Professional Documents

Culture Documents

Harm Melker, Lincoln Submerged Arc Welding ...

Uploaded by

Marinel1955Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Harm Melker, Lincoln Submerged Arc Welding ...

Uploaded by

Marinel1955Copyright:

Available Formats

Welding of X80.NF.12.1 Welding of X80.NF.12.

1

Submerged arc welding for the future

a new generation of power sources

Nordic Welding Conference, Oct. 2012

Harm Meelker

Lincoln Smitweld B.V.

Welding of X80.NF.12.2 Welding of X80.NF.12.2

Overview

Introduction

Traditional SAW equipment

Process variables

Next generation SAW equipment

Procedure development

Energy savings

Features

Conclusions

Welding of X80.NF.12.3 Welding of X80.NF.12.3

Market Demands

Lower production costs

increased production

Increased quality

Higher strength materials

less total weight of construction

+ possible lower material costs

Greater flexibility

Welding of X80.NF.12.4 Welding of X80.NF.12.4

Conventional equipment

Welding of X80.NF.12.5 Welding of X80.NF.12.5

SAW process variables

Single arc

Single wire

Welding on DC minus

Tubular Cored Wire

Iron powder

Long Stick Out

Narrow gap

Semi-narrow gap

Multiple arc

Twin-arc

Tandem

Tandem twin

3 - 4 - 5 wires

Cold wire

Hot wire

Semi-narrow gap

Welding of X80.NF.12.6 Welding of X80.NF.12.6

125

145

190

225

Welding of X80.NF.12.7 Welding of X80.NF.12.7

Machined Grooves Offer Greater

Savings Potential

Welding of X80.NF.12.8 Welding of X80.NF.12.8

Narrow Gap or Narrow Grove

Narrow Groove:

Larger gap and radius

Larger sidewall bevel angles, up to 50

o

Compound bevels also typical

Typically <100mm

Narrow Gap:

Very small gap at the bottom:

20mm typical (10mm radius)

Same sidewall angle bevel

Sidewall bevel: 1.5

o

typical (1.2

o

min.)

Results in a narrow gap at the top

of the bead

Typically employed on wall thickness

greater than 100mm up to 350mm

Narrow Gap

Welding of X80.NF.12.9 Welding of X80.NF.12.9

Narrow Gap

Advantages:

Lower joint volume

Reduced consumables cost

Higher weld productivity

Disadvantages:

Very difficult to weld

More difficult to repair and

remove slag

Higher capital cost

PQR requalification cost

Precise weld joint fit-up very

critical

Need for machined joint

Welding of X80.NF.12.10 Welding of X80.NF.12.10

The next generation in Submerged

Arc Welding

State-of-the-Art in inverter technology

Highest capacity available on the

market

High efficiency inverter

Waveform Control Technology TM

Greatest control over the welding

process

Solid State Switching Technology

AC or DC Welding Process

Welding of X80.NF.12.11 Welding of X80.NF.12.11

Constant wire diameter and stick-out

Current [A]

constant voltage

and travel speed

Voltage [V]

constant current

and travel speed

Travel speed

[cm/min]

constant current

and voltage

Influence of current Voltage and Travel

Speed on penetration in SAW

Welding of X80.NF.12.12 Welding of X80.NF.12.12

AC/DC Submerged Arc Welding

Unique in the industry

Variable polarity for better process

control

High deposition

high-speed welding

thick section welding

Penetration profile

Arc stability in multiple-arc applications

Reduction in heat input

Technologically advanced

Waveform control technology

Digital communications technology

Welding of X80.NF.12.13 Welding of X80.NF.12.13

time

C

u

r

r

e

n

t

,

V

o

l

t

a

g

e

o

r

P

o

w

e

r

Negative

Current Level =>

DEPOSITION

Positive

Current Level =>

PENETRATION

Frequency

Cycle Balance =>

PENETRATION & DEPOSITION

Infinitely variable AC

The waveform can be varied to control penetration,

bead shape, electrode negative deposition eliminates

arc blow & arc-to-arc interaction by phase shirt control

Welding of X80.NF.12.14 Welding of X80.NF.12.14

Wave Balance

Typically run at 25% positive & 75% negative

Welding of X80.NF.12.15 Welding of X80.NF.12.15

DC Offset

Offset is a very

sensitive parameter

Typical range limited

to 0 to -10%.

8% offset => 25%

balance.

Large values of

current offset

interferes with

voltage regulation

causing system

instability

Welding of X80.NF.12.16 Welding of X80.NF.12.16

Waveform Control Technology

70% Positive

Penetration = 0.387

50% Positive

Penetration = 0.346

30% Positive

Penetration = 0.242

Positive = 835 Amps

Negative = 519 Amps

Penetration = .366

Positive = 450 Amps

Negative = 822 Amps

Penetration = .280

Wave Balance

Offset

Welding of X80.NF.12.17 Welding of X80.NF.12.17

Deposition rates

Welding of X80.NF.12.18 Welding of X80.NF.12.18

Power Wave

AC/DC 1000

SD

Inverter Power Source

Energy Efficient

DC+, DC- & AC (3 Phase)

CV and CC Modes

AC to DC Electronic Switch

Wave Balance Control

100% Duty Cycle

Frequency Control

Wave Shape Design

Production Monitoring 2

Weld History

Integrated Multi Arcs

Waveform Control

Technology

Welding of X80.NF.12.19 Welding of X80.NF.12.19

Systems

Welding of X80.NF.12.20 Welding of X80.NF.12.20

Arc configurations

Welding of X80.NF.12.21 Welding of X80.NF.12.21

Multiple Arc Welding

Welding of X80.NF.12.22 Welding of X80.NF.12.22

Company Herstaco Tube Welding B.V.

Adress Nijverheidsweg 24, Middelburg, The Netherlands

Type of business

Metal trading company

Tube/pile welding

Project team

Distributor Wagenvoorde Lastechniek, P.Keultjes, T. van Dorst, F, Meyer

Area of cost savings/target

Higher deposition rate by use of Powerwave AC/DC 1000

Target; 30% Cost Reduction

Procedure/Follow up

Introduce and demonstrate PW AC/DC 1000

Results

More than 33% reduction in labor costs

Sold SAW welding station, PW AC/DC 1000 with column & Boom

Consumables; L61/LW860

Deposition rate filling layers from 6 up to 9 Kg/Hr

Welding time per weld (1060x28mm) in a pile was 60 min., decreased to 40 min.

Practical example: Tube welding

Welding of X80.NF.12.23 Welding of X80.NF.12.23

Practical example: Tube welding

1060 x 35mm

Equipment

Fill

Cap

Travel speed

Welding time

Equipment

Fill

Cap

Travel speed

Welding time

Conventional

DC 1000

500/520 A - 31 Volt

= 6 kg/h

650/680 A - 34 Volt

= 7.6 kg/h

40 cm/min

60 min.

Conventional

DC 1000

500/520 A - 31 Volt

= 6 kg/h

650/680 A - 34 Volt

= 7.6 kg/h

40 cm/min

60 min.

Wave Control

PW AC/DC; with 40 Hz;

55% DC-; 5% offset

550 - 34 Volt

= 9 kg/h

720 A - 38/40 Volt

= 10.2 kg/h

60 cm/min

40 min.

Wave Control

PW AC/DC; with 40 Hz;

55% DC-; 5% offset

550 - 34 Volt

= 9 kg/h

720 A - 38/40 Volt

= 10.2 kg/h

60 cm/min

40 min.

Welding of X80.NF.12.24 Welding of X80.NF.12.24

Herstako cost reduction result based on

labor rate (35,-/hr

Project Humber UK; 350 Piles x 4 = 1400 Welds

Conventional process

Labor costs 1400 x 1hr x 35,-/hr = 49.000,-

Wave Control process

Labor costs 1400 x 0.67 hr x 35,-/hr = 32.830.-

Labor Cost savings for this project; 16.170,-

Energy savings are there too, but were not calculated, so the total cost saving is more than the calculated 33%. The investment of 1

machine is almost paid in 1 project.

Welding of X80.NF.12.25 Welding of X80.NF.12.25

A new procedure replaced a 9 pass single arc

approach with a 2 pass tandem arc

Cost Savings greater than 50% reduction in

weld time and consumable savings

70

36mm

2mm

BEFORE

36mm

6mm

50

AFTER

13mm Plate

19mm Plate

36mm Plate

Optimising procedures

Welding of X80.NF.12.26 Welding of X80.NF.12.26

Single V

Three Meter Diameter Can

Travel Speed Procedure 1(IPM)

27

Number of Passes 5

Deposition Rate (Lbs/hr) 43.24

Time to weld 1 Linear Foot of Weld (Min) 2.222

Time to weld Circumferential Weld (Min) 69.78

Welding Consumables per Joint (Lbs) 50.29

Double V Travel Speed Procedure 2 (IPM) 30

Number of Passes 2

Deposition Rate (Lbs/hr) 62

Time to weld 1 Linear Foot of Weld (Min) 0.8

Time to weld Circumferential Weld (Min) 25.12

Welding Consumables per Joint (Lbs) 25.96

Volume saved (24.32 Kg) 48 %

Time Saved (44.66 Min) 65 %

Optimising procedures

Welding of X80.NF.12.27 Welding of X80.NF.12.27

ORIGINAL PROCEDURES

Impacts: 27J @ -20C

Travel Speed = 530 mm/min.

4.0 mm 4.0 mm .

950 A 700 A .

30 V 34 V

AC

CC+

Deposition rate = 21,5 Kg/hr

Traditional procedure

Welding of X80.NF.12.28 Welding of X80.NF.12.28

Powerwave technology

TANDEM CAPABILITIES

Advantages:

CV & CC mode (CC is prefered).

Short distance between wires (one puddle).

Better duty cycle rating.

25-35 mm

Welding of X80.NF.12.29 Welding of X80.NF.12.29

Procedure development

Welding of X80.NF.12.30 Welding of X80.NF.12.30

Procedure development

Welding of X80.NF.12.31 Welding of X80.NF.12.31

Procedure development

Welding of X80.NF.12.32 Welding of X80.NF.12.32

Procedure development

Welding of X80.NF.12.33 Welding of X80.NF.12.33

Deposition rates

Summary;

Traditional tandem, 2x4.0mm -20 C and 21kg/hr

Powerwave 1x4.0mm/2x2.4mm -50 C and 35 kg/h

Powerwave 3x4.0mm -40 C and 45 kg/hr

Welding of X80.NF.12.34 Welding of X80.NF.12.34

Savings with the PW1000AC/DC

Welding of X80.NF.12.35 Welding of X80.NF.12.35

Idle consumption

Increased machine efficiency

Process efficiency

The power consumption of the PW1000AC/DC when the

machine is running but not welding.

The Inverter technology used in the PW1000AC/DC has a high

efficiency.

PW 1000AC/DC

400V 3Ph 50Hz

The Advanced AC Sub Arc process is showing higher deposition

and lower Heat input. The energy required to complete one joint is

reduced

Importance

Three ways to save energy

Welding of X80.NF.12.36 Welding of X80.NF.12.36

PW1000 AC/DC

Efficiency 86%

Power Factor 0.95

AC 1200

Efficiency 80%

Power Factor 0.81

DC1000

Efficiency 78%

Power Factor 0.73

Three machines running 600A 30V Comparison Three machines running 600A 30V Comparison

KW 20.9

KVA 22

Line current 32A

Idle Power 300W

KW 22.5

KVA 27

Line current 67A

Idle Power 2500W

KW 23.1

KVA 31.6

Line current 32A

Idle Power 2000W

Efficiency, line current and idle power levels are supporting savings Efficiency, line current and idle power levels are supporting savings

Commonly used in the

industry

PW1000AC/DC versus conventional inverter

Welding of X80.NF.12.37 Welding of X80.NF.12.37

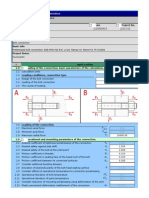

50

Vessel fabrication

Material SA517 Grade 65

Wire LNS 133 2.4mm

FLUX 960

Vessel diameter 1250mm

DC1000

16mm

Layer Amps Volts TS (cm/min) HI (Kj/cm) KJ/layer

1 325 27 75 7.020 2.755

2 340 27 75 7.344 2.883

3 640 30 95 12.126 4.760

4 800 32 110 13.964 5.481

5 885 33 110 15.930 6.253

6 850 33 110 15.300 6.005

28.136

PowerWave 1000AC/DC

Layer Amps Volts TS (cm/min) HI (Kj/cm) KJ/layer

1 325 27 66 7.977 3.131

2 340 27 66 8.345 3.276

3 640 30 95 12.126 4.760

4 800 32 95 16.168 6.346

5 885 33 85 20.615 8.092

6 880 33 85 20.499 8.046

7 850 33 85 19.800 7.772

41.421

Total time per joint 26 minutes Total time per joint 34 minutes

Savings: 23.5% weld time per joint, 32% energy cost

The PW1000AC/DC is saving joint time + Energy

GMAWroot pass

Field experience Application: SA Twin 2.0mm

Welding of X80.NF.12.38 Welding of X80.NF.12.38

Quality Analysis

Advanced analysis tool for calculating overall

quality

of a weld based on deviation of wire deposition rate.

Lincoln Smitweld

Start Quality Analysis

Welding of X80.NF.12.39 Welding of X80.NF.12.39

Welding of X80.NF.12.40 Welding of X80.NF.12.40

Production Monitoring

Weld History

Diagnostics

Welding of X80.NF.12.41 Welding of X80.NF.12.41

Arc Link - TCP/IP

All components communicate via a network using Arc Link over

TCP/IP Protocol

Positioning Control &

Power Supply

Wire Drive Control &

Power Supply

Clock Signal

Wide Area Network

Monitor Application

Distributed system architecture

Welding of X80.NF.12.42 Welding of X80.NF.12.42

Application Pipe Mills

Longitudinal pipe welding

Conversion standard 3-

and 4-arc welding to

wave control 3- and 4- arc

welding

1.7m/min travel speed

increased to 2.3m/min

No change to weld bead

profile or mechanical

properties

35% increase in

production

Welding of X80.NF.12.43 Welding of X80.NF.12.43

Welding of X80.NF.12.44 Welding of X80.NF.12.44

STT powerwave MIG + SAW set-up

Welding of X80.NF.12.45 Welding of X80.NF.12.45

Welding of X80.NF.12.46 Welding of X80.NF.12.46

Shipbuilding with SAW robot

Welding of X80.NF.12.47 Welding of X80.NF.12.47

SAW robot

Welding of X80.NF.12.48 Welding of X80.NF.12.48

SAW robot

Welding of X80.NF.12.49 Welding of X80.NF.12.49

Conclusions

New technology for SA-welding was developed

Inverter technology

Waveform control

Cost savings

Energy

Higher deposition rage up to 30%

Pay-back time of equipment investment

Increasing quality

Superior parameter control

Diagnostics

Weld-log

Energy

Higher productivity

Fast responding

Welding of X80.NF.12.50 Welding of X80.NF.12.50

Conclusions/Benefits

Welding of X80.NF.12.51 Welding of X80.NF.12.51

Thank you! Questions?

You might also like

- UT TransducersDocument20 pagesUT TransducersSamanyarak AnanNo ratings yet

- ABS Guide For Application of Higher-Strength Hull Structural Thick Steel Plates in Container CarriersDocument72 pagesABS Guide For Application of Higher-Strength Hull Structural Thick Steel Plates in Container Carriersamin_corporationNo ratings yet

- CSWIP Plant Inspectors 5th Edition, May 2012Document13 pagesCSWIP Plant Inspectors 5th Edition, May 2012Er Faiyaz AhmedNo ratings yet

- SAQCC IPE Initial Certification MetallicsDocument23 pagesSAQCC IPE Initial Certification MetallicsAlexander RichardsonNo ratings yet

- BS en 1335-3-2009Document30 pagesBS en 1335-3-2009Adel A. Abdelaziz100% (1)

- European Welding Inspection Personnel: EWF GuidelineDocument19 pagesEuropean Welding Inspection Personnel: EWF GuidelineBrandon EricksonNo ratings yet

- Al WeldingDocument70 pagesAl WeldingTuyen NguyenNo ratings yet

- User ManualDocument32 pagesUser ManualasmaNo ratings yet

- Ri 1Document39 pagesRi 1Team PipingNo ratings yet

- Lincoln Diagnostic UtilityDocument19 pagesLincoln Diagnostic UtilityMicheal SmithNo ratings yet

- Ri 2Document42 pagesRi 2Team PipingNo ratings yet

- Microstructure Materials SelectionDocument49 pagesMicrostructure Materials SelectionSaptarshi SenguptaNo ratings yet

- Hyundai Welding Handbook 2006Document147 pagesHyundai Welding Handbook 2006전상문No ratings yet

- Welding Procedure Standards and Qualification CodesDocument4 pagesWelding Procedure Standards and Qualification CodesBalkishan DyavanapellyNo ratings yet

- Probe Catalog From United-NDTDocument19 pagesProbe Catalog From United-NDTtanzil10100% (1)

- Multiscan Ms5800: User'S ManualDocument160 pagesMultiscan Ms5800: User'S ManualSoorajNo ratings yet

- 450 User Guide PDFDocument109 pages450 User Guide PDFMi LemusNo ratings yet

- Previews AWS CM-2000-ALL PreDocument16 pagesPreviews AWS CM-2000-ALL PreWanderley Fonseca50% (2)

- Part 1 (Final 2022-11-21)Document28 pagesPart 1 (Final 2022-11-21)saraNo ratings yet

- Competitive Solutions For Joining TechnologyDocument19 pagesCompetitive Solutions For Joining Technologyjy12bhuNo ratings yet

- Arclog X Manual 1.19Document55 pagesArclog X Manual 1.19davmac79No ratings yet

- Alla Priser Anges Exkl. Moms. Kontakta Din Säljare Vid FrågorDocument46 pagesAlla Priser Anges Exkl. Moms. Kontakta Din Säljare Vid FrågorSamuelNo ratings yet

- Ferrite Machine ManualDocument240 pagesFerrite Machine ManualRonel John Rodriguez CustodioNo ratings yet

- R W C Technology BookDocument106 pagesR W C Technology BookScott TrainorNo ratings yet

- PDF Created With Pdffactory Pro Trial VersionDocument98 pagesPDF Created With Pdffactory Pro Trial VersionRavindra Kumar KaulNo ratings yet

- Comparison Between ASME and RCC-M Requirements For Welding and NDTDocument22 pagesComparison Between ASME and RCC-M Requirements For Welding and NDTsusanwebNo ratings yet

- Submerged Arc Welding: Training & EducationDocument17 pagesSubmerged Arc Welding: Training & Educationtanveer ahmedNo ratings yet

- Asnt RT Iii PDFDocument93 pagesAsnt RT Iii PDFkhizer mohamedNo ratings yet

- Regulatory Guide for Industrial RadiographyDocument39 pagesRegulatory Guide for Industrial Radiographyaemech100% (1)

- Mil STD 2175aDocument34 pagesMil STD 2175aAlex TollesonNo ratings yet

- 350 Master CanDocument113 pages350 Master CanSangeeth.KpNo ratings yet

- SLIVER DEFECTS ON LOW CARBON STEELSDocument5 pagesSLIVER DEFECTS ON LOW CARBON STEELSVarun MishraNo ratings yet

- Calibration-Validation - Good ArticleDocument12 pagesCalibration-Validation - Good ArticleVijay KumarNo ratings yet

- ACA Education and Training GuideDocument28 pagesACA Education and Training GuiderakacyuNo ratings yet

- Procedure Manual: Cast Valve ProductionDocument10 pagesProcedure Manual: Cast Valve ProductionParveen Kohli0% (1)

- PFIDocument2 pagesPFIYulianus SReaNo ratings yet

- Sitescan 500S User GuideDocument144 pagesSitescan 500S User GuideNguyen binhNo ratings yet

- Gas Cutting WLDNG Process - 06 - Module 6Document100 pagesGas Cutting WLDNG Process - 06 - Module 6sskiitb100% (1)

- EN 14727 05-2005 Laborfurniture EDocument22 pagesEN 14727 05-2005 Laborfurniture EDavid Gonzalez100% (1)

- TWI Paper On Fatigue and GridingDocument42 pagesTWI Paper On Fatigue and GridingKatsaras SotirisNo ratings yet

- 2017 Welding School CatalogDocument34 pages2017 Welding School CatalogDiego AlonsoNo ratings yet

- Technical Manual for Steel TubesDocument122 pagesTechnical Manual for Steel TubesAlejandroBolanos100% (1)

- Hybrid Laser Arc Welding PresentationDocument8 pagesHybrid Laser Arc Welding Presentationbionda_otrovNo ratings yet

- STTDocument11 pagesSTTamr kouranyNo ratings yet

- BS 499-1-2009Document154 pagesBS 499-1-2009momo0% (1)

- Portable, battery-powered materialographic equipmentDocument8 pagesPortable, battery-powered materialographic equipmentsantanuriniNo ratings yet

- Electron Beam Welding Process - Equipment's, Working Principle With DiagramDocument7 pagesElectron Beam Welding Process - Equipment's, Working Principle With DiagramDr.S.Ravi CITNo ratings yet

- Strategy & Recommended Contents for Inspection ProceduresDocument24 pagesStrategy & Recommended Contents for Inspection ProceduresOtso CronvallNo ratings yet

- Index For Welding InspectorDocument3 pagesIndex For Welding InspectorShrikant MojeNo ratings yet

- En 12517Document15 pagesEn 12517Nguyen Huu TriNo ratings yet

- Asnt MTDocument99 pagesAsnt MTGanesh MoorthyNo ratings yet

- Iso 14692 4 2017Document15 pagesIso 14692 4 2017Mayara AlvesNo ratings yet

- WPS Presentation on Welding Procedures SpecificationsDocument30 pagesWPS Presentation on Welding Procedures SpecificationsHarish RamalingamNo ratings yet

- 67229-BS 6072-1981 Method For Magnetic Particle Flaw DetectionDocument35 pages67229-BS 6072-1981 Method For Magnetic Particle Flaw DetectionANNADURAINo ratings yet

- QT2109958 - ITP For 1T-1201 Buffer Water Tank Itp PDFDocument3 pagesQT2109958 - ITP For 1T-1201 Buffer Water Tank Itp PDFGanesh EswaranNo ratings yet

- NDT Book For Printing17022015Document181 pagesNDT Book For Printing17022015Rabish ANo ratings yet

- The Complete Guide to Telephone Interview Questions and AnswersFrom EverandThe Complete Guide to Telephone Interview Questions and AnswersNo ratings yet

- Shallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceFrom EverandShallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceNo ratings yet

- Trash Cleaner CraneDocument1 pageTrash Cleaner CraneMarinel1955No ratings yet

- Productive ShipyardsDocument2 pagesProductive ShipyardsMarinel1955No ratings yet

- Fundamentals - ValvesDocument52 pagesFundamentals - Valvesapi-3808778100% (2)

- Dbi-Sala Rollgliss R350: Rescue Descent SystemDocument1 pageDbi-Sala Rollgliss R350: Rescue Descent SystemMarinel1955No ratings yet

- BoltCon - 02Document105 pagesBoltCon - 02Marinel1955100% (1)

- ISO Standards Collection - CranesDocument4 pagesISO Standards Collection - CranesJosé Rezende0% (1)

- SilDocument9 pagesSilMarinel123No ratings yet

- Manual RS422 e RS485Document137 pagesManual RS422 e RS485Marinel123No ratings yet

- Comparison TableDocument6 pagesComparison TablePand AemonaEonNo ratings yet

- Perioperative HypothermiaDocument4 pagesPerioperative Hypothermiasri utari masyitahNo ratings yet

- Mahindra Powertrain - Market StrategyDocument4 pagesMahindra Powertrain - Market StrategyEshan KapoorNo ratings yet

- Ped 201 Toddler Observation LabDocument6 pagesPed 201 Toddler Observation Labapi-477856901No ratings yet

- Paradise Pools Flyer With Price ListDocument5 pagesParadise Pools Flyer With Price ListKhuzaima HussainNo ratings yet

- Plant LayoutDocument16 pagesPlant LayoutAli MahmoudNo ratings yet

- Larrabee JChem Educ 1990,67,267Document3 pagesLarrabee JChem Educ 1990,67,267κ.μ.α «— Brakat»No ratings yet

- Nest Installation GuideDocument8 pagesNest Installation GuideOzzyNo ratings yet

- Civil Eng Internship ReportDocument6 pagesCivil Eng Internship ReportAromatic-O PNo ratings yet

- VGHV NBV GH fc7fvbn BN NGCJHGDocument16 pagesVGHV NBV GH fc7fvbn BN NGCJHGRahul GNo ratings yet

- Monsterology Activity KitDocument2 pagesMonsterology Activity KitCandlewick PressNo ratings yet

- CERT Basic Training Participant Manual - 2011Document332 pagesCERT Basic Training Participant Manual - 2011jegodfreyNo ratings yet

- Horizontal Projectile WSDocument3 pagesHorizontal Projectile WSForsbergPhysicsNo ratings yet

- Metric Heavy Hex Nuts: ASME B18.2.4.6M-2010Document16 pagesMetric Heavy Hex Nuts: ASME B18.2.4.6M-2010CarlitosNo ratings yet

- 03.can-Bus and Sae-Bus j1939 - CatDocument29 pages03.can-Bus and Sae-Bus j1939 - CatEdison Pfoccori BarrionuevoNo ratings yet

- Regular Manual Cleaning: Mimaki Printer Maintenance and Long-Term Storage OptionsDocument3 pagesRegular Manual Cleaning: Mimaki Printer Maintenance and Long-Term Storage OptionshumbyxNo ratings yet

- Polycab HT XlpeDocument33 pagesPolycab HT Xlpezafrikhan875No ratings yet

- Dr. Blyden: Chronic Obstructive Pulmonary Disease (Copd)Document63 pagesDr. Blyden: Chronic Obstructive Pulmonary Disease (Copd)Blyden NoahNo ratings yet

- Matrix Algebra by A.S.HadiDocument4 pagesMatrix Algebra by A.S.HadiHevantBhojaram0% (1)

- Production Management Midterm ReviewDocument21 pagesProduction Management Midterm Reviewielsiu21184No ratings yet

- ABYIPDocument18 pagesABYIP千住 マリエルNo ratings yet

- 20 N 60 C 3Document13 pages20 N 60 C 3rashidmirzaNo ratings yet

- Classification of Placenta PDFDocument5 pagesClassification of Placenta PDFAdarsh jainNo ratings yet

- SI44M 60H 80H-DeN1730-V12web DownloadedDocument4 pagesSI44M 60H 80H-DeN1730-V12web DownloadedtauraimukumbaNo ratings yet

- Mycotoxin Test ProcedureDocument3 pagesMycotoxin Test ProcedureKishenthi KerisnanNo ratings yet

- Manual of Curatorship: A Guide To Museum PracticeDocument7 pagesManual of Curatorship: A Guide To Museum PracticeLuísa MenezesNo ratings yet

- S10 Electric Power PackDocument12 pagesS10 Electric Power PackrolandNo ratings yet

- Great Gatsby Study NotesDocument69 pagesGreat Gatsby Study NotesLara Westwood100% (2)

- Ficha Tecnica Cat. Bard 36kbtu Act.Document15 pagesFicha Tecnica Cat. Bard 36kbtu Act.Jehison M Patiño TenorioNo ratings yet

- Turbine Stress EvaluatorDocument14 pagesTurbine Stress EvaluatorsumitNo ratings yet

- Hyundai Elevator Manual Helmon 2000 InstructionDocument27 pagesHyundai Elevator Manual Helmon 2000 InstructionReynold Suarez100% (1)