Professional Documents

Culture Documents

Glass Fiber Manufacturing Is The High

Uploaded by

Maysara Maawia MukhtarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Glass Fiber Manufacturing Is The High

Uploaded by

Maysara Maawia MukhtarCopyright:

Available Formats

Fibre Forms

Fibres are combined with the polymer matrix in several forms,

depending on the properties desired in the material and the processing

method to be used to shape the composite. In some fabrication processes,

fibres are continuous, while in others they are chopped into short lengths.

In the continuous form, individual fibres are usually available as roving .

Rovings

A roving is a collection of untwisted (parallel) continuous strands,

which is a convenient form for handling and processing. Rovings

typically contain from 12 to 120 individual strands. By contrast, a yarn is

a twisted collection of filaments. Continuous rovings are used in several

polymeric composite processes including filament winding and

pultrusion .

Chopped Strands

Continuous rovings or yarns can be chopped into short lengths,

usually between 3mm 50mm long. Chopped strands are available with

different sizings for compatibility with most plastics, the amount and type

of size having a major influence on the integrity of the strand before and

after chopping. A strand of of high integrity is termed hard, and strand

which separates more easily soft. They can be used ina spray-up process,

where chopped strands are sprayed simultaneously with liquid polymer to

build reinforced parts on a mould. Chopped fibres are widely used as

reinforcement in the thermoplastic injection moulding industry. Chopped

glass may also be used as reinforcement in some thermosetting

applications, such as sheet and bulk moulding compounds .

Mats

A mat is a blanket of chopped strand or of continuous strands laid

down as a continuous thin flat sheet. The strands are evenly distributed in

a randon pattern, and are held together by adhesive resinous binders or

mechanically bound by needling. A chopped-strand mat is formed by

randomly depositing chopped fibres onto a belt or chain and binding them

with a chemical binder. Continuous-strand mat is formed in a similar

manner, but without chopping, and less binder is usually required because

of increased entanglement, which provides some inherent integrity. The

reinforcing ability of both types is essentially the same, but they have

different handling and moulding characteristics. Continuous-strand mat

can be moulded into more complicated shapes without tearing. Mats are

used in hand lay-up, press moulding, bag moulding, autoclave moulding,

and in various impregnating processes .

Woven Roving & Yarn

The most familiar forms of continuous fibres are woven rovings

and woven yarns, i.e., fabrics of rovings and yarns with various weave

patterns. Woven composites are finding increasing application since they

can be processed via injection moulding. The main advantages of woven

materials are that they retain some of their orthogonal properties when

draped over or in non-flat moulds. The weave also acts to enhance their

impact performance. There are several different patterns for the weave

including plain weave, which is the most highly interlaced; a basket

weave, which has warp and weft yarns that are paired up and satin

weaves. The last has a minimum of interlacing. The satin weaves are

produced in a standard four, five or eight-harness configuration. An eight-

harness configuration has a higher resistance to shear distortion than a

four harness weave. Woven roving reinforcements consist of flattened

bundles of continuous strands in a plain weave pattern with slightly more

material in the warp direction .

Common Weave Patterns include

a) box or plain weave

b) basket or twill weave

c) crowfoot or five-harness stain weave

d) long-shaft (satin) or eight-harness stain weave

e) leno weave

Glass fiber manufacturing is the high-temperature conversion of

various raw materials (predominantly borosilicate) into a homogeneous

melt, followed by the fabrication of this melt into glass fibers. The two

basic types of glass fiber products, textile and wool, are manufactured by

similar processes Glass fiber production can be segmented into three

phases: raw materials handling, glass melting and refining, and wool

glass fiber forming and finishing, this last phase being slightly different

for textile and wool glass fiber production.

Raw Materials Handling :

The primary component of glass fiber is sand, but it also includes

varying quantities of feldspar, sodium sulfate, anhydrous borax, boric

acid, and many other materials. The bulk supplies are received by rail car

and truck, and the lesser-volume supplies are received in drums and

packages.

These raw materials are unloaded by a variety of methods, including drag

shovels, vacuum systems, and vibrator/gravity systems. Conveying to and

from storage piles and silos is accomplished by belts, screws, and bucket

elevators. From storage, the materials are weighed according to the

desired

product recipe and then blended well before their introduction into the

melting unit. The weighing, mixing, and charging operations may be

conducted in either batch or continuous mode.

Glass melting and refining :

In the glass melting furnace, the raw materials are heated to temperatures

rangin g from 1500 to 1700C (2700 to 3100F) and are transformed

through a sequence of chemical reactions to molten glass. Although there

are many furnace designs, furnaces are generally large, shallow, and well-

insulated vessels that are heated from above. In operation, raw materials

are introduced continuously on top of a bed of molten glass, where they

slowly mix and dissolve. Mixing is effected by natural convection, gases

rising from chemical reactions, and, in some operations, by air injection

into the bottom of the bed.

Glass melting furnaces can be categorized by their fuel source and

method of heat application into 4 types: recuperative, regenerative, unit,

and electric melter. The recuperative, regenerative, and unit melter

furnaces can be fueled by either gas or oil. The current trend is from gas-

fired to oil-fired.

Recuperative furnaces use a steel heat exchanger, recovering heat from

the exhaust gases by exchange with the combustion air. Regenerative

furnaces use a lattice of brickwork to recover waste heat from exhaust

gases. In the initial mode of operation, hot exhaust gases are routed

through a chamber containing a brickwork lattice, while combustion air is

heated by passage through another corresponding brickwork lattice.

About every 20 minutes, the airflow is reversed, so that the combustion

air is always being passed through hot brickwork previously heated by

exhaust gases.

Electric furnaces melt glass by passing an electric current through the

melt. Electric furnaces are either hot-top or cold-top. The former use gas

for auxiliary heating, and the latter use only the electric current. Electric

furnaces are currently used only for wool glass fiber production because

of the electrical properties of the glass formulation. Unit melters are used

only for the "indirect" marble melting process, getting raw materials from

a continuous screw at the back of the furnace adjacent to the exhaust air

discharge. There are no provisions for heat recovery with unit melters.

In the "indirect" melting process, molten glass passes to a forehearth,

where it is drawn off, shered into globs, and formed into marbles by roll-

forming. The marbles are then stress-relieved in annealing ovens, cooled,

and conveyed to storage or to other plants for later use. In the "direct"

glass fiber process, molten glass passes from the furnace into a refining

unit, where bubbles and particles are removed by settling, and the melt is

allowed to cool to the proper viscosity for the fiber forming operation.

Wool Glass Fiber Forming and Finishing:

Wool fiberglass is produced for insulation and is formed into mats that

are cut into batts.)Loose wool is primarily a waste product formed from

mat trimming, although some is a primary product, and is only a small

part of the total wool fiberglass produced. No specific emission data for

loose wool production are available.) The insulation is used primarily in

the construction industry and is produced to comply with ASTM C167-

64, the "Standard Test Method for Thickness and Density of Blanket- or

Batt-Type Thermal Insulating Material."

Wool fiberglass insulation production lines usually consist of the

following processes preparation of molten glass, formation of fibers into

a wool fiberglass mat, curing the binder-coated fiberglass mat, cooling

the mat, and backing, cutting, and packaging the insulation. Fiberglass

plants contain various sizes, types, and numbers of production lines,

although a typical plant has 3 lines. Backing (gluing a flat flexible

material, usually paper, to the mat), cutting and packaging operations are

not, significant sources of emissions to the atmosphere.

The trimmed edge waste from the mat and the fibrous dust generated

during the cutting and packaging operations are collected by a cyclone

and either are transported to a hammer mill to be chopped into blown

wool (loose insulation) and bulk packaged or are recycled to the forming

section

and blended with newly formed product.

During the formation of fibers into a wool fiberglass mat (the process

known as "forming" in

the industry), glass fibers are made from molten glass, and a chemical

binder is simultaneously sprayed on the fibers as they are created. The

binder is a thermosetting resin that holds the glass fibers together.

Although the binder composition varies with product type, typically the

binder

consists of a solution of phenol-formaldehyde resin, water, urea, lignin,

silane, and ammonia. Coloring agents may also be added to the binder.

Two methods of creating fibers are used by the industry. In the rotary

spin process, centrifugal force causes molten glass to flow through small

holes in the wall of a rapidly rotating cylinder to create fibers that are

broken into pieces by an air stream. This is the newer of the 2 processes

and dominates the industry today.

In the flame attenuation process, molten glass flows by gravity from a

furnace through numerous small orifices to create threads that are then

attenuated (stretched to the point of breaking) by high velocity, hot air,

and/or a flame. After the glass fibers are created (by either process) and

sprayed with the binder solution, they are collected by gravity on a

conveyor belt in the form of a mat.

The conveyor carries the newly formed mat through a large oven to cure

the thermosetting binder and then through a cooling section where

ambient air is drawn down through the mat.

The cooled mat remains on the conveyor for trimming of the uneven

edges. Then, if product specifications require it, a backing is applied with

an adhesive to form a vapor barrier. The mat is then cut into batts of the

desired dimensions and packaged.

You might also like

- Member AE EG EF BC BDDocument1 pageMember AE EG EF BC BDMaysara Maawia MukhtarNo ratings yet

- Assignment#1 RecapDocument2 pagesAssignment#1 RecapMaysara Maawia MukhtarNo ratings yet

- Recap - Final ExamDocument6 pagesRecap - Final ExamMaysara Maawia MukhtarNo ratings yet

- Final ExamDocument5 pagesFinal ExamMaysara Maawia MukhtarNo ratings yet

- Biomass Energy LectureDocument9 pagesBiomass Energy LectureRishant YadavNo ratings yet

- Biomass Energy LectureDocument9 pagesBiomass Energy LectureRishant YadavNo ratings yet

- Biomass Energy LectureDocument9 pagesBiomass Energy LectureRishant YadavNo ratings yet

- 6-Energy Loss in BendsDocument12 pages6-Energy Loss in BendsMaysara Maawia Mukhtar60% (10)

- Triaxial TestDocument7 pagesTriaxial TestMaysara Maawia MukhtarNo ratings yet

- Assignment PDFDocument2 pagesAssignment PDFMaysara Maawia MukhtarNo ratings yet

- Hooke's Law Lab Report 1 SunealDocument5 pagesHooke's Law Lab Report 1 SunealMonari Perera67% (3)

- IntroductionDocument1 pageIntroductionMaysara Maawia MukhtarNo ratings yet

- Assignment PDFDocument2 pagesAssignment PDFMaysara Maawia MukhtarNo ratings yet

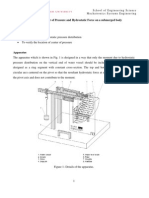

- Center of Pressure and Hydrostatic Force On A Submerged Body-RevDocument7 pagesCenter of Pressure and Hydrostatic Force On A Submerged Body-RevAnkit MittalNo ratings yet

- Losses in Bends FittingsDocument26 pagesLosses in Bends Fittingsdainer08No ratings yet

- STR AnalysisDocument136 pagesSTR AnalysisWeha Yu100% (1)

- Fluid Mechanics: Laboratory ManualDocument8 pagesFluid Mechanics: Laboratory Manualloki654321No ratings yet

- CE 428 Trickling Filters-StuDocument4 pagesCE 428 Trickling Filters-StuMaysara Maawia MukhtarNo ratings yet

- Exp 3 - Impact of A Jet - NewDocument5 pagesExp 3 - Impact of A Jet - NewaadhanNo ratings yet

- Announcement For Prof Chin Lecture 2013 FinalDocument2 pagesAnnouncement For Prof Chin Lecture 2013 FinalMaysara Maawia MukhtarNo ratings yet

- National PolicenvironmentalDocument12 pagesNational PolicenvironmentalMaysara Maawia MukhtarNo ratings yet

- As Highway Engineering EquipmentDocument6 pagesAs Highway Engineering EquipmentMaysara Maawia MukhtarNo ratings yet

- Chapter 1 Lecture1 Kcs3233Document40 pagesChapter 1 Lecture1 Kcs3233Maysara Maawia MukhtarNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Textile Design Technology-UpdatedDocument18 pagesTextile Design Technology-Updatedmahe_ftNo ratings yet

- Project in MAPEHDocument5 pagesProject in MAPEHAnonymous aZgdOUNo ratings yet

- Arts and Crafts of MindanaoDocument30 pagesArts and Crafts of MindanaoShiena EndayaNo ratings yet

- Noduri Și ÎmpletituriDocument95 pagesNoduri Și ÎmpletituriCristea NeculaeNo ratings yet

- I Year All BranchDocument12 pagesI Year All BranchRahul SrivastavaNo ratings yet

- Learning Module IN: Indigenous Creative CraftsDocument10 pagesLearning Module IN: Indigenous Creative CraftsReñer Aquino BystanderNo ratings yet

- Karastan Contract Woven Broadloom Carpet Catalog 2016Document40 pagesKarastan Contract Woven Broadloom Carpet Catalog 2016susantoNo ratings yet

- CHAPTER 19 - Industrialization and NationalismDocument27 pagesCHAPTER 19 - Industrialization and NationalismJonathan Daniel KeckNo ratings yet

- Jamuma Kumari BBADocument58 pagesJamuma Kumari BBAMukesh SinghviNo ratings yet

- FabricDocument13 pagesFabricRobelyn SantiagoNo ratings yet

- Planning Garments DesignDocument19 pagesPlanning Garments DesignAvery SheperdNo ratings yet

- Digital Photo Weaving PDFDocument11 pagesDigital Photo Weaving PDFapi-266967947No ratings yet

- Conklin 1978 (The Revolutionary Weaving Inventions of The Early Horizon)Document19 pagesConklin 1978 (The Revolutionary Weaving Inventions of The Early Horizon)José A. Quispe HuamaníNo ratings yet

- Quarter 1 - Module 1 Southeast Asian ArtDocument40 pagesQuarter 1 - Module 1 Southeast Asian ArtJia BustaliñoNo ratings yet

- Wangi-Wangi Wakatobi Travel BrochureDocument10 pagesWangi-Wangi Wakatobi Travel BrochureDaniel HookinsNo ratings yet

- CHAPPERS MAMTA VAGHADIA GP May 2017Document72 pagesCHAPPERS MAMTA VAGHADIA GP May 2017IshikaNo ratings yet

- Monografia - Techniques of Decoration PDFDocument42 pagesMonografia - Techniques of Decoration PDFSilvana BorgesNo ratings yet

- Characteristics of Cottage IndustriesDocument39 pagesCharacteristics of Cottage Industriesharsh143352No ratings yet

- Chubby Milky CowDocument11 pagesChubby Milky CowroxNo ratings yet

- Effects of Woven Fabric Construction and Color On Ultraviolet ProtectionDocument9 pagesEffects of Woven Fabric Construction and Color On Ultraviolet Protectionthelazyllama444No ratings yet

- Mid Report of Woven (201011037)Document9 pagesMid Report of Woven (201011037)Abid hasanNo ratings yet

- Geography: Connect Geography by Locating The Philippines On The Map. DefineDocument6 pagesGeography: Connect Geography by Locating The Philippines On The Map. DefineAbegail Oplado Gereña100% (1)

- A Level Revision GuideDocument111 pagesA Level Revision GuideDiaz Jose CarlosNo ratings yet

- Sparkly Stars CompressedDocument9 pagesSparkly Stars CompressedNicola Preston100% (1)

- Fundamental of Textile and Their Care BookDocument364 pagesFundamental of Textile and Their Care BookBharti Pahuja100% (4)

- Summary Souvenir From TubanDocument3 pagesSummary Souvenir From TubanCorry nor FahmiNo ratings yet

- Global Textile & Apparels - E-Paper - 18 August 2021Document7 pagesGlobal Textile & Apparels - E-Paper - 18 August 2021Rahul SoodNo ratings yet

- CBLM Tle H.E Gr. 10 DressmakingDocument187 pagesCBLM Tle H.E Gr. 10 DressmakingIce Jimenez100% (4)

- Development of Philippine EmbroideryDocument31 pagesDevelopment of Philippine EmbroideryCeleste D. Bering100% (4)

- OS ReportDocument72 pagesOS ReportPrasanth C NairNo ratings yet