Professional Documents

Culture Documents

N Spring2013

Uploaded by

indapantsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

N Spring2013

Uploaded by

indapantsCopyright:

Available Formats

Celebrating 40 Years of

Technical Excellence

Modified Black Oil Properties: A Practical

Treatment of Gas Condensate and Volatile

Oil PVT

Community Update

Fekete News & Notes

Engineering & Business News from Fekete Associates Inc.

news

p

a

g

e

1 2-3 p

a

g

e

p

a

g

e

4

S

p

r

i

n

g

2

0

1

3

1

This year, Fekete is celebrating its 40th year of service to

the oil and gas industry. Fekete started as an

Alberta-based two-man organization, and has since

grown into an internationally recognized company with

more than 190 employees. We have been on the leading

edge of research in reservoir engineering for the last 40

years, and our employees are some of the most sought-after technical

experts in their respective fields.

Were frequently asked about the meaning of Fekete. The company was

named after its founder, Tibor Fekete. Tibor immigrated to Canada as a

young engineer after the failed Hungarian revolution of 1956. After working

for a producing company, Tibor established a consulting service in 1973 to

provide reserve and deliverability studies to supply natural gas to farm

co-operatives. He was one of the early adopters of pressure transient

analysis techniques, which in those days consisted of hand-drawn Horner

and AOF plots. In 1979, the first F.A.S.T. WellTest software was

programmed by one of our earliest (and current) employees, Karel Zaoral,

on an HP-9845. This was in the days before the first IBM PC and there were

no programming courses available in universities.

For many years, the software we designed was principally a tool used by

Feketes engineers in performing consulting services for our clients. In

1983, after many lengthy and passionate debates, we made a critical

business decision to license our software to the rest of the industry. That

decision is symbolic of much of what Fekete has done in the past 40 years.

Our staff believed that, by committing to technical excellence, trusting our

own instincts and going for it, we could build a company of which we

would be proud; where we thrived on challenges and where we loved

learning from each other.

Again, in 2013 we have made another critical business decision. It is our

pleasure to announce that Fekete has recently been acquired by IHS Inc.

We believe that this new alignment provides the best in energy technical

Dave Dunn

President

Spring 2013

intelligence. It will combine Feketes

engineering software products, consulting

services and training programs with the IHS

Energy Insight, reservoir engineering and

information products to address the needs of

oil and gas engineers all over the world.

One thing Ive learned, after my 25 years in this business, is that it is the

people, and not the processes, that define the success and character of a

company. Ive been blessed to spend my career working with an

extraordinary group of friends who have all contributed their unique skills

and who have chosen to stick together through the years. So, to the

Feketies, Im immensely proud of each and every one of you and look

forward to what the future will bring.

Finally, to you, our clients, we say THANK YOU. It is your support,

encouragement, challenges and friendships that we take away as the

rewards for continuing to push the boundaries of new ideas in the

constantly changing oil patch.

In Hungarian,

Fekete means

black.

FUN FACT!

n

e

w

s

Copyright 2013FeketeAssociatesInc. PrintedinCanada

Feketes Community of Best Practice program continues

to grow. With over 200 wells and 11 member companies,

the Eagle Ford Community of Best Practice is well into its

second year, and continues to advance our understanding

of this complex liquids-rich play. Our Bakken Community

of Best Practice is forming in a few months. Much interest

has been expressed in founding communities in other

plays such as the Utica, Niobrara, Horn River, Haynesville,

Marcellus, and Montney.

Feketes Community of Best Practice program is a

collaborative platform for sharing data, well analysis, and

play-specific knowledge between companies. As land

positions solidify, turn your competitors into collaborators

to ensure youre able to take maximum advantage of the

land positions your company has secured. Work together

to understand completion strategies, operational

considerations, and the best workflow for analyzing wells

in your area. Fekete works with both organizations to

ensure the data is shared equally. Fekete holds all

4

contributed data until both parties meet their reporting

obligations. If your organization contributes data over

and above that of the other party, Feketes expert

judgment will ensure equity between all community

members, and will only release data that ensures a level

playing field. All data will be documented and organized

so that it can easily be incorporated into your Reservoir

Engineering program.

In all of our communities, Fekete ensures that

interpretations are harmonized on a common set of

workflows. These workflows, and all methods developed

to meet community objectives, become a valuable

toolset for training your engineers in the latest

unconventional analysis techniques.

Contact us at community@fekete.com to discuss how

our Community of Best Practice program can help your

organization stay on the leading edge of unconventional

analysis.

You have paid

a lot of

attention to our

feedback and

have done an

excellent job

incorporating it

into your

software.

- Nathan McMahan

Sr. Reservoir Engineer,

ConocoPhillips, Oct 2012

Fekete News & Notes

It is our pleasure to

announce that Fekete has

been acquired by IHS Inc.

(NYSE: IHS www.ihs.com), a

leading provider of business

information, insight and analytics in

key areas shaping todays global

business landscape. Both the Fekete

and IHS teams are very excited

about the positive impact this

acquisition will have on the

capabilities, solutions and value we

deliver to you and your organization.

You

Tube

Were on YouTube

Have you visited our YouTube channel yet? Video resources for all of our software

products are available at youtube.com/user/feketesoftware.

Training

In addition to the public software and engineering courses that we hold regularly, we

also offer custom in-house software and engineering workshops to groups of eight or

more learners. Book an existing course for your group, or allow us to customize your

training to include analysis of your data, and to create a workflow to suit your specific

assets. Visit fekete.com to learn more about Fekete training.

Introducing our NEW Website

Have you visited fekete.com lately?

In honor of our 40th Anniversary, we have completely re-designed our website. Our

new site is user friendly and easy to navigate. You can effortlessly locate all of the

great technical content youve come to expect from us, including published papers,

our complete technical video series, and software training videos. You can register for

one of our public training courses, learn the Golden Rules of Well Test Interpretation,

or find out about current employment opportunities.

Figure 2- Black Oil properties vs. Modified Black Oil Properties

Black Oil Properties Modified Black Oil Properties

Rs = Go / No

Bo = Vo / No

Bgd = Vg / Gg

Rs = Go / No

Rc = Ng / Gg

Bo = Vo / No

Bgd = Vg / Gg

The modified black oil PVT model allows reservoir engineers to

account for complex PVT behavior that arises in gas condensate and

volatile oil reservoirs.

Gas-Condensate and Volatile Oil systems contain gas which may

have non-negligible amounts of vaporized liquid hydrocarbons, and

this may have a significant impact on fluid behavior. Nowadays, the

increasing price of liquid hydrocarbons compared to the gas price

has raised more interest in improving the modeling of these reservoirs

and for devising better tools for more realistic forecasts of surface

liquid yields.

Common black oil properties do not consider the liquid hydrocarbon

content of the gas phase. Black Oil properties have been well-defined

and applied in different areas of modeling and analysis; however

modified black oil properties for usage with gas condensate and

volatile oil have been largely overlooked. In the modified black oil

model, two new properties are needed; vaporized oil ratio (Rv) and

dry gas formation volume factor (Bgd).

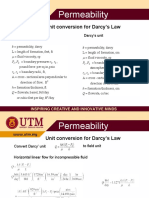

To explain these new properties, first consider Figure 1, which

illustrates the distribution between the phases at given reservoir

conditions. Excluding water, in both black oil and modified black oil

modeling, it is assumed that there are two components (separator gas

(G) and stock tank oil (N)) and two phases (gas phase (g) and oil

standard conditions, "Rv" describes the volume of oil (condensate) that

will be produced, given a certain volume of separator gas (see Figure 2).

For a specific rich-gas system, the vaporized gas ratio (Rv) is a function

of pressure, temperature and separator conditions.

There are only few correlations for estimating Rv. We assessed all of

the available correlations qualitatively and the "Rv" correlation that was

chosen for Feketes software was Ovalle et al.s correlation (2005)

i

. This

correlation showed more reasonable responses to the controlling

parameters (i.e. reservoir temperature, oil API gravity and separator

conditions).

The other distinct modified black oil property is the dry gas formation

volume factor (Bgd). Before any discussion, we need to distinguish

between wet gas formation volume factor (Bg) and Bgd. Referring to

Figure 1, the wet gas formation volume factor is the ratio of the gas phase

at given pressure and temperature (Vg) to the equivalent volume of the

whole gas phase at standard condition; however, the dry gas formation

volume factor (Bgd) is the ratio between the volume of gas phase at given

conditions (Vg) to the volume of its Gas component (Gg) at standard

conditions. In conventional black oil applications, Ng is zero, which

causes Bgd and Bg to become the same. However, for modified

black oil applications, we need to differentiate between Bg and Bgd.

Although there is no correlation available for "Bgd", it can be calculated

simply by using the following relationship between Bg and Bgd

ii

:

measurement of oil density during CCE and CVD experiments to be used for

volume shift corrections.

S

p

r

i

n

g

2

0

1

3

2

For gas condensates, Walsh and Towler (1995)

v

presented another procedure

which is based on the material balance calculation. This procedure does not

use EOS modeling; it uses only the measured quantities from a CVD test.

Fekete has improved upon this method and has developed a workflow to

calculate all the modified black oil properties simultaneously only based on

the results of CVD and CCE tests. The procedure honors both material

balance and consistency checks. Our Software Development team plans to

make this feature available in Fekete Harmony soon.

Applications:

All the current numerical models in Fekete Harmony are black oil models.

Therefore, the simulation results for gas condensates and volatile oil

reservoirs may not be fully accurate in some cases. Particularly for gas

condensate reservoirs, the black oil numerical models cannot predict the

condensate drop-out in the reservoir, which affects both condensate surface

yield and well productivity. The modified black oil numerical simulator is

currently under development and will be added to the existing numerical

models in Fekete Harmony.

The current analytical models, on the other hand, have the ability to provide a

split condensate forecast based on Rv. One assumption of this feature is

that the bottomhole pressure is the controlling pressure for splitting the

condensate from dry gas, in conjunction with Rv functionality. Numerical

simulations (both compositional and modified black oil simulations)

(Whitson, 2012)

vi

verified that this is a reasonable assumption. Although the

analytical models cannot simulate the liquid drop-out around the wellbore

nor its influence on flow hindrance, they can mimic it using the existing

feature of changing skin with time.

In wellbore and pipeline multiphase calculations, it is important to have a

good estimation of liquid hold-up and also in-situ rates of different phases at

any pressure and temperature. Consequently, Rv can be used here. The

difference between the gas phase liquid contents (Rv) at two ends of any

segment of the pipe is the indication of liquid hold-up in that segment. For

calculations of the in-situ rates, we need to recall the concept of material

balance of oil- and gas-components all along the wellbore or any pipe. At

any point along a pipeline, we know that the total amount of the oil- and

gas-components are the same; the only thing which is different is their

distribution in terms of oil and gas phases.

n

e

w

s

3

Modified Black Oil

Properties

A Practical Treatment of Gas

Condensate and Volatile Oil PVT

Mohammad Rahmanian

Reservoir Engineer/Numerical Technical Advisor

(1) Gg Go G + =

(2) Ng No N + =

i A.P. Ovalle; C.P. Lenn; and W.D. McCain Jr.; Tools To Manage Gas/Condensate Reservoirs: Novel

Fluid-Property Correlations Based on Commonly Available Field Data; SPE 10320; (2005).

ii Curtis H. Whitson and Michael R. Brul; Phase Behavior; Monograph Volume 20 SPE, Henry L.

Doherty Series, Chapter 7, Richardson, Texas (2000).

iii K. H. Coats; Simulation of Gas Condensate Reservoir Performance; SPE 10512; (1985).

iv C. H. Whitson; S. B. Trop; Evaluating Constant Volume Depletion Data; SPE 10067; (1983).

v M. P. Walsh; B. F. Towler; Methods Computes PVT Properties for Gas Condensate; oil and gas

journal; July 31, 1995; 93, 31, p 83-86.

vi C. H. Whitson and S. Sunjerga; PVT in Liquid-Rich Shale Reservoirs; SPE 155499; (2012).

pressure is used to distinguish

between saturated and

undersaturated oil.

For calculating "Rv" and "Bgd"

from conventional laboratory

tests, Coat (1985)

iii

and

Whitson and Trop (1983)

iv

have

suggested two compositional

algorithms using

equation-of-state (EOS)

modeling. In both algorithms,

the EOS model should be

tuned based on the available

PVT tests. Unfortunately, the

oil phase properties (Bo and

Rs) obtained by these two

methods are not reliable due to

the error in the EOS-calculated

oil density. Furthermore, for

gas condensate, there is no

phase (o)); each of the components can exist

in either phase. The amount of the produced

gas at the separator is the summation of gas

component that comes from of the gas phase

(Gg), and the gas component that comes from

the oil phase (dissolved gas, Go). Likewise,

the stock tank oil (N) comes from both the oil

phase (No) and the gas phase (vaporized oil,

Ng). In the conventional black oil properties

the Ng is neglected (Figure 2).

In situ gas phase ow rate

In situ oil phase ow rate

Gas component (separator gas) ow rate

Oil component (stock tank) ow rate

Soluton gas rato

Vaporized oil rato

Oil formaton volume factor

Wet gas formaton volume factor

Dry gas formaton volume factor

Gas component (separator gas) in oil phase

Gas component (separator gas) in gas phase

Oil component (stock tank) in oil phase

Oil component (stock tank) in gas phase

Universal gas constant

Conversion factor

Standard conditon temperature

Standard conditon pressure

Temperature, absolute

Pressure

Oil density at standard conditon

Stock tank oil molecular weight

Gas compressibility factor

CCE Constant Compositon Expansion

CVD Constant Volume Depleton

Nomenclature

(4)

Psc Z T

Tsc P

Bg =

(3)

ST

o M

ST

o

=

1 Rv

Bg Bgd +

RTsc

Psc

Figure 1- Typical Reservoir Fluid Sample at Reservoir Condition

(Explanation of hydrocarbon phases and components)

By rearrangement, the in situ rates of the gas and oil phases at each

location of the pipe can be calculated as:

(6)

Bgd

q

G

= + Rs

qg q

o

Bo

* *

(5)

Bo

q

N

= + Rv

q

o

qg

Bgd

* *

(7) =

q

N Rs

q

G

qg

*

Bgd

Rs Rv 1

(8) =

q

G Rv

q

N

q

o

*

Bo

Rs Rv 1

In summary, the inclusion of modified black oil properties will

provide significant benefits across Feketes suite of software, while

maintaining ease of use and practicality. For F.A.S.T. RTA and

F.A.S.T. WellTest, it will allow us to simulate liquid dropout and

associated productivity loss in retrograde condensate and volatile

oil reservoirs. In F.A.S.T. VirtuWell, it will allow us to account for

the condensation of hydrocarbon liquids within the wellstream, prior

to reaching the separator, thereby providing more reliable pressure

loss predictions. In F.A.S.T. Piper, it will allow us to account for

liquid holdup due to condensate dropout in pipelines.

Vaporized Oil Ratio (Rv) and Dry Gas

Formation Volume Factor (Bgd):

Analogous to the solution gas ratio (Rs) in

the oil phase, the vaporized oil ratio (Rv) is

defined in the gas phase. Physically, if a gas

sample at reservoir conditions is brought to

This equation also shows that if the "Rv" is zero (as in conventional

black oil); the "Bg" and "Bgd" are equal. Though the calculation of "Bg"

is as easy as the equation shown below, the gas compressibility factor

"Z" is a function of gas specific gravity which itself is a function of the

liquid content of the gas "Rv". Therefore, since the gas specific gravity

and the "Z" factor may not be constant in modified black oil properties,

the "Bg" needs to be updated accordingly.

Another complication that we track is the effect of the degree of gas

saturation on "Bgd" as described by the dew point pressure. This is

analogous to computing "Bo" in the oil case, where the bubble point

Figure 2- Black Oil properties vs. Modified Black Oil Properties

Black Oil Properties Modified Black Oil Properties

Rs = Go / No

Bo = Vo / No

Bgd = Vg / Gg

Rs = Go / No

Rc = Ng / Gg

Bo = Vo / No

Bgd = Vg / Gg

The modified black oil PVT model allows reservoir engineers to

account for complex PVT behavior that arises in gas condensate and

volatile oil reservoirs.

Gas-Condensate and Volatile Oil systems contain gas which may

have non-negligible amounts of vaporized liquid hydrocarbons, and

this may have a significant impact on fluid behavior. Nowadays, the

increasing price of liquid hydrocarbons compared to the gas price

has raised more interest in improving the modeling of these reservoirs

and for devising better tools for more realistic forecasts of surface

liquid yields.

Common black oil properties do not consider the liquid hydrocarbon

content of the gas phase. Black Oil properties have been well-defined

and applied in different areas of modeling and analysis; however

modified black oil properties for usage with gas condensate and

volatile oil have been largely overlooked. In the modified black oil

model, two new properties are needed; vaporized oil ratio (Rv) and

dry gas formation volume factor (Bgd).

To explain these new properties, first consider Figure 1, which

illustrates the distribution between the phases at given reservoir

conditions. Excluding water, in both black oil and modified black oil

modeling, it is assumed that there are two components (separator gas

(G) and stock tank oil (N)) and two phases (gas phase (g) and oil

standard conditions, "Rv" describes the volume of oil (condensate) that

will be produced, given a certain volume of separator gas (see Figure 2).

For a specific rich-gas system, the vaporized gas ratio (Rv) is a function

of pressure, temperature and separator conditions.

There are only few correlations for estimating Rv. We assessed all of

the available correlations qualitatively and the "Rv" correlation that was

chosen for Feketes software was Ovalle et al.s correlation (2005)

i

. This

correlation showed more reasonable responses to the controlling

parameters (i.e. reservoir temperature, oil API gravity and separator

conditions).

The other distinct modified black oil property is the dry gas formation

volume factor (Bgd). Before any discussion, we need to distinguish

between wet gas formation volume factor (Bg) and Bgd. Referring to

Figure 1, the wet gas formation volume factor is the ratio of the gas phase

at given pressure and temperature (Vg) to the equivalent volume of the

whole gas phase at standard condition; however, the dry gas formation

volume factor (Bgd) is the ratio between the volume of gas phase at given

conditions (Vg) to the volume of its Gas component (Gg) at standard

conditions. In conventional black oil applications, Ng is zero, which

causes Bgd and Bg to become the same. However, for modified

black oil applications, we need to differentiate between Bg and Bgd.

Although there is no correlation available for "Bgd", it can be calculated

simply by using the following relationship between Bg and Bgd

ii

:

measurement of oil density during CCE and CVD experiments to be used for

volume shift corrections.

S

p

r

i

n

g

2

0

1

3

2

For gas condensates, Walsh and Towler (1995)

v

presented another procedure

which is based on the material balance calculation. This procedure does not

use EOS modeling; it uses only the measured quantities from a CVD test.

Fekete has improved upon this method and has developed a workflow to

calculate all the modified black oil properties simultaneously only based on

the results of CVD and CCE tests. The procedure honors both material

balance and consistency checks. Our Software Development team plans to

make this feature available in Fekete Harmony soon.

Applications:

All the current numerical models in Fekete Harmony are black oil models.

Therefore, the simulation results for gas condensates and volatile oil

reservoirs may not be fully accurate in some cases. Particularly for gas

condensate reservoirs, the black oil numerical models cannot predict the

condensate drop-out in the reservoir, which affects both condensate surface

yield and well productivity. The modified black oil numerical simulator is

currently under development and will be added to the existing numerical

models in Fekete Harmony.

The current analytical models, on the other hand, have the ability to provide a

split condensate forecast based on Rv. One assumption of this feature is

that the bottomhole pressure is the controlling pressure for splitting the

condensate from dry gas, in conjunction with Rv functionality. Numerical

simulations (both compositional and modified black oil simulations)

(Whitson, 2012)

vi

verified that this is a reasonable assumption. Although the

analytical models cannot simulate the liquid drop-out around the wellbore

nor its influence on flow hindrance, they can mimic it using the existing

feature of changing skin with time.

In wellbore and pipeline multiphase calculations, it is important to have a

good estimation of liquid hold-up and also in-situ rates of different phases at

any pressure and temperature. Consequently, Rv can be used here. The

difference between the gas phase liquid contents (Rv) at two ends of any

segment of the pipe is the indication of liquid hold-up in that segment. For

calculations of the in-situ rates, we need to recall the concept of material

balance of oil- and gas-components all along the wellbore or any pipe. At

any point along a pipeline, we know that the total amount of the oil- and

gas-components are the same; the only thing which is different is their

distribution in terms of oil and gas phases.

n

e

w

s

3

Modified Black Oil

Properties

A Practical Treatment of Gas

Condensate and Volatile Oil PVT

Mohammad Rahmanian

Reservoir Engineer/Numerical Technical Advisor

(1) Gg Go G + =

(2) Ng No N + =

i A.P. Ovalle; C.P. Lenn; and W.D. McCain Jr.; Tools To Manage Gas/Condensate Reservoirs: Novel

Fluid-Property Correlations Based on Commonly Available Field Data; SPE 10320; (2005).

ii Curtis H. Whitson and Michael R. Brul; Phase Behavior; Monograph Volume 20 SPE, Henry L.

Doherty Series, Chapter 7, Richardson, Texas (2000).

iii K. H. Coats; Simulation of Gas Condensate Reservoir Performance; SPE 10512; (1985).

iv C. H. Whitson; S. B. Trop; Evaluating Constant Volume Depletion Data; SPE 10067; (1983).

v M. P. Walsh; B. F. Towler; Methods Computes PVT Properties for Gas Condensate; oil and gas

journal; July 31, 1995; 93, 31, p 83-86.

vi C. H. Whitson and S. Sunjerga; PVT in Liquid-Rich Shale Reservoirs; SPE 155499; (2012).

pressure is used to distinguish

between saturated and

undersaturated oil.

For calculating "Rv" and "Bgd"

from conventional laboratory

tests, Coat (1985)

iii

and

Whitson and Trop (1983)

iv

have

suggested two compositional

algorithms using

equation-of-state (EOS)

modeling. In both algorithms,

the EOS model should be

tuned based on the available

PVT tests. Unfortunately, the

oil phase properties (Bo and

Rs) obtained by these two

methods are not reliable due to

the error in the EOS-calculated

oil density. Furthermore, for

gas condensate, there is no

phase (o)); each of the components can exist

in either phase. The amount of the produced

gas at the separator is the summation of gas

component that comes from of the gas phase

(Gg), and the gas component that comes from

the oil phase (dissolved gas, Go). Likewise,

the stock tank oil (N) comes from both the oil

phase (No) and the gas phase (vaporized oil,

Ng). In the conventional black oil properties

the Ng is neglected (Figure 2).

In situ gas phase ow rate

In situ oil phase ow rate

Gas component (separator gas) ow rate

Oil component (stock tank) ow rate

Soluton gas rato

Vaporized oil rato

Oil formaton volume factor

Wet gas formaton volume factor

Dry gas formaton volume factor

Gas component (separator gas) in oil phase

Gas component (separator gas) in gas phase

Oil component (stock tank) in oil phase

Oil component (stock tank) in gas phase

Universal gas constant

Conversion factor

Standard conditon temperature

Standard conditon pressure

Temperature, absolute

Pressure

Oil density at standard conditon

Stock tank oil molecular weight

Gas compressibility factor

CCE Constant Compositon Expansion

CVD Constant Volume Depleton

Nomenclature

(4)

Psc Z T

Tsc P

Bg =

(3)

ST

o M

ST

o

=

1 Rv

Bg Bgd +

RTsc

Psc

Figure 1- Typical Reservoir Fluid Sample at Reservoir Condition

(Explanation of hydrocarbon phases and components)

By rearrangement, the in situ rates of the gas and oil phases at each

location of the pipe can be calculated as:

(6)

Bgd

q

G

= + Rs

qg q

o

Bo

* *

(5)

Bo

q

N

= + Rv

q

o

qg

Bgd

* *

(7) =

q

N Rs

q

G

qg

*

Bgd

Rs Rv 1

(8) =

q

G Rv

q

N

q

o

*

Bo

Rs Rv 1

In summary, the inclusion of modified black oil properties will

provide significant benefits across Feketes suite of software, while

maintaining ease of use and practicality. For F.A.S.T. RTA and

F.A.S.T. WellTest, it will allow us to simulate liquid dropout and

associated productivity loss in retrograde condensate and volatile

oil reservoirs. In F.A.S.T. VirtuWell, it will allow us to account for

the condensation of hydrocarbon liquids within the wellstream, prior

to reaching the separator, thereby providing more reliable pressure

loss predictions. In F.A.S.T. Piper, it will allow us to account for

liquid holdup due to condensate dropout in pipelines.

Vaporized Oil Ratio (Rv) and Dry Gas

Formation Volume Factor (Bgd):

Analogous to the solution gas ratio (Rs) in

the oil phase, the vaporized oil ratio (Rv) is

defined in the gas phase. Physically, if a gas

sample at reservoir conditions is brought to

This equation also shows that if the "Rv" is zero (as in conventional

black oil); the "Bg" and "Bgd" are equal. Though the calculation of "Bg"

is as easy as the equation shown below, the gas compressibility factor

"Z" is a function of gas specific gravity which itself is a function of the

liquid content of the gas "Rv". Therefore, since the gas specific gravity

and the "Z" factor may not be constant in modified black oil properties,

the "Bg" needs to be updated accordingly.

Another complication that we track is the effect of the degree of gas

saturation on "Bgd" as described by the dew point pressure. This is

analogous to computing "Bo" in the oil case, where the bubble point

Celebrating 40 Years of

Technical Excellence

Modified Black Oil Properties: A Practical

Treatment of Gas Condensate and Volatile

Oil PVT

Community Update

Fekete News & Notes

Engineering & Business News from Fekete Associates Inc.

news

p

a

g

e

1 2-3 p

a

g

e

p

a

g

e

4

S

p

r

i

n

g

2

0

1

3

1

This year, Fekete is celebrating its 40th year of service to

the oil and gas industry. Fekete started as an

Alberta-based two-man organization, and has since

grown into an internationally recognized company with

more than 190 employees. We have been on the leading

edge of research in reservoir engineering for the last 40

years, and our employees are some of the most sought-after technical

experts in their respective fields.

Were frequently asked about the meaning of Fekete. The company was

named after its founder, Tibor Fekete. Tibor immigrated to Canada as a

young engineer after the failed Hungarian revolution of 1956. After working

for a producing company, Tibor established a consulting service in 1973 to

provide reserve and deliverability studies to supply natural gas to farm

co-operatives. He was one of the early adopters of pressure transient

analysis techniques, which in those days consisted of hand-drawn Horner

and AOF plots. In 1979, the first F.A.S.T. WellTest software was

programmed by one of our earliest (and current) employees, Karel Zaoral,

on an HP-9845. This was in the days before the first IBM PC and there were

no programming courses available in universities.

For many years, the software we designed was principally a tool used by

Feketes engineers in performing consulting services for our clients. In

1983, after many lengthy and passionate debates, we made a critical

business decision to license our software to the rest of the industry. That

decision is symbolic of much of what Fekete has done in the past 40 years.

Our staff believed that, by committing to technical excellence, trusting our

own instincts and going for it, we could build a company of which we

would be proud; where we thrived on challenges and where we loved

learning from each other.

Again, in 2013 we have made another critical business decision. It is our

pleasure to announce that Fekete has recently been acquired by IHS Inc.

We believe that this new alignment provides the best in energy technical

Dave Dunn

President

Spring 2013

intelligence. It will combine Feketes

engineering software products, consulting

services and training programs with the IHS

Energy Insight, reservoir engineering and

information products to address the needs of

oil and gas engineers all over the world.

One thing Ive learned, after my 25 years in this business, is that it is the

people, and not the processes, that define the success and character of a

company. Ive been blessed to spend my career working with an

extraordinary group of friends who have all contributed their unique skills

and who have chosen to stick together through the years. So, to the

Feketies, Im immensely proud of each and every one of you and look

forward to what the future will bring.

Finally, to you, our clients, we say THANK YOU. It is your support,

encouragement, challenges and friendships that we take away as the

rewards for continuing to push the boundaries of new ideas in the

constantly changing oil patch.

In Hungarian,

Fekete means

black.

FUN FACT!

n

e

w

s

Copyright 2013FeketeAssociatesInc. PrintedinCanada

Feketes Community of Best Practice program continues

to grow. With over 200 wells and 11 member companies,

the Eagle Ford Community of Best Practice is well into its

second year, and continues to advance our understanding

of this complex liquids-rich play. Our Bakken Community

of Best Practice is forming in a few months. Much interest

has been expressed in founding communities in other

plays such as the Utica, Niobrara, Horn River, Haynesville,

Marcellus, and Montney.

Feketes Community of Best Practice program is a

collaborative platform for sharing data, well analysis, and

play-specific knowledge between companies. As land

positions solidify, turn your competitors into collaborators

to ensure youre able to take maximum advantage of the

land positions your company has secured. Work together

to understand completion strategies, operational

considerations, and the best workflow for analyzing wells

in your area. Fekete works with both organizations to

ensure the data is shared equally. Fekete holds all

4

contributed data until both parties meet their reporting

obligations. If your organization contributes data over

and above that of the other party, Feketes expert

judgment will ensure equity between all community

members, and will only release data that ensures a level

playing field. All data will be documented and organized

so that it can easily be incorporated into your Reservoir

Engineering program.

In all of our communities, Fekete ensures that

interpretations are harmonized on a common set of

workflows. These workflows, and all methods developed

to meet community objectives, become a valuable

toolset for training your engineers in the latest

unconventional analysis techniques.

Contact us at community@fekete.com to discuss how

our Community of Best Practice program can help your

organization stay on the leading edge of unconventional

analysis.

You have paid

a lot of

attention to our

feedback and

have done an

excellent job

incorporating it

into your

software.

- Nathan McMahan

Sr. Reservoir Engineer,

ConocoPhillips, Oct 2012

Fekete News & Notes

It is our pleasure to

announce that Fekete has

been acquired by IHS Inc.

(NYSE: IHS www.ihs.com), a

leading provider of business

information, insight and analytics in

key areas shaping todays global

business landscape. Both the Fekete

and IHS teams are very excited

about the positive impact this

acquisition will have on the

capabilities, solutions and value we

deliver to you and your organization.

You

Tube

Were on YouTube

Have you visited our YouTube channel yet? Video resources for all of our software

products are available at youtube.com/user/feketesoftware.

Training

In addition to the public software and engineering courses that we hold regularly, we

also offer custom in-house software and engineering workshops to groups of eight or

more learners. Book an existing course for your group, or allow us to customize your

training to include analysis of your data, and to create a workflow to suit your specific

assets. Visit fekete.com to learn more about Fekete training.

Introducing our NEW Website

Have you visited fekete.com lately?

In honor of our 40th Anniversary, we have completely re-designed our website. Our

new site is user friendly and easy to navigate. You can effortlessly locate all of the

great technical content youve come to expect from us, including published papers,

our complete technical video series, and software training videos. You can register for

one of our public training courses, learn the Golden Rules of Well Test Interpretation,

or find out about current employment opportunities.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- TheoryMind EF 2017Document13 pagesTheoryMind EF 2017indapantsNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- RepBehaviourAutsim 2017Document13 pagesRepBehaviourAutsim 2017indapantsNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Appendix 1: List of SubmissionsDocument4 pagesAppendix 1: List of SubmissionsindapantsNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Sample Lab ReportDocument3 pagesSample Lab ReportindapantsNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Teaching Mathematics - Using Research-Informed StrategiesDocument64 pagesTeaching Mathematics - Using Research-Informed Strategiesindapants100% (1)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- 28 Polarization of LightDocument3 pages28 Polarization of LightindapantsNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- B-Mathematical Literacy FlyerDocument1 pageB-Mathematical Literacy FlyerindapantsNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Minimum Standards Document - West Australian Mobile Food Vendors AssociationDocument27 pagesMinimum Standards Document - West Australian Mobile Food Vendors AssociationindapantsNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Mod 2 ContinuumDocument18 pagesMod 2 ContinuumindapantsNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Boy in The Striped Pajamas Full Text Holocaust PDFDocument112 pagesThe Boy in The Striped Pajamas Full Text Holocaust PDFindapantsNo ratings yet

- Chapter 16 AnswersDocument6 pagesChapter 16 AnswersindapantsNo ratings yet

- Effective TeachersPART2Document7 pagesEffective TeachersPART2indapantsNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- AT1 - Task 1 - Student 1 ResponseDocument7 pagesAT1 - Task 1 - Student 1 ResponseindapantsNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Product ListingDocument34 pagesProduct ListingindapantsNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Learn FrenchDocument249 pagesLearn Frenchv155r97% (89)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Simulations (Take Home) Math Methods Units 3,4Document4 pagesSimulations (Take Home) Math Methods Units 3,4indapantsNo ratings yet

- Learning French EbookDocument36 pagesLearning French EbookDonnette Davis100% (20)

- Topic5 - Diffraction - Fill in Blanks NoteDocument2 pagesTopic5 - Diffraction - Fill in Blanks NoteindapantsNo ratings yet

- 3AB Trial CalculatorFree 2011Document8 pages3AB Trial CalculatorFree 2011indapantsNo ratings yet

- Solutions 2001 (1) WaceDocument22 pagesSolutions 2001 (1) WaceindapantsNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Year 12 Chemistry Year Planner 2013Document1 pageYear 12 Chemistry Year Planner 2013indapantsNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Stage 3 Physics 2010 Trial WACE Examination SolutionDocument32 pagesStage 3 Physics 2010 Trial WACE Examination Solutionindapants100% (1)

- Lecture 2 (1) - Chapter 6Document5 pagesLecture 2 (1) - Chapter 6indapantsNo ratings yet

- 2AB CHEM Test 1practiceDocument8 pages2AB CHEM Test 1practiceindapantsNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Year 10 Algebra WorksheetDocument1 pageYear 10 Algebra WorksheetindapantsNo ratings yet

- Unit OutlineDocument1 pageUnit OutlineindapantsNo ratings yet

- Physics Motion 1Document6 pagesPhysics Motion 1indapantsNo ratings yet

- 1Document2 pages1indapantsNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Tutorial 1 - Statistical Thermodynamics 1Document15 pagesTutorial 1 - Statistical Thermodynamics 1JoserineNo ratings yet

- Chapter 3 - Microscopic Displacement Eficiency - Part IIDocument40 pagesChapter 3 - Microscopic Displacement Eficiency - Part IIMohamed ModerNo ratings yet

- Realistic P&ID DiagramsDocument20 pagesRealistic P&ID Diagramsgerson castroNo ratings yet

- BPH Fluid Mechanics Tutorial SolutionsDocument10 pagesBPH Fluid Mechanics Tutorial SolutionsLingyu LiuNo ratings yet

- Analisa Faktor Penyebab Cacat Produksi Pengisian Gas Oksigen: Studi Kasus Di Pt. Samator Gas Kota BatamDocument7 pagesAnalisa Faktor Penyebab Cacat Produksi Pengisian Gas Oksigen: Studi Kasus Di Pt. Samator Gas Kota BatamGame ASMRNo ratings yet

- Air Receivers Volume CalculationDocument123 pagesAir Receivers Volume CalculationsdgthdtrtretNo ratings yet

- Steam Distillation 2014Document4 pagesSteam Distillation 2014nityaNo ratings yet

- Calculation Flow and CalculatorDocument37 pagesCalculation Flow and CalculatorDavid LambertNo ratings yet

- International Equations For The Saturation Properties of Ordinary Water Substance-2Document10 pagesInternational Equations For The Saturation Properties of Ordinary Water Substance-2Ruben AlexisNo ratings yet

- Packed Column Pressure DropDocument1 pagePacked Column Pressure DropdinakaranpatelNo ratings yet

- Chapter 3 Permeability Part 2Document18 pagesChapter 3 Permeability Part 2Pugal100% (1)

- SSC JE Pressure ProblemsDocument15 pagesSSC JE Pressure Problemscooper sheldonNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Conversion And: Gas LawsDocument17 pagesConversion And: Gas LawsLynne Joie Laroza TapayNo ratings yet

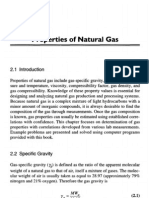

- Natural Gas Engineering Hand Book (2005) Ch.2Document21 pagesNatural Gas Engineering Hand Book (2005) Ch.2Abdelrahman Saeed89% (9)

- Natural Gas Production and OperationsDocument2 pagesNatural Gas Production and OperationsHossam M. Abd El RahmanNo ratings yet

- Fiziks: Chapter - 1Document47 pagesFiziks: Chapter - 1SURAJ PRATAP SINGHNo ratings yet

- Presion de Vapor Del ClorometanoDocument2 pagesPresion de Vapor Del ClorometanoSandra MilenaNo ratings yet

- Hall-Yarborough Gas Compressibility Factor CalculatorDocument3 pagesHall-Yarborough Gas Compressibility Factor CalculatoricaNo ratings yet

- Centrifugal CompressorDocument20 pagesCentrifugal CompressorMir Aqueel AliNo ratings yet

- Flow Regimes and Pressure Losses in Closed ConduitsDocument18 pagesFlow Regimes and Pressure Losses in Closed ConduitsJay Wilmer RoqueroNo ratings yet

- Osborn Reynolds Experiment Visualizes Laminar & Turbulent FlowDocument6 pagesOsborn Reynolds Experiment Visualizes Laminar & Turbulent Flowsanduni33% (3)

- Guide To Gases: NitrogenDocument3 pagesGuide To Gases: Nitrogenbilalak1990No ratings yet

- ME1823 - Properties of Pure SubstancesDocument23 pagesME1823 - Properties of Pure SubstancesNadun Sasanga KumarasingheNo ratings yet

- Newton's Law of ViscosityDocument8 pagesNewton's Law of ViscosityAn FakeihahNo ratings yet

- Slug CatcherDocument2 pagesSlug CatcherToyinNo ratings yet

- UAS Semester Ganjil Tahun Ajaran 2020/2021Document1 pageUAS Semester Ganjil Tahun Ajaran 2020/2021Aldi WaladiNo ratings yet

- Assignment 3 PDFDocument3 pagesAssignment 3 PDFk l mandalNo ratings yet

- Standards and Protocols For Use of DP Flowmeters in Natural GasDocument2 pagesStandards and Protocols For Use of DP Flowmeters in Natural GasJuan JaramilloNo ratings yet

- Melting Boiling and EvaporationDocument19 pagesMelting Boiling and EvaporationAnmol MalgotraNo ratings yet

- Physical Chemistry ExamDocument5 pagesPhysical Chemistry ExamelnurorucluNo ratings yet