Professional Documents

Culture Documents

Jurnal KLP 11

Uploaded by

Niluh Komang Tri Andyani0 ratings0% found this document useful (0 votes)

80 views11 pagesPhenolic compounds are promising candidates for use in cosmetic formulations. But most of them have been shown to be light sensitive with a decrease in their efficacy due to photo-degradation. Four of the most common used phenolics, ellagic acid ( EA ), ferulic acid ( FA ), caffeic acid ( CA ) and chlorogenic acid ( CHA) were examined.

Original Description:

Original Title

Jurnal Klp 11

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPhenolic compounds are promising candidates for use in cosmetic formulations. But most of them have been shown to be light sensitive with a decrease in their efficacy due to photo-degradation. Four of the most common used phenolics, ellagic acid ( EA ), ferulic acid ( FA ), caffeic acid ( CA ) and chlorogenic acid ( CHA) were examined.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

80 views11 pagesJurnal KLP 11

Uploaded by

Niluh Komang Tri AndyaniPhenolic compounds are promising candidates for use in cosmetic formulations. But most of them have been shown to be light sensitive with a decrease in their efficacy due to photo-degradation. Four of the most common used phenolics, ellagic acid ( EA ), ferulic acid ( FA ), caffeic acid ( CA ) and chlorogenic acid ( CHA) were examined.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 11

Determination of four lipophilic phenolics in o/w

emulsions as well as their stability

Miaw Lin Chang

1

Chur Min Chang

2*

1

Department of Cosmetic Science,

2

Department of Applied Chemistry,

Chia-Nan University of Pharmacy and Science, Tainan, Taiwan 71710, R.O.C.

Abstract

Phenolic compounds are promising candidates for use in cosmetic formulations thanks to their

characteristics such as antioxidant activity, UV-absorbing and melanogenesis inbibition. But most

of them have been shown to be light sensitive with a decrease in their efficacy due to

photo-degradation. Therefore, for optimizing the efficacy of functional cosmetics, it is important

to recognize the unstable profiles of phenolic compounds in cosmetic products upon ambient

sunlight exposure. Four of the most common used phenolic compounds, ellagic acid ( EA ),

ferulic acid ( FA ), caffeic acid ( CA ), and chlorogenic acid (CHA), were examined. The

phenolic compounds, as a single one and a combination, were formulated into o/w emulsion. And

then the chemical stability of each of the phenolic compounds in o/w emulsions with and without

the sunlight was investigated. Their different stability was evaluated by a high performance liquid

chromatography using an isocratic mobile phase consisting of methanol:acetonitrile:water

(10:19:71, v/v/v; pH 3.5). The results demonstrated that the developed mobile phase is very

suitable for the simultaneous determination of the four phenolic compounds in emulsions without

the interference with the corresponding oxidation products from the phenolic compounds or the

excipients from cosmetic emulsions. Moreover, the degradation rate of the phenolic compounds

in o/w emulsion is much lower than in solvent, indicating the ability of o/w emulsion to protect

the phenolic compounds from rapid degradation. In all cases EA is the most stability due to no

degradation product, while CHA has the least stability. In addition, stability of CA was improved

markedly when it combined with FA, CHA and EA. This suggests that a suitable combination of

phenolic compounds would be required to optimize their efficacy in final products.

Keyword: Phenolic compounds; Ellagic acid ( EA ); ferulic acid ( FA ); caffeic acid ( CA );

chlorogenic acid (CHA); Stability; Degradation; o/w emulsion; isocratic HPLC

method

*Correspondence: Department of Applied Chemistry, Chia-Nan University of Pharmacy and Science,

Tainan, Taiwan 71710, R.O.C.

Tel:+886-6-2664911ext2304

Fax:+886-6-2667219

E-mail: jchurmin@mail.chna.edu.tw

91~101 101

CHIA-NAN ANNUAL BULLETIN

V O L . 3 8 , P P . 9 1 - 1 0 1 , 2 0 1 2

-

1. Introduction

Phenolic compounds are abundant in

naturally occurring plants. Significant amounts of

phenolic compounds have been isolated from them.

Pharmacological studies showed that they are able to

enrich blood, activate blood circulation, regulate

menstruation, relieve pain and resax bowels,

stimulate smooth muscle, or even inhibit the

multiplicity of tumors

(1)

. Moreover, they also possess

anti-inflammatory, anti-carcinogenic, anti-allergic,

antimicrobial, antimelanogenic, and antioxidant

activities

(2-4)

. Therefore, using them in cosmetics as

functional ingredients has been studied extensively. It

is demonstrated, for example, that the use of skin care

products including phenolic compounds, such as

ferulic acid ( FA ), ellagic acid ( EA ), caffeic acid

( CA ), and chlorogenic acid (CHA) is efficacious in

the treatment of skin conditions such as rosacea,

sensitive skin and in the prevention of skin

photodamage

(5,6)

. Some authors have even reported

the transdermal delivery of ferulic acid and

chlorogenic acid out of different cosmetic

formulations

(7)

. In addition, it have been suggested

that they are also used as UV-protective enhancer,

UV protector and skin-whitening agents in cosmetic

products

(8-10)

.

In order to make sure the effectiveness of

cosmetic products during the shelf life, the phenolic

compounds incorporated into cosmetics should be

stable. Unfortunately, most phenolic compounds

exhibit unstable properties because they would take

place the isomerization of trans-form to cis-

form

(11,12)

. They alsohave been shown to be high

sensitive upon light exposure, and their oxidation

products were identified as various quinines,

dimmers and aldehydes by using LC-MS method

(13)

.

Whether the isomerization of phenolic compounds

may induce adversely effect on human skin is

unknown, but various reports on photocontact

sensitization and on less UV-protecting efficacy

induced by the photo-isomerization of typical

UV-filters have been issued

(14,15)

. We wondered if

maybe instability of phenolic compounds can result

in less efficacious product like those UV-filters. In

order to satisfy both effective and healthy

requirements, the phenolic compounds used should

have a longer useful life in cosmetic formulations and

be limited at a suitable level to be safe for application

to the skin. In our country the use of ellagic acid is

allowed up to a maximum limit of 3% in cosmetic

formulations, but the others has not yet been issued.

On the other hand, using the phenolic compounds,

either alone or as a complex, has become quite

popular. Actually, more than two ingredients present

in one emulsion will influence or change their

stability each other due to their different antioxidant

activity

(16)

. Therefore, it is important to look at the

stable profile of each phenolic compound while the

phenolic compounds were formulated into cosmetic

emulsions by alone or a combination.

Although many authors have published the

stability for phenolic compounds in solution with

different pH values, in medicinal materials, and in

extracts

(17-20)

, there are no data available about the

stability of the phenolic compounds in cosmetic

emulsions. Aiming at a determination of chemical

stability of phenolic compounds in cosmetic

emulsions upon sunlight exposure, we established an

isocratic- HPLC method. For this purpose the four

most wildly used phenolic compounds-ellagic acid,

ferulic acid, caffeic acid and chlorogenic acid, were

selected as functional ingredients. And an o/w

emulsion, one of the most popular personal care

formulations, is prepared following the procedure

used in commercial practice for o/w emulsions.

Determination of four lipophilic phenolics in o/w emulsions as well as their stability

92 - -

During the emulsification each single one and the

combination of the four phenolic compounds were

separately mixed with oil phase, and then the

mixtures were added into water phase for producing

o/w emulsions with different phenolic compound. For

comparison, these phenolics were also prepared in

methanol solvent. The stability of each phenolic

compound both in methanol solvent and in o/w

emulsion was evaluated.

2. Experimental

2.1. Materials and reagents

All the four active phenolic compounds were

purchased from Merck ( Germany ). Span 80and

Tween 60, as emulsifiers, were obtained from First

Chemical Co( Taiwan). Carbopol 940, glycerin, and

mineral were also from First Chemical Co(Taiwan).

U-13 and phenoxy ethanol were obtained from

Induchem.Co.(Switzerland). The rest of cosmetic

materials were purchased by Lipo Co.(USA ). HPLC

grade methanol and acetonitrile (Sigma-Aldrich,

Cermany ) were used for the preparation of mobile

phase. Analytical grade of phosphoric acid and

sodium hydroxide was purchased from Toyao (J apan).

Deionized water was obtained from a Milli-Q water

system ( Millipore, USA).

2.2. Formulations studied

An o/w emulsion was chosen and tested in this

work. Six emulsions (Table 1) were formulated in a

Ika Eurostar Digital/P1 mixer. The active phenolic

compound is first mixed with oil phase. The o/w

emulsion was prepared by a dropwise addition of the

aqueous phase into the oil phase containing active

agents followed by agitation for 15min at high speed

(1000rpm) and room temperature, and then given by

a low speed (300rpm) until a homogenous emulsion

was formed. Emulsion A dose not contain any

phenolic compound. Emulsion B-E (with individual

phenolic compound) and emulsion F (with a

combination) are obtained, respectively.

Table 1 Compositions of the o/w emulsions

Compositions Percentage of components in each emulsion

A B C D E F

(I) Oil phase

Span80 3.0 3.0 3.0 3.0 3.0 3.0

Tween60 2.0 2.0 2.0 2.0 2.0 2.0

Finsolv TN 2.0 2.0 2.0 2.0 2.0 2.0

Squalane 3.0 3.0 3.0 3.0 3.0 3.0

Mineral oil 1.0 1.0 1.0 1.0 1.0 1.0

Finsolv TN 2.0 2.0 2.0 2.0 2.0 2.0

Caprylic/capric

Triglyceride 5.0 5.0 5.0 5.0 5.0 5.0

(II)Active agents

Ellagic acid - 1.0 - - - 0.25

Chlorogenic acid - - 1.0 - - 0.25

Caffeic acid - - - 1.0 - 0.25

Ferulic acid - - - - 1.0 0.25

(III)Weter phase

U-13 0.4 0.4 0.4 0.4 0.4 0.4

Pheoxyethanol 0.4 0.4 0.4 0.4 0.4 0.4

Carbopol 940 0.5 0.5 0.5 0.5 0.5 0.5

Glycerin 3.0 3.0 3.0 3.0 3.0 3.0

Distilled water to 100 100 100 100 100 100

2.3 Instrumentation

An Model I-7100 HPLC-UV system consisting

of a single pump, a degasser, an injection valve with

25ul sample loop (Model 7725, Rheodyne, Cotati,

US ), and UV detector was used. And a Mightysil

RP-18CP column was used for chromatographic

analysis. The mobile phase consisted of the mixture

Miaw Lin Chang Chur Min Chang 93 - -

of methanol:acetonitrile:water (10:19:71, v/v/v), and

its pH value was adjusted to 3.5 by phosphoric acid.

The isocratic separation was performed and the flow

rate was 0.8mL/min at ambient temperature. VU

detector was set at 320nm for acquiring the

chromatogram. Data acquisition and processing were

accomplished with a personal computer including

Sisc software (Taiwan).

2.4 Recovery study in o/w emulsion

Emulsion A (without phenolic compound)

shown in Table 1 was used as a control in the

recovery study. To test the recovery, each of the four

phenolics standards was formulated into the control

emulsion at low and high concentrations (0.25 and

2.5 %, w/v) during the emulsification. For the assay

of the phenolic compounds, about 1g of each of the

formulated emulsion was weighed into a glass flask

and 25 ml of methanol was added and then the flask

was immersed in an ultrasonic bath for 20 min at

ambient temperature. The extraction samples were

centrifuged for 1min. Of each of the centrifuged

samples, 1 ml were taken, and then diluted to 10 ml

with methanol before injecting onto the HPLC

system. Table 2 summarized the recovery of the

phenolic compounds in the type of o/w emulsion

using various extraction solvents.

2.5 Stability studies

The difference in stability of each phenolic

compound in emulsion (B-F) without or with sunlight

exposure was evaluated by HPLC analysis with

isocratic separation during the study period. For

comparison, the tested phenolic compounds, as a

single one or the combination of the four phenolic

compounds, is separately prepared into methanol

solvent. Approximately 10-ml of aliquots of each

sample were kept in glass vials and placed in sunlight

at ambient temperature (30-36). After either

exposing them to the sun or protecting from the sun

by covering with aluminum foil during a period of 28

days, these samples were assayed at the following

time points: 0, 1, 7, 14, 21, and 28 days. For the assay

of phenolic compounds, each of the emulsion and

solution samples is treated as the same with those

described in section 2.4.

3. Results and Discussion

3.1. Chromatography and resolution

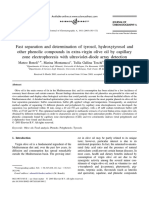

The structure of the four phenolic compounds,

ferulic acid ( FA ) , ellagic acid ( EA ), caffeic acid

( CA ), and chlorogenic acid (CHA), is shown in

Figure 1. Containing carboxylic acid group or

phenolic hydroxyl group in each molecular structure,

they are all weak acidic substances with a strong

hydrophobicity. Two of major factors, mobile phase

and pH value, which affect the separation

performance, are examined in order to optimize

chromatographic conditions with no interference with

matrix in cosmetic samples. When the mixture of

methanol:water with vary pH value was used as

mobile phase, peak overlap and poor symmetry

appeared (not displayed ). Instead, the use of isocratic

elution with a methanol:acetonitrile:water (10:19:71,

v/v/v) adjusted to a pH value of 3.19 by phosphoric

acid gave good results in separation of the four

phenolic compounds either in solvent or in emulsion

without and with sunlight exposure, as shown in

Figure 2. The HPLC chromatograph showed good

resolution and separation with retention time of less

than14 min. In Figure 2(a)(sample treated with dark

conditions), it can be seen that the retention time of

CHA, CA, EA and FA appear at 4.8 min, 6.3 min, 8.7

min and 10.3 min, respectively. Figure 2(d) resulted

Determination of four lipophilic phenolics in o/w emulsions as well as their stability

94 - -

from a control emulsion. On the other hand, the

changes of the phenolic compounds in methanol and

in emulsion with sunlight exposure are shown in

Figure 2(b) and 2(c), respectively. The results of

Figure 2(c) are similar to those in Fig 2(b). It is clear

that there were extra three peaks to appear by

comparing them with Fig 2(a), suggesting all the

tested phenolic compounds could cause

decomposition but EA by sunlight exposure.

OMe

CO

2

H CH CH

HO

Ellagic acid Ferulic acid

CO

2

H CH CH

OH

HO

CO 2H

O

O

OH

HO

HO

OH

OH

R

R

S

R

Caffeic acid Chlorogenic acid

Figure1.Chemical structures of four phenolic

compounds

Figure 2. HPLC chromatographic analysis of the four

tested phenolic compounds (a) in methanol solvent

with dark conditions (b) in methanol solvent with 7

days sunlight exposure (c) in o/w emulsion F with 7

days sunlight exposure, and chromatogram of (d)

placebo(emulsion A) with 7 days sunlight exposure.

Peaks: EA=ellagic acid; CHA= chlorogenic acid;

DP1=degradation product of CHA; CA=caffeic acid;

DP2=degradation product of CA; FA=ferulic acid

and DP3=degradation product of FA.

3.2. Linearity and Assay precision

Our results were validated in terms of linearity

and precision. Excellent linearty was obtained over

the range 1~200 ug / ml for all compounds except

EA for which the range was 5~200 ug / ml. The

coefficients were all above 0.998. The precision (CV)

was between 0.9~ 4.5. The minimum detectable

limits, calculated as greater than three times the

baseline noise level in the assay, were below 0.02 ug /

ml for all the phenolic compounds.

3.3. Recovery study

It was necessary to evaluate the influence of the

different solvent on the recovery of the four phenolic

compounds. Table 2 summarizes recovery of the four

phenolic compounds in the o/w emulsion when they

Miaw Lin Chang Chur Min Chang 95 - -

were treated with tetrahydrogenfuran (THF ),

menthanol (MeOH ) and ethanol ( EtOH ) as the

extraction solvents, respectively. It was found that at

the low and high concentrations their recoveries were

at a range of 68.5~102.3 % with regard to different

kinds of solvents and the coefficients of variance

calculated from three replicates were all less than 8.0

%. However, some problems would occur when using

EtOH or THF as extraction solvent. In the use of THF,

the interference peak was observed and results in

wide broad peak by which the peak of the tested

analytes were overlapped. Regarding the use of EtOH,

there were low recovery and the ease of filtration is

troublesome. As a consequence, an accepted recovery

for all the four analytes and no matrix interference

were observed in the use of MeOH. Therefore,

MeOH is a suitable choice as solvent for the

treatment of cosmetic samples.

Table 2 Recovery of the phenolic compounds in o/w

emulsion using various extraction solvents

Compound

AmountsA

dded

(w/w%)

MeOH EtOH THF

Recovery CV Recovery CV Recovery CV

EA 0.25 96.3 2.3% 68.5 3.4% 80.3 5.2%

2.50 94.5 1.5% 70.5 2.8% 85.9 6.9%

FA 0.25 96.8 1.2% 82.1 2.6% 87.8 4.6%

2.50 97.5 0.7% 80.6 3.1% 79.1 8.0%

CA 0.25 102.3 1.8% 83.2 2.8% 82.8 5.8%

2.50 100.5 2.1% 81.9 3.2% 92.4 6.9%

CHA 0.25 98.6 1.6% 69.4 2.6% 83.2 7.2%

2.50 97.3 1.9% 71.8 1.6% 91.6 6.7%

3.4. Stability study

Due to photo unstable property, the phenolic

compounds present in cosmetic products would

greatly influence the effectiveness and the safety of

final products. Hence, using them as UV-protector in

emulsions will exhibit less UV-protecting capacity

due to isomerization. Therefore, it is important to

know if any degradation or isomerization occurs in

phenolics-containing emulsions. Although many

reports on decomposition and isomerization of

phenolic compounds in solution following the

elevated temperature or UV irradiation have been

issued, there is little documentation related to their

chemical stability in cosmetic emulsions upon

sunlight exposure. We present the isocratic HPLC

method that simultaneously determines the different

amounts of the four phenolic compounds both in

solvent and o/w emulsion during exposing them to

the sunlight. As the mention above, only four

separated peaks for the four phenolic compounds in

methanol are observed in Figure 2(a), indicating no

degradation to occur in the dark. When compared to

Fig 2(a), three extra peaks appear in figure 2(b) under

sunlight exposure. After confirmed alone, the three

extra peaks are degradation product of CHA, CA and

FA. It is obvious that only EA did not undergo

degradation either in methanol or in emulsion upon

exposed to sunlight. The difference in stability can be

attributed to their different molecular structure.

Unlike CA or CHA or FA, EA does not include

double bond having the ability of isomerzation in its

molecular structure. That is the reason why EAs

degradation product is not found. Based on the

findings, we deduce that these extra peaks should be

degradation products resulted from isomerzation of

phenolic compounds upon sunlight exposure. Table 3

summarizes the degradation of the four tested

compounds as a single one in methanol. The

degradation was observed in the samples as a

decrease in the level of the active component or as an

increase in the level of degradation product. The

unidentified degradation product, ispresented as the

Determination of four lipophilic phenolics in o/w emulsions as well as their stability

96 - -

ratio of A

D.P

and A

Ph

and is expressed as a percentage:

%A=A

D.P.

/A

Ph

100%, where A

D.P

is area of the

degradation product peak and A

Ph

is area of its

phenolic compound peak. The more the degradation

is, the less the stability. Table 3 showed that among

these phenolic compounds EA has the most stable

behavior without any degradation product. In contrast,

after 28 days sunlight exposure CHA is worse- its

concentration was decreased by up to 24.1% of the

initial concentration, and its degradation product

increases rapidly in peak area with time, up to 17.7%

of area ratio. In addition, Figure 3 and Figure 4

illustrate the degree of phenolics degradation in

methanol and emulsion, respectively. Degradation

extent of each of the assayed phenolic compounds,

either alone (Figure 3(a), Figure 4(a)) or a

combination (Figure 3(b), Figure 4(b)), was

represented as percent remaining,

[Pheno]

mt

/ [Pheno]

m

o 100%, where [Pheno]

mt

is

the measured concentration of phenolics at any time,

t. and [Pheno]

mo

is the concentration of phenolics at

initial time, t =0. All the cases, EA is among the most

stable phenolic compounds with no change in

amounts during the study period, but it has a smaller

recovery than the other assayed phenolic compounds

(table 2). The stability profile of EA in emulsions is

similar to that of EA present in natural fruits and nuts

published by Daniel, Elaine M and his coworkers

(21)

.

The rest of them are in different decline because the

percent remaining decrease with time. Importantly,

FA, CHA, and CA, have a better stability in emulsion

than in methanol solvent whenever they exist as a

single one or a combination. By comparing Figure

3(a) with Figure 4(a) at 28 days sunlight exposure,

the percent remaining of CHA, CA, and FA in

methanol solvent drop to 77%, 78%, and 83%,

respectively, but be maintained on 82%, 85% and

90% in emulsion (C, D E), respectively. Moreover,

by comparing Figure 3(b) with Figure 4(b), it is clear

that the percent remaining of FA, CHA, and CA in

emulsion do increases, too. Especially, CA and FA in

emulsion F reach to a high level of 95% and 93%,

respectively. In summarizes, these results suggest that

emulsions seem to provide an environment protecting

them from a rapid degradation induced by exposed to

sunlight. This could be attributed to the less

concentration of oxygen in the media of emulsions or

the less radiation-dose due to the sunlight absorbed

by the excipients in emulsions.

On the other hand, stability of CA is different

from that of CHA and FA. An improvement in

stability of CA could be achieved easily by

combination with other phenolic compounds, but not

for FA and CHA. For example, Figure 3(a) showed

that when existed as alone in solvent 28 days sunlight

exposure, CA drop to 82%, but existed as a

combination in solvent (Figure 3(b)), it is maintained

on 86%. Moreover, as shown in Figure 4(a) and

Figure 4(b), CA in emulsion F also exhibited also

higher percent remaining (95%) than in emulsion E

(85%). In other words, in the presence of FA and

CHA and EA can markedly improve stability of CA.

Some reports on stability study of antioxidants have

been issued. Lin, Fu-Hsiung and his coworkers have

reported on the increasing stability of antioxidants

vitamins (C +E) by combination with Ferulic acid

(22 )

and A.Segall and his colleagues have studied stability

of lipoic acid in the presence of vitamins A and E

(23)

.

Unlike CA, percent remaining of FA in emulsion F do

not change much, when compared to that in emulsion

E over time. However, stability of CHA is different

from FA. At the beginning CHA in emulsion F

exhibited slighter decline than in emulsion C, but 21

days after sunlight exposure the degree of CHA

decline in emulsion F and in emulsion C stay the

same.

Miaw Lin Chang Chur Min Chang 97 - -

Table 3 Stability of phenolic compound as a single

one in solvent upon sunlight exposure

Time FA D.P. EA D.P. CA D.P. CHA D.P.

(days) (ppm) (%A) (ppm) (%A) (ppm) (%A) (ppm) (%A)

0 100.31.2 0 99.51.5 0 100.02.1 0 99.91.6 0

1 99.81.4 1.0 99.91.6 0 100.21.8 0.8 95.61.8 5.0

7 97.21.9 2.7 100.11.3 0 98.31.9 2.3 91.81.2 9.3

14 93.91.7 4.8 100.11.2 0 95.72.2 4.0 88.01.7 12.3

21 88.11.7 6.8 99.81.9 0 90.41.5 5.4 84.21.1 15.2

28 78.12.1 10.3 100.01.9 0 81.91.5 7.8 75.91.1 17.7

*

Thedataisapercentageof theratio of thepeak of degradationproduct to phenolic compound: % A

=AD.P./APh 100%

Time (Day)

0 5 10 15 20 25 30

[

A

]

m

/

[

A

]

i

x

1

0

0

%

70

75

80

85

90

95

100

105

(a)

Time (Day)

0 5 10 15 20 25 30

[

A

]

m

/

[

A

i x

1

0

0

%

70

75

80

85

90

95

100

105

(b)

Figure 3. In methanol solvent stability change of the

four tested phenolic compounds, as (a)

individual single one and (b) a combination.

Measurement was performed at time, t=0, 1,

7, 14, 21, and 28 days after sunlight

exposure

Time (Day)

0 5 10 15 20 25 30

70

80

90

100

110

[

A

]

m

/

[

A

]

i

x

1

0

0

%

(a)

Time (Day)

0 5 10 15 20 25 30

70

80

90

100

110

[

A

]

m

/

[

A

]

i x

1

0

0

%

(b)

Figure4. In o/w emulsion stability change of the four

tested phenolic compounds, (a) as individual

single one (emulsion B-E) and (b) as a

combination (emulsion F). Measurement

was performed at time, t=0, 1, 7, 14, 21, and

28 days after sunlight exposure

4. Conclusion

In the stability studies, the phenolic compounds

contained in either solution or an emulsion exhibit

much less stability under sunlight exposure than

under dark condition. Obviously, this is due to the

Determination of four lipophilic phenolics in o/w emulsions as well as their stability

98 - -

occurrence of photo-degradation under sunlight

exposure. It seems that molecule itself and the types

of media can impact on their stability. In all cases, for

example, EA dose not occur degradation due to the

lack of double bond to result in isomerization,

maintaining the most stability under even sunlight

exposure. Based on this finding, when cosmetics

need for single phenolic agent to optimize their

effectiveness, EA will be the first selected phenolic

compound for gaining more effective cosmetics. In

addition, we found that it is easy to improve stability

of CA using combination with FA and CHA and EA.

However, further research on the stability of the

phenolic compounds by any combination of two or

more phenolic compounds is required to acquire

whole acknowledge about what the stability of

phenolic compounds in various combinations is

different. A right combination of phenolic compounds

should be incorporated into functional cosmetic

emulsions to optimize their efficacy and to give them

longer shelf life. And cosmetic emulsions including

phenolic compounds do shield from sunlight during

the production, too. Then the selected containers for

packing cosmetic emulsions with active phenolic

compounds must have the ability to protect them

from degradation. Importantly, the HPLC assay

developed is simple, rapid and convenient method. It

can accurately quantify the four phenolic compounds

in different types of media and ensure the quality

control.

Acknowledgements

The authors would like to thank CNCS for financial

support of the research. We are grateful to of Dr.

Ginger Lee for her deep and broad knowledge and

technical support.

References

1. Guang-Hua Lu, Kelvin Chan, Kelvin Leung,

Chi-Leung Chan, Zhong-Zhen Zhao, Zhi-Hong

J iang. 1996. Assay of free ferulic acid and total

ferulic acid for quality assessment of Angelica

sinensis. J ournal of Chromatography A

1068(2005)209-219.

2. Lanzani, A.; Cardillo, M.; Fedeli, E. 1979. Study

on the antioxidant ability of chlorogenic acid

isolated from sunflower seed. Rivista Italiana

delle Sostanze Grasse 57(7), 273-5.

3. Eggensperger, Heinz; Wilker, M.1996.

Multiactivity of gerulic acid and its esters in

cosmetics. Part 2. SOFW J ournal 122(4), 210, 212,

215.

4. Chikuno, Takao; Dato, Hiroshi; Kadota, Megumi.

2005. Skin external use medicine for beauty

white. J pn.Kokai Tokkyo Koho 10 pp.

5. Facino R M; Carini M; Aldini G; Saibene L; Pietta

P; Mauri P. 1995. Echinacoside and caffeoyl

conjugates protect collagen from free

radical-induced degradation: a potential use of

Echinacea extracts in the prevention of skin

photodamage. Planta medica 61(6), 510-4

6. Smith, Wendy A.; Gupta, Ramesh C.1996. Use of a

microsome-mediated test system to assess

efficacy and mechanisms of cancer

chemopreventive agents, Carcinogenesis 17(6),

1285-1290.

7. Ping-Bo, Ma. 2002. Promotion of ferulic acid

transdermal absorption by water-soluble

azone in Shengfaling tincture. Diyi J unyl Daxue

Xuebao 22(1), 56-58.

8. Vanessa V. da Silva, Cristina D. Ropke, Rebeca

L.de Almeida, Denise V. Miranda, Clarissa Z. Kera,

Diogo P. Rivelli, Tania C.H. Sawada, Silvia B.M.

Barros 2005. Chemical stability and SPF

determination of Pothomorphe umbellate

extract gel and photostability of 4-

nerolidycathecol. International J ournal of

Pharmaceutics 303, 125-131.

Miaw Lin Chang Chur Min Chang 99 - -

9. Shimogaki,H.; Tanaka, Y.; Tamai, H.; Nasuda, M.

2000. In vitro and in vivo evaluation of ellagic

acid on melanogenesis inhibition. International

J ournal of Cosmetic Science 22(4), 291-303.

10. M. Turkoglu and N.Cigirgil, 2007. Evaluation of

black tea gel and its protection potential

against UV. International J ournal of Cosmetic

Science 29, 437-442.

11. Lorant, Bela., 1968. Thermal degradation of

coffee and cocoa constituents of interest to food

chemistry, Nahrung 12(4), 351-6.

12. Ding Mingyu, Ma Shuaiwu, Liu Delin. 2004.

Stability of ferulic acid and its existing form in

Ligusticum chuanxiong and Angelica sinensis.

Zhongcaoyao 35(1), 28-30.

13. Antolovich, Michael; Bedgood, Danny R.,J u.;

Bishop, ndrea G..; J ardine, Daniel; Prenzler, Paul

D.; Robards, Kevin, 2004. LC-MS Investigation

of Oxidation Products of Phenolic Antioxidants.

J ournal of Agricultural and Food Chemistry

52(4), 962-971.

14. Paola Perugini, Manuela Vettor, Rosanna Tursilli,

Santo Scalia, Ida Genta, Tiziana Modena, Franca

Pavanetto, Bice Conti. 2005 Technological

strabegies to improve photostability of a

sunscreen agent. J .Appl. Cosmetol. 23,59-69

15. S. Pattanaaargson and P. Limphong, 2001.

Stability of octyl methoxycinnamate and

identification of its photo-degradation product.

International J ournal of Cosmetic Science 23,

153-160.

16. Oszmianski, J an; Chang Y.,Lee, 1990. Enzymic

oxidative reaction of catechin and chlorogenic

acid in a model system. J ournal of Agricultural

and Food Chemistry 38(50), 1202-4.

17. Chen, Gang; Shixiang, Hou; Ping, Hu; Ning, He;

Yaning, Zhu; Lun, Cao. 2003. Studies on

stability of chlorogenic acid in extract of flos

Ionicerae. Zhongguo Zhongyao Zazhi 28(3),

223-226.

18. Friedman, Mendei; Juergens, Hella S., 2000.

Effect of pH on the Stability of Plant Phenolic

Compounds. J ournal of Agricultural and Food

Chemistry 48(6), 2101-2110.

19. Lorant, Bela., 1968. Thermal degradation of

coffee and cocoa constituents of interest to

food chemistry, Nahrung 12(4), 351-6.

20. Boles, J ennifer Snow; Crerar, David A.; Grissom,

Grady; Key, Tonalee C., 1988. Aqueous thermal

degradation of gallic acid. Geochimical et

Cosmochimica Acta 52(2), 341-4.

21.Daniel, Elaine M.; Krupnick, Alexander S.; Hiur,

Toung Hun; Blinzler, J ane A.; Nims, Raymond W.;

Stoner, Gary D.,1989. Extraction, stability, and

quantitation of ellagic acid in various fruits

and nuts. J ournal of Food Composition and

Analysis 2(4), 338-49.

22.Lin, Fu-Hsiung; Lin, J ing-Yi; Gupta, Ravindra D.;

Tournas, J oshua A.; Burch, J ames A.; Selim, M.

Angelica; Monteiro-Riviere, Nancy A.; Grichnik,

J ames M.; Zielinski, J an; Pinnell, Sheldon R.

2005. Ferulic acid stabilizes a solution of

vitamins C and E and doubles its

photoprotection of skin. Journal of Investigative

Dermatology 125(4), 826-832.

23.A. Segall, M.Sosa, A. Alami, C.Enero, F.

Hormaechea, M.T.Pizzzorno, C. Bergni, and R.

Serrao, 2004. Stability study of lipoic acid in

the presence of vitamins A and E in o/w

emulsions for cosmetic application. J . Cosmet.

Sci., 55, 449-461.

Determination of four lipophilic phenolics in o/w emulsions as well as their stability

100 - -

O/W

1

2

*

1

2

-Ellagic acid(EA)Ferulic acid(FA)Caffeic acid(CA) Chlorogenic acid(CHA)

EA

;CHA FACHA

EA CA

*:

Tel:+886-6-2664911Ext2304

Fax:+886-6-2667219

E-mail: jchurmin@mail.chna.edu.tw

CHIA-NAN ANNUAL BULLETIN

V O L . 3 8 , P P . 9 1 - 1 0 1 , 2 0 1 2

You might also like

- Stability of Vitamin A in Oil in Water in Oil TypeDocument7 pagesStability of Vitamin A in Oil in Water in Oil TypeMuhammad Akbar SusenoNo ratings yet

- Preparation and Evaluation of Azelaic Acid TopicalDocument8 pagesPreparation and Evaluation of Azelaic Acid TopicalGourav SainNo ratings yet

- Mohamed, 2004, Optimization of Chlorphenesin Emulgel FormulationDocument7 pagesMohamed, 2004, Optimization of Chlorphenesin Emulgel FormulationDevrat Rizkiawan WicaksonoNo ratings yet

- Bono Li 2003Document10 pagesBono Li 2003Jorge RomeroNo ratings yet

- 5 Effects of Monoacylglycerols On The Oil Oxidation of Acidic Water Perilla Oil Emulsion Under Light in The Presence of Chlorophyll (7p)Document7 pages5 Effects of Monoacylglycerols On The Oil Oxidation of Acidic Water Perilla Oil Emulsion Under Light in The Presence of Chlorophyll (7p)Linh PhamNo ratings yet

- Antioxidant Activity of Ethanolic Extract of Mustard SeedDocument3 pagesAntioxidant Activity of Ethanolic Extract of Mustard SeedLilia RotariNo ratings yet

- Formulation and Evaluation of Benzyl Benzoate EmulgelDocument4 pagesFormulation and Evaluation of Benzyl Benzoate EmulgelIOSRjournalNo ratings yet

- Skin Moisturizing Effects of Panthenol Based FormulationsDocument10 pagesSkin Moisturizing Effects of Panthenol Based FormulationsYudha Amandangi SyahputeraNo ratings yet

- Some Physico-Chemical Properties of Red Fruit Oil (Pandanus Conoideus Lam) From Hexane and Chloroform FractionsDocument5 pagesSome Physico-Chemical Properties of Red Fruit Oil (Pandanus Conoideus Lam) From Hexane and Chloroform FractionsDevy AndikaNo ratings yet

- Archive of SID: Total Phenolic Contents and Antioxidant Activity of Pomegranate (Punica Granatum L.) Peel ExtractsDocument7 pagesArchive of SID: Total Phenolic Contents and Antioxidant Activity of Pomegranate (Punica Granatum L.) Peel ExtractsVida Faith GalvezNo ratings yet

- Sensory Testing For Powder - Ref 2Document8 pagesSensory Testing For Powder - Ref 2a.guptaNo ratings yet

- Extractionand Formulationof Oilin Water 2761 EAP1120136Document7 pagesExtractionand Formulationof Oilin Water 2761 EAP1120136ahedhashasheNo ratings yet

- Article WJPR 1461924337Document9 pagesArticle WJPR 1461924337saras unggulNo ratings yet

- Fast and sensitive high performance liquid chromatography analysis of cosmetic creams for hydroquinone, phenol and six preservatives Wenhui Gaoa, Cristina Legido-Quigleyb,∗ a College of Biological Science and Engineering, Hebei University of Science and Technology, Shijiazhuang 050018, China b Institute of Pharmaceutical Science, School of Biomedical and Health Sciences, King’s College London, United KingdomDocument5 pagesFast and sensitive high performance liquid chromatography analysis of cosmetic creams for hydroquinone, phenol and six preservatives Wenhui Gaoa, Cristina Legido-Quigleyb,∗ a College of Biological Science and Engineering, Hebei University of Science and Technology, Shijiazhuang 050018, China b Institute of Pharmaceutical Science, School of Biomedical and Health Sciences, King’s College London, United KingdomTatjana BrankovićNo ratings yet

- 51LB Exp1 W11Document4 pages51LB Exp1 W11KeVin Dean LimNo ratings yet

- Phenolic and Antioxidant Potential of Olive Oil Mill WastesDocument7 pagesPhenolic and Antioxidant Potential of Olive Oil Mill WastesIeqa HaziqahNo ratings yet

- Alfa Tokoferol PDFDocument16 pagesAlfa Tokoferol PDFHadijahhNo ratings yet

- Determination of Phenolic Acids in Fruit Juices by Isocratic Column Liquid ChromatographyDocument6 pagesDetermination of Phenolic Acids in Fruit Juices by Isocratic Column Liquid ChromatographycsandrasNo ratings yet

- Application of Ftir For The Characterisation of Sustainable Cosmetics and Ingredients With Antioxidant PotentialDocument9 pagesApplication of Ftir For The Characterisation of Sustainable Cosmetics and Ingredients With Antioxidant PotentialChiper Zaharia DanielaNo ratings yet

- Synergistic Effects of Ascorbyl Palmitate and Sodium Ascorbyl Phosphate Loaded in Multiple Emulsions On Facial Skin Melanin and ErDocument7 pagesSynergistic Effects of Ascorbyl Palmitate and Sodium Ascorbyl Phosphate Loaded in Multiple Emulsions On Facial Skin Melanin and ErDoinaNo ratings yet

- Comparative Study of Different Formulations of Aceclofenac As A Topical Drug Delivery System and It'S in Vitro and in Vivo CharacterizationDocument8 pagesComparative Study of Different Formulations of Aceclofenac As A Topical Drug Delivery System and It'S in Vitro and in Vivo Characterizationrizki lisya nugrahaNo ratings yet

- Pharmaceutical ExcipientsDocument19 pagesPharmaceutical ExcipientsTikaUlamNo ratings yet

- Antioxidants: Phenolic Profile and Antioxidant Activity of Italian Monovarietal Extra Virgin Olive OilsDocument14 pagesAntioxidants: Phenolic Profile and Antioxidant Activity of Italian Monovarietal Extra Virgin Olive OilsDina BougandouraNo ratings yet

- 1356-Article Text-7207-2-10-20140805Document5 pages1356-Article Text-7207-2-10-20140805safrinpujiNo ratings yet

- 10.1016@s0378 51730000521 4Document14 pages10.1016@s0378 51730000521 4CoNo ratings yet

- Antioxidant Activity of Seaweed Extracts in VitroDocument17 pagesAntioxidant Activity of Seaweed Extracts in VitroMoisés Nehémias HernandezNo ratings yet

- Endang Wahyu - Formulation and Physical Stability Test of Oleanolic Acid Cream and GelDocument19 pagesEndang Wahyu - Formulation and Physical Stability Test of Oleanolic Acid Cream and GelJEAN GEMNo ratings yet

- Chen12-Flavonoid-Shift ReagentsDocument26 pagesChen12-Flavonoid-Shift ReagentsMarvinNo ratings yet

- The Olive Oil Oxygen Radical Absorbance Capacity (DPPH Assay) As A Quality IndicatorDocument8 pagesThe Olive Oil Oxygen Radical Absorbance Capacity (DPPH Assay) As A Quality IndicatorSoulef ZemzoumNo ratings yet

- Molecules: Development of Water-in-Oil Emulsions As Delivery Vehicles and Testing With A Natural Antimicrobial ExtractDocument15 pagesMolecules: Development of Water-in-Oil Emulsions As Delivery Vehicles and Testing With A Natural Antimicrobial ExtractKing in The northNo ratings yet

- Stabilization of Ferulic Acid in Topical Gel Formulation Via Nanoencapsulation and PH OptimizationDocument18 pagesStabilization of Ferulic Acid in Topical Gel Formulation Via Nanoencapsulation and PH Optimizationelang revyNo ratings yet

- FlavocillinspecificationDocument12 pagesFlavocillinspecificationjeyiy92174No ratings yet

- Effect of Degumming Process On Physicochemical Properties of Sunflower Oil-Lamas y Col 2016Document6 pagesEffect of Degumming Process On Physicochemical Properties of Sunflower Oil-Lamas y Col 2016eugeniaNo ratings yet

- Formulation and Evaluation of Multiple Emulation of Diclofenac SodiumDocument7 pagesFormulation and Evaluation of Multiple Emulation of Diclofenac SodiumIJRASETPublicationsNo ratings yet

- Utilisation of Red Palm Olein in Formulating Functional Chocolate SpreadDocument6 pagesUtilisation of Red Palm Olein in Formulating Functional Chocolate SpreadRod LopNo ratings yet

- Papadopoulos1991 PDFDocument3 pagesPapadopoulos1991 PDFMarta MichiNo ratings yet

- Preparation of W/O/W Multiple Emulsions With Polymers in The Outer Aqueous PhaseDocument6 pagesPreparation of W/O/W Multiple Emulsions With Polymers in The Outer Aqueous Phasepayam102No ratings yet

- Antiulcerative Properties of Crude Polyphenols and Juice of Apple, and Chinese Quince ExtractsDocument21 pagesAntiulcerative Properties of Crude Polyphenols and Juice of Apple, and Chinese Quince ExtractsLoredana Veronica ZalischiNo ratings yet

- 10 1088@1757-899X@523@1@012011Document7 pages10 1088@1757-899X@523@1@012011Monyet...No ratings yet

- Khalid 2013Document7 pagesKhalid 2013ionut ivanNo ratings yet

- Carrasco-Pancorbo 2005-Review PDFDocument22 pagesCarrasco-Pancorbo 2005-Review PDFRodrigo PinheiroNo ratings yet

- 7.formulation and Evaluation of Lycopene Emulgel PDFDocument15 pages7.formulation and Evaluation of Lycopene Emulgel PDFYuppie RajNo ratings yet

- Emulan PDocument1 pageEmulan ParguijNo ratings yet

- Kinetic Study of The in Vitro Release andDocument24 pagesKinetic Study of The in Vitro Release andEpha Lumban GaolNo ratings yet

- 13918PDF PDFDocument5 pages13918PDF PDFSiti SyahirahNo ratings yet

- Uji Stabilitas Formula Krim Tabir Surya EKSTRAK UMBI BAWANG DAYAK (Eleutherine Americana L. Merr.)Document7 pagesUji Stabilitas Formula Krim Tabir Surya EKSTRAK UMBI BAWANG DAYAK (Eleutherine Americana L. Merr.)Firda AndiNo ratings yet

- Determination of Marked Components - Aloin and Aloe-Emodin - in Aloe Vera Before and After HydrolysisDocument7 pagesDetermination of Marked Components - Aloin and Aloe-Emodin - in Aloe Vera Before and After Hydrolysisdotcomg007No ratings yet

- Cap EsiDocument12 pagesCap EsiducngoctrinhNo ratings yet

- Phenoxy Ethanol Safety AssesmentDocument19 pagesPhenoxy Ethanol Safety AssesmentsahilNo ratings yet

- Cosmetic Vite hplc-4 PDFDocument14 pagesCosmetic Vite hplc-4 PDFZahiroh Maulida A NNo ratings yet

- Multiple Emulsions Containing Amazon OilDocument7 pagesMultiple Emulsions Containing Amazon OilGabriela CavalcantiNo ratings yet

- CONICET Digital Nro.7cc5afb8 1375 4b75 b937 F2be2eec9ac6 SDocument10 pagesCONICET Digital Nro.7cc5afb8 1375 4b75 b937 F2be2eec9ac6 SRey MuhamadNo ratings yet

- Stability Studies of New Cosmetic Formulations With VegetableDocument5 pagesStability Studies of New Cosmetic Formulations With VegetableClaudia SouzaNo ratings yet

- Phenolic Profile and Antioxidant ActivitDocument7 pagesPhenolic Profile and Antioxidant ActivithocineNo ratings yet

- Boon Chiang Ma 2009Document13 pagesBoon Chiang Ma 2009Nguyễn QuangNo ratings yet

- 2005 - Masmoudi Et Al. - The Evaluation of Cosmetic and Pharmaceutical Emulsions Aging Process Using Classical Techniques and A New Method FTIRDocument15 pages2005 - Masmoudi Et Al. - The Evaluation of Cosmetic and Pharmaceutical Emulsions Aging Process Using Classical Techniques and A New Method FTIRymiyazyNo ratings yet

- Foods-02-00018 - Phenolic Extracts From Wild Olive Leaves and Their Potential As Edible Oils AntioxidantsDocument14 pagesFoods-02-00018 - Phenolic Extracts From Wild Olive Leaves and Their Potential As Edible Oils AntioxidantsDiego MattarocciNo ratings yet

- Anggun-Neni-Dadan FORMULATION AND EVALUATION OF SHEET MASK FROM RED RICEDocument6 pagesAnggun-Neni-Dadan FORMULATION AND EVALUATION OF SHEET MASK FROM RED RICENeni Sri GunartiNo ratings yet

- Teknologi Farmasi Steril: Najma Annuria Fithri Universitas Sriwijaya Ganjil 2014/2015Document22 pagesTeknologi Farmasi Steril: Najma Annuria Fithri Universitas Sriwijaya Ganjil 2014/2015Niluh Komang Tri AndyaniNo ratings yet

- Tugas 1 FPEDocument4 pagesTugas 1 FPENiluh Komang Tri AndyaniNo ratings yet

- Tugas 1 FPEDocument4 pagesTugas 1 FPENiluh Komang Tri AndyaniNo ratings yet

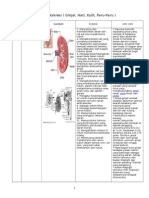

- System Ekskresi (Ginjal, Hati, Kulit, Paru-Paru) : Suprarenal)Document5 pagesSystem Ekskresi (Ginjal, Hati, Kulit, Paru-Paru) : Suprarenal)Niluh Komang Tri AndyaniNo ratings yet

- FIRE FIGHTING ROBOT (Mini Project)Document21 pagesFIRE FIGHTING ROBOT (Mini Project)Hisham Kunjumuhammed100% (2)

- Environmental Auditing For Building Construction: Energy and Air Pollution Indices For Building MaterialsDocument8 pagesEnvironmental Auditing For Building Construction: Energy and Air Pollution Indices For Building MaterialsAhmad Zubair Hj YahayaNo ratings yet

- Brochure Ref 670Document4 pagesBrochure Ref 670veerabossNo ratings yet

- QUIZ Group 1 Answer KeyDocument3 pagesQUIZ Group 1 Answer KeyJames MercadoNo ratings yet

- HealthInsuranceCertificate-Group CPGDHAB303500662021Document2 pagesHealthInsuranceCertificate-Group CPGDHAB303500662021Ruban JebaduraiNo ratings yet

- Pneumatic Fly Ash Conveying0 PDFDocument1 pagePneumatic Fly Ash Conveying0 PDFnjc6151No ratings yet

- PLT Lecture NotesDocument5 pagesPLT Lecture NotesRamzi AbdochNo ratings yet

- Form Three Physics Handbook-1Document94 pagesForm Three Physics Handbook-1Kisaka G100% (1)

- DC Servo MotorDocument6 pagesDC Servo MotortaindiNo ratings yet

- Mat Boundary Spring Generator With KX Ky KZ KMX KMy KMZDocument3 pagesMat Boundary Spring Generator With KX Ky KZ KMX KMy KMZcesar rodriguezNo ratings yet

- Apm p5 Course NotesDocument267 pagesApm p5 Course NotesMusumbulwe Sue MambweNo ratings yet

- CDKR Web v0.2rcDocument3 pagesCDKR Web v0.2rcAGUSTIN SEVERINONo ratings yet

- Section 26 08 13 - Electrical Systems Prefunctional Checklists and Start-UpsDocument27 pagesSection 26 08 13 - Electrical Systems Prefunctional Checklists and Start-UpsMhya Thu UlunNo ratings yet

- Engine Diesel PerfomanceDocument32 pagesEngine Diesel PerfomancerizalNo ratings yet

- Weekly Learning PlanDocument2 pagesWeekly Learning PlanJunrick DalaguitNo ratings yet

- Introduce Letter - CV IDS (Company Profile)Document13 pagesIntroduce Letter - CV IDS (Company Profile)katnissNo ratings yet

- CI Principles of EconomicsDocument833 pagesCI Principles of EconomicsJamieNo ratings yet

- Dike Calculation Sheet eDocument2 pagesDike Calculation Sheet eSaravanan Ganesan100% (1)

- Microwave Drying of Gelatin Membranes and Dried Product Properties CharacterizationDocument28 pagesMicrowave Drying of Gelatin Membranes and Dried Product Properties CharacterizationDominico Delven YapinskiNo ratings yet

- The Internal Environment: Resources, Capabilities, Competencies, and Competitive AdvantageDocument5 pagesThe Internal Environment: Resources, Capabilities, Competencies, and Competitive AdvantageHenny ZahranyNo ratings yet

- Asphalt Plant Technical SpecificationsDocument5 pagesAsphalt Plant Technical SpecificationsEljoy AgsamosamNo ratings yet

- Difference Between Mountain Bike and BMXDocument3 pagesDifference Between Mountain Bike and BMXShakirNo ratings yet

- Methodical Pointing For Work of Students On Practical EmploymentDocument32 pagesMethodical Pointing For Work of Students On Practical EmploymentVidhu YadavNo ratings yet

- A Review Paper On Improvement of Impeller Design A Centrifugal Pump Using FEM and CFDDocument3 pagesA Review Paper On Improvement of Impeller Design A Centrifugal Pump Using FEM and CFDIJIRSTNo ratings yet

- Functions of Commercial Banks: Primary and Secondary FunctionsDocument3 pagesFunctions of Commercial Banks: Primary and Secondary FunctionsPavan Kumar SuralaNo ratings yet

- Cabling and Connection System PDFDocument16 pagesCabling and Connection System PDFLyndryl ProvidoNo ratings yet

- Expectation Vs Reality: Job Order and Contract of ServiceDocument10 pagesExpectation Vs Reality: Job Order and Contract of ServiceMikee Louise MirasolNo ratings yet

- MMC Pipe Inspection RobotDocument2 pagesMMC Pipe Inspection RobotSharad Agrawal0% (1)

- Ces Presentation 08 23 23Document13 pagesCes Presentation 08 23 23api-317062486No ratings yet

- 4109 CPC For ExamDocument380 pages4109 CPC For ExamMMM-2012No ratings yet

- The Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactFrom EverandThe Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactRating: 5 out of 5 stars5/5 (5)

- It's Elemental: The Hidden Chemistry in EverythingFrom EverandIt's Elemental: The Hidden Chemistry in EverythingRating: 4 out of 5 stars4/5 (10)

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincFrom EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincRating: 3.5 out of 5 stars3.5/5 (137)

- AP® Chemistry Crash Course, For the 2020 Exam, Book + Online: Get a Higher Score in Less TimeFrom EverandAP® Chemistry Crash Course, For the 2020 Exam, Book + Online: Get a Higher Score in Less TimeRating: 5 out of 5 stars5/5 (1)

- Taste: Surprising Stories and Science About Why Food Tastes GoodFrom EverandTaste: Surprising Stories and Science About Why Food Tastes GoodRating: 3 out of 5 stars3/5 (20)

- Guidelines for Defining Process Safety Competency RequirementsFrom EverandGuidelines for Defining Process Safety Competency RequirementsRating: 3 out of 5 stars3/5 (1)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeFrom EverandChemistry for Breakfast: The Amazing Science of Everyday LifeRating: 4.5 out of 5 stars4.5/5 (14)

- The Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactFrom EverandThe Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactRating: 5 out of 5 stars5/5 (1)

- Monkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeFrom EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeRating: 4 out of 5 stars4/5 (1)

- Is That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeFrom EverandIs That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeRating: 5 out of 5 stars5/5 (4)

- Handbook of Formulating Dermal Applications: A Definitive Practical GuideFrom EverandHandbook of Formulating Dermal Applications: A Definitive Practical GuideNo ratings yet

- Chemistry for Breakfast: The Amazing Science of Everyday LifeFrom EverandChemistry for Breakfast: The Amazing Science of Everyday LifeRating: 4.5 out of 5 stars4.5/5 (90)

- AP Chemistry Flashcards, Fourth Edition: Up-to-Date Review and PracticeFrom EverandAP Chemistry Flashcards, Fourth Edition: Up-to-Date Review and PracticeNo ratings yet

- Formulating, Packaging, and Marketing of Natural Cosmetic ProductsFrom EverandFormulating, Packaging, and Marketing of Natural Cosmetic ProductsNo ratings yet

- The Periodic Table: A Very Short IntroductionFrom EverandThe Periodic Table: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (3)

- Tribology: Friction and Wear of Engineering MaterialsFrom EverandTribology: Friction and Wear of Engineering MaterialsRating: 5 out of 5 stars5/5 (1)

- Fundamentals of Chemistry: A Modern IntroductionFrom EverandFundamentals of Chemistry: A Modern IntroductionRating: 5 out of 5 stars5/5 (1)

- Guidelines for Integrating Process Safety into Engineering ProjectsFrom EverandGuidelines for Integrating Process Safety into Engineering ProjectsNo ratings yet

- Organic Chemistry for Schools: Advanced Level and Senior High SchoolFrom EverandOrganic Chemistry for Schools: Advanced Level and Senior High SchoolNo ratings yet

- The Billion-Dollar Molecule: The Quest for the Perfect DrugFrom EverandThe Billion-Dollar Molecule: The Quest for the Perfect DrugRating: 5 out of 5 stars5/5 (2)