Professional Documents

Culture Documents

Coal Conveyor Guard

Uploaded by

DSGOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Coal Conveyor Guard

Uploaded by

DSGCopyright:

Available Formats

w w w .PRBCoal s.c om w w w .PRBCoal sFor um.

c om

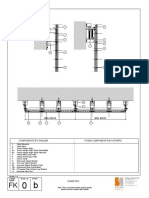

Conveyor Guarding Case Study

featuring

Belt Conveyor Guarding

w w w .PRBCoal s.c om w w w .PRBCoal sFor um.c om

Project Scope

To identify conveyor nip and shear

points and install protection to

eliminate caught-in or struck by

potentials.

w w w .PRBCoal s.c om w w w .PRBCoal sFor um.c om

Nip and Shear Points

w w w .PRBCoal s.c om w w w .PRBCoal sFor um.c om

Initial Safety

Considerations

Typical nip and shear point locations include:

Terminals, drives, take-ups, pulleys, and snub

rollers where the belt changes directions

Where belts wrap around pulleys

At discharge ends of a belt conveyor

At Take ups.

At bearings and couplings

w w w .PRBCoal s.c om w w w .PRBCoal sFor um.c om

Tail Pulley Area

Needs Guarded-Exposed nip at tail

pulley

Properly

Guarded

Tail

Pulley

Before

After

w w w .PRBCoal s.c om w w w .PRBCoal sFor um.c om

Tail Pulley Area

Properly

guarded

tail section

Tail pulley

with

inadequate

guarding

w w w .PRBCoal s.c om w w w .PRBCoal sFor um.c om

Tail Pulley Area

Properly

guarded tail

section.

Floor

clearance

provided for

clean out

purposes.

w w w .PRBCoal s.c om w w w .PRBCoal sFor um.c om

Take-Up Area

Before

After

Take Up

Guarded by

Handrail

Properly

Guarded

Take-Up

w w w .PRBCoal s.c om w w w .PRBCoal sFor um.c om

Take-Up Area

Barrier guard that

surrounds dual conveyor

counter weights. Mid-wall

partition allows for

Conveyors to be locked

out for service independently.

Barrier guard

inadequate

opening makes

area accessible.

Before

After

w w w .PRBCoal s.c om w w w .PRBCoal sFor um.c om

Head Pulley/Discharge Area

Pinch points

exposed

Pinch points

are properly

covered

Before

After

w w w .PRBCoal s.c om w w w .PRBCoal sFor um.c om

Return Roller Area

Roller and belt

exposes <7

clearance

Roller

and

belt

guarded

Before After

w w w .PRBCoal s.c om w w w .PRBCoal sFor um.c om

Bend Pulley Area

Exposed

pulley and

bearing needs

guarding.

Standard flat

guards and

mounting rails

ensure pulleys

and rollers are

guarded

properly.

Before After

w w w .PRBCoal s.c om w w w .PRBCoal sFor um.c om

Bearing and Coupling

Area

Coupling

Guard

Bearing &

Coupling

Guards

Exposed

shafts and

bearings

Before After

w w w .PRBCoal s.c om w w w .PRBCoal sFor um.c om

Bearing and Coupling

Area

Bearing guard

with removable

panels for

access.

Oversize mesh

openings and

gaps around

guard.

Coupling guard

with adjustable

fill plates ensure

all gaps are

properly

covered.

Guard does

not cover

bearing

Before After

w w w .PRBCoal s.c om w w w .PRBCoal sFor um.c om

Not ThisBut This

Handrail

does not

constitute a

guard.

Barrier

guarding

designed to

accommodate

existing

obstructions.

Before After

w w w .PRBCoal s.c om w w w .PRBCoal sFor um.c om

Obstructed Areas

Barrier wall

shortened to

accommodate

existing

obstructions

Barrier guard

modified to

allow access to

electrical

panel.

w w w .PRBCoal s.c om w w w .PRBCoal sFor um.c om

Greasing Accommodation

Grease lines

routed to

common external

location to

simplify routine

maintenance.

Common guard

mounting holes

are ideal for

routing grease

lines.

w w w .PRBCoal s.c om w w w .PRBCoal sFor um.c om

American Electric Power

&

Belt Conveyor Guarding

Thank You!!

You might also like

- NZ Guarding of Belt ConveyorsDocument28 pagesNZ Guarding of Belt Conveyors450gasgasNo ratings yet

- Project Proposal Wind MillDocument8 pagesProject Proposal Wind MillAbdul BasitNo ratings yet

- Iso 17893 2004Document15 pagesIso 17893 2004RAVIKANT SINDHENo ratings yet

- Disclosure To Promote The Right To Information: IS 11521 (1985) : Cargo Handling Nets (TXD 9: Cordage)Document16 pagesDisclosure To Promote The Right To Information: IS 11521 (1985) : Cargo Handling Nets (TXD 9: Cordage)Ganesh ModiNo ratings yet

- BS en Iso 3691-6-2013Document38 pagesBS en Iso 3691-6-2013yamen sayedNo ratings yet

- Cargo Net l3 Ast Le Adma 314Document6 pagesCargo Net l3 Ast Le Adma 314Anwar DeenNo ratings yet

- Rope Stuff For NDT Is GreatDocument6 pagesRope Stuff For NDT Is GreatSteve MorrisonNo ratings yet

- Crane Wire Rope Code PDFDocument1 pageCrane Wire Rope Code PDFraulbrlunaNo ratings yet

- OMHEC Guidance For Training StandardDocument32 pagesOMHEC Guidance For Training StandardDimitar LevskiNo ratings yet

- Machinery Safety ChecklistDocument4 pagesMachinery Safety ChecklistOHNo ratings yet

- 5102037E - 120 - User ManualTX, TXS, TXR PDFDocument76 pages5102037E - 120 - User ManualTX, TXS, TXR PDFAbhijeet SahuNo ratings yet

- Cica GN 0001 A Wind Guidance NoteDocument3 pagesCica GN 0001 A Wind Guidance Noteconsulting2No ratings yet

- Portable Hardness Tester TIME5300Document4 pagesPortable Hardness Tester TIME5300Wadie KhatiNo ratings yet

- Ihs267.tmp (bs3481-2 - 1983 - Webbing Sling)Document13 pagesIhs267.tmp (bs3481-2 - 1983 - Webbing Sling)Ariq Fauzan100% (1)

- Machine GuardingDocument66 pagesMachine GuardingRizwan BangashNo ratings yet

- THIELE Grade80 A5 EnglishDocument52 pagesTHIELE Grade80 A5 EnglishalpNo ratings yet

- SS-22 Forklift Safety Management Training - Materi PDFDocument54 pagesSS-22 Forklift Safety Management Training - Materi PDFAgung PramonoNo ratings yet

- REPORT Model of Wire RopesDocument32 pagesREPORT Model of Wire RopesalexremNo ratings yet

- Basic Fire Safety: Directorate of Fire and Emergency Services ST - Inez, Panaji-GoaDocument28 pagesBasic Fire Safety: Directorate of Fire and Emergency Services ST - Inez, Panaji-GoaSunita YadavNo ratings yet

- BSI PPE Factsheet UK EN PDFDocument2 pagesBSI PPE Factsheet UK EN PDFMDNV RAONo ratings yet

- Textile Belt SplicingDocument3 pagesTextile Belt SplicingWaris La Joi WakatobiNo ratings yet

- HSE Alert 07-16 Damage To Drilling Mast IncidentDocument1 pageHSE Alert 07-16 Damage To Drilling Mast IncidentSajid HussainNo ratings yet

- Power AscenderDocument6 pagesPower AscenderApriliando KurniawanNo ratings yet

- Webbing SlingDocument3 pagesWebbing Slingmoha19841No ratings yet

- Conveyor Safety ChecklistDocument1 pageConveyor Safety Checklistdana setiawanNo ratings yet

- Mechanical Vacuum Lifter - Manual - 11 May 2015Document72 pagesMechanical Vacuum Lifter - Manual - 11 May 2015quyenhuynhhaNo ratings yet

- Speedyscaf - TechnicalDocument20 pagesSpeedyscaf - TechnicalMohamed MerchantNo ratings yet

- Lever Hoist ManualDocument40 pagesLever Hoist Manualbeshoy100% (1)

- Cables de Acero Usha Martin User Manual1Document60 pagesCables de Acero Usha Martin User Manual1luis100% (1)

- Grader PPT Sample-WebDocument22 pagesGrader PPT Sample-WebKenan mira Mohammed NasherNo ratings yet

- Munck CraneDocument268 pagesMunck CraneEduardo OvalleNo ratings yet

- REP-045 Report Record of Socketing Termination by Wire Lock ResinDocument1 pageREP-045 Report Record of Socketing Termination by Wire Lock ResinHendra LimNo ratings yet

- SB 85XP - MS 3015 DSS13Document4 pagesSB 85XP - MS 3015 DSS13amin110110100% (1)

- Wstda-Ws-1: ©2015 Web Sling & Tie Down AssociationDocument39 pagesWstda-Ws-1: ©2015 Web Sling & Tie Down AssociationAditya GuptaNo ratings yet

- Api RP 2D - Offshore Crane Inspector Certification ProgramDocument5 pagesApi RP 2D - Offshore Crane Inspector Certification Programzulfadli izaraeeNo ratings yet

- 10 Frequently Asked Questions About The Machinery DirectiveDocument5 pages10 Frequently Asked Questions About The Machinery Directivesujal_aminNo ratings yet

- Side Boom TrainingDocument40 pagesSide Boom TrainingMauricio Bulla ValenciaNo ratings yet

- Katalog Wampfler Narazniky EN PDFDocument34 pagesKatalog Wampfler Narazniky EN PDFpich222100% (1)

- Cranes Hoisting and RiggingDocument25 pagesCranes Hoisting and Riggingkanakarao1No ratings yet

- Iso 4310 - 2009 Cranes - Test Code and Procedures - PDFDocument19 pagesIso 4310 - 2009 Cranes - Test Code and Procedures - PDFpranayasharma022No ratings yet

- Taglineuse PEERREVIEWDOCDocument56 pagesTaglineuse PEERREVIEWDOCMohamed Said0% (1)

- As 1353.1-1997 Flat Synthetic-Webbing Slings Product SpecificationDocument7 pagesAs 1353.1-1997 Flat Synthetic-Webbing Slings Product SpecificationSAI Global - APAC0% (1)

- 56 3260Document188 pages56 3260Abdul RachmanNo ratings yet

- StandardsDocument7 pagesStandardsmac1677No ratings yet

- AIS-099 & Amd 1 To 3Document112 pagesAIS-099 & Amd 1 To 3김동은No ratings yet

- Astm E1571Document6 pagesAstm E1571Juan CarmonaNo ratings yet

- Australian Standard: Cranes, Hoists and Winches-Safe Use Part 1: General RequirementsDocument8 pagesAustralian Standard: Cranes, Hoists and Winches-Safe Use Part 1: General RequirementsMaxaNo ratings yet

- U LectureDocument234 pagesU LectureTran DucNo ratings yet

- Spec BookDocument194 pagesSpec BookCataNo ratings yet

- Design Analysis and Improvement of EOT Crane WheelDocument4 pagesDesign Analysis and Improvement of EOT Crane WheelIJSTENo ratings yet

- BS Iso 4250-1-2006Document26 pagesBS Iso 4250-1-2006marksuseNo ratings yet

- Handling of The GAS Cylinders PDFDocument4 pagesHandling of The GAS Cylinders PDFZubair KhanNo ratings yet

- 50T Drop Table SEC RailwayDocument28 pages50T Drop Table SEC RailwaymailbkraoNo ratings yet

- Scan APIDocument183 pagesScan APIChitradeep Dutta RoyNo ratings yet

- Conveyor SafetyDocument18 pagesConveyor Safetyshaik sakeemNo ratings yet

- DNV, TIFF TIN For Case-Hardened GearsDocument6 pagesDNV, TIFF TIN For Case-Hardened GearsPeter Carden100% (1)

- Splice Belt DesignDocument9 pagesSplice Belt DesignriteshsamantrayNo ratings yet

- LOLERDocument82 pagesLOLERNguyen Phuc LinhNo ratings yet

- Bridge and Gantry Crane Drivers Guide 0001Document72 pagesBridge and Gantry Crane Drivers Guide 0001John Henry SinuratNo ratings yet

- Physical Metallurgy-18 Heat Treatment of SteelDocument7 pagesPhysical Metallurgy-18 Heat Treatment of SteelDSGNo ratings yet

- Assignment 1 Mech 321 Properties and Failure of Materials Jan 2009Document2 pagesAssignment 1 Mech 321 Properties and Failure of Materials Jan 2009DSGNo ratings yet

- EPRI Materials Degradation - Aging 2008 - P041.01Document44 pagesEPRI Materials Degradation - Aging 2008 - P041.01DSGNo ratings yet

- How To Use This Severity Chart: Example Fan 625 Um (25 Mils)Document2 pagesHow To Use This Severity Chart: Example Fan 625 Um (25 Mils)Aminul Haque SaikiaNo ratings yet

- The Storage of High Volatile CoalDocument2 pagesThe Storage of High Volatile CoalcoalspotNo ratings yet

- @ M/S.N.R.Agarwal Industries LTD Unit 3&4, Gidc, Phase-3, Vapi, GujratDocument28 pages@ M/S.N.R.Agarwal Industries LTD Unit 3&4, Gidc, Phase-3, Vapi, GujratDSGNo ratings yet

- TATA Power Scaffold Safety StandardDocument7 pagesTATA Power Scaffold Safety StandardDSG100% (1)

- Chapter Outline:: Heat Treatment (And Temperature)Document24 pagesChapter Outline:: Heat Treatment (And Temperature)DSGNo ratings yet

- L18 Lecture 18 Wear 1 PDFDocument6 pagesL18 Lecture 18 Wear 1 PDFDSGNo ratings yet

- 3 APH PERFORMANCE in NTPC STATIONS AjaySharmaDocument15 pages3 APH PERFORMANCE in NTPC STATIONS AjaySharmaDSGNo ratings yet

- Battery Charger Manual - HBL PDFDocument12 pagesBattery Charger Manual - HBL PDFDSG0% (1)

- Technical Report On Electrostatic Precipitator: Geeco Enercon PVT LTD Tiruchirapalli - 620015 IndiaDocument21 pagesTechnical Report On Electrostatic Precipitator: Geeco Enercon PVT LTD Tiruchirapalli - 620015 IndiaDSGNo ratings yet

- Fighting Fire With CO: by Dominique Dieken, P.E., Starr Technical Risks Agency IncDocument6 pagesFighting Fire With CO: by Dominique Dieken, P.E., Starr Technical Risks Agency IncDSGNo ratings yet

- Bowl Mill Study 1Document10 pagesBowl Mill Study 1DSG100% (1)

- Performance Improvement by Expert ConsultancyDocument19 pagesPerformance Improvement by Expert ConsultancyDSGNo ratings yet

- Cladding Technology Processes and ImagesDocument7 pagesCladding Technology Processes and ImagesDSGNo ratings yet

- Lubrication Oil TestingDocument2 pagesLubrication Oil TestingDSGNo ratings yet

- Technofit Technofit: Geeco Seminar Geeco SeminarDocument12 pagesTechnofit Technofit: Geeco Seminar Geeco SeminarDSGNo ratings yet

- Reliability Improvement Bearing MaintenanceDocument8 pagesReliability Improvement Bearing MaintenanceDSGNo ratings yet

- CUMI Note On PowerDocument6 pagesCUMI Note On PowerDSGNo ratings yet

- Pronouns 9 PDFDocument1 pagePronouns 9 PDFDSGNo ratings yet

- Remote Control RCR815 - ManualDocument25 pagesRemote Control RCR815 - Manualbob187ncNo ratings yet

- 2017 List of Poker BooksDocument5 pages2017 List of Poker BooksMert İstanbullNo ratings yet

- Sweet Paul's Almond BunsDocument2 pagesSweet Paul's Almond BunsThe WorldNo ratings yet

- SUPER 30 VILLAS PRESENTATION April 2021Document31 pagesSUPER 30 VILLAS PRESENTATION April 2021DEEPAK KUMARNo ratings yet

- Egyptian Sweet Pastry Dessert (Umm Ali) : Start Reacting TodayDocument1 pageEgyptian Sweet Pastry Dessert (Umm Ali) : Start Reacting TodaySike Silvia GunawanNo ratings yet

- Dipabrsm QuestionsDocument10 pagesDipabrsm Questionsdennn100% (5)

- Fabrik DetailsDocument2 pagesFabrik DetailsKarthik Keyan ThiagarajanNo ratings yet

- CREATING Tourism Awareness atDocument29 pagesCREATING Tourism Awareness atMonette de GuzmanNo ratings yet

- Colinde de Craciun (Moderne)Document3 pagesColinde de Craciun (Moderne)Andreea DemirNo ratings yet

- DOS-100 PCB (LOCAL Monitoring Board)Document4 pagesDOS-100 PCB (LOCAL Monitoring Board)AdjieNo ratings yet

- Harold Bloom Nathaniel Hawthorne Blooms Major Short Story WritersDocument89 pagesHarold Bloom Nathaniel Hawthorne Blooms Major Short Story WritersshakedogshakeNo ratings yet

- Using The PhoneDocument6 pagesUsing The PhoneVarga CasianaNo ratings yet

- Ata 24Document118 pagesAta 24Sohaib Aslam ChaudharyNo ratings yet

- Group ChatsDocument7 pagesGroup ChatsDennis HaNo ratings yet

- Suggested Syllabi, Smart Choice 1Document4 pagesSuggested Syllabi, Smart Choice 1Carol FlanneryNo ratings yet

- Iready 207Document8 pagesIready 207api-292667474No ratings yet

- Linux Command Enigma2Document3 pagesLinux Command Enigma2Hassan Mody TotaNo ratings yet

- Mapeh-P eDocument35 pagesMapeh-P eVergil TanNo ratings yet

- Easiest Trick To Modulate PDFDocument1 pageEasiest Trick To Modulate PDFŁukasz RomanowskiNo ratings yet

- Oye Happy DeckDocument15 pagesOye Happy DeckOye HappyNo ratings yet

- Virtual Staff Case StudyDocument15 pagesVirtual Staff Case StudySreenivas KazaNo ratings yet

- Border Reiver Feud War Rules 7Document11 pagesBorder Reiver Feud War Rules 7Anthony RhodesNo ratings yet

- Mil Reviewer 4TH QuarterDocument3 pagesMil Reviewer 4TH QuarterPauline Jean Cueto BundaNo ratings yet

- Rainsteal Oil and Gas Contract LetterDocument3 pagesRainsteal Oil and Gas Contract LetterMark Tambus JhonsNo ratings yet

- Community Blend Issue 3Document12 pagesCommunity Blend Issue 3bsb_fcpNo ratings yet

- Access Literature: An Introduction To Fiction, Poetry, and DramaDocument3 pagesAccess Literature: An Introduction To Fiction, Poetry, and DramaNova Julianta SiagianNo ratings yet

- Ball Bearing Classification PDFDocument5 pagesBall Bearing Classification PDFshihabjamaan50% (2)

- Personal - Best - A1 - Unit - 3 - Vocabulary - Test ResueltoDocument3 pagesPersonal - Best - A1 - Unit - 3 - Vocabulary - Test ResueltoMerly Lizeth Contreras Infantes100% (4)

- КнигиDocument2 pagesКнигиЮлия ДорошеваNo ratings yet

- CCTV Trade Catalogue Summer-Autum 2007Document34 pagesCCTV Trade Catalogue Summer-Autum 2007api-3770143No ratings yet