap - Cracks

Initial crack size and

geometry (multiple cracks)

Usually excluded

- Overlap - Cracks

Specified by

weldment

quality

system

Steel 350WT

Crack initiation in WAZ

0.3 mm deep surfacerdefect

(Josi, 2010)

Discontinuity VD (normal quality) VC (high quality) VB (post weld treated)

Overlap < 0,5 mm < 0,1 mm not permissable

Lack of fusion not permissable not permissable not permissable

Example: Weldment quality grades: VOLVO

Group Weld Quality Standard 181-0004, 2008

Lack of fusion not permissable not permissable not permissable

Transition > 0,25 mm > 1 mm > 4 mm

radius

Undecut < 0,05 t (max 1 mm) < 0,025 t (max 0,5 mm) not permissable

inadequate < - 0,2a (max 2 mm) smaller not permissable smaller not permissable

weld thickness

Misalignment < 0,1 t (max 2 mm) not permissable not permissable

Single Pore 0,4 t (max 4) 0,3 t (max 4) 0,2 t (max 2)

0,3 t (max 3) 0,2 t (max 2) 0,1 t (max 1)

Pores cluster 6% / 3% 4% / 2% 2% / 1%

- Crack initiation N

i

- short crack growth N

Contributions to fatigue life

Contribution to overall lifetime Nt:

Polak (CSI, 2003):

- short crack growth N

s

- long crack growth N

l

t i s l

N N N N = + +

Crack initiation stage N

i

at smooth, nominally defect-free surfaces:

- less than 5-20% of overall lifetime N

t

- even less for existing initial defects

Allows to treat defects as initial cracks in a fracture mechanics model

Long crack growth

(a > 0,5 mm, 2c > 1 mm)

Short crack growth

K concept not applicable

Alternatives:

plasticity corrected K

Specifica of mechanically short cracks

plasticity corrected K

(e.g., plastic zone size corrected)

J-Integral

CTOD

Gradual built-up of plasticity-induced

crack closure effect:

Fracture and Crack Propagation in Weldments.

A Fracture Mechanics Perspective A Fracture Mechanics Perspective

Specific aspects of weldments

Determination of fracture toughness

Determination of the crack driving force

Uwe.zerbst@bam.de

Determination of the crack driving force

Shallow crack propagation and fatigue strength

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Material Grade Comparison Chart PDFDocument1 pageMaterial Grade Comparison Chart PDFHelen Kate Saccuan100% (1)

- Experimental Investigation On Weld Ability of Cast IronDocument5 pagesExperimental Investigation On Weld Ability of Cast IronKhin Aung ShweNo ratings yet

- Safety of Machinery - Principles of Risk AssessmentDocument27 pagesSafety of Machinery - Principles of Risk AssessmentKhin Aung ShweNo ratings yet

- Microscopy With Light and ElectronsDocument36 pagesMicroscopy With Light and ElectronsCORE Materials100% (1)

- Focus On Proper Weld Size When Developing WPS Parameter Ranges - Fabricating and MetalworkingDocument4 pagesFocus On Proper Weld Size When Developing WPS Parameter Ranges - Fabricating and MetalworkingKhin Aung ShweNo ratings yet

- DryerDocument80 pagesDryerAaron Paulo Bernardo100% (2)

- Theweldignofaluminiumcastingsoctober2011 111210001526 Phpapp02Document68 pagesTheweldignofaluminiumcastingsoctober2011 111210001526 Phpapp02Khin Aung ShweNo ratings yet

- Effect of Heat Input To Weld Residual StressDocument4 pagesEffect of Heat Input To Weld Residual StressSurya DharmaNo ratings yet

- ERNI-1 Cast Iron ElectrodeDocument1 pageERNI-1 Cast Iron ElectrodeKhin Aung ShweNo ratings yet

- Austenitic Ductile Iron For Low Temperature ApplicationDocument6 pagesAustenitic Ductile Iron For Low Temperature ApplicationKhin Aung ShweNo ratings yet

- JK Stereo1Document26 pagesJK Stereo1Yongliang LiuNo ratings yet

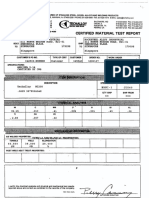

- Lampiran PQR 003Document3 pagesLampiran PQR 003Khin Aung ShweNo ratings yet

- Manual de Servicio Olympus SZ-IIIDocument18 pagesManual de Servicio Olympus SZ-IIIcarlosibaNo ratings yet

- Lab Exericise 3 For MicroscopeDocument9 pagesLab Exericise 3 For MicroscopeKhin Aung ShweNo ratings yet

- Investigation of The Cause of Reinforcing Steel Fracture Induced by Alkali-Silica Reaction and Study On MaintenanceDocument10 pagesInvestigation of The Cause of Reinforcing Steel Fracture Induced by Alkali-Silica Reaction and Study On MaintenanceKhin Aung ShweNo ratings yet

- Mo SteelDocument0 pagesMo SteelSamsi B HanifNo ratings yet

- Cast Iron Welding AlloysDocument4 pagesCast Iron Welding AlloysKhin Aung ShweNo ratings yet

- အမ်ားသံုး ျမန္မာ-အဂၤလိပ္-ပါဠိ အဘိဓါန္ PDFDocument1,080 pagesအမ်ားသံုး ျမန္မာ-အဂၤလိပ္-ပါဠိ အဘိဓါန္ PDFKo Lin96% (45)

- Fundamentals of Metal CastingDocument14 pagesFundamentals of Metal CastingKhin Aung ShweNo ratings yet

- Brazil: "PLANTAR" Project: Sustainable Fuelwood and Charcoal Production and Substitution of Coke in Pig Iron ProductionDocument33 pagesBrazil: "PLANTAR" Project: Sustainable Fuelwood and Charcoal Production and Substitution of Coke in Pig Iron ProductionKhin Aung ShweNo ratings yet

- Braze Cast Iron - Videos, Tips and ProceduresDocument5 pagesBraze Cast Iron - Videos, Tips and ProceduresKhin Aung ShweNo ratings yet

- Welding of Nonferrous Metal and Their AlloysDocument62 pagesWelding of Nonferrous Metal and Their AlloysKhin Aung ShweNo ratings yet

- Casting Material WCBDocument8 pagesCasting Material WCBYusri WyeuserieyNo ratings yet

- The Crucible Arthur Miller Play AllegoryDocument11 pagesThe Crucible Arthur Miller Play AllegoryKhin Aung Shwe100% (1)

- Effect of Pouring Temperature and Stirring Speed OnDocument6 pagesEffect of Pouring Temperature and Stirring Speed OnInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Boiler Furnace TheoryDocument8 pagesBoiler Furnace TheoryArun YogaNo ratings yet