Professional Documents

Culture Documents

Installation Manual - GRE PIPE - For Marine - Rev.2

Uploaded by

HuongtrinhAkayOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation Manual - GRE PIPE - For Marine - Rev.2

Uploaded by

HuongtrinhAkayCopyright:

Available Formats

HYUNDAI LIFEBOATS CO.

,LTD

Installation Manual of HGP

PIPE

For Marine

1/37

HGP

GRE PIPE

INSTALLATION MANUAL OF

HGP

GRE PIPE

FOR MARINE

Complete Pipe System Solutions

Marine Offshore Industry Oil & Gas

Underground

HYUNDAI LIFEBOATS CO.,LTD

Installation Manual of HGP

PIPE

For Marine

2/37

HGP

GRE PIPE

Content

1. Introduction

2. Jointing Pipes

2.1 Butt and Wrap (Overlay, Laminate) Joint

2.2 Bell & Spigot joint (Adhesive Bonding Joint)

2.3 Flanged Joint

2.4 Flexible Steel Coupling

2.5 GRE Expansion Coupling Joint

3. U.V. Resistance

4. Supports, Anchors, And Guides

4.1 Six basic rules

4.2 Guides Support

4.3 Fixed Support

4.4 Flange Frame

4.5 Support

4.6 Maximum Support Span

4.7 Maximum Alignment Allowance

5. Installation in Hull Block

6. Squareness Tolerance

7. Repair

8. Cutting Edge

HYUNDAI LIFEBOATS CO.,LTD

Installation Manual of HGP

PIPE

For Marine

3/37

HGP

GRE PIPE

1. Introduction

This manual is written as a guide for supervisors and field engineers and explains the correct

methods of handling and installing HGP

(Hyundai GRE PIPE) GRE PIPE systems. In addition

this manual provides guidance on how to avoid and solve problems during installation. Glass

Reinforced Plastic (GRE) pipe systems offer, by their specific nature, many applications and

advantages compared with other materials, to carefully observe these guidelines. Please note

that these instructions are for guidance only. Specifications written for a particular project will

have precedence.

Although the procedures written in this manual are as complete as possible, it is not possible to

describe all the different circumstances you may meet. For this reason our experienced

supervisors may vary the described procedures in order to achieve an optimum installation.

2. Jointing Pipes

2.1 Butt and Wrap (Overlay, Lamination) Joint

HGP

pipe sections are typically jointed to overlay method. Other jointing systems such as

flanges, Spigot joints (bonding joint), Coupling (Mechanical, Sliding Expansion) may also be

used for jointing HGP

pipe. HGP

jointing system on pipe and overlay is all butt joint unless

otherwise requirement

The Butt & Wrap joint consists of plain-ended pipes and fittings, prepared, aligned and

laminated with reinforcing fibers and adhesives. The pipe ends are abutted end to end, aligned

on the same centerline, and the joint over wrapped with layers of resin impregnated glass-fiber

materials. Before work on laminated joint is started, all necessary equipment for completing the

procedure must be available. A jig or other holding device should be used to ensure that the

HYUNDAI LIFEBOATS CO.,LTD

Installation Manual of HGP

PIPE

For Marine

4/37

HGP

GRE PIPE

pipes are maintained with joint faces held tightly together without offset. The restraints should be

left in place until the joints has fully cured.

All butt welds are to be made in accordance with ASTM C582 or NBS Specification PS 15-69.

The actual procedure will be performed as follows:

Procedure for Butt & Warp (Overlay, Laminate)

1. Cutting , Puttying on the pipe and Grinding

- Measure off length of pipe (or duct) required and using a

marker and straight edge, draw a line completely around

surface to be cut

Wipe the sanded area with a clean, dry, lint-free cloth, and

avoid touching the surfaces with bare hands or dirty gloves.

Do not use solvents.

- For 24" and larger piping, use a die grinder to sand the

interior surface of the pipe 3" from the joint ends. This will

provide a proper bonding surface for applying the veil, mat,

and resin to the pipe's interior surface.

2. Preparing fiberglass

- Lay out fiberglass mat strips on work table. Length of each

strip(fiberglass) should be 50mm longer than circumference of

the pipe. The width of strip (fiber-glass) in accordance with

HGPmanual (See table for length of Laminate). The width of

the first layer shall be 50mm minimum. The woven roving shall

not be greater in width than the layer of chopped strand mat.

HYUNDAI LIFEBOATS CO.,LTD

Installation Manual of HGP

PIPE

For Marine

5/37

HGP

GRE PIPE

3. Laminating

- The precut fiberglass kit is then saturated with catalyzed

resin along side of joint area

4. Overlaying

- Pipe will be placed in the position in which they are to be

welded. Epoxy will be applied to the joint seam. This will

eliminate resin flow through the crack as the actual weld is

applied. Make certain work area and surfaces are as clean

as possible and dry.

- The precut fiberglass kit is then saturated with catalyzed

resin along side of joint area

- The saturated weld is then picked up like a bandage and

wrapped around the joint

5. Remove bubble

- A serrated roller is then used to smooth the weld and remove

any air bubbles that may have been trapped beneath the weld

when applied

HYUNDAI LIFEBOATS CO.,LTD

Installation Manual of HGP

PIPE

For Marine

6/37

HGP

GRE PIPE

5. Curing

- For complete curing, it needs heating pad.

Wrap up installation point with a heating pad and increase the

heat up to 80~90c and keep maintain temperature during 2

hours or more.

6. U.V(ultraviolet) Coating

- A final U.V(gel coat) is applied after the weld has taken its

initial cure.(Option), In case of underground and inside of

structure, it is not necessary.

HYUNDAI LIFEBOATS CO.,LTD

Installation Manual of HGP

PIPE

For Marine

7/37

HGP

GRE PIPE

Pipe

Size

5 bar 7 bar 10 bar 12 bar 15 bar

(DN)

mm

t

(mm)

L

(mm)

t

(mm)

L

(mm)

t

(mm)

L

(mm)

t

(mm)

L

(mm)

t

(mm)

L

(mm)

50 5 100 5 100 5 100 5 100 6 120

100 5 120 5 120 5 120 5 130 6 170

150 5 150 5 150 5 150 6 160 6 200

200 5 200 5 200 5 200 7 210 8 230

250 6 220 6 220 6 220 8 250 10 290

300 6 250 7 250 8 250 9 280 11 350

350 7 300 7 300 9 300 11 330 13 410

400 7 330 7 330 10 330 12 380 15 470

450 7 350 8 350 11 350 14 420 17 520

500 8 400 9 400 13 400 15 466 19 580

600 9 500 11 500 15 500 18 560 23 700

650 10 400 12 400 17 550 20 610 25 760

700 11 450 12 450 18 600 21 650 27 810

750 11 480 13 480 19 650 23 700 29 870

800 12 500 14 500 20 680 24 750 30 930

850 12 550 15 550 22 700 26 800 32 990

900 13 600 16 600 23 750 27 840 34 1,050

950 13 650 180 650 25 800 29 890 38 1,160

1,000 13 650 18 650 25 800 30 940 38 1,160

HYUNDAI LIFEBOATS CO.,LTD

Installation Manual of HGP

PIPE

For Marine

8/37

HGP

GRE PIPE

Pipe

Size

5 bar 7 bar 10 bar 12 bar 15 bar

(DN)

mm

t

(mm)

L

(mm)

t

(mm)

L

(mm)

t

(mm)

L

(mm)

t

(mm)

L

(mm)

t

(mm)

L

(mm)

1,300 17 850 23 850 33 1,050 40 1,220 50 1,510

1,400 18 900 24 900 34 1,100 41 1,310 51 1,570

1,500 19 950 27 950 38 1,200 46 1,400 57 1,740

1,600 21 1,000 29 1,000 42 1,300 50 1,500 63 1,920

1,700 21 1,000 29 1,000 42 1,300 52 1,600 63 1,920

1,800 23 1,050 32 1,050 46 1,400 55 1,680 69 2,090

1,900 25 1,100 35 1,100 50 1,550 68 1,800 74 2,270

2,000 25 1,100 35 1,100 50 1,550 61 1,870 74 2,270

2,200 29 1,300 40 1,300 57 1,750 65 2,050 86 2,620

2,400 30 1,400 43 1,400 61 1,900 73 2,240 91 2,790

2,600 33 1,450 46 1,450 66 2,050 79 2,420 99 3,020

2,800 34 1,500 48 1,500 69 2,100 86 2,610 103 3,140

3,000 38 1,650 53 1,650 76 2,400 91 2,790 114 3,490

Note 1: The recommended maximum tolerance of butt joint gap will not be over than below

dimensions;

Nominal Pipe Size gap (mm)

For 15mm through 500mm 2.0

For 600mm through 700mm 2.7

For 750mm through 950mm 3.6

For Lager than 1000mm 4.5

Note 2: If necessary, over 600mm pipe may be structural laminate in pipe internal. (2mm)

Note 3: putty and beveling works are used in severe chemical (ex: acid, severe corrosion fluid)

fluid piping and piping that is not accessible inside. It is not necessary for putty and beveling for

piping in water supply (Sea water, Demi. water, Potable water, etc)

Note 4: In case of 500mm or under, please, only fill V-notch between pipes with putty. Dont fill

gap with putty.

HYUNDAI LIFEBOATS CO.,LTD

Installation Manual of HGP

PIPE

For Marine

9/37

HGP

GRE PIPE

2.1.1 Tools for Butt Joint

For butt and wrap joints the following is needed:

- Measuring tape - Gloves, brushes

- Marker pen - hardener and glass reinforcement

- Cleaning-rags Steel rollers , Paint rollers - A pair of scissors +knife

- Grinder - Dust masks

- Sanding - Heating Pad(Important Item)

2.1.2 Gel time

Since many variables affect the cure of the resins. In case of HGP GRE PIPE for marine, Gel

Time is as in the following.

EPOXY Resin: SE-510B

EPOXY Hardener: SH-420B

Typical Gel Time for Resin ()

Temperature

()

Gel Time

(hour)

Mixing (%)

SE-510B SH-420B Remark

80~90 2 hours 100 40 100 : 40

HYUNDAI LIFEBOATS CO.,LTD

Installation Manual of HGP

PIPE

For Marine

10/37

HGP

GRE PIPE

2.2 Bell & Spigot joint (Adhesive Bonding joint)

Procedure for Bell & Spigot joint (Adhesive Bonding joint)

1. Determine the desired length and Cut the pipe

- Scribe the pipe using a pipe fitters wrap-around.

- When holding the pipe in a vice, use rubber padding or

similar to protect the pipe from damage.

- Contaminated pipe surfaces should be cleaned prior to

machining the pipe ends.

- Use a hacksaw or an abrasive wheel.

- Ensure that cut ends remain within the tolerances

- These tolerances can be checked by using e.g. the arbor of

the shaver flush with the cut end of the pipe.

2. Support and fix the pipe firmly

- Prevent the pipe from being damaged

3. Adjust the shaver to the required pipe size.

- Be sure to use the correct taper angle and Length

-Take care when shaving the first layer, because the pipe-

wall may be not be equally thick on all sides.

4. Shave the taper spigot.

- Maximum shaving depth / feed is 2 mm.

- Repeat the shaving action until the required spigot diameter /

spigot nose thickness is achieved.

- Due to possible tolerance spreading it is recommended to

use a nominal sized dummy bell end. This may avoid too long

or too short assembly lengths. If the insertion depth in the

dummy is too small, the spigot end to be shaved has to be

adjusted.

- Shaving the diameter of a taper spigot 1 mm smaller, with a

taper angle of 0.5 will result in 23 mm additional insertion in

HYUNDAI LIFEBOATS CO.,LTD

Installation Manual of HGP

PIPE

For Marine

11/37

HGP

GRE PIPE

the socket. For a taper angle of 1.75 this is 33 mm.

5. Sand all bonding surfaces.

- Thoroughly sand within 2 hours from assembly.

- Use flapper wheel sanders with a small drilling machine

(1700 - 2000 rpm) or emery cloth with a grid of 60.

- Bonding surfaces must be dry and clean before sanding.

Refer to step 10.

- Sanded surfaces must have a dull, fresh finish, not a

polished look.

- Check the assembly length and mark pipe and fitting for

alignment of elbows, flanges, etc.

- Use a clean dry cloth or brush to remove sanding dust etc.

- Do not touch the sanded surfaces after sanding and

cleaning.

6. Prepare the adhesive.

- Add the curing agent to the resin.

- Stir thoroughly until no streaks are visible and the mixture

has an even colour (after 2 to 3 minutes).

HYUNDAI LIFEBOATS CO.,LTD

Installation Manual of HGP

PIPE

For Marine

12/37

HGP

GRE PIPE

7. Apply a thin layer of adhesive

- Use a spatula or an adhesive scraper for applying the

adhesive.

- All surfaces to be bonded (sanded areas) must be

completely covered with adhesive, approximately 0.5 mm in

the bell and 1 mm on the spigot.

- A too thick layer of adhesive may result in flow restrictions

8. Insert the spigot in the bell.

- When inserting the spigot pay attention to the marks and

position and keep the joint together. Letting the spigot slip

back or turning the spigot after complete insertion may result

in a bad joint.

- For removing excessive adhesive, also from the inside if

possible, a spatula may be used.

- Wrap the required size HGP heating blanket around the joint

keeping the power supply cable free from the blanket.

- Make sure the voltage is correct.

- Good blanket to pipe surface contact is essential for proper

curing of the adhesive

- Open pipe ends should be closed during curing preventing

cooling down by draught

HYUNDAI LIFEBOATS CO.,LTD

Installation Manual of HGP

PIPE

For Marine

13/37

HGP

GRE PIPE

Maximum tolerance on squareness of cut spigot end

Pipe Size Range Tolerance

mm inch mm

25 100 1 4 1.5

150 - 400 6 -16 3.0

400 1000 16- 40 5.0

Adhesive per joint

PIPE Size Spigot Length Taper Angle Adhesive

mm mm degrees g

50 30 0.5 80

100 52 0.5 80

150 57 0.5 125

200 64 0.5 125

250 70 0.5 300

300 76 0.5 300

350 89 1.75 450

400 102 1.75 500

450 111 1.75 500

500 127 1.75 600

600 178 1.75 600

650 178 1.75 900

700 178 1.75 1200

750 178 1.75 1500

800 178 1.75 2000

850 178 1.75 2500

900 203 1.75 3000

950 203 1.75 4000

1,000 410 1.75 5000

Note1 : Adhesive Packing Kit Resin : 450g, Hardness : 600g

Note2 : Adhesive Cure time - 2hr(Heating Pad), 24hr(Natural Curing)

HYUNDAI LIFEBOATS CO.,LTD

Installation Manual of HGP

PIPE

For Marine

14/37

HGP

GRE PIPE

2.3 Flanged Joints

Flanged joints are used in piping systems for easy of installation and connection to equipment

or other material. All flanges are designed for the requirement pressures specified by the client.

Connecting to FF Flange

Full Face Gasket

Full Face Flange

Full Face Gasket

Full Face Flange

All flanges manufactured by HGP

are continuous glass fiber reinforcing from the hub into the

flange face.

Manufacturing method for flanges are filament winding method and hand lay-up & contact

molded with smooth radius.

The Neck flange type was used for the pipes below 12, and Lap joint flange was used for the

pipes over 12

HGP

standard is a bolting pattern which flanges are manufactured in accordance with

international codes. Bolting dimension system such as ANSI, AWWA, DIN, J IS can be supplied.

Flat face GRE flanges must be bolted to flat face companion flanges, with full gaskets or O-ring.

HGP

flanges thickness design in accordance with ASME, ANSI standards. (If you want to

detail information see the our Manufacturing guide)

GRE flanges should be jointed according to the following procedure;

1. Thoroughly clean the flange face and O-ring groove.

2. Ensure the O-ring gasket is cleaned and undamaged. Do not use defective gaskets.

HYUNDAI LIFEBOATS CO.,LTD

Installation Manual of HGP

PIPE

For Marine

15/37

HGP

GRE PIPE

3. Position O-ring in groove and secure in position with small strips of adhesive tape.

4. Align flanges to be jointed.

5. Insert bolts, washers and nuts. All hardware must be cleaned and lubricated to avoid

incorrect tihtening. Washer must be used on the all GRE flanges.

6. Using the torque wrench, tighten all bolts to 40 N.m(4 kg.m) torque 20 N.m(2 kg.m) for

small diameter in accordance with standard flanges bolt tightening sequences.

7. Repeat this procedure, increasing torque untile the recommend value for bolt torque. Do not

exceed this torque. To do may cause permanent damage to GRE flanges.

8. Check bolt torques one hour later and adjust to recommend bolt torque for each size of

flanges

GASKET

1. NBR Gasket (Standard)

- Maximum service temperature : 100C

- Thickness : 3t

- Color : Black

Used by itself or in combination with other outstanding polymers, NBR is ideally

suited for the manufacture of all Connecting to RF Flange

HYUNDAI LIFEBOATS CO.,LTD

Installation Manual of HGP

PIPE

For Marine

16/37

HGP

GRE PIPE

2. HNBR Gasket (Option)

- Maximum service temperature : 151 C

- Thickness : 3t

- Color : Black

Similar to NBR, HNBR provides broader thermal and chemical resistance.

3. EPDM Gasket (Option)

- Maximum service temperature : 150 C

- Thickness : 3t

- Color : Black

Incompatible with mineral oils, EPDM is resistant to many fluids that are

incompatible with other elastomers, including steam and brake fluid.

Connecting to RF Flange

If raised face flanged equipment is connected to GRE flanges, a hard plastic or metal filler ring

must be added to provide a flat connection surface, in figure. The best material for filler ring may

be the same as the full face gasket material or the hardness shall be more than full face gasket

(EX: PE, PVC).

2.3.1 Bolt, Nut & Washer

All nuts, bolts and washers will be in accordance with piping material specifications.

Dimensional requirement for bolts and nut will comply with ANSI standard (inch or metric

Thread) and the length of bolts will be in accordance with ANSI B16.5. When jointing HGP

fiberglass products flanges to flanges of other material or manufactures, bolt length will be

calculated.

HYUNDAI LIFEBOATS CO.,LTD

Installation Manual of HGP

PIPE

For Marine

17/37

HGP

GRE PIPE

2.3.2 Recommended Bolt Torque

Based on Full Face Flat Gaskets 15mm through 1000 mm and O-ring Gaskets 300mm through

2500mm diameter experience has shown these values to work. However, these values may be

increased 50% safely. Call HGP

before exceeding 100% of these values. Bolt torque must be

uniform within a 10% range of recommended values.

Note: Uniformity of bolt torque is critical.

<Flat Face Flange>

Bolt Torque Depend on Pressure Unit : kgm

Diameter 5 bar 7 bar 10 bar 12 bar 15 bar 20 bar

50 4 4 4 4 4 4

80 4 4 4 4 4 4

100 6 6 6 6 6 6

150 8 8 8 8 8 8

200 10 10 10 10 10 10

250 15 15 15 15 15 15

300 17 17 17 20 20 25

350 23 23 23 25 25 30

400 26 26 26 30 30 30

500 35 35 35 40 40 50

600 50 50 50 60 60 80

700 50 50 50 60 70 -

800 60 60 60 70 70 -

900 60 60 60 80 100 -

1000 65 65 65 100 100 -

HYUNDAI LIFEBOATS CO.,LTD

Installation Manual of HGP

PIPE

For Marine

18/37

HGP

GRE PIPE

<RF Flange>

Bolt Torque Depend on Pressure Unit : kgm

Diameter 5 bar 7 bar 10 bar 12 bar 15 bar 20 bar

50 5 5 5 5 5 5

80 5 5 5 5 5 5

100 7 7 7 7 7 7

150 10 10 10 10 10 10

200 12 12 12 12 12 12

250 18 18 18 18 18 18

300 20 20 20 24 24 30

350 27 27 27 30 30 36

400 30 30 30 36 36 48

500 41 41 41 48 48 60

600 60 60 60 72 72 96

700 60 60 60 72 84 -

800 72 72 72 84 84 -

900 72 72 72 96 120 -

1000 76 76 84 120 120 -

HYUNDAI LIFEBOATS CO.,LTD

Installation Manual of HGP

PIPE

For Marine

19/37

HGP

GRE PIPE

2.3.3 Recommend Procedure for Flange Installation

In butt joint (overlay) the flange to the GRE pipe, first ensure that the bolt holes are aligned with

those on the mating flange. Do not joint the pipe to pipe or fitting before flange connection. The

use of flat washers on all nuts and bolts must be required. The maximum allowable torque is

indicated on each flange and is also shown in Table (Bolt Torque Depend on Pressure). Full

face gasket materials, 3.0mm thick, with a Shore A hardness of 60 to 70 hardness are

recommended for HGP

fiberglass products flanges.

Procedure of Flange J oint

Cut pipe vertically & Grind

end of pipe by grinder

Cover adhesive inside of

flange and insert flange to

pipe.

Maintain level horizontally

by horizontal instrument and

curing by heating pad.

HYUNDAI LIFEBOATS CO.,LTD

Installation Manual of HGP

PIPE

For Marine

20/37

HGP

GRE PIPE

Insert gasket between flange

and other side.

At last, fasten a bolt with a

nut as correct bolt torque.

2.4 Flexible Steel Coupling

When connecting HGP

GRE pipe to pipe, fitting and other pipe materials with different

diameter, flexible steel coupling are one of the preferred jointing methods. These couplings

consist of a steel mantle with an interior rubber sealing sleeve. They may also be used to join

HGP

GRE pipe sections together, for example in a repair or for closure.

Regardless of the corrosion protection applied to the steel mantle, the balance of the coupling

needs to be corrosion protection as well. Control of the bolting torque value of flexible steel

coupling is most important. Do not over torque as this may over stress the bolt or the pipe.

Follow the coupling manufactures recommended assembly instructions, but HGP

will be

recommended for bolt torque limits.

HYUNDAI LIFEBOATS CO.,LTD

Installation Manual of HGP

PIPE

For Marine

21/37

HGP

GRE PIPE

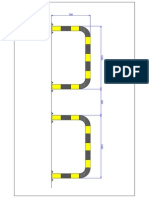

2.5 GRE Expansion Coupling Joint

Expansion couplings are used to board ships to replace conventional steel mechanical

couplings. It does not require corrosion protection or maintenance.

Procedure of GRE Expansion Coupling joint

Pipes which is located at expansion

coupling is aligned.

HYUNDAI LIFEBOATS CO.,LTD

Installation Manual of HGP

PIPE

For Marine

22/37

HGP

GRE PIPE

Install adaptor for expansion coupling to

each pipes by using taper/taper joint

method.

Adaptor which has two grooves is for

moving part, Adaptor which has three

grooves is for fixing part by key lock.

Insert two rubber-ring on each adaptor

and Lubricate entire surface of rubber-ring.

Insert key socket into each adaptor.

Key socket should be installed correct

direction, key hole direction should be

located on adaptor which has three

grooves.

Adjust key hole to locate on 3

rd

groove and

insert Key-Lock in to key hole.

HYUNDAI LIFEBOATS CO.,LTD

Installation Manual of HGP

PIPE

For Marine

23/37

HGP

GRE PIPE

4. Supports, Anchors, And Guides

4.1 Six basic rules

There are six basic rules to follow then designing and positioning supports, anchors, guides.

These are described in the following paragraphs.

Rule 1 : Avoid point loads

Use curved supports fitted to contact the bottom 120 of the pipe and that have a maximum

bearing stress of 586kPa. Do not allow unprotected pipe to press against roller supports, flat

supports, such as angle iron or I-Beams, or U-bolts. Do not allow pipe to bear against ridges

or points on support surfaces. Use metal or fiberglass sleeves to protect pipe if these

conditions exist.

Rule 2 : Meet minimum support dimensions

Standard pipe supports designed for steel pipe can support fiberglass pipe if the minimum

support widths provided in Table are met. Supports failing to meet the minimum must be

augmented with a protective sleeve of split fiberglass pipe or metal. In all cases, the support

must be wide enough that the bearing stress does not exceed 586kPa.

Sleeves augmenting supports must be bonded in place using adhesives stable at the systems

maximum operating temperature.

Prepare all pipe and sleeve bonding surfaces by sanding the contacting surfaces.

Support Spacing vs. Specific Gravity

Specific Gravity of Liquid

0.75 0.90 1.00 1.10 1.25 1.50

Adjustment

Factor

1.05 1.02 1.00 0.98 0.95 0.91

Rule 3 : Protect against external abrasion

If vibrations or pulsations are possible, protect contacting surfaces from wear. When frequent

thermal cycles, vibrations, or pulsating loadings affect the pipe, all contact points must be

protected. This is typically accomplished by bonding a wear saddle made of fiberglass, steel,

or one half of a section of the same pipe to the wall.

HYUNDAI LIFEBOATS CO.,LTD

Installation Manual of HGP

PIPE

For Marine

24/37

HGP

GRE PIPE

Rule 4 : Support heavy equipment independently

Valves and other heavy equipment must be supported independently in both horizontal and

vertical directions.

Rule 5 : Avoid excessive bending

When laying lines directly on the surface, take care to ensure there are no excessive bends

that would impose undue stress on the pipe.

Laminate

Vertical

Support

Wrong

Right

Rule 6 : Avoid excessive loading in vertical runs

Support vertical pipe runs as shown in figure. The preferred method is to design for pipe in

compression. If the pipe in tension method cannot be avoided, take care to limit the tensile

loadings below the recommended maximum tensile rating of the pipe. Install guide collars using

the same spacing intervals used for horizontal lines.

HYUNDAI LIFEBOATS CO.,LTD

Installation Manual of HGP

PIPE

For Marine

25/37

HGP

GRE PIPE

Support

Member

Steel Cradle

Allows Movement in Axial Direction Only

Typical Guide

4.2 Guides/Sliding Support

The guide mechanism must loose so as to allow free axial movement of the pipe. However, the

guides must be rigidly attached to supporting structure so that the pipe moves only in the axial

direction. All guides also act as supports and must meet the minimum requirements for supports

as set forth in General Rules.

4.2.1 U-Clamp

1) Protection between pipe and clamp

2) Maintain a gap between pip and clamp

3) The sample shown here is not suitable for strong lateral force.

4.2.1 Double half-clamp

1) Protection between pipe and clamp

2) Maintain a small gap between pip and clamp to allow axial movement between pipe and

clamp.

3) Lining material shall be permanently fixed to clamp or restrained by clamp.

HYUNDAI LIFEBOATS CO.,LTD

Installation Manual of HGP

PIPE

For Marine

26/37

HGP

GRE PIPE

4.3 Fixed Support

An anchor must restrain the movement of the pipe against all applied forces. GRP PIPE

anchors divide a pipe system into sections. They attach to structural material capable of

withstanding the applied forces. In some cases, pumps, tanks, and other similar equipment

function as anchors. However, most installations require additional anchors where pipe sizes

change and fiberglass pipe joins another material or a product from another manufacturer.

Additional anchors usually occur at valve locations, changes in direction of piping runs, and

major branch connections. Saddles and laterals are particularly sensitive to bending stresses.

To minimize stresses. To minimize stresses on saddles and laterals, anchor the pipe on either

side of the saddle or anchor the side run. Figure shows a typical anchor. Operating experience

with piping systems indicates that it is a good practice to anchor long, straight runs of

aboveground piping at approximately 90m intervals. These anchors prevent pipe movement due

to vibration or water hammer. One anchoring method features a clamp placed between anchor

sleeves or a set of anchor sleeves and a fitting. The sleeves bonded on the pipe prevent

movement in either direction. Sleeve thickness must equal or exceed the clamp thickness. To

achieve this, it often is necessary to bond two sleeves on each side of the clamp. Anchor

sleeves are usually 1 pipe diameter in length and cover 180 of circumference. Anchors act as

supports and guides and must meet minimum requirements for supports.

4.3.1 Light Anchor

1) Protection between pipe and clamp

2) Double nuts installation, locking and preventing excessive clamping force.

3) Gap between clamp and stopper shall not be greater than 3mm

4) Not suitable for vertical pipe due to support instability.

HYUNDAI LIFEBOATS CO.,LTD

Installation Manual of HGP

PIPE

For Marine

27/37

HGP

GRE PIPE

4.3.2 Anchor

Rubber

Pad

1) Protection between pipe and clamp

2) Double nuts installation, locking and preventing excessive clamping force.

3) Gap between clamp and stopper shall not be greater than 3mm

4) Strength of the support structure is important.

4.4 Flange Frame

Flange Frames are used for supporting flanged valves and flanged heavy inline items

independently. Flange frames can also be installed to pipe flange for other supporting purpose.

The flange frame can be fully welded to structure, thus being a fixed type or anchor type support

also the flange frame can sit loose on a support base with guide bars, thus being a guide type

support.

1) Sufficient coverage of number of bolts

2) Flange frame shall be as short as possible

3) Reinforcement wedge plate if necessary

4) Bolted to flange prior to final secure to structure

5) It can be anchor, guide or rest.

HYUNDAI LIFEBOATS CO.,LTD

Installation Manual of HGP

PIPE

For Marine

28/37

HGP

GRE PIPE

4.5 Support

To prevent excessive pipe deflection due to the weight of the pipe and the fluid, horizontal pipe

should be supported at intervals recommended in the support spacing Table (support spacing)

with adjustments for temperature and specific gravity.

HYUNDAI LIFEBOATS CO.,LTD

Installation Manual of HGP

PIPE

For Marine

29/37

HGP

GRE PIPE

4.6 Maximum Support Span

Recommended maximum spans for HGP PIPE at operating temperatures 60C and

below are listed below. These spans are intended for normal horizontal piping

arrangements. The tabular values are for partial span that represent a compromise

between continuous and simple spans.

Pipe

(mm)

5 bar

Span (m)

10 bar

Span (m)

15 bar (m)

Span (m)

20 2 2 2

25 3 3 3

40 3.5 3.5 3.5

50 3.8 3.8 3.8

80 4.3 4.3 4.5

100 4.9 5.0 5.2

125 5.2 5.5 5.6

150 5.5 5.8 6.0

200 6.0 6.0 6.0

250 6.0 6.0 6.0

300 6.0 6.0 6.0

350 6.0 6.0 6.0

400 6.0 6.0 6.0

450 6.0 6.0 6.0

500 6.0 6.0 6.0

600 6.0 6.0 6.0

650 6.0 6.0 6.0

700 6.0 6.0 6.0

750 6.0 6.0 6.0

800 6.0 6.0 6.0

850 6.0 6.0 6.0

900 6.0 6.0 6.0

1000 6.0 6.0 6.0

HYUNDAI LIFEBOATS CO.,LTD

Installation Manual of HGP

PIPE

For Marine

30/37

HGP

GRE PIPE

4.7 Maximum Alignment Allowance

Force to joint misaligned GRE piping will result in damage on fiber-glass components and/or

leaking at bonding joint. When fiber-glass piping is jointed, the misalignment shall not exceed

maximum allowable misalignment tolerances shown below.

Pipe Size

Maximum Tolerance (Base on 6m)

mm

20 ~ 100 mm 22

125 ~ 300 mm 18

350 ~ 500 mm 12

550 ~ 1000 mm 10

HYUNDAI LIFEBOATS CO.,LTD

Installation Manual of HGP

PIPE

For Marine

31/37

HGP

GRE PIPE

5. Installation in Hull Block

HGP PIPE fabricated spools shall be placed into hull blocks in block stage. HGP PIPE spools

shall be installed into hull blocks after block painting and blasting. If HGP PIPE spool have to be

installed into bull block prior to blasting and painting, HGP PIPE spools shall be wrapped with

protection canvas or equivalent protection materials.

When HGP PIPE is exposed to the possibility of damage by falling objects, HGP PIPE shall be

protected by wooden plank on top. The protection wooden plank shall be secured.

During installation in hull block, HGP PIPE/SPOOL shall be handled with care, surrounding

hazards shall be observed all the time, thus to prevent;

1) Impact damage due to dropping to hull structure or collision with hull structure

2) Scratch damage when pipe/spool passing through a manhole and/or opening on non-

watertight bulkhead.

During block installation stage, it is recommended to

1) Not fully weld the bulkhead penetration piece so that adjustment at steel can be done at

later stage to accommodate minor piping misalignment.

2) Not fully weld the support structure so that piping alignment can be easily adjusted after

block joint.

3) Install metal expansion coupling or GRE expansion coupling on the pipe end in accordance

with predetermined location shown on lay out.

HYUNDAI LIFEBOATS CO.,LTD

Installation Manual of HGP

PIPE

For Marine

32/37

HGP

GRE PIPE

6. Squareness Tolerance

Squareness of end cuts. B shall not deviate more than 3.0mm up to and including

600mm diameter and 5.0mm for diameters up to 1200mm.

Summary of Dimension Tolerance

Nominal

Dia.

(mm)

A

(mm)

Nominal

Dia.

(mm)

B

(mm)

Nominal

Dia.

(mm)

C

(mm)

D

(mm)

15 to 25 3.2 15 to 600 3.2

All Size 1.0mm/25cm 2.0

300 to 900 4.8 Over 600 4.8

Q

R

Tolerance of Manufacturing - Fittings

Nominal

Dia.

(mm)

A

(mm)

R

(mm)

L

(mm)

For

Angularlty

Tolerance

Nominal

Dia.

(mm)

Q

(mm)

15 to 200 1.5 1.5 1.5 15 to 100 0.8

250 to 600 2.3 2.3 2.3 125 to 200 1.5

650 to 750 3.1 3.1 4.8 250 to 400 2.3

800 to 1000 4.8 4.8 4.8 450 to 600 3.1

650 to 1000 4.8

HYUNDAI LIFEBOATS CO.,LTD

Installation Manual of HGP

PIPE

For Marine

33/37

HGP

GRE PIPE

7. Repair

Typically, damaged pipe can be repaired quickly and easily by qualified personnel at a job site.

The repair design depends on the wall thickness, wall composition, application, and the type

and extent of damage. Do not attempt to repair damaged or defective pipe without consulting

the HLB.

Scrapes and gouges on the pipe exterior that are less than 10% the pipe wall thickness

generally require no repair, while deeper scrapes generally require repair. Repair for damage to

the inner layer depends on the damage depth. Scratches, scrapes, and abrasion that do not

penetrate through the entire liner layer generally require no repair.

This HLB Repair manual describes two methods for the eventual repair of HGP

glass fiber

reinforced pipe systems. Procedure 1 is applied when a small damage or large diameter on pipe

and fittings. Procedure 2 is applied for severe damage or small diameter on pipe and fittings.

HLB recommend that repair of pipe as following;

Procedure 1. Applied for a small damage on pipe 600mm through larger.

1. damage of pipe 2. Grinding

Before installation of the straight pipe and

fitting section the installer should inspect if any

damage has occurred due to transport or

storage. If damage on pipe and fitting installer

should be repaired in the field.

Damage area caused during transportation

and installation shall be grinded by grinder up

to inner face. The width of grind should be

enough in order to overlay on damage

location.

HYUNDAI LIFEBOATS CO.,LTD

Installation Manual of HGP

PIPE

For Marine

34/37

HGP

GRE PIPE

3. Fill up with putty 4. Grinding

After grinding, fill up with putty at first. Hollow

space must be filled by high speed acid

resistant resin and Chopped Strand Mat.

After filled in hollow should be grind until

same level of the pipe outside.

5. Preparing and cutting of fiberglass

Lay out fiberglass mat strips on work table. The overlay length and width depends on the extent

and nature of the damage. Our recommend for Length and width of each strip(fiberglass) will be

longer than10 time of wall thickness at damage end(See Figure Damage of pipe ).

6. Apply resin on fiberglass

Mix prescribed amount of catalyst with required amount of resin in a separate clean container.

Resin will harden in about 20-30 minutes. After mixing the catalyst thoroughly, apply resin to

fiberglass mat by the brush or paint roller.

7. Overlay on pipe 8. Remove bubble

Pick up the completed weld fiberglass by one

end and center it carefully on the pipe. Apply

the taper end first with the narrowest fiberglass

on the pipe weld.

Be sure weld is centered, with care taken to

avoid wrinkles on the under or back side of

the weld. Finished joint should be built up in

successive layer uniformly and without air

bubble. Successive layers shall increase

uniformly to provide minimum total width of

overlay which meet the width of the last layer.

Do not move or disturb weld until it is

thoroughly cured

HYUNDAI LIFEBOATS CO.,LTD

Installation Manual of HGP

PIPE

For Marine

35/37

HGP

GRE PIPE

9. damage of pipe

L

After overlaying finish, surface should be rough grind by sand paper grinder. After surface

grinding, pipe shall be coated by acid resistant or U.V protective gel coat resin. For top coating

reference is made to the HGP

U.V coating instructions. (See welding procedure on overlay

manual). Ensure that the complete laminate length L is observed on both sides of the damage

location. The total length of the laminate is larger than 10 times of the pipe wall thickness.

Procedure 2. Applied for severe damage on pipe 15mm through 500mm

1. Parch 2. Cutout and replace

Should severe or larger damage have occurred to existing pipelines, there is a risk of the

damaged section should be removed from the pipeline network. The length of cutting on pipe

shall be lager than damage area. The length depends on the extent and nature of the damage.

A diagram of the repair is shown below;

HYUNDAI LIFEBOATS CO.,LTD

Installation Manual of HGP

PIPE

For Marine

36/37

HGP

GRE PIPE

3. Severe damage on the pipe & Cutting

W

The principle behind this method is that the pipe section containing the leak is cut out the

existing pipeline. Cutting piece of a length W shall be over 50mm on both sides of the

damage end line.

5. Assembly 6. Laminating

A new joint is trimmed to length W and installed in the existing pipeline using two laminate joints,

as described in the HGP

Field Laminate Instructions (See welding procedure on overlay

manual).

HYUNDAI LIFEBOATS CO.,LTD

Installation Manual of HGP

PIPE

For Marine

37/37

HGP

GRE PIPE

8. Cutting Edge

The maximum gap between the pipe sections to be joined as following:

Maximum gap for Repair pieces

Application size (mm) Maximum gap (mm)

For 150 through 350 3.0

For 400 through 700 4.5

For 750 through 1,000 8.0

You might also like

- GRPDocument40 pagesGRPrty2100% (2)

- (GRE) Installation Manual For MarineDocument37 pages(GRE) Installation Manual For MarineQuy RomNo ratings yet

- Mos GRPDocument53 pagesMos GRPslxanto100% (3)

- HOBAS Pressure Pipes SystemsDocument40 pagesHOBAS Pressure Pipes Systemsu_florinNo ratings yet

- GRP - GRE - GRV Pipes and FittingDocument11 pagesGRP - GRE - GRV Pipes and FittingPankajNo ratings yet

- Plant Piping Pressure Testing: (Exam For Inspectors Performing Test PKG & Sis Sheet Calculation Reviews)Document3 pagesPlant Piping Pressure Testing: (Exam For Inspectors Performing Test PKG & Sis Sheet Calculation Reviews)aslam.ambNo ratings yet

- Method Statement For GRE PipingDocument16 pagesMethod Statement For GRE PipingJaveed Shaikh100% (3)

- Wavistrong Installation ManualDocument63 pagesWavistrong Installation ManualRenganathan Prabunath0% (1)

- Filament winding machine for GRP pipesDocument12 pagesFilament winding machine for GRP pipesBruno SimanNo ratings yet

- ASME Training-FRP Piping Fabrication and Installation ProcessesDocument1 pageASME Training-FRP Piping Fabrication and Installation Processesninju1No ratings yet

- 2 Specification For GRP PipingDocument4 pages2 Specification For GRP Pipinggc_panchaNo ratings yet

- Normas de Referencia - Fibra de VidroDocument12 pagesNormas de Referencia - Fibra de Vidroricardobor100% (1)

- GRP Pipe For SeawaterDocument22 pagesGRP Pipe For Seawatersethu1091100% (2)

- PVC CPVC Physical Properties and Astm Specifications For Piping PDFDocument1 pagePVC CPVC Physical Properties and Astm Specifications For Piping PDFShahfaraz AhmadNo ratings yet

- Hydro-Test Manifold Layout and DetailsDocument1 pageHydro-Test Manifold Layout and Detailsryan gumanitNo ratings yet

- 3LPE Coating SpecificationDocument21 pages3LPE Coating SpecificationHướng PhạmNo ratings yet

- Types of Flanges-Definition of FlangesDocument4 pagesTypes of Flanges-Definition of FlangesindikumaNo ratings yet

- Bondstrand Bonder TrainingDocument60 pagesBondstrand Bonder Trainingminhthanhmos100% (1)

- GRE Pipe InstallationDocument32 pagesGRE Pipe Installationelkhatri100% (3)

- Installation Guide For GRE PipingDocument32 pagesInstallation Guide For GRE PipingAnh Võ100% (5)

- GRP Pipe Joint ThesisDocument268 pagesGRP Pipe Joint ThesisA.Subin DasNo ratings yet

- W P Ss 004Document12 pagesW P Ss 004BETLAHORENo ratings yet

- FPI FiberglassbookDocument164 pagesFPI FiberglassbookA_ValsamisNo ratings yet

- Bonstrand PipeDocument24 pagesBonstrand Pipejayhuacat7743No ratings yet

- Dynaflow - GRE Piping - March 26 2009Document60 pagesDynaflow - GRE Piping - March 26 2009sammar_10100% (3)

- Design, Manufacture and Supply of GRE Piping SystemDocument44 pagesDesign, Manufacture and Supply of GRE Piping Systemaprabhakar15100% (1)

- Cement Lined PipingDocument14 pagesCement Lined PipingMohammad Fazal Khan75% (4)

- Hdpe Pipes Technical SubmittalDocument56 pagesHdpe Pipes Technical SubmittalJohn G Jose100% (1)

- FRP Repair of Corrosion-Damaged Concrete BeamsDocument13 pagesFRP Repair of Corrosion-Damaged Concrete BeamsahmadlieNo ratings yet

- Method Statement UG GRE R 3 PDFDocument46 pagesMethod Statement UG GRE R 3 PDFRashid Kayum50% (2)

- Oman-India Fertilizer Project OIFDocument24 pagesOman-India Fertilizer Project OIFBassam Dahham83% (6)

- GRP Bonding ProcedureDocument19 pagesGRP Bonding Proceduremahi1437100% (1)

- GREPipe Systems Marine Industry June 2010Document45 pagesGREPipe Systems Marine Industry June 2010vinonagu100% (1)

- GRP PipeDocument9 pagesGRP Pipesethu1091No ratings yet

- Catalogo General Future Pipe IndustriesDocument164 pagesCatalogo General Future Pipe IndustriesPaul Wowor100% (1)

- Polypropylene: Section GuideDocument55 pagesPolypropylene: Section GuideKarthik RajNo ratings yet

- Installation Method for GRE PipesDocument9 pagesInstallation Method for GRE PipesN P Srinivasarao100% (2)

- Quick Guide Into The ISO 14692 Revision 2016 Edition 26 May 2016Document44 pagesQuick Guide Into The ISO 14692 Revision 2016 Edition 26 May 2016pmr80_2004100% (1)

- Ameron GuidelineDocument97 pagesAmeron GuidelineamuihNo ratings yet

- Saep 311Document31 pagesSaep 311brecht1980No ratings yet

- Installation Instructions For High Pressure GRE Line PipeDocument27 pagesInstallation Instructions For High Pressure GRE Line PipeSajir Thiyam100% (1)

- 01 Samss 029Document23 pages01 Samss 029faisalNo ratings yet

- Pipe Dimensions (PLASTICON)Document104 pagesPipe Dimensions (PLASTICON)Branimir JankovicNo ratings yet

- SP-2092 - GRP Specification Qualification and ManufacturingDocument47 pagesSP-2092 - GRP Specification Qualification and Manufacturingchandana kumar100% (2)

- GRP Pipes Technical DossierDocument23 pagesGRP Pipes Technical DossierSuhail PashaNo ratings yet

- GRP pipe manufacturing process flowchartDocument69 pagesGRP pipe manufacturing process flowchartAhmedHussainQureshiNo ratings yet

- Oilfield Hoses Fittings AccembliesDocument29 pagesOilfield Hoses Fittings Accembliesthapa786mNo ratings yet

- Gasket BrochureDocument8 pagesGasket BrochureKumar JbsNo ratings yet

- Hose Technic DataDocument28 pagesHose Technic Dataerol_ay98No ratings yet

- Sae J51-2004Document11 pagesSae J51-2004khhoseNo ratings yet

- Polyken Utility Tape 900 910 908 911 920Document2 pagesPolyken Utility Tape 900 910 908 911 920Tracy EvansNo ratings yet

- Api Plan 11Document6 pagesApi Plan 11johnsaballaNo ratings yet

- Geberit Piping Systems Catalogue 2010/2011Document95 pagesGeberit Piping Systems Catalogue 2010/2011Catalin Frincu0% (1)

- Cr6 Geomat DetailsDocument27 pagesCr6 Geomat DetailsfastenersworldNo ratings yet

- Alcoa Lock Bolt PDFDocument8 pagesAlcoa Lock Bolt PDFMurugan PalanisamyNo ratings yet

- Conex Cuprofit TechnicalDocument24 pagesConex Cuprofit TechnicalLawrence FoxNo ratings yet

- MRT Lamination ProcedureDocument14 pagesMRT Lamination ProcedureRachman DarmawanNo ratings yet

- 1.airhose g261 Green LineDocument22 pages1.airhose g261 Green LineMichael ThomasNo ratings yet

- TYCO Keystone F14.Lined - Butterfly.valve enDocument4 pagesTYCO Keystone F14.Lined - Butterfly.valve enIrina CretuNo ratings yet

- Fence Propose 1Document1 pageFence Propose 1HuongtrinhAkayNo ratings yet

- Fence Propose 2Document1 pageFence Propose 2HuongtrinhAkayNo ratings yet

- 1Document1 page1HuongtrinhAkayNo ratings yet

- S 1Document1 pageS 1HuongtrinhAkayNo ratings yet

- S 7Document1 pageS 7HuongtrinhAkayNo ratings yet

- CASE1Document1 pageCASE1HuongtrinhAkayNo ratings yet

- CASE2Document1 pageCASE2HuongtrinhAkayNo ratings yet

- GRP 09122014Document5 pagesGRP 09122014HuongtrinhAkayNo ratings yet

- DITA Cataloge SS2020Document41 pagesDITA Cataloge SS2020MaxNo ratings yet

- MTD 13AO772H755 (2007) Parts Diagram For Deck Assembly 46 Inch 1Document6 pagesMTD 13AO772H755 (2007) Parts Diagram For Deck Assembly 46 Inch 1Cristhian De La BarraNo ratings yet

- AMRI ISORIA 16 Type Series Booklet DataDocument20 pagesAMRI ISORIA 16 Type Series Booklet Datarudiskw456No ratings yet

- STANDARDS LIST TITLEDocument22 pagesSTANDARDS LIST TITLEteguh prasetioNo ratings yet

- Service Letter: Without An ELT FromDocument16 pagesService Letter: Without An ELT FromFranco PugaNo ratings yet

- Devorex Classic Brochure-03.2015 Eng1Document2 pagesDevorex Classic Brochure-03.2015 Eng1evangelos!No ratings yet

- Design of Machine Elements - IDocument109 pagesDesign of Machine Elements - ISam prabhakarNo ratings yet

- Section Seven: Cash Acceptor, DPT & DialsDocument46 pagesSection Seven: Cash Acceptor, DPT & DialsJulian Camilo Moreno CárdenasNo ratings yet

- Jaw Couplings Installation Guide: Jaw In-Shear (LS, CS)Document5 pagesJaw Couplings Installation Guide: Jaw In-Shear (LS, CS)Eliana EmizasNo ratings yet

- Manual RXZ100Document53 pagesManual RXZ100sonico197710100% (2)

- LCM 09 Lattice Tower Load Testing Version 1.1Document6 pagesLCM 09 Lattice Tower Load Testing Version 1.1Muhammad BilalNo ratings yet

- 1 800 SpaldingDocument20 pages1 800 Spaldingjoeyb12120% (1)

- MAB 103B-24 - Parts - 2011Document60 pagesMAB 103B-24 - Parts - 2011Centrifugal SeparatorNo ratings yet

- Free Energy Projects 2Document91 pagesFree Energy Projects 2Jo DaleyNo ratings yet

- Series 611 Valve Setter - Flange by Flange Used With MasterSeries N-Shape Assemblies Specification SheetDocument1 pageSeries 611 Valve Setter - Flange by Flange Used With MasterSeries N-Shape Assemblies Specification SheetFEBCONo ratings yet

- Engine Brake Service Information SummaryDocument10 pagesEngine Brake Service Information SummaryHamilton MirandaNo ratings yet

- Installation Guidelines: Coastal Wave™Document33 pagesInstallation Guidelines: Coastal Wave™michael turcotteNo ratings yet

- Tl642 Cat Services Manual TelehandlerDocument197 pagesTl642 Cat Services Manual TelehandlerRoxana Elizabeth Valencia NavarrteNo ratings yet

- Design and Compliance Control of A Robotic Gripper For Orange HarvestingDocument5 pagesDesign and Compliance Control of A Robotic Gripper For Orange HarvestingLeonardoGrandiniAdamiNo ratings yet

- Voltas VVE BOPT 2T (AC)Document82 pagesVoltas VVE BOPT 2T (AC)Johnson James100% (2)

- Tech Paper Ringfeder Locking Assemblies RFN 7012 en 08 2019Document3 pagesTech Paper Ringfeder Locking Assemblies RFN 7012 en 08 2019Andres Byke SepulvedaNo ratings yet

- Alloy-Steel and Stainless Steel Bolting Materials For High-Temperature ServiceDocument13 pagesAlloy-Steel and Stainless Steel Bolting Materials For High-Temperature Servicehans ccNo ratings yet

- 035 - 37 - Technical Manual - Road Brakes - CampagnoloDocument10 pages035 - 37 - Technical Manual - Road Brakes - Campagnolodcy536No ratings yet

- Calculation and Analyzing of Braces ConnectionsDocument71 pagesCalculation and Analyzing of Braces Connectionsjuliefe robles100% (1)

- ISS PS Cat 793C2 Manuals 50110 (Model TS793C2)Document27 pagesISS PS Cat 793C2 Manuals 50110 (Model TS793C2)Nicole SmithNo ratings yet

- OMS-90 AssemblyManualDocument17 pagesOMS-90 AssemblyManualAbel Fencer0% (1)

- Style 28 Coupling: Applied Vic-Ring SystemDocument4 pagesStyle 28 Coupling: Applied Vic-Ring SystemMina MagdyNo ratings yet

- Manual TAS85 Poppet SettingDocument4 pagesManual TAS85 Poppet SettingNoeRtjahya AhmadNo ratings yet

- DP-2000 Drill Press GuideDocument34 pagesDP-2000 Drill Press GuideNeri MtzNo ratings yet

- Easy Robotics With CardboardDocument16 pagesEasy Robotics With Cardboardmarcelyjoana1227No ratings yet