Professional Documents

Culture Documents

Hydraulic and Pneumatic (CT322)

Uploaded by

Timothy FieldsCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydraulic and Pneumatic (CT322)

Uploaded by

Timothy FieldsCopyright:

Available Formats

75

MPI

Profibus DP

Data show

Text book

PC

Networking; hierarchical

structures.

Introduction to Field bus

systems.

Profibus

Device-net

Introduction to Industrial Ethernet

technology.

9. An introduction to process visualization

10. Definition, explanation the DCS systems in industrial application

11. An overview of SCADA system

Week

13-14

Practical Resources Specific Learning Outcomes

Board

Data show

Text book

PC

Process visualization, The man

(human)machine interface

(HMI)

Distributed Control System

(DCS)

SCADA system

76

Subject

Hydraulic and Pneumatic

Course Code CT322 Theoretical 3hrs / wk

Semester 6 Prerequisite NT220 Practical 3hrs / wk

Program Learning Component:

Theoretical classes

Resources Specific Learning Outcomes

Week

1 Data show

Introduction to pneumatics, i.e. Basic physical concepts.

1. Fluid properties: compressibility, incompressibility;

pressure, pressure scales, relative pressure,

atmospheric pressure, vacuum pressure, pressure

gages; flow rate, relation between flow rate, speed, and

pressure.

2. Gas laws: Boyles law; Charles law; gay-Lussacs

law; the general gas law.

3. Force transmission through a fluid, Pascals law; the

basic concept of a pneumatic system.

4. Advantages and disadvantages of pneumatic systems.

Resources Specific Learning Outcomes

Week

2-3 Data show

Pneumatic energy control, control valves:

1. Directional control valves DCV):

Symbols according to ISO 1219

Different types of DCV: cross sections to show

their internal parts, operating principles, methods

of actuation.

2. Pressure valves: pressure reducing valve, quick exhaust

valve, two - pressure valve, shuttle valve.

3. Flow control valves: one-way valve, variable flow control

valve, one-way variable flow control valve.

4. Compound valves: time-delay valve, sequence valve,

vacuum valve.

5. Simple examples, simple pneumatic machines.

Resources Specific Learning Outcomes Week

77

Data show

Design of pneumatic machines:

6. Motion (step) diagram.

7. Simple (one - cylinder) machines.

8. Compound (more than a cylinder) machines.

9. Over-lapped machines.

10. Different examples; methods of overcoming the problem

of over-lapping.

4-5

Resources Specific Learning Outcomes

Week

6 Data show

Pneumatic energy generation.

1. General concepts: free air, air compression process.

2. Compressor design principles.

3. A brief description of the mechanism of different types

of compressors:

Positive displacement compressors: piston

compressor; diaphragm compressor; vane

compressor; screw compressor.

Dynamic compressors: centrifugal compressor,

axial flow compressor.

4. Compressor staging.

5. Compressor capacity control.

6. Compressor house ventilation.

7. Selecting a Compressor for a system.

8. Installation of Compressor.

9. Compressor ancillary equipments: intake/ silencer

filter; after cooler; moisture separator; intercooler; air

receiver( tank), air receiver sizing; compressed air

dryers, refrigeration dryers, absorption dryers;

compressed air distribution.

Compressed air servicing ( service unit):

1. The importance of the service unit for a pneumatic

machine.

2. The main parts of a service unit:

Air filter.

Pressure regulator.

Pressure gauge.

Lubricator

78

Resources Specific Learning Outcomes

Week

7 Data show

Linear pneumatic actuators(pneumatic cylinders):

1. Single-acting cylinder, diaphragm cylinder.

2. Double-acting cylinders:

Pneumatic end-position cushioned cylinders.

Rodless cylinders: magnetically coupled,

mechanically coupled, belt coupled.

Impact cylinders.

Swivel (semi-rotary) cylinders.

3. Seals in linear actuators.

4. Linear actuators sizing: calculation of external forces,

static thrust force calculations, dynamic force calculation,

piston rod buckling, air consumption calculation.

Resources Specific Learning Outcomes

Week

8 Data show

Rotary pneumatic actuators(pneumatic motors):

1. Motor torque, motor output power, motor speed.

2. Different types of air motors: vane motor; gear motor;

radial piston motor; axial piston motor; turbine motor.

3. Air motor sizing and torque calculations.

4. Air motor performance.

5. Pressure and flow regulation on air motors.

Resources Specific Learning Outcomes

Week

9 Data show

Electropneumatics (electropneumatic systems):

1. Components and assemblies in the electrical signal

control section: power supply, switches different types),

proximity switches: reed switch, capacitive switch,

inductive switch, optical switch), pressure switches.

2. Application of magnetic effect of electrical current,

solenoid.

3. Control relays, time delayed relays.

4. Solenoid directional control valves, brief study of

different types, piloted valves.

5. Over-lapped machines.

6. Different examples.

Resources Specific Learning Outcomes Week

79

Data show

Hydraulics (hydraulic systems):

Introduction to hydraulics, i.e. Basic physical concepts.

1. Pressure in liquids, flow rate and velocity, force

transmission by liquids (force multipliers), Pascals law,

pressure intensifier, viscosity, flow types, Reynolds

number, friction, heat, pressure drop through hydraulic

systems, cavitations, power calculation in hydraulic

systems.

2. Hydraulic fluids, their task, types.

3. The concept of power transmission.

4. Advantages and disadvantages of hydraulic systems.

5. The main parts of a hydraulic system.

10

Resources Specific Learning Outcomes

Week

11 Data show

Hydraulic power generation (Hydraulic power pack):

1. Hydraulic pumps: the role of a pump in a hydraulic

system, pumping theory, pump characteristics.

2. Pump types:

Fixed displacement pumps: vane pump, piston

pump.

Variable displacement pumps: variable

displacement vane pump, : variable displacement

vane pump.

Control of variable displacement pumps.

3. Others: filter, heater, cooler, reservoir.

Resources Specific Learning Outcomes

Week

12 Data show

Hydraulic valves:

1. Directional control valves DCV):

Symbols according to ISO 1219

Different types of DCV: cross sections to show

their internal parts, operating principles, methods

of actuation.

2. Pressure valves: pressure relief valve, pressure regulating

valve, shuttle valve.

3. Flow control valves: one-way valve (check valve),

piloted-check valve, variable flow control valve, one-way

80

variable flow control valve, two-way flow control valve

with throttle, .two-way flow control valve with orifice,

three-way flow control valve, on-off valve.

Resources Specific Learning Outcomes

Week

13 Data show

Linear hydraulic actuators(hydraulic cylinders):

1. Cylinder construction.

2. Actuator types:

Single-acting cylinder, telescopic cylinder.

Double-acting cylinders:

Double-acting cylinder with rods on both

ends.

Double-acting cylinder with cushioning.

Double-acting cylinder with adjustable

cushioning.

Double-acting telescopic cylinder.

Tandem cylinder.

3. Seals in linear hydraulic actuators, stop tubes.

4. Actuators sizing

5. Piston rod buckling.

Resources Specific Learning Outcomes

Week

14 Data show

Rotary hydraulic actuators(hydraulic motors):

1. Motor torque, motor displacement (geometric volume),

motor output power, motor speed.

2. Different types of air motors: vane motor; external gear

motor; internal gear motor; radial piston motor; axial

piston motor.

3. Hydraulic motor sizing and torque calculations.

4. Hydraulic motor performance.

5. Motor sizing.

6. Hydraulic motor control: speed control, reversal control.

Resources Specific Learning Outcomes

Week

15 Data show

Hydraulic accumulators:

1. Role of a hydraulic accumulator in a hydraulic machine.

2. Accumulator sizing.

3. Accumulator calculation.

81

4. Types of accumulator:

Spring accumulator.

Weight-loaded accumulator.

Piston accumulator.

Diaphragm accumulator.

5. Accumulators in hydraulic circuits.

Resources Specific Learning Outcomes

Week

16 Data show

Examples of hydraulic and electrohydraulic machines.

Practical classes

Resources Specific Learning Outcomes

Week

3

Lab.

Performing some experiments to practice the function of

directional control valves, and how they control the motion

of pneumatic cylinders and motors.

Resources Specific Learning Outcomes

Week

4

Lab.

Experimenting the function of the variable flow control

valve, and how it controls the speed of pneumatic cylinders

and motors.

Resources Specific Learning Outcomes

Week

5

Lab.

Controlling the advance and return of pneumatic cylinders

with time-delay and sequence valve.

Resources Specific Learning Outcomes

Week

6

Lab.

Design, simulation and realization of some compound

pneumatic machines.

Resources Specific Learning Outcomes

Week

7

Lab.

Experimenting the function of electrically actuated

(solenoid) directional control valves, and how they control

the motion of pneumatic cylinders.

Resources Specific Learning Outcomes

Week

8

Lab.

Simple electropneumatic machines with different types of

limit switches.

Resources Specific Learning Outcomes Week

82

Lab.

Performing some experiments to practice the function of

control relays, and how they control Simple

electropneumatic machines.

9

Resources Specific Learning Outcomes

Week

10-11

Lab.

Realization of simple hydraulic machines.

Determining the operating pressure by adjusting the

pressure relieve valve.

Practicing the function of hydraulic directional control

valves, and how they control the motion of hydraulic

cylinders and motors.

Resources Specific Learning Outcomes

Week

12

Lab.

Practicing the function of pressure regulating valves, and

how they control they regulate the pressure in hydraulic

machines.

Resources Specific Learning Outcomes

Week

13

Lab.

Practicing the function of flow control valves, and how they

control they regulate the flow in hydraulic machines.

Resources Specific Learning Outcomes

Week

14

Lab.

Practicing the role of hydraulic accumulator in hydraulic

machines.

Resources Specific Learning Outcomes

Week

15-16

Lab.

Different examples of hydraulic and electrohydraulic

machines.

Text books:

Pneumatic Control for Industrial Automation, by: Peter Rohner& Gordon Smith.

Industrial Hydraulic Control, by: Peter Rohner.

Prepared by engineer Emhemmed Al-dardar.

You might also like

- Fluid Power Ebook Fluid Power BasicsDocument233 pagesFluid Power Ebook Fluid Power Basicspatil_raaj7234No ratings yet

- H & P SyllabusDocument3 pagesH & P SyllabusDrPrashant NeheNo ratings yet

- Fluid PowerDocument2 pagesFluid PowershreedharkolekarNo ratings yet

- Fluid Power and Control-Lecture 1Document16 pagesFluid Power and Control-Lecture 1Barnaba DionizNo ratings yet

- Hydraulics and Pneumatics SystemsDocument4 pagesHydraulics and Pneumatics SystemsKrista JacksonNo ratings yet

- Elements of Mechanical EngineeringDocument5 pagesElements of Mechanical EngineeringnavitgmNo ratings yet

- 2ME705-4-Hydraulic and Pneumatic SystemsDocument2 pages2ME705-4-Hydraulic and Pneumatic SystemsDev Chauhan100% (1)

- Applied Hydraulics and Pneumatics ME1305Document8 pagesApplied Hydraulics and Pneumatics ME1305kv19852009No ratings yet

- Flow Control ValveDocument5 pagesFlow Control Valvezakaria100% (1)

- Course Outline - EMG 2401 Industrial HydraulicsDocument2 pagesCourse Outline - EMG 2401 Industrial HydraulicsJimmy KariukiNo ratings yet

- Course Objectives:: Me3253: Hydraulic Machines and Fluid PowerDocument5 pagesCourse Objectives:: Me3253: Hydraulic Machines and Fluid Powergiriaj kokareNo ratings yet

- Vtu Mechanical Engineering 7th Sem SyllabusDocument15 pagesVtu Mechanical Engineering 7th Sem SyllabusHalesh T DNo ratings yet

- Hydraulic Control Circuit ExamplesDocument13 pagesHydraulic Control Circuit Examplessmarjan80% (5)

- Hydraulic Courses - Typical Content-2Document8 pagesHydraulic Courses - Typical Content-2Eza IRNo ratings yet

- Hydraulics and PneumaticsDocument6 pagesHydraulics and PneumaticslardominicNo ratings yet

- Untitled 1Document3 pagesUntitled 1divyaroopeshNo ratings yet

- Velammal Engineering College, Chennai - 600066.: Department of Mechanical Engineering University Question BankDocument6 pagesVelammal Engineering College, Chennai - 600066.: Department of Mechanical Engineering University Question BankmurugesanvNo ratings yet

- First SeminarDocument30 pagesFirst SeminarNan OoNo ratings yet

- McENG 6221-Advanced Fluid Power System (Mechatronics)Document4 pagesMcENG 6221-Advanced Fluid Power System (Mechatronics)duraiprakash83No ratings yet

- Project VTUDocument16 pagesProject VTUsameekshaNo ratings yet

- AbcDocument11 pagesAbcAchal SharmaNo ratings yet

- Links To This Post First Year QP Mechanical QB Mechnical: Posted by N R Rejin Paul LabelsDocument8 pagesLinks To This Post First Year QP Mechanical QB Mechnical: Posted by N R Rejin Paul LabelsSuresh KumarNo ratings yet

- Mechanical Engineering Department Two Mark Questions & AnswersDocument7 pagesMechanical Engineering Department Two Mark Questions & AnswersVVCET - MechNo ratings yet

- Basic Hydraulics and Pneumatics Module 1Document42 pagesBasic Hydraulics and Pneumatics Module 1vijay0% (1)

- UNIT-1 Hydraulic and Pneumatic DrivesDocument56 pagesUNIT-1 Hydraulic and Pneumatic DrivesChetuNo ratings yet

- Fluid Power Control (Jis University) (Z-Library)Document81 pagesFluid Power Control (Jis University) (Z-Library)Mauro PerezNo ratings yet

- HmsDocument2 pagesHmsKARTHIK RAJASHEKARNo ratings yet

- Special Topics in Mechanical Engineering/ Fluid Power ControlDocument21 pagesSpecial Topics in Mechanical Engineering/ Fluid Power ControlBassel DaradkehNo ratings yet

- Question Bank-Fluid Power System EngineeringDocument3 pagesQuestion Bank-Fluid Power System EngineeringShashank ShastriNo ratings yet

- Chapple CHPT 1Document35 pagesChapple CHPT 1CharleneKronstedtNo ratings yet

- MODULE 2 Intro - Lab HydraulicDocument3 pagesMODULE 2 Intro - Lab HydraulicHafiz Melliani100% (1)

- Hydraulic & Pneumatic ControlsDocument9 pagesHydraulic & Pneumatic ControlsVikram Rao100% (1)

- Bche205l Momentum-Transfer TH 1.0 70 Bche205lDocument2 pagesBche205l Momentum-Transfer TH 1.0 70 Bche205lLuha Fathima BasheerNo ratings yet

- Ihp Experiment Wise QBDocument2 pagesIhp Experiment Wise QByuvarajballalNo ratings yet

- Fluid Lab 2Document23 pagesFluid Lab 2Wong Wei HaoNo ratings yet

- ME656Document2 pagesME656hukNo ratings yet

- Unit - I: Two Mark Questions & AnswersDocument8 pagesUnit - I: Two Mark Questions & Answerssmg26thmayNo ratings yet

- Hydraulic 5 Day Fundamentals and PrinciplesDocument4 pagesHydraulic 5 Day Fundamentals and PrinciplesbrNo ratings yet

- Hydraulic and Pneumatic System: M.E. Technical Elective 1 (Mechatronics)Document58 pagesHydraulic and Pneumatic System: M.E. Technical Elective 1 (Mechatronics)Kim TanNo ratings yet

- Liquids Have No Shape of Their OwnDocument58 pagesLiquids Have No Shape of Their OwnAshraf Kamal EllamsyNo ratings yet

- Che1005 - Momentum-Transfer - Eth - 1.1 - 47 - Che1005 - 55 AcpDocument2 pagesChe1005 - Momentum-Transfer - Eth - 1.1 - 47 - Che1005 - 55 Acpblub blueNo ratings yet

- Lab 1 HydraulicDocument9 pagesLab 1 Hydraulicohoodalfowdaie123No ratings yet

- ME 206 Fluid MachineryDocument3 pagesME 206 Fluid MachinerySudeesh SudevanNo ratings yet

- MODULE II (A)Document65 pagesMODULE II (A)Nazeema TTNo ratings yet

- Hydraulic System 1Document28 pagesHydraulic System 1Udhaya Kumar100% (1)

- 2-Hydraulic Actuators and Control Compenents-2Document57 pages2-Hydraulic Actuators and Control Compenents-2akhilkrrish143No ratings yet

- Lab BombasDocument11 pagesLab BombasDAWANNY RODRIGUEZ CELISNo ratings yet

- Review Questions: Unit # 2: Hydraulic Actuators and MotorsDocument1 pageReview Questions: Unit # 2: Hydraulic Actuators and MotorsnikhiljmNo ratings yet

- VII Semester Sl. No. Sub-Code Subject Dept/Board Hours/week CreditsDocument22 pagesVII Semester Sl. No. Sub-Code Subject Dept/Board Hours/week CreditsMurali Krishna GbNo ratings yet

- Atm1122 Hydraulics Module 1Document20 pagesAtm1122 Hydraulics Module 1Masood AlamNo ratings yet

- Maintenance & Operation of Rotating MachineryDocument3 pagesMaintenance & Operation of Rotating MachineryElsayed AmerNo ratings yet

- Presentation ON Hydraulic Control System Control Engineering (2151908)Document26 pagesPresentation ON Hydraulic Control System Control Engineering (2151908)Marwan NasserNo ratings yet

- 308 Hydraulic Troubleshooting Course DescriptionDocument2 pages308 Hydraulic Troubleshooting Course Descriptionnuncafalha0% (1)

- Mee2003 Thermal Engineering Systems: Dr. Bibhuti B. SDocument53 pagesMee2003 Thermal Engineering Systems: Dr. Bibhuti B. SpapujapuNo ratings yet

- Energy and System Lab Part IDocument28 pagesEnergy and System Lab Part IAhmed MohamedNo ratings yet

- Lab 3 HydraulicDocument9 pagesLab 3 Hydraulicohoodalfowdaie123No ratings yet

- Cylinder SequencingDocument21 pagesCylinder Sequencingjoshi vivek0% (1)

- Course Outline: Return To Course IndexDocument9 pagesCourse Outline: Return To Course Indexoswaldo58No ratings yet

- Olympus Epoch XTDocument8 pagesOlympus Epoch XTTimothy FieldsNo ratings yet

- Ontrol Ystems Ociety: Publications Content DigestDocument11 pagesOntrol Ystems Ociety: Publications Content DigestTimothy FieldsNo ratings yet

- Liceet 2018 Paper 128Document5 pagesLiceet 2018 Paper 128Timothy FieldsNo ratings yet

- Industrial DevelopmentDocument221 pagesIndustrial DevelopmentTimothy FieldsNo ratings yet

- Speed Monitor PDFDocument30 pagesSpeed Monitor PDFTimothy FieldsNo ratings yet

- TURCK Ultrasonic SensorsDocument2 pagesTURCK Ultrasonic SensorsTimothy FieldsNo ratings yet

- Simatic St80 Add Ons Complete English 2015 OkDocument28 pagesSimatic St80 Add Ons Complete English 2015 OkTimothy FieldsNo ratings yet

- 2013 Engineering MagazineDocument28 pages2013 Engineering MagazineTimothy FieldsNo ratings yet

- CTACDocument13 pagesCTACTimothy FieldsNo ratings yet

- AC Drives: Siemens STEP 2000 CourseDocument37 pagesAC Drives: Siemens STEP 2000 CourseTimothy FieldsNo ratings yet

- Consultancy ProjectsDocument3 pagesConsultancy ProjectsTimothy FieldsNo ratings yet

- Fellowship Application 2016 enDocument3 pagesFellowship Application 2016 enTimothy FieldsNo ratings yet

- Che 436 Competencies For Exam 2: Level 3Document8 pagesChe 436 Competencies For Exam 2: Level 3Timothy FieldsNo ratings yet

- Training IEC CE For Control Panels - April 2014 PDFDocument195 pagesTraining IEC CE For Control Panels - April 2014 PDFTimothy Fields100% (1)

- Exam2 (Review Slides) PDFDocument8 pagesExam2 (Review Slides) PDFTimothy FieldsNo ratings yet

- GSSScholarship 2017 enDocument4 pagesGSSScholarship 2017 enTimothy FieldsNo ratings yet

- Mobilizare Pasiva SoldDocument1 pageMobilizare Pasiva SoldTimothy FieldsNo ratings yet

- Industrial AutomationDocument33 pagesIndustrial AutomationTimothy FieldsNo ratings yet

- Pedal Operated Mini Project ReportDocument6 pagesPedal Operated Mini Project ReportVikramsingh SinghNo ratings yet

- CaserearDocument2 pagesCaserearDaniel JosephNo ratings yet

- MMPX Separation System, Automatic - Installation - 1995Document47 pagesMMPX Separation System, Automatic - Installation - 1995Centrifugal SeparatorNo ratings yet

- Truck Selection J688 SAEDocument34 pagesTruck Selection J688 SAEGM Maquinaria100% (1)

- BMW e SeriesDocument9 pagesBMW e SeriesHabib HamdaniNo ratings yet

- Calibracion de Valvulas Perkins 400Document3 pagesCalibracion de Valvulas Perkins 400nolram23No ratings yet

- Pages From Chapter 17-19Document10 pagesPages From Chapter 17-19taNo ratings yet

- Claas Dominator 218 202 Mega II Hydraulics Electrics ServiceDocument208 pagesClaas Dominator 218 202 Mega II Hydraulics Electrics ServiceVlad Ptashnichenko100% (1)

- Parts Catalogue 6CTAA-8.3-G4Document125 pagesParts Catalogue 6CTAA-8.3-G4Joko Irawanto100% (2)

- Pistons and Connecting Rods - InstallDocument4 pagesPistons and Connecting Rods - InstallYudi setiawanNo ratings yet

- Pines MP7Document11 pagesPines MP7Jose MarotoNo ratings yet

- Matsushita Hermetic Compressors 64 Matsushita Hermetic Compressors MatsushitaDocument4 pagesMatsushita Hermetic Compressors 64 Matsushita Hermetic Compressors MatsushitaJesus Grillet100% (1)

- Kenmore 385.12216 Sewing Machine Instruction ManualDocument79 pagesKenmore 385.12216 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- 793C - 4GZ-ATY Slide-1Document208 pages793C - 4GZ-ATY Slide-1iscasanosalamNo ratings yet

- DK 1008-En 04.15 13 PDFDocument1 pageDK 1008-En 04.15 13 PDFIulia CostacheNo ratings yet

- LSM011S - 15k Check ValvesDocument2 pagesLSM011S - 15k Check ValvesFaizal KhalidNo ratings yet

- 6BTA5.9-G3: Description FeaturesDocument2 pages6BTA5.9-G3: Description FeaturesHugo MartinezNo ratings yet

- Tech List enDocument17 pagesTech List enserzo75No ratings yet

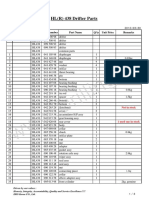

- WWW - Drilling.Kr: HL (R) 438 Drifter PartsDocument3 pagesWWW - Drilling.Kr: HL (R) 438 Drifter PartsRussell HayesNo ratings yet

- Rational Sccwe 101e PMDocument53 pagesRational Sccwe 101e PMDanny AlejandroNo ratings yet

- Dgms Tech Circular No 2 of 2002 Accident Due To TipperDocument4 pagesDgms Tech Circular No 2 of 2002 Accident Due To Tipperj subbaraoNo ratings yet

- Worm Gear Driven Lifting Winch MCDocument1 pageWorm Gear Driven Lifting Winch MCTarunPatraNo ratings yet

- TD27Document3 pagesTD27ETIENNENo ratings yet

- Engine Transmission 1Document65 pagesEngine Transmission 1RendiNo ratings yet

- Bergen B35-40 enDocument2 pagesBergen B35-40 encandranortonNo ratings yet

- Perkins 4.154 Torque Specs and Assembly Information Copy.Document42 pagesPerkins 4.154 Torque Specs and Assembly Information Copy.Engine PartsNo ratings yet

- Piaggio MP3 300 I e LT en PDFDocument360 pagesPiaggio MP3 300 I e LT en PDFMiroNo ratings yet

- SKF Spherical Roller Bearings For Wind Turbine Main ShaftsDocument5 pagesSKF Spherical Roller Bearings For Wind Turbine Main ShaftsDaniel FuhrNo ratings yet

- D2D Project With GuideDocument6 pagesD2D Project With GuideHiten KoriyaNo ratings yet

- Catalogo Cummins de Fabricacion ChinaDocument396 pagesCatalogo Cummins de Fabricacion ChinaVictor Hugo Rodriguez100% (1)