Professional Documents

Culture Documents

Haccp in Sea Food

Uploaded by

GloriyaJacob0 ratings0% found this document useful (0 votes)

37 views6 pageshaccp in sea food

Original Title

haccp in sea food

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documenthaccp in sea food

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

37 views6 pagesHaccp in Sea Food

Uploaded by

GloriyaJacobhaccp in sea food

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 6

ASSIGNMENT ON Hazard Analysis Critical

Control Point (HACCP)

Submitted by

Gloriya Jacob

Hazard Analysis Critical Control Point

HACCP (Hazard Analysis Critical Control Point) is an internationally accepted technique for

preventing microbiological, chemical and physical contamination along the food supply chain.

The HACCP technique does this by identifying the risks, establishing critical control points,

setting critical limits, and ensuring control measures are validated, verified and monitored before

implementation.

The effective implementation of HACCP will enhance the ability of companies to: protect and

enhance brands and private labels, promote consumer confidence and conform to regulatory and

market requirements.

Who can use HACCP?

All businesses involved in the food supply chain from producers to retailers can use HACCP.

Enterprises include, but are not restricted to, those linked with:

Fruits & Vegetables Meat & Meat Products

Dairy Products Spices & Condiments

Fish & Fishery Products Cereals

Nuts & Nut Products Restaurants

Bakery & Confectionary Fast Food Operations etc.

Hotels

How does it work?

The first step is to make a commitment. The next step is to learn about the Hazard Analysis

Critical Control Point (HACCP) system which allows you to develop and implement your own

quality system. HACCP is the premier tool used by the world's food industry to manage risks to

food safety and quality.

HACCP does this by identifying the risks and ensuring control ensures are validated, verified

and monitored before implementation.

Implementation and certification requires people with recognized quality, HACCP system

development and training skills. NCHC has certified trainers and auditors to assist companies

implementing HACCP systems.

The effective implementation of HACCP will enhance the ability of companies to: protect and

enhance brands and private labels, promote consumer confidence and conform to regulatory and

market requirements.

Certification Process

Proposal/Application for Certification

Pre-Assessment

Training

Certification Audit

Document Review

Certificate

The seven principles of HACCP

The seven principles of HACCP, which encompass a systematic approach to the identification,

prevention, and control of food safety hazards include:

1. Conduct a Hazard Analysis

2. Determine Critical Control Points

3. Establish Critical Limits

4. Establish Monitoring Procedures

5. Establish Corrective Actions

6. Establish Recordkeeping and Documentation Procedures

7. Establish Verification Procedures

Guidelines for Application of HACCP Principles

The following guidelines will facilitate the development and implementation of effective

HACCP plans. While the specific application of HACCP to manufacturing facilities is

emphasized here, these guidelines should be applied as appropriate to each segment of the food

industry under consideration.

Prerequisite Programs

The production of safe food products requires that the HACCP system be built upon a solid

foundation of prerequisite programs. Each segment of the food industry must provide the

conditions necessary to protect food while it is under their control. This has traditionally been

accomplished through the application of cGMPs. These conditions and practices are now

considered to be prerequisite to the development and implementation of effective HACCP plans.

Prerequisite programs provide the basic environmental and operating conditions that are

necessary for the production of safe, wholesome food. Many of the conditions and practices are

specified in federal, state and local regulations and guidelines (e.g., cGMPs and Food Code). The

Codex Alimentarius General Principles of Food Hygiene describe the basic conditions and

practices expected for foods intended for international trade. In addition to the requirements

specified in regulations, industry often adopts policies and procedures that are specific to their

operations. Many of these are proprietary. While prerequisite programs may impact upon the

safety of a food, they also are concerned with ensuring that foods are wholesome and suitable for

consumption. HACCP plans are narrower in scope, being limited to ensuring food is safe to

consume.

The existence and effectiveness of prerequisite programs should be assessed during the design

and implementation of each HACCP plan. All prerequisite programs should be documented and

regularly audited. Prerequisite programs are established and managed separately from the

HACCP plan. Certain aspects, however, of a prerequisite program may be incorporated into a

HACCP plan. For example, many establishments have preventive maintenance procedures for

processing equipment to avoid unexpected equipment failure and loss of production. During the

development of a HACCP plan, the HACCP team may decide that the routine maintenance and

calibration of an oven should be included in the plan as an activity of verification. This would

further ensure that all the food in the oven is cooked to the minimum internal temperature that is

necessary for food safety.

Education and Training

The success of a HACCP system depends on educating and training management and employees

in the importance of their role in producing safe foods. This should also include information the

control of foodborne hazards related to all stages of the food chain. It is important to recognize

that employees must first understand what HACCP is and then learn the skills necessary to make

it function properly. Specific training activities should include working instructions and

procedures that outline the tasks of employees monitoring each CCP.

Management must provide adequate time for thorough education and training. Personnel must be

given the materials and equipment necessary to perform these tasks. Effective training is an

important prerequisite to successful implementation of a HACCP plan.

Developing a HACCP Plan

The format of HACCP plans will vary. In many cases the plans will be product and process

specific. However, some plans may use a unit operations approach. Generic HACCP plans can

serve as useful guides in the development of process and product HACCP plans; however, it is

essential that the unique conditions within each facility be considered during the development of

all components of the HACCP plan.

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Contamination ControlDocument5 pagesContamination ControlPadmanabhan DhanasekaranNo ratings yet

- Matilda Vocabulary Building WorksheetsDocument23 pagesMatilda Vocabulary Building Worksheetseinstein66100% (1)

- Mountaineer March 2008Document8 pagesMountaineer March 2008Jeremy O'BryanNo ratings yet

- Creating An Effective China "Cold Supply Chain": Current Status, Challenges and Implementation ConsiderationsDocument20 pagesCreating An Effective China "Cold Supply Chain": Current Status, Challenges and Implementation ConsiderationsfarhafarhaNo ratings yet

- A Bio Social Approach To Environmental Psychology and Problems of StressDocument40 pagesA Bio Social Approach To Environmental Psychology and Problems of StressElackia100% (1)

- Introduction To Phonemic SymbolsDocument35 pagesIntroduction To Phonemic SymbolsJelena Jelena100% (2)

- The Organization of Modern KitchensDocument9 pagesThe Organization of Modern KitchensJohnson Macayan FernándezNo ratings yet

- English - II FinalDocument31 pagesEnglish - II FinalNaeem Akhtar0% (1)

- Takshashila International School, Kosamba: Food Menu For The Month of April 2022-23Document2 pagesTakshashila International School, Kosamba: Food Menu For The Month of April 2022-23Yell YashNo ratings yet

- Pathfinder - Basic Economics of DD v0.1Document10 pagesPathfinder - Basic Economics of DD v0.1S. BalcrickNo ratings yet

- Bosch PCG Price List 2023Document12 pagesBosch PCG Price List 2023kaliappa nNo ratings yet

- Cause and EffectDocument9 pagesCause and Effectrani rahmaniNo ratings yet

- Hurricane Preparedness QuestionnaireDocument3 pagesHurricane Preparedness QuestionnaireJulie NelsonNo ratings yet

- Fetal Nutrition: Santm OrgDocument11 pagesFetal Nutrition: Santm OrgMartin ClydeNo ratings yet

- A-Z of English Idioms: 150 Most Common Expressions: Quick IntroDocument16 pagesA-Z of English Idioms: 150 Most Common Expressions: Quick IntroDaphnie Joy De la CruzNo ratings yet

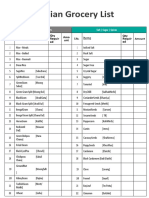

- Indian Grocery List: Items ItemsDocument4 pagesIndian Grocery List: Items ItemsToday's world50% (2)

- Ration WorksheetDocument16 pagesRation Worksheetvmcf9xwdntNo ratings yet

- MOOD CAFE'.BusinessPlan - DocsDocument45 pagesMOOD CAFE'.BusinessPlan - DocsAshe'sha Kate VillaluzNo ratings yet

- Guppy CheatDocument2 pagesGuppy Cheatasdasd asdasdNo ratings yet

- Energy Drinks and Sport DrinksDocument30 pagesEnergy Drinks and Sport DrinksMerryo SetyawanNo ratings yet

- A Project Report On Consumer Behaviour of Hybrid Maize Seeds and Study of Hybrid Maize Market Potential of Solapur DistrictDocument92 pagesA Project Report On Consumer Behaviour of Hybrid Maize Seeds and Study of Hybrid Maize Market Potential of Solapur DistrictAmol Jadhav100% (3)

- Basic English Grammar - Have, Has, Had - Lesson NotesDocument4 pagesBasic English Grammar - Have, Has, Had - Lesson NotesAkhil P SudhakaranNo ratings yet

- Food Culture of Kansai and Kanto5Document12 pagesFood Culture of Kansai and Kanto5Hans Morten Sundnes100% (1)

- Literacy Prop BoxDocument3 pagesLiteracy Prop Boxapi-349028589No ratings yet

- Chocolate Recipes 2Document81 pagesChocolate Recipes 2kathrynbax100% (2)

- EX-Featured Excipient Capsule and Tablet DiluentsDocument8 pagesEX-Featured Excipient Capsule and Tablet Diluentsraju1559405No ratings yet

- 5 Wish Practice PDFDocument6 pages5 Wish Practice PDFMilgam SalamNo ratings yet

- New - Zealand.listener 26.march.2022Document98 pagesNew - Zealand.listener 26.march.2022Belu Ion100% (1)

- Frozen ProductsDocument14 pagesFrozen ProductsSteffi ClaroNo ratings yet

- 4H Handbook 2012Document42 pages4H Handbook 2012StJamesHigh0% (1)