Professional Documents

Culture Documents

PETE 411 Well Drilling: Lesson 7 Drilling Bits - Drag Bits

Uploaded by

Oswaldo Chihuala BustamanteOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PETE 411 Well Drilling: Lesson 7 Drilling Bits - Drag Bits

Uploaded by

Oswaldo Chihuala BustamanteCopyright:

Available Formats

1

PETE 411

Well Drilling

Lesson 7

Drilling Bits - Drag Bits

2

Contents

The Ideal Bit

Drag Bits

Fishtail Type

Natural Diamond

Polycrystalline Diamond Compact

(PDC)

Relative Costs of Bits

3

Read: ADE, Ch.5 (bits)

HW # 3: due 9 -15 - 04

4

The purpose of Chapter 5 (ADE)

is to introduce the student

to the:

Rotary Drill bits

selection and

operation

of rotary drilling bits.

5

Rotary Drilling Bits

Bit types available

Criteria for selecting the best bit for a

given situation

Standard methods for evaluating dull bits

Factors affecting bit wear and drilling

speed

Optimization of bit weight and rotary

speed

6

Bit Types Available

Drag bits (fixed cutter blades)

Fishtail bit

Natural diamond bits

PDC Bits (Polycrystalline Diamond Compact)

Rolling cutter bits (rock bits - with cones)

Mill tooth bits

Tungsten carbide bits

7

The Ideal Bit *

1. High drilling rate

2. Long life

3. Drill full-gauge, straight hole

4. Moderate cost

* (Low cost per ft drilled)

8

The Ideal Bit

Hardness (soft, medium, hard)

abrasiveness

cuttings stickiness

other considerations e.g. cost

The Ideal Bit will depend on the type

of formation to be drilled

9

Drag Bits

Drag bits drill by physically plowing

or machining cuttings from the

bottom of the hole.

10

Drag Bits

Cutter may be made from:

Steel

Tungsten carbide

Natural diamonds

Polycrystalline diamonds (PDC)

Drag bits have no moving parts, so it is less likely

that junk will be left in the hole.

11 Fishtail type drag bit

12

Natural Diamond Bits PDC Bits

13

Natural

Diamond

bit

junk slot

cuttings

radial flow

high p

across face

14

Soft

Formation

Diamond bit

Larger diamonds

Fewer diamonds

Pointed nose

15

Hard

Formation

Diamond bit

Smaller diamonds

More diamonds

Flatter nose

16

Natural Diamonds

The size and spacing of diamonds on a

bit determine its use.

NOTE: One carat = 200 mg precious stones

What is 14 carat gold?

17

Natural Diamonds

2-5 carats - widely spaced diamonds

are used for drilling soft formations such as

soft sand and shale

1/4 - 1 carat - diamonds are used for drilling

sand, shale and limestone formations of

varying (intermediate) hardness.

1/8 - 1/4 carat - diamonds, closely spaced,

are used in hard and abrasive formations.

18

When to Consider Using a Natural

Diamond Bit?

1. Penetration rate of rock bit < 10 ft/hr.

2. Hole diameter < 6 inches.

3. When it is important to keep the bit and

pipe in the hole.

4. When bad weather precludes making trips.

5. When starting a side-tracked hole.

6. When coring.

* 7. When a lower cost/ft would result

19

Top view of diamond bit

20

Side view of

diamond bit

21

PDC

bits

Courtesy

Smith Bits

22

PDC Cutter

23

24

At about $10,000-150,000 apiece, PDC bits cost five to 15 times more

than roller cone bits

PDC Bits

25

The Rise in Diamond Bit Market Share

26

Coring

bit

PDC +

natural

diamond

27

Bi-Center bit

Courtesy Smith Bits

28

Relative Costs of Bits

Diamond WC Insert Milled

Bits Bits Tooth Bits

$/Bit

Diamond bits typically cost several times as much as tri-

cone bits with tungsten carbide inserts (same bit diam.)

A TCI bit may cost several times as much as a

milled tooth bit.

29

PDC Bits

Ref: Oil & Gas Journal, Aug. 14, 1995, p.12

Increase penetration rates in oil and gas

wells

Reduce drilling time and costs

Cost 5-15 times more than roller cone bits

1.5 times faster than those 2 years earlier

Work better in oil based muds; however,

these areas are strictly regulated

30

PDC Bits

Parameters for effective use

include

weight on bit

mud pressure

flow rate

rotational speed

31

PDC Bits

Economics

Cost per foot drilled measures Bit

performance economics

Bit Cost varies from 2% - 3% of total cost,

but bit affects up to 75% of total cost

Advantage comes when

- the No. of trips is reduced, and when

- the penetration rate increases

32

PDC Bits

Bit Demand

U.S Companies sell > 4,000 diamond drill

bits/year

Diamond bit Market is about $200

million/year

Market is large and difficult to reform

When bit design improves, bit drills longer

33

PDC Bits

Improvements in bit stability, hydraulics,

and cutter design => increased footage per bit

Now, bits can drill both harder and softer

formations

Formations in US are not as conducive to PDC

bits as formations in some other areas

Bit Demand, contd

34

PDC Bits

By year 2000:

PDC bits had control of about 1/3 of

the worldwide drilling market

The total PDC bit market had risen

to $400 million per year

U.S. bit manufacturers had a 2/3

share of this market

35

PDC Bits

Improvements are a result of the following:

Research

Good Engineering Practices

Competition with other PDC bit

manufacturers/rock bit industries

Bit Design

General Electric introduced PDC in 1973

Product Life = 2 years

36

PDC Bits

Bit Design, contd

Now, a speciality tool

PDC bit diameter varies from 3.5 in to 17.5 in

Goals of hydraulics:

clean bit without eroding it

clean cuttings from bottom of hole

37

PDC Bits

Factors that limit operating range

and economics:

Lower life from cutter fractures

Slower ROP from bad cleaning

Bit design, contd

38

PDC Bits

Cutters

Consist of thin layer of bonded diamond

particles + a thicker layer of tungsten carbide

Diamond

10x harder than steel

2x harder than tungsten carbide

Most wear resistant material

but is brittle and susceptible to damage

39

PDC Bits

Diamond/Tungsten Interface

Bond between two layers on cutter is

critical

Consider difference in thermal

expansion coefficients and avoid

overheating

Made with various geometric shapes to

reduce stress on diamond

Cutters, contd

40

PDC Bits

Various Sizes

Experimental dome shape

Round with a buttress edge for high

impact loads

Polished with lower coefficient of friction

Cutters, contd

41

PDC Bits

Bit Whirl (bit instability)

Bit whirl = any deviation of bit rotation

from the bits geometric center

Caused by cutter/rock interaction forces

PDC bit technology sometimes

reinforces whirl

Can cause PDC cutters to chip and break

42

PDC Bits

Preventing Bit Whirl

Cutter force balancing

Bit asymmetry

Gauge design

Bit profile

Cutter configuration

Cutter layout

43

PDC Bits

Applications

PDC bits are used primarily in

Deep and/or expensive wells

Soft - medium hard formations

44

PDC Bits

Advances in metallurgy, hydraulics

and cutter geometry

Have not cut cost of individual bits

Have allowed PDC bits to drill longer

and more effectively

Allowed bits to withstand harder

formations

Application, contd

45

PDC Bits

Application, contd

PDC bits advantageous for high rotational

speed drilling and in deviated hole section

drillings

Most effective: very weak, brittle formations

(sands, silty claystone, siliceous shales)

Least effective: cemented abrasive sandstone,

granites

46

Grading of Worn PDC Bits

CT - Chipped Cutter

Less than 1/3 of cutting

element is gone

BT - Broken Cutter

More than 1/3 of cutting

element is broken to

the substrate

47

Grading of Worn PDC Bits contd

LT - Lost Cutter

Bit is missing one or

more cutters

LN - Lost Nozzle

Bit is missing one or

more nozzles

48

Table 7.7 - Commonly Used Bit Sizes

For Running API Casing

Casing Size Coupling Size Common Bit

(OD in.) (OD in.) Sizes Used (in.)

4 1/2 5.0 6, 6

1/8

, 6

1/4

5 5.563 6

1/2

, 6

3/4

5 1/2 6.050 7

7/8

, 8

3/8

6 6.625 7

7/8

, 8

3/8

, 8

1/2

6 5/8 7.390 8

1/2

, 8

5/8

, 8

3/4

7 7.656 8

5/8

, 8

3/4

, 9

1/2

7 5/8 8.500 9

7/8

, 10

5/8

, 11

8 5/8 9.625 11, 12

1/4

9 5/8 10.625 12

1/4

, 14

3/4

10 3/4 11.750 15

13 3/8 14.375 17

1/2

16 17 20

20 21 24, 26

49

END

of

Lesson 7

- Drag Bits -

You might also like

- Phys 1Document5 pagesPhys 1Sandra Phan50% (2)

- Boiler Efficiency Calculations SheetDocument5 pagesBoiler Efficiency Calculations Sheetkalyanm20351578% (9)

- Bits NozzlesDocument197 pagesBits Nozzlesiman100% (2)

- Pete321 Chapter4Document20 pagesPete321 Chapter4Jessica Cecilia Silva AnguloNo ratings yet

- Drill CompleteDocument35 pagesDrill Completesiva kumarNo ratings yet

- Marine PurifierDocument30 pagesMarine PurifierJayDelosSantos100% (1)

- The Ideal Bit Drag Bits: Fishtail Type Natural Diamond Polycrystalline Diamond Compact (PDC)Document45 pagesThe Ideal Bit Drag Bits: Fishtail Type Natural Diamond Polycrystalline Diamond Compact (PDC)ShourovjossNo ratings yet

- Drilling Bits Selection GuideDocument35 pagesDrilling Bits Selection GuideMuhammad Shahid RahimNo ratings yet

- PDC BitsDocument40 pagesPDC BitsRizwan Farid100% (1)

- TRICONE VS PDC BITS: WHICH IS BETTERDocument6 pagesTRICONE VS PDC BITS: WHICH IS BETTERUlianov GilNo ratings yet

- Overview of Drilling OperationsDocument18 pagesOverview of Drilling Operationsali nahiNo ratings yet

- Notes 4Document18 pagesNotes 4Ruben ChirinosNo ratings yet

- BitsDocument94 pagesBitsBurt Powell100% (3)

- Fixed Cutter Bits: Early Diamond Bit HistoryDocument24 pagesFixed Cutter Bits: Early Diamond Bit HistoryTim Clarke100% (1)

- Drill BitsDocument38 pagesDrill Bitsrizky8474No ratings yet

- Ideal One Does The Job With Least Overall Cost - Many Manufacturers With Various Designs Suited For Different Formations and ConditionsDocument15 pagesIdeal One Does The Job With Least Overall Cost - Many Manufacturers With Various Designs Suited For Different Formations and ConditionsShiela ONo ratings yet

- 7 - Drill BitDocument17 pages7 - Drill Bitlovely petsNo ratings yet

- AsdDocument3 pagesAsdMuStafaAbbasNo ratings yet

- Part 6 Drilling BitsDocument27 pagesPart 6 Drilling BitsJood SultanNo ratings yet

- Bit TheoryDocument116 pagesBit Theoryjoonak konwar100% (8)

- Rotary Drilling Bits GuideDocument153 pagesRotary Drilling Bits GuideHeris SitompulNo ratings yet

- Drilling Bits SalamDocument93 pagesDrilling Bits Salamkmelloistaken100% (3)

- Rock BitsDocument17 pagesRock Bitssuresh_501No ratings yet

- Week 6 CasingsDocument21 pagesWeek 6 CasingsSidra IqbalNo ratings yet

- Drilling Bits: Islamic Azad University Science and Research Branch Drilling DepartmentDocument28 pagesDrilling Bits: Islamic Azad University Science and Research Branch Drilling Departmentali nahiNo ratings yet

- Drilling BitsDocument9 pagesDrilling BitsAli AbdelrahemNo ratings yet

- Introduction To Bits For Oil Well Drilling Introduction To Diamond BitsDocument9 pagesIntroduction To Bits For Oil Well Drilling Introduction To Diamond BitsRebar KakaNo ratings yet

- WEPS PDC Reamer Presentation Final5!18!12 AK Time 0425p 2Document37 pagesWEPS PDC Reamer Presentation Final5!18!12 AK Time 0425p 2eleceron7919No ratings yet

- PDC Bits CourseDocument76 pagesPDC Bits CourseRobert Koch100% (1)

- PDC BitsDocument75 pagesPDC Bitsamin peyvand100% (1)

- Drilling BitDocument21 pagesDrilling BitIzzatee Zainuddin100% (1)

- Drilling Bits RehanDocument11 pagesDrilling Bits Rehanrehanromeo010No ratings yet

- Overview of Drill BitsDocument153 pagesOverview of Drill BitsJohnSmithNo ratings yet

- 5.21 Drill BitsDocument52 pages5.21 Drill BitsSamuel OkezieNo ratings yet

- Drill BitsDocument52 pagesDrill BitsBoyNo ratings yet

- Drill Bit - WikipediaDocument55 pagesDrill Bit - Wikipediaaddisugebre2125No ratings yet

- Rotary Drilling BitsDocument17 pagesRotary Drilling BitsMin Thant MaungNo ratings yet

- Drilling Engineering Pe 311 An Introduction To Drilling Drill BitsDocument14 pagesDrilling Engineering Pe 311 An Introduction To Drilling Drill BitsHamaamNo ratings yet

- Drilling Bit SelectionDocument8 pagesDrilling Bit SelectionanateghpourNo ratings yet

- TSP Bits: by Jack Leave A CommentDocument8 pagesTSP Bits: by Jack Leave A CommentMuhammad Saqib JanNo ratings yet

- DI Geoset Stratapax EngDocument8 pagesDI Geoset Stratapax Engmyounis82No ratings yet

- Cutting Tool FundamentalsDocument25 pagesCutting Tool FundamentalssatenawuNo ratings yet

- Drilling bitsDocument23 pagesDrilling bitsFaniyi Hussein KehindeNo ratings yet

- Everything You Need to Know About Drill BitsDocument23 pagesEverything You Need to Know About Drill BitsIndah CharismasariNo ratings yet

- Trident PDC CuttersDocument2 pagesTrident PDC CuttersjobsNo ratings yet

- Steeringwheel BitDocument22 pagesSteeringwheel BitAaron MartinNo ratings yet

- Drill BitDocument22 pagesDrill BitPinto JovitaNo ratings yet

- Different Drill Bits Used in Drilling OperationsDocument31 pagesDifferent Drill Bits Used in Drilling OperationsPeterMarkNo ratings yet

- A Presentation ON Drill Bits: Submitted To: Er. Akash Rana (HOD) Petroleum DepttDocument26 pagesA Presentation ON Drill Bits: Submitted To: Er. Akash Rana (HOD) Petroleum DepttJohar marwatNo ratings yet

- Mechanics of Grinding ProcessesDocument11 pagesMechanics of Grinding ProcessesIndranil BhattacharyaNo ratings yet

- Bits Reamers & Stabilizer Types in Drilling Oil and Gas IndustryDocument15 pagesBits Reamers & Stabilizer Types in Drilling Oil and Gas IndustryrahulNo ratings yet

- Bit TechnologyDocument86 pagesBit TechnologyGlen RoelNo ratings yet

- Cutting Tools TechnologyDocument47 pagesCutting Tools TechnologyJeff HardyNo ratings yet

- Drilling & Geology 2012 ResourcePres Festningen LongDocument65 pagesDrilling & Geology 2012 ResourcePres Festningen Longruzzo2003No ratings yet

- Presentation1 PP Sem 3 Selection of Grinding WheelDocument41 pagesPresentation1 PP Sem 3 Selection of Grinding Wheeltanvi tamhaneNo ratings yet

- Selecting Bits Based on Formation DataDocument7 pagesSelecting Bits Based on Formation DataSamad Ali SiddiquiNo ratings yet

- Proposal of Stinger BitsDocument22 pagesProposal of Stinger BitsAbhinav SharmaNo ratings yet

- Turning Wood with Carbide Tools: Techniques and Projects for Every Skill LevelFrom EverandTurning Wood with Carbide Tools: Techniques and Projects for Every Skill LevelRating: 4.5 out of 5 stars4.5/5 (3)

- Classic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersFrom EverandClassic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersRating: 3.5 out of 5 stars3.5/5 (2)

- 2da PracticaDocument13 pages2da PracticaOswaldo Chihuala BustamanteNo ratings yet

- Solution 15Document15 pagesSolution 15Oswaldo Chihuala Bustamante100% (2)

- TA ED RegularDocument9 pagesTA ED RegularOswaldo Chihuala BustamanteNo ratings yet

- Exam 07Document10 pagesExam 07Oswaldo Chihuala BustamanteNo ratings yet

- PVTDocument3 pagesPVTOswaldo Chihuala BustamanteNo ratings yet

- Libro 1Document3 pagesLibro 1Oswaldo Chihuala BustamanteNo ratings yet

- Libro 1Document3 pagesLibro 1Oswaldo Chihuala BustamanteNo ratings yet

- Aws Gtaw Study GuideDocument2 pagesAws Gtaw Study GuideTouil HoussemNo ratings yet

- 1 SR Star Jee Main GTM 02 - 03 01 2024 KeyDocument14 pages1 SR Star Jee Main GTM 02 - 03 01 2024 Keyjahnavimogarala9No ratings yet

- Paper 4 Jun 2001 PhysicsDocument2 pagesPaper 4 Jun 2001 Physicssolarixe100% (1)

- PH Scale BrochureDocument1 pagePH Scale BrochureMherwin RetanalNo ratings yet

- Experiment 6Document6 pagesExperiment 6Sobana Kanthi33% (3)

- HPLC ExperimentDocument4 pagesHPLC ExperimentFrances PaulineNo ratings yet

- Manufacturing and Metal Working Process ClassificationDocument5 pagesManufacturing and Metal Working Process ClassificationPeeka Prabhakara RaoNo ratings yet

- Research PaperDocument12 pagesResearch PaperKiran Niazi100% (1)

- MKS 112 GEN AZ7 SP 01 A Specification For PaintingDocument31 pagesMKS 112 GEN AZ7 SP 01 A Specification For PaintingĐiệnBiênNhâm100% (2)

- Dental Materials: Metals (Alloys) Non-MetalsDocument32 pagesDental Materials: Metals (Alloys) Non-MetalsShahriar honarmandNo ratings yet

- HPLCDocument22 pagesHPLCKafi Mahmood NahinNo ratings yet

- Thermaline 400 Finish PDSDocument3 pagesThermaline 400 Finish PDSQuy RomNo ratings yet

- Msds Icr 122 LSFDocument12 pagesMsds Icr 122 LSFWisnu AbaraiNo ratings yet

- PSA Oxygen Generator: Typical ApplicationsDocument2 pagesPSA Oxygen Generator: Typical ApplicationsRaghu Vir ArjampudiNo ratings yet

- Ipc2022-86856 Influence of Strain Hardening Model On The Corlastm Model ForDocument12 pagesIpc2022-86856 Influence of Strain Hardening Model On The Corlastm Model ForOswaldo MontenegroNo ratings yet

- Macronutrient Project FinalDocument6 pagesMacronutrient Project Finalapi-259363834No ratings yet

- Techstuff 3.09Document117 pagesTechstuff 3.09Hazairin As-Shiddiq RahmanNo ratings yet

- Nuclear Power: Pros, Cons and FutureDocument4 pagesNuclear Power: Pros, Cons and FutureSamarthNo ratings yet

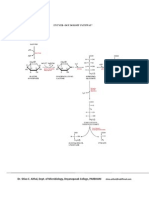

- Entner Duodroff PathwayDocument2 pagesEntner Duodroff PathwayDr. SHIVA AITHALNo ratings yet

- UTP ABRADISC 6000 Offers Cost-Efficient Wear ProtectionDocument4 pagesUTP ABRADISC 6000 Offers Cost-Efficient Wear ProtectionpakhansNo ratings yet

- Welds CracksDocument8 pagesWelds Cracksaltaf94No ratings yet

- Optical Emission From SemiconductorsDocument36 pagesOptical Emission From SemiconductorsvardhanNo ratings yet

- Prodinfo Antox-75-E Eng FinalDocument2 pagesProdinfo Antox-75-E Eng FinalKumar RamanNo ratings yet

- Characterization of Raw Wastewater From TanneriesDocument9 pagesCharacterization of Raw Wastewater From TanneriesMaliha CheemaNo ratings yet

- Pharmaceutical Organic Chemistry Unit II: Aromatic AminesDocument20 pagesPharmaceutical Organic Chemistry Unit II: Aromatic AminesSaili SawardekarNo ratings yet

- UOP PX-Plus ™ XPDocument2 pagesUOP PX-Plus ™ XPana_dcz7154No ratings yet

- Ellc Rmnbemae Llce Bmmneera Lecl Mebmaren Lcel Nbmemaer: Cell MembraneDocument9 pagesEllc Rmnbemae Llce Bmmneera Lecl Mebmaren Lcel Nbmemaer: Cell MembraneAlvin PaboresNo ratings yet