Professional Documents

Culture Documents

Computer Integrated Manufacturing For Fully Automated Manufacturing

Uploaded by

Larry Smith0 ratings0% found this document useful (0 votes)

21 views18 pagescomputer integrated manufacturing

Original Title

Computer Integrated Manufacturing for Fully Automated Manufacturing

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentcomputer integrated manufacturing

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views18 pagesComputer Integrated Manufacturing For Fully Automated Manufacturing

Uploaded by

Larry Smithcomputer integrated manufacturing

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 18

Computer Integrated Manufacturing for

Fully Automated Manufacturing

Se p 2 0 1 2

Computer Integrated Manufacturing for Fully Automated Manufacturing | Sep 2012

2011, HCL Technologies. Reproduction Prohibited. This document is protected under Copyright by the Author, all rights reserved.

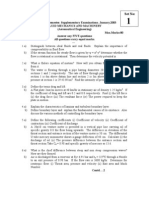

TABLE OF CONTENTS

Abstract ............................................................................................. 3

Abbreviations .................................................................................... 4

Introduction........................................................................................ 5

Computer Integrated Manufacturing ................................................. 6

CIM Business Case ........................................................................ 7

CIM Technical Analysis ................................................................ 10

Conclusion - Case Study ................................................................. 16

Author Info ....................................................................................... 17

Computer Integrated Manufacturing for Fully Automated Manufacturing | Sep 2012

2011, HCL Technologies, Ltd. Reproduction prohibited. This document is protected under copyright by the author. All rights reserved.

3

Abstract

Manually operated manufacturing lines are giving way to fully

automated lines with minimal manual intervention for the purpose of

reduction in cycle times and to enhance quality, with the prime

purpose of reducing variation in both. With the advent of automation

lines and reduction in manual work, there has been a need to

monitor and report the performance of these lines in terms of

productivity, quality and allied information that could prove vital to

establish the efficiency of the lines and the process. Since manual

reporting is time consuming, erroneous, biased and slow, automatic

reporting, and sometimes feedback, is the need of the day. The

solution lies with the advent and incorporation of Computer

Integrated Manufacturing systems (CIM). This paper describes the

hardware details and the software framework that encompasses a

CIM system.

Computer Integrated Manufacturing for Fully Automated Manufacturing | Sep 2012

2011, HCL Technologies, Ltd. Reproduction prohibited. This document is protected under copyright by the author. All rights reserved.

4

Abbreviations

Sl. No. Acronyms Full Form

1 CIM Computer Integrated Manufacturing

2 QC Quality Control

Computer Integrated Manufacturing for Fully Automated Manufacturing | Sep 2012

2011, HCL Technologies, Ltd. Reproduction prohibited. This document is protected under copyright by the author. All rights reserved.

5

Introduction

This paper shall elaborate the various aspects that go into

implementing CIM, starting from the need for a CIM system all the

way to deployment. In the process, details of the equipment, the

software essentials, the development team, hardware requirements

and effort shall be discussed. Features that could be a part of CIM,

based on the product being manufactured, shall also be discussed.

Computer Integrated Manufacturing for Fully Automated Manufacturing | Sep 2012

2011, HCL Technologies, Ltd. Reproduction prohibited. This document is protected under copyright by the author. All rights reserved.

6

Computer Integrated Manufacturing

In a simplistic sense, a computer integrated manufacturing system

does one or both of the following tasks:

A methodology for understanding the state of a process or

equipment, and reporting the related equipment performance,

quality delivered and the process parameters for real-time

continuous monitoring and analysis.

Correcting the current state of the equipment/process to

rectify any performance degradation caused either in the

product quality or the equipment productivity performance.

Extending this concept forward, the domain of feed-forward

control, which basically understands the quality of the product

from a process, and modifies the subsequent process to

nullify the bias caused in the previous. In short, the scope of

CIM lies in a closed-loop control of the manufacturing

process.

This paper shall elaborate more on the data collection process of

CIM, and hence, effectively portray CIM as an open loop system.

With this introduction to CIM, it is imperative to understand the

business impact of CIM.

CIM helps in understanding the

state of a process or

equipment, and in some cases,

correcting the state through

alarms or by feed-forward

control.

Computer Integrated Manufacturing for Fully Automated Manufacturing | Sep 2012

2011, HCL Technologies, Ltd. Reproduction prohibited. This document is protected under copyright by the author. All rights reserved.

7

CIM Business Case

The reasons why CIM is used in industries can be related to two

major aspects:

1. Technical benefits

2. Financial benefits

With the above two elaborated, any industry would be able to clearly

state the need for such a system.

Technical Benefits

1. Data, whether quality or productivity data, is available

immediately. This can help in quick decision making, thereby

reducing the risks involved in continuous manufacturing.

2. Each products signature and quality traits are clearly

observed and recorded, thus forming a basis in places where

traceability is used

3. Equipment performance and similar data like downtime can

be easily monitored

4. It is easy to correlate the performance of the product with the

condition of the equipment at that particular time

5. Occurrence can be easily tracked to kick-start Six Sigma

projects

6. Over 40% time reduction in data collection and aggregation

activity

Financial Benefits

1. Reduction in manpower of over one man per two assembly

lines for fully automated lines with manual QC checking and

reporting

2. Product data can be easily traced, thereby eliminating the

cost of rework and reducing the cost of recall. Estimated

recall cost reduction can be as high as 80% with some

products.

3. Quality enhancement using CIM systems can go as far as

90% where traditional systems can reach 70% through

quick correlation, thereby enhancing productivity results

4. Downtime can be reduced by over 80% through continuous

monitoring and predictive alarms

The technical benefits and financial benefits are summarized in the

charts shown below. As a word of caution, the results are based on

fully automated lines for high throughput (typically 30,000

> Over 40% time reduction in

data collection and

aggregation activity.

> Downtime can be reduced by

over 80% through continuous

monitoring and predictive

alarms.

Computer Integrated Manufacturing for Fully Automated Manufacturing | Sep 2012

2011, HCL Technologies, Ltd. Reproduction prohibited. This document is protected under copyright by the author. All rights reserved.

8

products/24 hours or more) employed with an open loop CIM

structure. The results may vary in cases of semi-automatic lines and

high speed equipment.

Return on Investment (ROI)

Based on the technical and financial benefits detailed above, the

estimates for ROI can be determined. For this purpose, let me

assume an electronic industry manufacturing high-precision, low-

value goods on a scale of ~300,000 goods/day. The ROI chart for

this scenario, based on a gradual ramp-up, would be as follows. The

graph assumes investment cost for CIM implementation and the

revenue that would be generated as a result of CIM.

The ROI sheet assumes a constant revenue generation through

quality enhancement of about 20% and a one-time saving through

The ratio of investment for a

CIM installation as opposed to

a typical electronics

manufacturing set-up as

considered above is 1:110

Computer Integrated Manufacturing for Fully Automated Manufacturing | Sep 2012

2011, HCL Technologies, Ltd. Reproduction prohibited. This document is protected under copyright by the author. All rights reserved.

9

traceable recall of 80%.The ratio of investment for a CIM installation

as opposed to a typical electronics manufacturing set-up as

considered above is 1:110. Having seen the benefits and the cost

economics of CIM system, the technical details for establishing a

CIM system are detailed next.

Computer Integrated Manufacturing for Fully Automated Manufacturing | Sep 2012

2011, HCL Technologies, Ltd. Reproduction prohibited. This document is protected under copyright by the author. All rights reserved.

10

CIM Technical Analysis

The technical details, requirements and design of the entire CIM

system is described below. A CIM system consists of the following

subsystems.

1. Equipment

Sensors

Programmable Logic Controller (PLC)

2. Hardware

Server/Computers

Room Requirement

3. Software Essential Features

4. Manpower Requirements

Equipment

The equipment dealt with is either a semi-automatic machine or a

fully automatic machine. A level of intelligence is expected to be

addressed during machine design such as installation of sensors for

safety mechanisms, equipment status signaling encoders, etc.,

which can feed back to a central intelligence system regarding the

status of the equipment.

a. Sensors

Sensors form an integral part of any CIM system. They are the

primary source of feedback to any CIM system. There are different

kinds of sensors used and selected depending upon the precision,

usage scenario and cost. Some sensors use light as a medium of

communication, such as through beam sensors, diffuse sensors,

laser beam sensors and other photoelectric sensors. If a situation

demands the detection of a magnetic material such as iron, reed

sensors are used. In places where safety is a concern, proximity

switches are used. Proximity sensors are also used in places where

positional detection is necessary. Let us analyze a case where a

particular sensor is used and how this would be of use to CIM. A

machine has a high-speed robot, and to ensure safety, a door

switch is installed. At times the door is opened for specific purposes

such as maintenance. Opening the door causes a reduction in

equipment productivity. At a review meeting, the detailed cause of

loss in productivity cannot be explained. With a system like CIM, the

exact cause of the productivity loss can be tabulated and a 5 Why

analysis can be completed. The methodology involves the sensor

communicating with the PLC, which takes note of how long the

Computer Integrated Manufacturing for Fully Automated Manufacturing | Sep 2012

2011, HCL Technologies, Ltd. Reproduction prohibited. This document is protected under copyright by the author. All rights reserved.

11

sensor is off and the time involved. The data is sent to a server

which decodes the data and presents it in the CIM format.

b. PLC

Programmable Logic Controllers form the electrical heart of the

machine, and are sometimes referred to as the brain of an

automatic machine. They control different mechanisms in a machine

like pneumatic parts, heaters, weld controllers, vision systems,

motors, etc. Apart from controlling, they also collect data from

different sensors like encoders, cam positioners, photoelectric

sensors, and ultrasonic sensors as well as take note of the time, the

occurrence frequency, and in some cases quality parameters. Apart

from the ladder program, PLCs also take input from the touch

screen, joystick controllers and hand-held consoles. Depending on

the program logic, PLCs can act as an activate/de-activate controller

for the entire machinery. In addition, the PLCs also communicate

with the next machine to know their status for acceptance of the

completed product. In short, the PLC is a device that is an interface

between the machine and the server for a CIM system.

Hardware

Once the PLC is ready to transmit data, suitable wiring needs to be

done to transmit the data to a server or a computer. The server or

computer shall store the data in a suitable format to be accessed by

computer throughout the network in a suitable format as defined by

the software structure. The server, being a precious store of data,

needs to be stored at ideal room conditions so it can work free from

crashes.

a. Server/Computers

The server shall store data sent from the equipment and shall be

sized to store and capable of handling huge amounts of data. Since

CIM is also a feature for traceability, care needs to be taken for

sizing the memory of the server. The server should be well isolated

from the development environment which will handle smaller

computers.

b. Room Requirements

The development area shall house computers which might range

from 6-10 for a mid-sized company from an electronics industry

perspective. The room temperature needs to be controlled at

Computer Integrated Manufacturing for Fully Automated Manufacturing | Sep 2012

2011, HCL Technologies, Ltd. Reproduction prohibited. This document is protected under copyright by the author. All rights reserved.

12

222C. The server room requires tighter control since it houses the

UPS which is comprised of lead acid batteries, which are

themselves heat generating. The server room needs to be

controlled at 211C. Because the server stores data critical to the

sustainability of the organization, measures should be taken to

protect it from accidental fire. A good example would be to have a

smoke alarm which could activate an inert gas like Argon so

combustion could be deterred due to the absence of oxygen. Care

should be taken before purging the entire room with argon, as a lack

of oxygen can asphyxiate personnel in the room. From a security

standpoint, the facility should be monitored by a Closed Circuit

Television Camera (CCTV). The development area and server room

should be accessible only by authorized personnel.

Software Essential Features

The software essentially should have the following features:

1. Quality Data

2. Production Data

3. Equipment Data

4. Material Movement and Inventory Data

5. Parts Traceability Data

6. Library Defects/Source

Quality Data

Under each of these categories, further drill-down can be enabled.

The various parameters for drill-down are:

a. Quality Type (Multiple)

b. Model

c. Process

d. Equipment Name

e. Type of Report Xbar R/Xbar - /Histogram

f. From Date/Time To Date/Time

g. Defect Type

h. Pareto Analysis

i. SPC Moving Average Charts

Computer Integrated Manufacturing for Fully Automated Manufacturing | Sep 2012

2011, HCL Technologies, Ltd. Reproduction prohibited. This document is protected under copyright by the author. All rights reserved.

13

j. Input to Operator for Manual Data Entry

k. Password Enablement for Operator Data Entry

l. Quality Summary and Report of Loss

This report generated should be downloadable as an Excel file for

data scrutiny. In addition, each report should show the existing

control limits set on the machine, based on which the machine

makes a judgment.

Production Data

The various drill-down parameters for this sub-set would be:

a. Model

b. Process

c. Equipment Name

d. Type of Report Histogram

e. From Date/Time To Date/Time

f. Defect Type (Quality and Equipment)

g. Pareto Analysis

h. Frequency of Reporting

i. Spare Name/Part No.

j. Spare Places of Usage

k. MSDS Input

l. Password Enablement for Operator Data Entry

Equipment Data

The various drill-down parameters for this sub-set would be:

a. Alarm Selection

b. Process

c. Equipment Name

d. From Date/Time To Date/Time

Computer Integrated Manufacturing for Fully Automated Manufacturing | Sep 2012

2011, HCL Technologies, Ltd. Reproduction prohibited. This document is protected under copyright by the author. All rights reserved.

14

e. Alarm Status on Diagram

f. Maintenance Criteria

g. Data Monitor for Specific Equipment Set-ups

Material Movement and Inventory Data

This feature would enable ordering and monitoring inventory based

on scheduling. At any point in time, the quantity of raw material

available for a specific process is known.

Parts Traceability Data

This forms a very key and integral part of a CIM system. For

instance, if a product delivered in the market is defective and the

entire batch needs to be recalled, this feature can help to identify

the serial number of the remaining products in the market with ease.

Going forward, the traceability system will help in drilling down into

the specifics of the raw material used, the manufacturing conditions,

etc., which can help in correlation analysis of the defect.

Library Defects/Source

The library is a source of past information and learning which can

quickly help identify and troubleshoot errors by locating the source

of the problem. In manufacturing, the transfer of knowledge is often

ineffective. Such a library can be a quick means of solving the issue.

This is the essence of software essentials for a CIM framework. The

last issue to be detailed is the manpower and skills requirement for

developing this system.

Computer Integrated Manufacturing for Fully Automated Manufacturing | Sep 2012

2011, HCL Technologies, Ltd. Reproduction prohibited. This document is protected under copyright by the author. All rights reserved.

15

Manpower Requirements

S.

No

Skill Subset Requirements

Manpower

Needed

1

Software

Engineers

Development of

Software System

7

2

Wiring and

Interfacing

Interface to m/c, Server

Issues

2

3

Electrical

Engineers

PLC Programming and

Interfacing

1/mc

4

Mechanical

Engineers

Sensor Selection,

Mounting Design

1/mc

5

Hard Wiring

Vendor

Wire from Server to mc 1 Vendor

6 Project Lead

Envision the entire set-

up, estimate

1

The resources above are needed for a minimum of eight months to

a maximum of ten months. The ideal starting point to have the

resources available would be one month ahead of new equipment

installation.

This concludes the analysis of CIM implementation from a business

point of view and from a technical standpoint.

Computer Integrated Manufacturing for Fully Automated Manufacturing | Sep 2012

2011, HCL Technologies, Ltd. Reproduction prohibited. This document is protected under copyright by the author. All rights reserved.

16

Conclusion - Case Study

As detailed earlier, CIM has a significant role in predictive

maintenance of machinery. This shall be explained with the help of

a simple case study:

Let us consider a mechanical coupling whose failure is the subject

of concern. The mechanical coupling on one side is connected to a

rotary encoder, and on the other side, is connected to a drive shaft.

In short, for every one rotation of the drive shaft, the rotary encoder

turns one rotation, and based on various angles from 0 to 360, the

encoder activates different controls like valves, solenoids, vacuum

switches, etc., through the cam-positioner/PLC which takes note of

different angle values. An incorrect input from the encoder can

activate the controls out of sequence, which can cause damage to

the machinery and the product, and often lead to long downtime.

Now, let us consider a case where the coupling tends to fail. A

scenario where a part tends to fail but hasnt failed is more

challenging for engineers to troubleshoot. This is where CIM, with

the help from sensors, can significantly reduce engineering analysis

and troubleshooting time. Once the coupling tends to fail, for every

rotation of the shaft the encoder might rotate more or less

depending on the side on which the coupling fails. This will activate

different controls in an incorrect sequence and cause machine

damage. And above all, it is very hard for engineers to understand

this phenomenon. With the use of sensors for checking the

mechanical timing of the machinery, and cross-verifying it with the

encoders value with a given tolerance, CIM can quickly provide

data to engineers on the deterioration in the couplings performance

through alerts. And each piece of this data is actually available on

the engineers computer, rather than having to connect to the PLC

to understand this.

Computer Integrated Manufacturing for Fully Automated Manufacturing | Sep 2012

2011, HCL Technologies, Ltd. Reproduction prohibited. This document is protected under copyright by the author. All rights reserved.

17

Author Info

Sandeep Venkatraman

Sandeep has over eight years of experience,

five of which have been in manufacturing,

vendor quality, new plant set-up, automation

equipment design/development, Lean

implementation, Six Sigma and Plant Kaizen.

The remaining three years were with factory

automation design, and his current role

involves creating solutions for the industrial

and sustainability divisions.

Hello, Im from HCLs Engineering and R&D Services. We enable

technology led organizations to go to market with innovative products

and solutions. We partner with our customers in building world class

products and creating associated solution delivery ecosystems to help

bring market leadership. We develop engineering products, solutions

and platforms across Aerospace and Defense, Automotive, Consumer

Electronics, Software, Online, Industrial Manufacturing, Medical

Devices, Networking & Telecom, Office Automation, Semiconductor

and Servers & Storage for our customers.

For more details contact eootb@hcl.com

Follow us on twitter: http://twitter.com/hclers

Visit our blog: http://ers.hclblogs.com/

Visit our website: http://www.hcltech.com/engineering-services/

About HCL

About HCL Technologies

HCL Technologies is a leading global IT services company, working

with clients in the areas that impact and redefine the core of their

businesses. Since its inception into the global landscape after its IPO in

1999, HCL focuses on transformational outsourcing, underlined by

innovation and value creation, and offers integrated portfolio of services

including software-led IT solutions, remote infrastructure management,

engineering and R&D services and BPO. HCL leverages its extensive

global offshore infrastructure and network of offices in 26 countries to

provide holistic, multi-service delivery in key industry verticals including

Financial Services, Manufacturing, Consumer Services, Public Services

and Healthcare. HCL takes pride in its philosophy of 'Employees First,

Customers Second' which empowers our 84,319 transformers to create

a real value for the customers. HCL Technologies, along with its

subsidiaries, has reported consolidated revenues of US$ 4 billion (Rs.

21031 crores), as on TTM ended Jun 30 '12.

For more information, please visit www.hcltech.com

About HCL Enterprise

HCL is a $6.2 billion leading global technology and IT enterprise

comprising two companies listed in India - HCL Technologies and HCL

Infosystems. Founded in 1976, HCL is one of India's original IT garage

start-ups. A pioneer of modern computing, HCL is a global

transformational enterprise today. Its range of offerings includes

product engineering, custom & package applications, BPO, IT

infrastructure services, IT hardware, systems integration, and

distribution of information and communications technology (ICT)

products across a wide range of focused industry verticals. The HCL

team consists of over 90,000 professionals of diverse nationalities, who

operate from 31 countries including over 500 points of presence in

India. HCL has partnerships with several leading global 1000 firms,

including leading IT and technology firms.

For more information, please visit www.hcl.com

You might also like

- Pneumatic Comparators (Metrology)Document17 pagesPneumatic Comparators (Metrology)Larry Smith100% (2)

- Fluid Mechanics and Machinery Laboratory ManualDocument54 pagesFluid Mechanics and Machinery Laboratory ManualLarry SmithNo ratings yet

- Fluid Mechanics and Machinery (May2013)Document3 pagesFluid Mechanics and Machinery (May2013)Dmj Anbu RajNo ratings yet

- NE May2013Document2 pagesNE May2013Larry SmithNo ratings yet

- Me 1004 Nuclear ENGINEERING Questions Bank 2014: SubscribeDocument14 pagesMe 1004 Nuclear ENGINEERING Questions Bank 2014: SubscribeLarry SmithNo ratings yet

- Fluid Mechanics and Machinery (May2012)Document4 pagesFluid Mechanics and Machinery (May2012)Dmj Anbu RajNo ratings yet

- Fluid Mechanics and Machinery LabDocument43 pagesFluid Mechanics and Machinery LabLarry SmithNo ratings yet

- NR-222101-Fluid Mechanics and MachineryDocument8 pagesNR-222101-Fluid Mechanics and MachinerySrinivasa Rao G100% (1)

- Fluid Mechanics and MachineryDocument10 pagesFluid Mechanics and Machinerysrajapraty50% (2)

- Me 2204 - Fluid Mechanics and MachineryDocument3 pagesMe 2204 - Fluid Mechanics and MachineryKarthik SubramaniNo ratings yet

- Fluid Mechanics and MachineryDocument2 pagesFluid Mechanics and MachineryNellai VprNo ratings yet

- Me2034 QB PDFDocument2 pagesMe2034 QB PDFekanthamoorthyNo ratings yet

- Ansys PDFDocument2 pagesAnsys PDFLarry SmithNo ratings yet

- ME 1004 NUCLEAR ENGINEERING Questions Bank 2014 Vidyarthiplus (V+) Blog - A Blog For StudentsDocument14 pagesME 1004 NUCLEAR ENGINEERING Questions Bank 2014 Vidyarthiplus (V+) Blog - A Blog For StudentsLarry SmithNo ratings yet

- 20041709Document62 pages20041709Larry SmithNo ratings yet

- Grouptechnology1 131203094018 Phpapp01Document9 pagesGrouptechnology1 131203094018 Phpapp01Larry SmithNo ratings yet

- NE May2013Document2 pagesNE May2013Larry SmithNo ratings yet

- Gtbylathu 101231003739 Phpapp01Document25 pagesGtbylathu 101231003739 Phpapp01Larry SmithNo ratings yet

- Group Technology AND Cellular Manufacturing: Submitted By: GROUP NO: 8 (ROLL NO 1111041 TO 1111045)Document30 pagesGroup Technology AND Cellular Manufacturing: Submitted By: GROUP NO: 8 (ROLL NO 1111041 TO 1111045)Larry SmithNo ratings yet

- Group Technology PPT at Bec DomsDocument34 pagesGroup Technology PPT at Bec DomsBabasab Patil (Karrisatte)No ratings yet

- Group Technology AND Cellular Manufacturing: Submitted By: GROUP NO: 8 (ROLL NO 1111041 TO 1111045)Document30 pagesGroup Technology AND Cellular Manufacturing: Submitted By: GROUP NO: 8 (ROLL NO 1111041 TO 1111045)Larry SmithNo ratings yet

- Group Technology: Job Shop Production System Batch Production System Mass Production SystemDocument11 pagesGroup Technology: Job Shop Production System Batch Production System Mass Production SystemLarry SmithNo ratings yet

- Grouptechnology1 131203094018 Phpapp01Document9 pagesGrouptechnology1 131203094018 Phpapp01Larry SmithNo ratings yet

- Group Technology (GT)Document15 pagesGroup Technology (GT)Larry SmithNo ratings yet

- Grouptechnology 140412022931 Phpapp01Document22 pagesGrouptechnology 140412022931 Phpapp01Larry SmithNo ratings yet

- Gtbylathu 101231003739 Phpapp01Document25 pagesGtbylathu 101231003739 Phpapp01Larry SmithNo ratings yet

- Grouptechnology1 131203094018 Phpapp01Document9 pagesGrouptechnology1 131203094018 Phpapp01Larry SmithNo ratings yet

- Group Technology: Job Shop Production System Batch Production System Mass Production SystemDocument11 pagesGroup Technology: Job Shop Production System Batch Production System Mass Production SystemLarry SmithNo ratings yet

- Cellular Manufacturing & Group Technology: Benefits and ImplementationDocument24 pagesCellular Manufacturing & Group Technology: Benefits and ImplementationLarry SmithNo ratings yet

- Group Technology PPT at Bec DomsDocument34 pagesGroup Technology PPT at Bec DomsBabasab Patil (Karrisatte)No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Lab 7: Amplitude Modulation and Complex Lowpass Signals: ECEN 4652/5002 Communications Lab Spring 2020Document28 pagesLab 7: Amplitude Modulation and Complex Lowpass Signals: ECEN 4652/5002 Communications Lab Spring 2020bushrabatoolNo ratings yet

- 3 Cat M1Document18 pages3 Cat M1DJRashDownloadNo ratings yet

- Database exam questions and answers from Arid Agriculture UniversityDocument3 pagesDatabase exam questions and answers from Arid Agriculture UniversityUmair KhanNo ratings yet

- 7800 Series Burner ControlDocument27 pages7800 Series Burner Controlrizky ListyawanNo ratings yet

- USB Download Version 1.3 Release Notes PDFDocument2 pagesUSB Download Version 1.3 Release Notes PDFCarlos HurtadoNo ratings yet

- Panasonic KX td1232 - CompressDocument6 pagesPanasonic KX td1232 - CompressasfdsadfNo ratings yet

- Scada Hack SandhuDocument6 pagesScada Hack SandhuSatinder Singh SandhuNo ratings yet

- Oracle Service Bus 12c Development GuideDocument5 pagesOracle Service Bus 12c Development GuideImran MominNo ratings yet

- Computer Operation: Competency StandardDocument55 pagesComputer Operation: Competency Standardsumaiya akterNo ratings yet

- Animation: COM269 Multiplatform Interactive Design Wan Anis Aqilah Megat ZambriDocument23 pagesAnimation: COM269 Multiplatform Interactive Design Wan Anis Aqilah Megat ZambriAhmad Shah BullahNo ratings yet

- Medal Log 20230820Document11 pagesMedal Log 20230820Pedro HenriqueNo ratings yet

- Yealink SIP IP Phones Release Notes of Version 84: Yealink Network Technology Co., LTDDocument30 pagesYealink SIP IP Phones Release Notes of Version 84: Yealink Network Technology Co., LTDYesith Berbel RicardoNo ratings yet

- IADC/SPE-201088-MS Well Design and Engineering Process AutomationDocument12 pagesIADC/SPE-201088-MS Well Design and Engineering Process AutomationAleksey SolominNo ratings yet

- Survival Part 5Document36 pagesSurvival Part 5bmartindoyle6396No ratings yet

- White PaperDocument13 pagesWhite PapercrissalahNo ratings yet

- Introduction, Basics of Cryptography, Secret Key CryptographyDocument48 pagesIntroduction, Basics of Cryptography, Secret Key CryptographySudha SreedeviNo ratings yet

- Analisis Pemanfaatan Teknologi Informasi Dan Komunikasi Oleh Penyuluh Dan Petani Padi Sawah Di Kabupaten Sidenreng RappangDocument20 pagesAnalisis Pemanfaatan Teknologi Informasi Dan Komunikasi Oleh Penyuluh Dan Petani Padi Sawah Di Kabupaten Sidenreng RappangAyhuJuliyaANo ratings yet

- ReleaseDocument39 pagesReleaseThanh VuNo ratings yet

- End Sem - Solution & Marking SchemeDocument41 pagesEnd Sem - Solution & Marking SchemeHaryanvi ChhoraNo ratings yet

- Experiment 3Document3 pagesExperiment 3AAAAALLENNNo ratings yet

- Implementation and Analysis of A ComputerisedDocument8 pagesImplementation and Analysis of A ComputerisedInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- NS 1Document96 pagesNS 1elitejoker622No ratings yet

- Ultimate Boot CD: Reset Hard Disk PasswordDocument3 pagesUltimate Boot CD: Reset Hard Disk Passwordamaha alemayehuNo ratings yet

- Experiment No:01 Full Adder: Aim AlgorithmDocument25 pagesExperiment No:01 Full Adder: Aim AlgorithmKiran AthaniNo ratings yet

- Mini Hi-Fi System Service ManualDocument95 pagesMini Hi-Fi System Service ManualyoyneerNo ratings yet

- Ken Verstaan Ekonomiese en Bestuurswetenskappe Graad 8 OnderwysersgidsDocument266 pagesKen Verstaan Ekonomiese en Bestuurswetenskappe Graad 8 Onderwysersgidsbritneykoen02No ratings yet

- Gsm/Gprs/Gps Tracker User Manual: PrefaceDocument13 pagesGsm/Gprs/Gps Tracker User Manual: PrefaceMichel PaisibleNo ratings yet

- 2349b - Programming With The MS .NET Framework MS VCSharp PDFDocument938 pages2349b - Programming With The MS .NET Framework MS VCSharp PDFlaptarosulNo ratings yet

- Business Proposal: Goods DeliveryDocument20 pagesBusiness Proposal: Goods Deliverysam100% (1)

- Data preprocessing and filtering using WekaDocument14 pagesData preprocessing and filtering using WekaB. Srini VasanNo ratings yet