Professional Documents

Culture Documents

Steps For Addition or Removal of Reinforcement

Uploaded by

Dikshant Hasbe0 ratings0% found this document useful (0 votes)

12 views2 pagesThe exposed reinforcing bars shall be cleaned thoroughly to remove all traces of rust, scales, etc., by using wire brush. Additional reinforcement shall be provided as per the design with shear connectors. Weld mesh may also be provided if found necessary.

Original Description:

Original Title

Steps for Addition or Removal of Reinforcement

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe exposed reinforcing bars shall be cleaned thoroughly to remove all traces of rust, scales, etc., by using wire brush. Additional reinforcement shall be provided as per the design with shear connectors. Weld mesh may also be provided if found necessary.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views2 pagesSteps For Addition or Removal of Reinforcement

Uploaded by

Dikshant HasbeThe exposed reinforcing bars shall be cleaned thoroughly to remove all traces of rust, scales, etc., by using wire brush. Additional reinforcement shall be provided as per the design with shear connectors. Weld mesh may also be provided if found necessary.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

STEPS FOR ADDITION OR REMOVAL OF REINFORCEMENT

1 Supports: The R C members should be properly supported before chipping the

Spalled / loose concrete. The props provided shall be adequate to provide sufficient

structural support to the load carrying members.

2 Surface Preparation of concrete: All the spalled cracked concrete or any other pre-applied

mortar shall be removed by chipping to expose the reinforcing bars. The concrete

shall be chipped to a minimum depth of 10mm behind the reinforcing bars. The areas to

be repaired shall be profiled to get rectangular or square shape with an inward tapering

edge

3 Surface preparation of reinforcement :The exposed reinforcing bars should be

cleaned thoroughly to remove all traces of rust, scales, etc., by using wire brush, emery

paper etc. The lateral ties/stirrups shall also be cleaned in the same way. After removal of

corroded portion, the diameter of the reinforcement shall be checked and compared with

the drawings.

4 Provision of additional reinforcement: As the diameter of reinforcing bars is

reduced substantially (say >20%) additional bars shall be provided as per the design. This

additional reinforcement shall be properly anchored to the existing concrete by providing

adequate shear connectors. Weld mesh may also be provided if found necessary.

5 Provision of shear connectors: Shear connectors of 8mm diameter shall be provided

in holes of 14mm diameter and 75 mm deep. These shall be provided at every 500 mm

c/c on all the faces of the beams in staggered form. The holes shall be cleaned with

compressed air or water jet to remove all the dust etc. and then the shear connectors shall

be fixed in the holes using polyester resin anchor grout

6 Priming of reinforcement bars: The exposed and cleaned reinforcing bar shall be

provided with a coat of Epoxy Zinc Primer such that the coated film will have a dry film

thickness of 40 microns. The film shall be continuous especially in the regions where

pitting, imperfections etc., are present on the surface of the bars. It is important that the

rear portion of the bars should not be left without coating. A second coat if needed may

be provided to achieve a uniform and continuous film. The additional reinforcement

provided and also the shear connectors shall be coated with Epoxy Zinc Primer. The weld

mesh if provided shall also be coated with Epoxy Zinc Primer.

7 Provision of Epoxy based bonding agent: The base and hardener component of

epoxy resin based bonding agent must be mixed well to get a uniform grey coloured mix.

Apply the material to properly cleaned and dry concrete substrate using stiff nylon brush

by scrubbing it well into the substrate. The coat should be uniform and well spread on the

entire surface area of the repair patch. The mixed material must be applied before the

elapse of its pot life and the new repair mortar must be applied before the elapse of

overlay time. As a fully dried epoxy resin coat acts as debonding layer, the repair

material should be applied whilst the bonding coat is tacky. In case the applied epoxy

bond coat gets dry, an extra coat should be applied before application of repair mortar.

8 Formwork and shuttering: Slurry tight and strong form work shall be provided. The

shuttering for encasement shall be kept ready such that the formwork shall be placed in

position and fixed such that the micro concrete can be poured into the formwork within

the overlay time of the bonding agent (5 hours). Adequate supports shall be provided for

the formwork. Care should be taken to ensure leak proof shuttering. Under no

circumstance the slurry should flow out of the shuttering during pouring of micro

concrete.

9 Mixing of micro concrete: It should be mixed using the appropriate water powder

ratio as mentioned in the product data sheet. The mixing shall be done mechanically and

under no circumstance hand mixing shall be done. Mixing shall be carried out for 3 to

5minutes to ensure that homogeneous mix is obtained without any bleeding or

segregation. In hot climate ice cooled water shall be used to maintain the temperature of

mixed material. If the encasing thickness is more than 100 mm, add stone aggregates up

to 50 % by weight of micro concrete to the mixed micro concrete directly into the mixer

hopper. The stone aggregates must be 12 mm and down and shall be clean, washed and

dried. The mixing should be done for 3 minutes in mixer and then pre weighed stone

aggregates into the mixer. Mix further for 2 minutes till lump free mix is obtained

10 Deshuttering: The shuttering from the sides of the R C members shall be removed

after a period of 24 hours. However, the formwork of the soffit shall be retained and

removed after 3 days.

11 Pouring of micro concrete: The mixer should be poured into the formwork using a

suitable funnel or through a hose pipe. It must be poured from one end only. A suitable

hopper / funnel arrangement shall be made at site to facilitate the pouring operations. The

pouring operation shall be continuous and it shall not be stopped unless the job is

completed. To achieve this sufficient mixers / drilling machines and wok force shall be

arranged at site.

12 Curing: All the repaired and encased area shall be fully cured as per standard

concrete practices. Curing compound shall be used for effective curing of sides and

soffits of beams. If a curing compound is applied, care shall be taken to ensure that

proper surface preparation is carried out so as to remove any traces of curing compound

on the surface. If this is not done, it may lead to de bonding of any protective coating

applied on top.

You might also like

- The Art of Calligraphy by David Harris PDFDocument128 pagesThe Art of Calligraphy by David Harris PDFamandabraunNo ratings yet

- Rich Dad Poor Dad PDFDocument189 pagesRich Dad Poor Dad PDFSd2cool DoiphodeNo ratings yet

- Hawkers Survey - B Ward: SR No ID Date Name Profession Location Contact NoDocument13 pagesHawkers Survey - B Ward: SR No ID Date Name Profession Location Contact NoDikshant HasbeNo ratings yet

- Lecture 1423904717Document102 pagesLecture 1423904717moondonoo7No ratings yet

- Bridge RuleDocument105 pagesBridge Ruleamawauce78% (9)

- 74781-Civil Diploma PDFDocument21 pages74781-Civil Diploma PDFCgpscAspirantNo ratings yet

- Appendix E3 PDFDocument22 pagesAppendix E3 PDFDikshant HasbeNo ratings yet

- Solid Mechanics 94 10Document89 pagesSolid Mechanics 94 10landatoNo ratings yet

- Seismic Retrofitting Buildings for Earthquake ResistanceDocument1 pageSeismic Retrofitting Buildings for Earthquake ResistanceDikshant HasbeNo ratings yet

- FRC Concrete Fibers Improve PropertiesDocument3 pagesFRC Concrete Fibers Improve PropertiesDikshant HasbeNo ratings yet

- Tunnel RepairsDocument7 pagesTunnel RepairsDikshant HasbeNo ratings yet

- Strengthening of Reinforced Concrete Columns Is Needed WhenDocument6 pagesStrengthening of Reinforced Concrete Columns Is Needed WhenDikshant Hasbe100% (1)

- Seismic Retrofitting MethodsDocument1 pageSeismic Retrofitting MethodsDikshant HasbeNo ratings yet

- Bubble DeckDocument16 pagesBubble Deckdeepuvarghese100% (1)

- Textile Reinforcement ConcreteDocument2 pagesTextile Reinforcement ConcreteDikshant HasbeNo ratings yet

- Requirement of StrengtheningDocument6 pagesRequirement of StrengtheningDikshant HasbeNo ratings yet

- Microconcrete UseDocument7 pagesMicroconcrete UseMd. Mynul HossainNo ratings yet

- Masonary 2Document3 pagesMasonary 2Dikshant HasbeNo ratings yet

- Re AlkalizationDocument18 pagesRe AlkalizationDikshant HasbeNo ratings yet

- Re Alkalization 1Document2 pagesRe Alkalization 1Dikshant Hasbe100% (1)

- Fibre Reinforced ConcreteDocument2 pagesFibre Reinforced ConcreteDikshant HasbeNo ratings yet

- ProjectDocument26 pagesProjectDikshant HasbeNo ratings yet

- Plate BondingDocument6 pagesPlate BondingDikshant HasbeNo ratings yet

- Repair and Retrofit Using External Post-TensioningDocument4 pagesRepair and Retrofit Using External Post-TensioningLevente SikoNo ratings yet

- ProjectDocument26 pagesProjectDikshant HasbeNo ratings yet

- Recent Advances in Repair and Rehabilitation of RCC Structures With Nonmetallic FibersDocument12 pagesRecent Advances in Repair and Rehabilitation of RCC Structures With Nonmetallic FibersWasim KhanNo ratings yet

- Fibre Wrapping (Carbon, Aramid, Glass)Document1 pageFibre Wrapping (Carbon, Aramid, Glass)Dikshant HasbeNo ratings yet

- FRPC Reinforced Concrete Beam-Column Joints Under Cyclic ExcitationDocument15 pagesFRPC Reinforced Concrete Beam-Column Joints Under Cyclic ExcitationMagdy BakryNo ratings yet

- Masonary RetrofitDocument1 pageMasonary RetrofitDikshant HasbeNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- LPS precision fastener manufacturerDocument16 pagesLPS precision fastener manufacturerHiren SonarNo ratings yet

- Flanges and Their Joints IDENTITYDocument3 pagesFlanges and Their Joints IDENTITYSamuel Blandes RwegasiraNo ratings yet

- BREF Glass Manufacturing Industry enDocument323 pagesBREF Glass Manufacturing Industry enAleINo ratings yet

- How To Build A Catalytic Test Reactor: Raoul Naumann D'alnoncourtDocument55 pagesHow To Build A Catalytic Test Reactor: Raoul Naumann D'alnoncourtFrançois LeroyNo ratings yet

- Spec of HA-EP-N2.5Document1 pageSpec of HA-EP-N2.5rafaeldelperu1982No ratings yet

- Consumable Log Sheet - 2019Document3 pagesConsumable Log Sheet - 2019vinothNo ratings yet

- Experiment No. 6: Determination of The Solubility Product Constant of Calcium HydroxideDocument2 pagesExperiment No. 6: Determination of The Solubility Product Constant of Calcium HydroxideAliaArellano100% (1)

- Gunj Glass Works. LTD Visit ReportDocument26 pagesGunj Glass Works. LTD Visit ReportHM Bhatti100% (1)

- U-1000 R2V (Industrial Unarmoured) : DescriptionDocument5 pagesU-1000 R2V (Industrial Unarmoured) : DescriptionJayagurunathanNo ratings yet

- Sandvik Metal Cutting Technology Training HandbookDocument364 pagesSandvik Metal Cutting Technology Training HandbookITL200_U95% (21)

- ChemicalDocument1 pageChemicalTimothy John IgnacioNo ratings yet

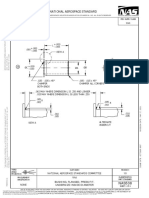

- National Aerospace Standard: Fed. Supply ClassDocument4 pagesNational Aerospace Standard: Fed. Supply ClassGlenn CHOU100% (1)

- Guide For The Gas Shielded Arc Welding of Aluminum and Aluminum Alloy PipeDocument38 pagesGuide For The Gas Shielded Arc Welding of Aluminum and Aluminum Alloy PipeCGRRNo ratings yet

- In-plant vocational training report process designDocument54 pagesIn-plant vocational training report process designniraj_bairagi100% (2)

- Cambridge IGCSE: Combined Science 0653/13Document20 pagesCambridge IGCSE: Combined Science 0653/13Paca GorriónNo ratings yet

- Ultra FJ BrochureDocument3 pagesUltra FJ Brochureamigofirm100% (1)

- STEELFORCE Welded Beam Catalogue Nov2021Document20 pagesSTEELFORCE Welded Beam Catalogue Nov2021Bobby CurrieNo ratings yet

- Metalshield Info BrochureDocument12 pagesMetalshield Info Brochuresiva_nagesh_2No ratings yet

- Astm C 27 1998Document2 pagesAstm C 27 1998joel estradosoNo ratings yet

- Beg 2105 Physical Electronics I - 1 IntroDocument166 pagesBeg 2105 Physical Electronics I - 1 IntroElias keNo ratings yet

- K DMAC Technology Structural AnalysisDocument2 pagesK DMAC Technology Structural AnalysisSalvatore ShwNo ratings yet

- Saes A 007 PDFDocument29 pagesSaes A 007 PDFsindalisindiNo ratings yet

- CRS Resolution SheetDocument24 pagesCRS Resolution SheetTĩnh Hồ TrungNo ratings yet

- 1-Pump Selection Guide by Goulds - Rev - PSG PDFDocument24 pages1-Pump Selection Guide by Goulds - Rev - PSG PDFMelvin MagbanuaNo ratings yet

- Epoxy Coating GuideDocument8 pagesEpoxy Coating GuideAzlan Othman100% (1)

- The Chemistry Name GameDocument18 pagesThe Chemistry Name GameBrandon Baxter100% (1)

- D2879-Standard Test Method For Vapor Pressure-Temperature Relationship and Initial Decomposition Temperature of Liquids by IsoteniscopeDocument6 pagesD2879-Standard Test Method For Vapor Pressure-Temperature Relationship and Initial Decomposition Temperature of Liquids by IsoteniscoperezaNo ratings yet

- Guide To Polyolefin Injection Molding 5979Document50 pagesGuide To Polyolefin Injection Molding 5979brijeshmaurya2100% (1)

- "Chemical Names and Formulas": Grade 9 Science 2 QuarterDocument60 pages"Chemical Names and Formulas": Grade 9 Science 2 QuarterJulius Memeg PanayoNo ratings yet

- p2 Energy Transfer by Heating Mark SchemeDocument15 pagesp2 Energy Transfer by Heating Mark SchemeKimberly OburuNo ratings yet