Professional Documents

Culture Documents

MnDOT Pavement Design Examples

Uploaded by

rrj44Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MnDOT Pavement Design Examples

Uploaded by

rrj44Copyright:

Available Formats

April 27, 2009 Mn/DOT Pavement Design Examples

The following examples are intended to demonstrate the procedures used to design the options

required by Technical Memo No. 04-19-MAT-02. In some of these design examples the design

R-value (average minus one standard deviation) of the native/in-place soil is adjusted to reflect

the increase in support provided by the use of select granular material. This adjusted R-value

may be used with the Rigid Pavement Design program (RigidPavement.exe) and the Flexible

Pavement Design program (FlexiblePavement.exe) to determine pavement thickness.

Web sites:

Software: http://www.dot.state.mn.us/materials/pvmtdesign/software.html

Pavement Design Manual: http://www.dot.state.mn.us/materials/pvmtdesign/manual.html

Technical Memos: http://www.dot.state.mn.us/materials/pvmtdesign/docs

Design Parameters

The following parameters will be used in the examples.

Traffic

(a) 20 year design lane BESALs =4,179,000

(b) 20 year design lane CESAL =6,471,000

(c) 35 year design lane CESAL (12,942,000 x 0.93*) =12,036,060

(* frozen subgrade effect factor)

Load Transfer

For a PCC protected edge design (27 wide): Load Transfer, J =2.6

Subgrade Support

Native/in-place sub-grade soil design R-value (average minus one standard deviation) is

equal to 12.

Example No. 1 - Concrete Pavement with Drainage Layer

(a) The applicability of this design should be established in accordance with Figure 1

provided in the Permeable Aggregate Base Drainage System Design Guidelines, dated

J uly 1994.

(b) The concrete thickness is determined using standard procedures with the RigidPavement

program.

Enter the following parameters into the RigidPavement program:

Soil Characteristic, R-value =12

Load Transfer, J =2.6 (for protected edge design)

35 year design lane CESAL (12,942,000 x 0.93) =12,036,060

1

April 27, 2009 Mn/DOT Pavement Design Examples

The RigidPavement program calculated thickness is 8.867.

Reduce the thickness by 0.5 as per Permeable Aggregate Base Drainage System Design

Guidelines

8.867 0.5 =8.367

Round the design thickness to 8.5.

Example No. 2 - Concrete Pavement Overlying 12 Select Granular Material

(a) Adjust the R-value to account for increase support provided by the 12 select granular

material. (The Class 5 Aggregate Base is not included in the adjustment procedure).

The adjustment is made as follows:

1. Use the Bituminous Aggregate Base (BAB) design chart (Figure 5-3.7, Pavement

Design Manual).

2. Convert the 12 select granular material to a granular equivalent (GE) by using a

granular equivalent factor of 0.5. The GE is 12 x 0.5 =6.

3. Using the BAB design chart, locate on the chart the point x established with design

parameters ESALs =4,179,000 and R =12. Count upwards 6 GE inches and

estimate the R-value at this point. The adjusted R-value is estimated to be

approximately equal to 24.

(b) The concrete thickness is determined using standard procedures with the RigidPavement

program.

Enter the following parameters into the RigidPavement program:

Soil Characteristic, R-value =24

Load Transfer, J =2.6 (for protected edge design)

35 year design lane CESAL (12,942,000 x 0.93) =12,036,000

The RigidPavement program calculated thickness is 8.661.

Round the design thickness to 9.0.

Example No.3 - Concrete Pavement with 3/5 Class 5

This design is used for low volume traffic loads (less than 1,000,000 ESALs). Use the

current design procedures (RigidPavement program) for determination of the pavement

thickness. The minimum concrete thickness is 7.

2

April 27, 2009 Mn/DOT Pavement Design Examples

Example No.4 - Bituminous Aggregate Base (BAB Design

(a) Determine the structural thickness using the current design procedure (FlexiblePavement

or Figure 5-3.7, Pavement Design Manual).

(b) The minimum structural thickness is 30 inches, unless the 20 year BESALs exceed 7

million, in which case, the minimum thickness is increased to 36 inches. The Z

thickness is the additional material required if the FlexiblePavement or Figure 5-3.7

thickness results in a total structural thickness that is less than the minimum 30 (36)

inches. The material that is used to meet the additional required thickness to satisfy the

minimum standard thickness may be Select Granular, Class 4, or Class 5 or a

combination thereof. However, the final materials selection should be based on an

economic analysis and ease of construction.

(c) If the current design procedure provides a total structural thickness that is greater than the

minimum standard thickness, then that total thickness should be incorporated into the

design.

(d) Using the design parameters R=12 and BESALs =4,179,000 the FlexiblePavement

program results in the following:

G.E. =36.8 inches

1.5 Type 41 Wear

2.5 Type 41 Binder

2.5 Type 31 Base

6.0 Class 6, Aggregate Base

6.0 Class 4, Aggregate Base

16.5 Class 3, Aggregate Base

(e) The FlexiblePavement program was developed using a previous version of Mn/DOT

specifications and Type 41, 61, and 31 bituminous material is no longer specified. Type

31 material used a GE factor of 2.0 and currently all plant-mix bituminous pavement uses

a GE factor of 2.25. To adjust the Type 31 thickness to current specifications, multiply it

by .889. Type 41 and Type 61 material does not require a thickness adjustment.

2.5 (Type 31 Base) x .889 =2.225 round to 2.5.

The thicknesses in accordance with current Mn/DOT specification 2360 -

4.0 Wearing Course

2.5 Non-Wearing Course

6.0 Class 6, Aggregate Base

6.0 Class 4, Aggregate Base

16.5 Class 3, Aggregate Base

The total thickness is 35.0 which is greater than the 30 minimum, so no additional

aggregate or granular material is required.

3

April 27, 2009 Mn/DOT Pavement Design Examples

Example No.5 Bituminous Deep Strength (BDS) Design

(a) The design procedure for BDS is an iterative process.

(b) Determine the structural thickness using the current full-depth design procedure

(FlexiblePavement or Figure 5-3.8, Pavement Design Manual).

(c) Subtract the thickness determined in (b) plus 3 inch of Class 5 from the 30 minimum

depth to determine the estimated Z thickness of select granular material.

(d) Multiply the Z x 0.5 to determine the granular equivalent in inches.

(e) Adjust the in-place/native soil design R-value to account for the increase support

provided by the Z thickness of select granular material. (The Class 5, Aggregate Base,

is not included in the adjustment procedure). The adjustment is made as described under

item (a) 3. Design No. 2.

(f) Using the design parameters R =12 and BESALs =4,179,000.

1. Full-Depth Design =12.21 inches (from FlexiblePavement or Figure 5-3.8)

2. Determine depth Z inches

30 - 3 12.0 =15 of select granular

3. Determine GE of the select granular

15 x 0.5 =7.5 GE

4. Using the BAB design chart, locate on the chart the point x established with design

parameters ESALs =4,179,000 and R =12. Count upwards 7.5 GE inches and

estimate the R-value at this point. The adjusted R-value is estimated to be

approximately equal to 29.

5. Determine new BDS thickness using full-depth design chart or FlexiblePavement

using design parameters R =29 and BESAL =4,179,000.

The resulting thickness is 10.6 (round to 10.5).

6. Trial No. 2 uses 10.5

Z =30 3 10.5 =16.5 of select granular

GE =16.5 x 0.5 =8.25

Adjusted/new design R-value =31

New Bituminous thickness equals 10.4, use 10.5 (no change from Trial No. 1)

10.5 (Bituminous) +3 (Class 5, Aggregate Base) +17 (select granular) =31

which is greater than the required 30 inch minimum thickness.

Example No.6 - BAB/BDS

(a) These designs are used for low volume traffic loads (less than 1,000,000 BESALs.)

(b) The design procedures are the same as examples No. 4 (BAB) and No. 5 (BDS) except

that there is no requirement for a minimum total depth. There is a requirement for a

minimum of 6 granular treatment (Class 5 Aggregate Base or Select Granular Material.)

Unbonded Concrete Overlay Design

The un-bonded concrete overlay thickness should be determined in accordance with the

design procedures illustrated in Appendix D, Pavement Design Manual.

4

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Water Pressure Grid TutorialDocument17 pagesWater Pressure Grid Tutorialrrj44No ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Phase Relations Explained in Simple TermsDocument9 pagesPhase Relations Explained in Simple TermsHarish Lambadi100% (2)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Tutorial 08 Probabilistic AnalysisDocument24 pagesTutorial 08 Probabilistic Analysisrrj44No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Tutorial 06 SupportDocument21 pagesTutorial 06 Supportrrj44No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Soil Classification TechnicalDocument11 pagesSoil Classification TechnicalRupam PathakNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Shallow Foundation (Bearing Capacity) TERZAGHI's Bearing Capacity FormulaDocument3 pagesShallow Foundation (Bearing Capacity) TERZAGHI's Bearing Capacity Formularrj44No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Slope Deflection MethodDocument17 pagesSlope Deflection Methodmshahryar50% (2)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- DR Chap04 Shear ReinforcementDocument5 pagesDR Chap04 Shear Reinforcementrrj44No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Engineering Properties of MaterialsDocument6 pagesEngineering Properties of Materialspapilolo2008No ratings yet

- PondDocument5 pagesPondrrj44No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Beam DeflectionDocument65 pagesBeam Deflectionrrj44No ratings yet

- Goldart - Resco ProductsDocument3 pagesGoldart - Resco Productsrrj44No ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- How ADAM WorksDocument9 pagesHow ADAM Worksrrj44No ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Custom GraphDocument1 pageCustom Graphrrj44No ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- 8 Slope StabilityDocument10 pages8 Slope StabilityGaspard PierristalNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Slope - Guia de EnseñanzaDocument24 pagesSlope - Guia de EnseñanzaDavid SupoNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Phys 2012 Exam 1 EquationsDocument1 pagePhys 2012 Exam 1 Equationsrrj44No ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Vertical Stress2Document9 pagesVertical Stress2nephembaniNo ratings yet

- Mohr 1Document7 pagesMohr 1Christer PereiraNo ratings yet

- Linear Interpolation in TablesDocument1 pageLinear Interpolation in TableswaheedamerNo ratings yet

- Fhwa Ed 88 053Document42 pagesFhwa Ed 88 053rshaghayan100% (1)

- Effective Stresses in The GroundDocument5 pagesEffective Stresses in The Groundrrj44No ratings yet

- Linear Interpolation in TablesDocument1 pageLinear Interpolation in TableswaheedamerNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- American Light Ale Partial Mash InstructionsDocument2 pagesAmerican Light Ale Partial Mash Instructionsrrj44No ratings yet

- Trig RefDocument2 pagesTrig Refrrj44No ratings yet

- Specific Gravity FormulasDocument1 pageSpecific Gravity Formulasrrj44No ratings yet

- Trig RefDocument2 pagesTrig Refrrj44No ratings yet

- Trig RefDocument2 pagesTrig Refrrj44No ratings yet

- Trig RefDocument2 pagesTrig Refrrj44No ratings yet

- Piping OverviewDocument28 pagesPiping Overviewعزت عبد المنعمNo ratings yet

- Installation & Maintenacne Manual: Variable-Frequency One-Drive-Two Split Room Air Conditioner SeriesDocument35 pagesInstallation & Maintenacne Manual: Variable-Frequency One-Drive-Two Split Room Air Conditioner SeriesKostas AstrinisNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Huot Henglong - Shop DrawingDocument21 pagesHuot Henglong - Shop Drawinghuothenglong.sdh231No ratings yet

- Local Buckling Tests On Cold-Formed Steel Beams by Yu 2003Document11 pagesLocal Buckling Tests On Cold-Formed Steel Beams by Yu 2003fahmi aballiNo ratings yet

- Poster-Septic Tanks Dos and Donts PDFDocument1 pagePoster-Septic Tanks Dos and Donts PDFRavi TejNo ratings yet

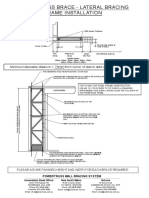

- PT Brace Installation 1Document1 pagePT Brace Installation 1Tony PedaNo ratings yet

- Wiring Design & CalculationsDocument36 pagesWiring Design & CalculationsSerrano Ivan Jasper100% (1)

- amm 467 349Document6 pagesamm 467 349Dinesh JagadisanNo ratings yet

- Structure RFI Status Summary For The Month of December-2021Document11 pagesStructure RFI Status Summary For The Month of December-2021Thakur Ravi ChauhanNo ratings yet

- Examining The Evolution of Jaipur S ArchDocument13 pagesExamining The Evolution of Jaipur S ArchSham ParitNo ratings yet

- On Vertical Formwork: Concr Ete PressureDocument7 pagesOn Vertical Formwork: Concr Ete PressureatiNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Tree DeclarationDocument2 pagesTree DeclarationMichael TilbrookNo ratings yet

- TEC-221300 - MET-DoR-003 (Method Statement For Storm Water Works) (H)Document15 pagesTEC-221300 - MET-DoR-003 (Method Statement For Storm Water Works) (H)Roderick Hipol100% (1)

- Type of Wiring DevicesDocument21 pagesType of Wiring DevicesChristopher GalivoNo ratings yet

- QAP Format - QA 01 F 01Document1 pageQAP Format - QA 01 F 01Murukan PadmanabhanNo ratings yet

- AnnexureDocument16 pagesAnnexureAmirNo ratings yet

- Cable-Stayed Bridge Final and Construction Stage Analysis TutorialDocument69 pagesCable-Stayed Bridge Final and Construction Stage Analysis TutorialHafiz DoyoxNo ratings yet

- Rehabilitation of Sindangan-Siayan-Dumingag-Mahayag RoadDocument2 pagesRehabilitation of Sindangan-Siayan-Dumingag-Mahayag RoadAljie CañeteNo ratings yet

- Chapter 1 - Bill of QuantitiesDocument27 pagesChapter 1 - Bill of QuantitiesAmin SardariNo ratings yet

- Technobond Insulation BRANZ Appraisl No 693 Ceiling and Wall PDFDocument5 pagesTechnobond Insulation BRANZ Appraisl No 693 Ceiling and Wall PDFJohn SmithNo ratings yet

- Fdas - Specs PDFDocument10 pagesFdas - Specs PDFAiron Jay MangabatNo ratings yet

- Piping Layout: Philosophy of Yard PipingDocument11 pagesPiping Layout: Philosophy of Yard PipingdasubhaiNo ratings yet

- Donggwang Clark ConcominiumDocument15 pagesDonggwang Clark ConcominiumJay-Ar Chris CariagaNo ratings yet

- NTRBTDocument12 pagesNTRBTRanjanDsNo ratings yet

- Summary of Changes ASME BPVC - Ii.dDocument16 pagesSummary of Changes ASME BPVC - Ii.dAnonymous xr4GVHNo ratings yet

- En-353GF Head & Lower HalfDocument22 pagesEn-353GF Head & Lower HalfVaeco Đoàn Tncs HcmNo ratings yet

- KDW 2204 - 7396335 Vista Explodida - CompressedDocument50 pagesKDW 2204 - 7396335 Vista Explodida - Compressedjoildo juniorNo ratings yet

- Bridge Building PDFDocument4 pagesBridge Building PDFGio PadillaNo ratings yet

- Spare Parts Catalog: 4 WG 160 Material Number: 4656.054.039 Current Date: 10.06.2020Document70 pagesSpare Parts Catalog: 4 WG 160 Material Number: 4656.054.039 Current Date: 10.06.2020Romuald Pogorzelczyk100% (2)

- Boiler Basics, Operation and MaintenanceDocument121 pagesBoiler Basics, Operation and MaintenanceCosmin IulianNo ratings yet

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetFrom EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetRating: 4.5 out of 5 stars4.5/5 (10)

- Dark Aeon: Transhumanism and the War Against HumanityFrom EverandDark Aeon: Transhumanism and the War Against HumanityRating: 5 out of 5 stars5/5 (1)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindFrom EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo ratings yet

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansFrom EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansNo ratings yet

- Comprehensive Guide to Robotic Process Automation (RPA): Tips, Recommendations, and Strategies for SuccessFrom EverandComprehensive Guide to Robotic Process Automation (RPA): Tips, Recommendations, and Strategies for SuccessNo ratings yet

- The Great Bridge: The Epic Story of the Building of the Brooklyn BridgeFrom EverandThe Great Bridge: The Epic Story of the Building of the Brooklyn BridgeRating: 4.5 out of 5 stars4.5/5 (59)

- Atlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceFrom EverandAtlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceRating: 5 out of 5 stars5/5 (9)

- To Engineer Is Human: The Role of Failure in Successful DesignFrom EverandTo Engineer Is Human: The Role of Failure in Successful DesignRating: 4 out of 5 stars4/5 (137)

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsFrom EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsNo ratings yet