Professional Documents

Culture Documents

BUTTING Vessels Tanks Columns

Uploaded by

ThiênSứBanPhúcOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BUTTING Vessels Tanks Columns

Uploaded by

ThiênSứBanPhúcCopyright:

Available Formats

VESSELS, TANKS AND COLUMNS

Vessels, tanks and columns

Spools and welded components

Assemblies

Corrosion resistant pipes

Vessels, tanks and columns

Clad pipes

Special pipes and

components ready for installation

2 VESSELS, TANKS AND COLUMNS

3

Vessel construction

BUTTING vessels have been used in a wide range of

industries for decades. In so doing, they have proven

their worth in a very wide variety of requirements.

Countless projects have been implemented worldwide

with BUTTING participation.

This has led to customers valuing our effective project

completion, high quality products, exibility and cost

leadership. High-performance production facilities and

competent staff offer you a large number of possibili-

ties. We can produce and install the following for you:

Vessels

Equipment

Large tanks

Columns

Our name is a byword for on-time delivery, reliability,

a product-related high level of quality and an excellent

value for money.

VESSELS, TANKS AND COLUMNS

Your contact person

Ulrich Menter

Managing Director

BUTTING Anlagenbau in Schwedt

Phone: +49 3332 2097-0

ulrich.menter@butting-schwedt.de

Your contact person

Mario Kulow

Managing Director

BUTTING Anlagenbau in Schwedt

Phone: +49 3332 2097-0

mario.kulow@butting-schwedt.de

4 VESSELS, TANKS AND COLUMNS

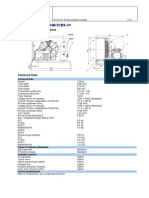

Our production

BUTTING manufactures vessels, equipment, large

tanks and columns in multiple pieces or in one piece in

line with customer specications.

Vessels have already been manufactured in the

dimensions of:

40 m length

6 m diameter

60 t individual weight

in one piece.

Segmented construction is on offer for specic local

situations. We manufacture the vessel in our plant

under ideal production conditions.

We dismantle it into as large modules as possible for

transport and assembly. Thus we transfer workshop

quality and the benet of short installation times to the

construction site.

If construction in one piece or segmented construction

is not possible, for example in the construction of large

tanks, we supply absolutely precisely cut and formed

materials to the construction site. These are assembled

and welded by our experienced installation teams.

Our proved and tested welding processes are:

Plasma

WIG

MIG

MAG

SAW

5 VESSELS, TANKS AND COLUMNS

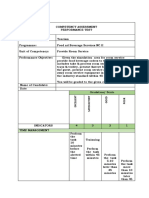

Your quality guarantee

The individual production of the vessels is done as solid

handicraft work, our welding processes are automated,

as far as possible. We monitor the performance of our

machines and staff on a permanent basis.

The production results are evaluated immediately,

taking quality requirements into account.

We continuously monitor the quality of our longitudinal

and circumferential welds on video or in other ways

while welding is taking place and we also carry out

internal x-ray and dye-penetrant tests.

Another factor which is crucial for the quality of the

welds and products is a metallic bright surface.

We ensure corrosion resistance of the stainless steels

by subjecting them to a chemical full body pickling

or alternatively, spray pickling, brushing, glass bead

blasting or shot peening. Our pickling equipment is

designed to ensure the complete surface treatment of

vessels.

We have considerable experience and expertise in se-

parating, forming and welding. This benets customers

from many sectors.

6 VESSELS, TANKS AND COLUMNS

Extensive capacities for worldwide use

BUTTING Anlagenbau in Schwedt / Oder is our expert

unit for vessel and pipeline construction as well as for

installation work. We have taken responsibility for vessel

construction and installation for a number of major

projects in Germany and abroad in various sectors.

Extensive capacities are available in Schwedt:

More than 6 000 t of stainless steel processed

per year

Approx. 350 employees and an additional figure

of more than 400 on service contracts

More than 14 000 m of hall space for vessel

construction and prefabrication of pipelines

Halls for vessel construction are up to 21 m high

and are equipped with cranes for piece weights

of up to 50 t

Outdoor areas of over 85 000 m

2

for storage and

logistics

7 VESSELS, TANKS AND COLUMNS

Diversity of materials

In Schwedt, more than 3 000 t of stainless steels and

special steels are processed for the construction of

vessels per year. There are also production capacities

in our parent plant in Knesebeck / Germany and in China.

Our extensive stainless steel plate store with an

inventory of more than 2 000 t ensures that we can

supply you fast and exibly.

The purpose of use and the process requirements

determine the selection of the material in vessel

construction.

BUTTING processes a wide range of materials to

provide the customer with a cost-effective solution.

These materials include:

Titanium stabilized steels (V2A and V4A) like

1.4401 or 1.4301 / 1.4307

Duplex steels, e. g. 1.4462

Lean duplex steels, e. g. 1.4162

Carbon steels, also weld-clad with liners made

from titanium stabilised steels

8 VESSELS, TANKS AND COLUMNS

Quality to a standard

The quality management system at BUTTING is

certied under DIN EN ISO 9001 by the internationally

known DEKRA company. We hold many other appro-

vals. In order to ensure that we meet project-specic

demands, a wide range of internal and external testing

equipment is available for material testing.

Your quality requirements set the standard.

Customers place their trust in us based on our

long-term experience and reliability.

Our approvals include the following:

DIN EN ISO 9001

Health and safety at work SCC approval

Manufacturer and welding company with AD 2000

HP0 approval acc. to DIN EN ISO 3834-3

Certified specialist acc. to the German Federal

Water Act (Wasserhaushaltsgesetz - WHG), 19

DIN EN 1090-2 EXC3

System for transferring the marking of materials

under Directive 97 / 23 / EC

9 VESSELS, TANKS AND COLUMNS

Your benets

Do you need a vessel for a particularly special process?

BUTTING manufactures vessels in line with customers

requirements. Each vessel is custom-made.

We offer our customers:

An extensive raw material store

Technical consultancy services, static calculations

and detail drawings

Extensive capacities

Correct handling of materials

Fast delivery times at short notice

High degree of prefabrication

Product quality through consistent quality

assurance

High degree of transportation competence

worldwide

High level of flexibility

Bundled responsibility and smooth project

completion

Long-term experience with international projects

In so doing, we can optimise our services to meet your

needs.

Benet from our extensive range of services:

we can produce and install spools and vessels for you.

For more information, please visit

www.butting.com!

10 VESSELS, TANKS AND COLUMNS

Diverse use

BUTTING produces vessels individually for each and

every customer. Your requirements and conditions of

use are decisive. They determine the production and

quality standards.

This results in diverse product variations such as:

Tanks for the paper mill

Pressure vessels

Special water separators

Equipment with complex fittings for cooling or

heating systems

Reaction columns with customised add-ons

Large tanks with internal and external

heating coils

Converting vessel

Our vessels are used for example in

Paper and pulp industry

Bio-energy technology

Chemical industry

Water and waste water treatment

Food industry

11 VESSELS, TANKS AND COLUMNS

Experience and competence

In the past decades, the expertise, reliability and

exibility of BUTTINGs staff has become our trademark

in the implementation of countless projects.

With its strong customer orientation, a team of

experienced staff ensures that projects are completed

smoothly. This has resulted in us being given responsi-

bility for the prefabrication and installation of vessels,

e. g. for:

Metso Paper Karlstad project, SCA Mexico PM1:

Prefabrication and installation supervision for all

containers and towers

Rhein Papier (Rhine Paper) project,

Plattling PM1, Germany:

Delivery and installation of 12 towers with

volumes of up to 4 000 m

Botnia S.A. project, Uruguay:

Delivery and installation of 53 vessels

Metso Paper Jyvskyl project, Amcor Australia:

Prefabrication and installation supervision for

containers and towers

Palm project, Kings Lynn, UK:

Delivery and installation of 10 towers and

100 vessels for the paper factory

Bioethanol Premnitz project, Germany:

Delivery and installation of all stainless steel

vessels, including fermenters

Sdra Cell Vr project, Sweden:

Delivery and installation of a liquor pressure

vessel made from LDX 2101, measuring 5 600 m

in size

Metso Power project, Skrblacka evaporation

plant, Sweden:

Delivery and installation of a black liquor pressure

vessel made from LDX 2101, measuring 700 m

3

in size

12 VESSELS, TANKS AND COLUMNS

Paper and pulp mill project in Austria

Austrian paper and pulp factory

Customer Zellstoff Pls, Pls / Austria

Sector Paper and pulp industry

Object Construction of a new paper machine

Scope of

delivery

1 storage tower with a volume of 5 000 m, diameter of 15 m and height of 34 m

More than 40 vessels including stacking towers, pulpers and internal process vessels

Special features The stacking tower, weighing 220 t, was mainly

prefabricated and assembled using duplex 1.4462 in a mere four months

13 VESSELS, TANKS AND COLUMNS

Biodiesel plants in Europe and South America

Biodiesel plants in Europe and South America

Customer Lurgi, Frankfurt am Main / Germany

Sector Bio-energy technology

Object 9 different biodiesel plants worldwide

Scope of

delivery

The projects were delivered in packages, consisting for example of storage vessels, various

pressure vessels, process columns for methanol and methylester made from 1.4404 or

1.4462 and vessels made from carbon steel

14 VESSELS, TANKS AND COLUMNS

Whiskey distillery in Ireland

Whiskey distillery in Ireland

Customer GEA Wiegand, Ettlingen / Germany

Sector Food and beverage industry

Object Whiskey distillery

Scope of

delivery

3 columns, 2 of which were pressure vessels with diameters of 1.20 and 2.00 m and a

height of more than 30 m

With built-in customised features in each case made from materials 1.4404 and 1.4301

Special features Realisation of short delivery times

Pressure test when laying at

15 VESSELS, TANKS AND COLUMNS

0

3

2

0

1

4

Production site in China

BUTTING manufactures products for the Chinese mar-

ket at two production sites in China: in Shanghai and

in Tieling. A number of projects and package projects

have been produced jointly by BUTTING in Germany and

in China, taking advantage of the synergy effects.

There are clear economic arguments in favour of

BUTTING China: on the one hand our customers

receive tried and tested BUTTING quality as a result

of the good technical performance of our Chinese

employees. They are trained, inducted and monitored

by BUTTING staff from Schwedt who are always on-

site. On the other hand, the moderate price level is an

argument in favour of carrying out the work directly

in China.

In Shanghai we have manufacturing possibilities for

piping systems and components ready for installation.

All the necessary machinery and facilities are available

for professional processing, along with qualied staff.

In Tieling, we use a production hall of more than

6 000 m which is equipped with comprehensive

production facilities for vessel and plant construction.

For the production of thin-walled vessels in standing

positions, the hall has a crane height of 18 m.

BUTTING in China is able to impress with these high

quality products:

Spools

Pressureless vessels

Pressure vessels

Columns

Flotation cells

Cleaner banks

VESSELS, TANKS AND COLUMNS

BUTTING

Knesebeck

Germany

Phone: +49 5834 50-0

info@butting.de

BUTTING Anlagenbau

Schwedt / Oder

Germany

Phone: +49 3332 2097-0

info@butting-schwedt.de www.butting.com

You might also like

- AccountantDocument3 pagesAccountantThiênSứBanPhúcNo ratings yet

- Giao DucDocument9 pagesGiao DucThiênSứBanPhúcNo ratings yet

- Jazz ArrangementsDocument238 pagesJazz ArrangementsVignesh En100% (1)

- Rao PresentationDocument36 pagesRao PresentationThiênSứBanPhúcNo ratings yet

- XSXSXSXSXDocument40 pagesXSXSXSXSXAfiq JuwaidiNo ratings yet

- Untitled Extract PagesDocument1 pageUntitled Extract PagesThiênSứBanPhúcNo ratings yet

- Septic Tank Analysis PDFDocument34 pagesSeptic Tank Analysis PDFChristian D. Orbe100% (3)

- Septic Tank Analysis PDFDocument34 pagesSeptic Tank Analysis PDFChristian D. Orbe100% (3)

- Gear Pump and API 676Document42 pagesGear Pump and API 676ThiênSứBanPhúc50% (2)

- Rao PresentationDocument36 pagesRao PresentationThiênSứBanPhúcNo ratings yet

- Untitled Extract PagesDocument1 pageUntitled Extract PagesThiênSứBanPhúcNo ratings yet

- Aço Sa 537 cl1Document23 pagesAço Sa 537 cl1pcorreia68100% (1)

- Untitled Extract PagesDocument1 pageUntitled Extract PagesThiênSứBanPhúcNo ratings yet

- Beam Deflection FormulaeDocument2 pagesBeam Deflection Formulae7575757575100% (6)

- Department of Agriculture and Food: MARCH 2006Document29 pagesDepartment of Agriculture and Food: MARCH 2006ThiênSứBanPhúcNo ratings yet

- Department of Agriculture and Food: MARCH 2006Document29 pagesDepartment of Agriculture and Food: MARCH 2006ThiênSứBanPhúcNo ratings yet

- Hazard Sheet 12: Lifting OperationsDocument6 pagesHazard Sheet 12: Lifting OperationsThiênSứBanPhúcNo ratings yet

- Usda Guidelines For The Sanitary Design and Fabrication of Dairy Processing EquipmentDocument54 pagesUsda Guidelines For The Sanitary Design and Fabrication of Dairy Processing EquipmentThiênSứBanPhúcNo ratings yet

- XSXSXSXSXDocument40 pagesXSXSXSXSXAfiq JuwaidiNo ratings yet

- TOYO-VIETNAM Corp. LTD.: Project: Dap-No Client: Vinachem Fabricator: Lisemco 2 - Hai Phong LILAMA 69.3 - Hai DuongDocument41 pagesTOYO-VIETNAM Corp. LTD.: Project: Dap-No Client: Vinachem Fabricator: Lisemco 2 - Hai Phong LILAMA 69.3 - Hai DuongThiênSứBanPhúcNo ratings yet

- A01 PEDFinal ReportDocument33 pagesA01 PEDFinal ReportThiênSứBanPhúcNo ratings yet

- Hazard Sheet 12: Lifting OperationsDocument6 pagesHazard Sheet 12: Lifting OperationsThiênSứBanPhúcNo ratings yet

- PHU LUC 3 - Co KhiDocument18 pagesPHU LUC 3 - Co KhiThiênSứBanPhúcNo ratings yet

- Mat SelecDocument7 pagesMat SelecmeskeydegamaNo ratings yet

- Ijmet: ©iaemeDocument7 pagesIjmet: ©iaemeIAEME PublicationNo ratings yet

- 03 Energy Efficient Electric Motor Selection Handbook PDFDocument65 pages03 Energy Efficient Electric Motor Selection Handbook PDFnicu_psiNo ratings yet

- ABC Siemens IECMotorsDocument168 pagesABC Siemens IECMotorsFernando MuneraNo ratings yet

- Difference Between Hot - & Cold-Rolled Steel - EHowDocument4 pagesDifference Between Hot - & Cold-Rolled Steel - EHowThiênSứBanPhúcNo ratings yet

- Data Sheet FOR Centrifugal Pump: Page 1 of 3Document3 pagesData Sheet FOR Centrifugal Pump: Page 1 of 3ThiênSứBanPhúcNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- NORSOK M-630 Edition 6 Draft For HearingDocument146 pagesNORSOK M-630 Edition 6 Draft For Hearingcaod1712100% (1)

- IsoTherming® Hydroprocessing TechnologyDocument4 pagesIsoTherming® Hydroprocessing Technologyromi moriNo ratings yet

- TC 10 emDocument7 pagesTC 10 emDina LydaNo ratings yet

- Birding The Gulf Stream: Inside This IssueDocument5 pagesBirding The Gulf Stream: Inside This IssueChoctawhatchee Audubon SocietyNo ratings yet

- Neurocisticercosis PDFDocument7 pagesNeurocisticercosis PDFFiorella Alexandra HRNo ratings yet

- Royal British College IncDocument5 pagesRoyal British College IncLester MojadoNo ratings yet

- Turning Risk Into ResultsDocument14 pagesTurning Risk Into Resultsririschristin_171952No ratings yet

- Method Statement (RC Slab)Document3 pagesMethod Statement (RC Slab)group2sd131486% (7)

- Model Probabilistik: "Variable Demand and Variable Lead Time" & Konsep Service LevelDocument30 pagesModel Probabilistik: "Variable Demand and Variable Lead Time" & Konsep Service LevelVladimir Hery WijannarkoNo ratings yet

- Women and ViolenceDocument8 pagesWomen and ViolenceStyrich Nyl AbayonNo ratings yet

- S ELITE Nina Authors Certain Ivey This Reproduce Western Material Management Gupta Names Do OntarioDocument15 pagesS ELITE Nina Authors Certain Ivey This Reproduce Western Material Management Gupta Names Do Ontariocarlos menaNo ratings yet

- Contractor: Item No. MRS-1st 2021 Ref. Description Unit Quantity Rate of Contractor Unit Rate in Words AmountDocument1 pageContractor: Item No. MRS-1st 2021 Ref. Description Unit Quantity Rate of Contractor Unit Rate in Words AmountusmanaliNo ratings yet

- Case Report CMV RetinitisDocument27 pagesCase Report CMV RetinitistaniamaulaniNo ratings yet

- FEM 3004 - Lab 10 Part 2editedDocument26 pagesFEM 3004 - Lab 10 Part 2editedAINA NADHIRAH BINTI A ROZEY / UPMNo ratings yet

- Revision Ror The First TermDocument29 pagesRevision Ror The First TermNguyễn MinhNo ratings yet

- Given The Simulation Area For Room ServiceDocument3 pagesGiven The Simulation Area For Room ServiceRico EsponillaNo ratings yet

- Assignment - Lab Accidents and PrecautionsDocument6 pagesAssignment - Lab Accidents and PrecautionsAnchu AvinashNo ratings yet

- Dr. Sajjad Hussain Sumrra Isomerism (CHEM-305) Inorganic Chemistry-IIDocument48 pagesDr. Sajjad Hussain Sumrra Isomerism (CHEM-305) Inorganic Chemistry-IITanya DilshadNo ratings yet

- Village Survey Form For Project Gaon-Setu (Village Questionnaire)Document4 pagesVillage Survey Form For Project Gaon-Setu (Village Questionnaire)Yash Kotadiya100% (2)

- Report in Per Dev CorrectedDocument34 pagesReport in Per Dev CorrectedJosh lyan RiveraNo ratings yet

- Weld Metal Overlay & CladdingDocument2 pagesWeld Metal Overlay & CladdingbobyNo ratings yet

- PEOPLE V JAURIGUE - Art 14 Aggravating CircumstancesDocument2 pagesPEOPLE V JAURIGUE - Art 14 Aggravating CircumstancesLady Diana TiangcoNo ratings yet

- Fast FashionDocument9 pagesFast FashionTeresa GonzalezNo ratings yet

- PolydactylyDocument43 pagesPolydactylyWara Samsarga GedeNo ratings yet

- Goals in LifeDocument4 pagesGoals in LifeNessa Layos MorilloNo ratings yet

- Pantera 900Document3 pagesPantera 900Tuan Pham AnhNo ratings yet

- 2005 Harley Davidson Sportster 883 66418Document136 pages2005 Harley Davidson Sportster 883 66418Josef Bruno SchlittenbauerNo ratings yet

- Answers To Your Questions About Circumcision and HIV/AIDSDocument2 pagesAnswers To Your Questions About Circumcision and HIV/AIDSAlex BrownNo ratings yet

- "Next Friend" and "Guardian Ad Litem" - Difference BetweenDocument1 page"Next Friend" and "Guardian Ad Litem" - Difference BetweenTeh Hong Xhe100% (2)

- Latest Low NOx Combustion TechnologyDocument7 pagesLatest Low NOx Combustion Technology95113309No ratings yet