Professional Documents

Culture Documents

Two Way Slab

Uploaded by

Lie Fang0 ratings0% found this document useful (0 votes)

60 views21 pagesDesign 2 way slab

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentDesign 2 way slab

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

60 views21 pagesTwo Way Slab

Uploaded by

Lie FangDesign 2 way slab

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 21

5.

2 COLUMN-SUPPORTED SLAB (TWO-WAY SYSTEM)

The objective of this section is to demonstrate the step-by-step procedure of ADAPT PT to

analyze and design a column-supported slab with drop caps. The structure qualifies as a

two-way system. The tutorial covers the following features of the program:

Generation of input data, using the simple Conventional option of the program.

Design based on the effective force method, as opposed to selection of number of

strands

The structure selected is a typical design strip from a floor system. The breakdown of a

floor system into design strips is covered elsewhere. The geometry, material, loading and

other particulars of the structure are given below. The geometry of the design strip of this

tutorial is shown in Fig.: 5.2-1.

Thickness of slab = 6.5 in (165.1 mm)

FIGURE. 5.2-1

Material Properties

o Concrete:

Compressive strength, f

c

= 4000 psi (27.58 MPa)

Weight = 150 pcf (2403 kg/m

3

)

Modulus of Elasticity = 3604 ksi (24849 MPa)

o Prestressing:

Low Relaxation, Unbonded System

Strand Diameter = in (13 mm)

Strand Area = 0.153 in

2

(98 mm

2

)

Modulus of Elasticity = 28000 ksi (193054 MPa)

Ultimate strength of strand, f

pu

= 270 ksi (1862MPa)

Minimum strand cover

From top fiber = 1 in all spans (25.4 mm)

From bottom fiber

Interior spans = 1 in (25.4 mm)

Exterior spans = 1.5 in (38.1 mm)

o Nonprestressed Reinforcing:

Yield stress f

y

= 60 ksi (413.69 MPa)

Modulus of Elasticity = 29000 ksi (199,949 MPa)

Minimum Rebar Cover = 1in Top and Bottom (25.4 mm)

Loading:

Dead load = self weight + 15 psf (superimposed)

= (6.5/12) * 150 + 15

= 96 psf (4.60 kN/m

2

)

Live load = 40 psf (1.92 kN/m

2

)

5.2.1 Generate the Structural Model

In the ADAPT PT screen, click Options menu and set Default Code as ACI

02;UBC 97;IBC 2003 and Default Units as American.

A. Edit the project information

i. General Settings (Fig. 5.2.1-1)

Open the new project by clicking either New on the file menu or New

Project button on the toolbar. This automatically opens the General Settings

input screen as in Fig. 5.2.1-1. You can enter the General Title and /or

Specific Title of the project in that window.

For the purpose of tutorial enter the General Title as Three-Span Two-Way

Slab, this will appear at the top of the first page of output and enter Specific

Title as Example 2, this will appear at the top of the each subsequent page of

the output.

Next, select the Structural System as Two-Way slab. Then there is an option

to include drop caps, transverse beam and/or drop panels. In this case select

No.

Next, select Geometry Input as Conventional; segmental input is used for

entering non-prismatic structures, i.e., those where the tributary width or the

depth of the section changes within a span. Click Help button at the bottom

line if you want to know about conventional and segmental Geometry input.

Click Next button at the bottom right of this screen to open the next input

screen, Design Settings.

FIGURE 5.2.1-1

ii. Design Settings (Fig. 5.2.1-2)

This screen is used to select various calculation and design settings.

First, select the execution mode as interactive. In this mode, you have an

opportunity to optimize the design by adjusting the tendon forces and tendon drapes

in each span in the Recycle window. This will explain later in this section.

Next, select Yes for Reduce Moments to Face-of-Support option. It indicates

that the calculated centerline moments, at each support are adjusted to the face-of

support. In addition to the centerline moments, ADAPT PT prints out the moments

reduced to face-of- support.

For two-way slab systems you have the option of modeling the structure using the

Equivalent Frame method. Select Yes for this option.

FIGURE 5.2.1-2

Click Next at the bottom right of the Design Settings screen to open the Span

Geometry input screen.

B. Edit The Geometry of The Structure

i. Enter Span Geometry (Fig. 5.2.1-3)

This screen is used to enter the cross-sectional geometry of the slab at mid span.

Set the Number of Spans as 3 either by clicking up arrow at the left of the screen or

use CTRL +.

Next, enter the dimensions. All dimensions are defined in the legend at the top of the

screen and/or illustrated in the appropriate section FIGURE. The section type for any

span can be changed by clicking on the button in the Section (Sec) column.

Select the section, Sec as Rectangular and edit 17ft for length, L, 12 in for width, b,

and 6.5in for height, h, for all spans. You can use Typical input row (top row) to

enter the similar dimensions. To enter typical values, type the value into the appropriate

cell in the top row and then press enter. The typical value will be copied to all the

spans.

The reference height (Rh) identifies the position of a reference line that is used in

determining how to display the tendon heights. Typically, the reference height is set

equal to the slab depth. Click? button with the Rh definition in the legend to know

more about this.

Edit reference height, Rh as 6.5 inches, i.e.,slab depth, for all spans.

The left and right multiplier columns (<-M and M->) are used to specify the tributary

width to indicate how much of the tributary falls on either side of the support line.

Tributary widths can be specified using either the Unit Strip method or the Tributary

method.

For this tutorial, unit strip (12 inches) method is used, i.e., unit strip, 12 inches is

entered as width, b, and tributary width on either side of the support line is entered as

left and right multiplier.

FIGURE 5.2.1-3

Click Next at the bottom line to open the next input screen.

ii. Enter Support Geometry (Fig. 5.2.1-4)

This screen is used to input column /wall heights, widths and depths. You may enter

dimensions for columns/walls above and/or below the slab.

Select the Both Columns from the support selection and enter 8.58 ft for H1 &H2 in

the typical row and press ENTER, since all the supports are the same height.

Next, enter the dimensions of the supports. B is the dimension of the column cross-

section normal to the direction of the frame. D is the column dimension parallel to

the frame.

Enter the given column dimensions as in Fig. .5.2.1-4

FIGURE 5.2.1-4

Click Next at the bottom line to open the Supports Boundary conditions input

screen.

iii. Enter Support Boundary Conditions (Fig. 5.2.1-5)

This screen is used to enter support widths and column boundary conditions.

Support widths are only entered if you answered Yes to the Reduce Moments to

face-of support question on the Design Settings screen, i.e., if you answered No,

you cannot input the value in the SW column. This input value will be used to

calculate the reduced moments.

Since the support width SW is set to the column dimension (D) as a default, the SW

values will automatically determine from the support geometry and cannot be

modified by the user. If you want to input the SW values, uncheck the

SW=Column Dimension box.

Select the boundary conditions for lower and upper columns as 1(fixed) from the drop

down list.

Leave the End Support Fixity for both left and right support as default No. This

will be used when the slab or beam is attached to a stiff member. If you want to know

more about this, click Help button at the bottom screen.

FIGURE 5.2.1-5

Click Next button at the bottom screen to open the input screen Loading.

5.2.2 Enter Data

A. Edit the Loading Information (Fig. 5.2.2-1)

Any number of different loads and load types may be entered for a span.

Enter the span number as 1 in the Span column. If the loads are the same for all

the spans, you can type ALL or all in the span column. This will copy the data

to all the spans.

Select the class as DL from the drop down list and specify the load type as

uniform either by typing U in L-? or by dragging the icon from the graphics of

the uniform loading.

The default of the load type when you select the load class is L-U, so leave as it is

for this turorial.

Type 0.096 k/ft

2

for dead load in the w column. You can enter DL with or

without self-weight, since the program can calculate self-weight automatically. In

order to calculate automatically, you must answer Yes to Include Self-Weight

question at the top right of the screen and enter unit weight of concrete.

Repeat the procedure for live load by entering the span number and changing the

Class to LL and w value to 0.034 k/ft

2

for first and third span and 0.029 k/ft

2

for

second span.

Answer Yes to Skip Live Load? at the top left of the screen and enter the skip

factor as 1.

FIGURE 5.2.2-1

Click Next button at the bottom screen to open Material-Concrete input

screen.

B. Edit the material properties (Fig. 5.2.2-2)

i. Enter the Properties of Concrete

Select the Normal weight and enter the strength at 28 days for slab/beam and

column. When you press enter from the strength input value, modulus of elasticity

will be calculated automatically based on the concrete strength and the appropriate

code formula.

For this tutorial, keep the default values of strength and creep coefficient. Creep

coefficient will be used in the calculation of long-term deflection.

FIGURE 5.2.2-2 (???5.4.2-2 non-prismatic two-way slab//Fig.

Click Next at the bottom screen to open the next input screen Material

Reinforcement .

ii. Enter the Properties of Reinforcement (Fig. 5.2.2-3)

Keep the default values for yield strength and modulus of elasticity. Change the

preferred bar sizes for top and bottom to 5 and 6 respectively. This will be used

when calculating the number of bars required.

FIGURE 5.2.2-3 (???5.1.2-3- PTI one-way slab///Fig.

Click Next at the bottom screen to open the next input screen.

iii. Enter the Post-Tensioning System Parameters (Fig. 5.2.2-4)

Select the post-tensioning system as Unbonded and leave the default values of

properties as it is.

FIGURE 5.2.2-4 (???5.1.2-4 PTI one-way slab///Fig.

Click Next at the bottom screen to open the input screen, Criteria Allowable

Stresses.

C. Edit the Design Criteria

i. Enter the Initial and Final Allowable Stresses. (Fig. 5.2.2-5)

Tensile stresses are input as a multiple of the square root of f

c

, and compressive

stresses are input as multiple of f

c

.

Change the final allowable tensile stress to 6f

c

for both top and bottom fiber.

(Although the code limits the allowable tensile stress to the modulus of rupture

7.5f

c

, a more conservative limit equal to 6f

c

will be used)

FIGURE 5.2.2-5 (???5.1.2-5 PTI one-way

slab///Fig.

Click Next at the bottom screen to open the next input screen, Criteria

Recommended Post-Tensioning Values.

ii. Enter the Recommended Post-Tensioning Values (Fig. 5.2.2-6)

This screen is used to specify minimum and maximum values for average

precompression (P/A; total prestressing divided by gross cross-sectional area)

and percentage of dead load to balance (Wbal). These values are used by the

program to determine the post-tensioning requirements and the status of the

Pmin/Pmax and WBAL Min/ Max indicators on the Recycle window.

The values given as default are according to the code and the experience of

economical design. So keep the default values.

FIGURE 5.2.2-6

Click Next at the bottom screen to open the input screen, Criteria

Calculation Options.

iii. Select the Post-Tensioning Design Option

The two design options are Force selection and Force/Tendon Selection as

in Fig. 5.2.2-7. Force Selection is the default option. Keep the default option.

FIGURE 5.2.2-7

In this option, a tendon will be assigned a final and constant effective force,

equal to the jacking force minus all stress losses, expressed as a single value.

Click Next at the bottom screen to open the next input screen, Criteria

Tendon Profile.

iv. Specify the Tendon Profiles (Fig. 5.2.2-8)

From the Type drop down list select 1 for reversed parabola option and

change the inflection points (X1/L & X3/L) to zero, since we assumed a

parabola with no inflection points. For the second span keep the low point

(X2/L) at mid span, i.e., at 0.5. From the calculation, the low point for first

and third span is at 0.490*L and 0.510* L respectively from left support. So

enter X2/L for first and third spans as 0.490 and 0.510 respectively.

FIGURE 5.2.2-8

Click Next at the bottom screen to open the next input screen, Criteria

Minimum Covers.

v. Specify Minimum Covers for Post-Tensioning Tendons and Mild Steel

Reinforcement (Fig. 5.2.2-9)

The cover for the pre-stressing steel is specified to the center of gravity

of the strand (cgs). Therefore, for inch strand, cgs is minimum cover +

* .

Edit CGS of tendon as 1.25 inches for interior spans from both top and

bottom fiber and 1.75 inches for exterior span from the bottom fiber.

For nonprestressed reinforcement edit 1in cover for both top and bottom.

FIGURE 5.2.2-9

Click Next at the bottom screen to open the input screen, Criteria

Minimum Bar Extension.

vi. Specify Minimum Bar Length and Bar Extension of Mild Steel

Reinforcement (Fig. 5.2.2-10)

The values given as default are according to the appropriate code, for this

tutorial according to ACI-02 code. So keep the default values.

The values entered for cut-off lengths are used to calculate top and bottom bar

lengths when minimum reinforcement requirements govern. Click Help

button to know about minimum steel.

FIGURE 5.2.2-10 (???5.1.2-11 PTI one-way

slab///Fig.

Click Next at the bottom screen to open the input screen, Load Combinations.

vii. Input Load Combinations (Fig. 5.2.2-11)

This screen is used to input the load combination factors for service and strength

(ultimate) load conditions. It is also used to enter any applicable strength reduction

factors.

The default values are according to the ACI-02. So leave as it is.

FIGURE 5.2.2-11(???5.1.2-12 PTI one-way slab///Fig.

Click Next at the bottom screen to open the next input screen, Criteria Design

Code.

viii. Choose the Design Code (Fig. 5.2.2-12)

This screen can be used if you want to change the default code.

For this tutorial, keep ACI-02 code selection.

This is the last input screen; so click OK to close it. Then you can see main

program window without any opened screen.

FIGURE 5.2.2-12(???5.1.2-13 PTI one-way slab///Fig.

5.2.3 Save and Execute the Input Data

To save the input data and execute the analysis, either select Execute Analysis from

the Action menu on the menu bar or click on the Save & Execute Analysis button

. Then, give a file name and directory in which to save the file. Once the file is

saved, program will automatically execute the analysis by reading the data files and

performing a number of preliminary data checks.

Once the execution is finished successfully, i.e., without any error, (If an error is

detected, the program will stop and display a message box indicating the most

likely source of the error) the PT Recycling window as shown in Fig. 5.2.3-1

opens.

FIGURE 5.2.3-1

Here you can optimize the design by changing the tendon forces and tendon

heights.

Change first and third span force to 201.2 k/ft and second span to 201.5 k/ft. Then

the status indicator at the top right of the Recycle window begins to flash.

Since we selected Force Selection option during data entry, the program will only

allow using Force Selection mode for the execution.

Once all of the changes are made as shown in Fig. 5.2.3-2, click on the Recycle

button to update all of the tabs, the Design Indicator box and the Recycle Graphs.

FIGURE 5.2.3-2

After the recalculation of the stresses and required forces along the member based

on current values, the window as shown in Fig. (5.2.3-3) with Valid status

indicator opens.

FIGURE 5.2.3-3

Next, click Exit at the top left of the screen to close the Recycle window. Then

the program continues with the calculations based on the most recent tendon forces

and profile selection.

Once finished successfully, it returns to the main program window with the screen as

shown in Fig. 5.2.3-4.

FIGURE 5.2.3-4(???5.1.3-4 PTI one-way slab///Fig.

Close the above window by clicking X at the top right corner.

Next, setup the report by selecting the Report Setup item on the Options menu or

clicking the Report Setup button on the program tool bar. Then the screen

shown in Fig. 5.2.3-5 opens.

FIGURE 5.2.3-5(???5.1.3-5 PTI one-way slab///Fig.

Setup the basic output as in the Fig. 5.2.3-5 and the detailed out put as in the Fig. 5.2.3-

6. After setup, click OK.

FIGURE 5.2.3-6 (???5.1.3-6 PTI one-way slab///Fig.

The electronic file of this tutorial is given in the program CD.

To open the PT Summary Report(Fig. 5.2.3-7) either click PTSum button from

the program tool bar or select the PT Summary item on the View menu on the

menu bar.

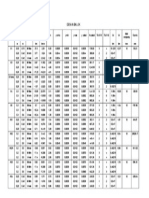

ADAPT - STRUCTURAL CONCRETE SOFTWARE SYSTEM

ADAPT-PT Version 7. 00 Dat e: 8/ 30/2004 Time: 3: 25:21 PM File: PT-2Way

1- PROJECT TITLE THREE SPAN TWO-WAY SLAB

1.1 DESI GN STRI P Example 2

2 - MEMBER ELEVATION

[ft] 17.00 25.00 17.00

3 - TOP REBAR

3.1 User selected

3.2 User selected

3.3 ADAPT selected

3.4 ADAPT selected

2 7#5X11'6" 1 4#5X5'6" 3 7#5X11'6" 6 4#5X5' 6"

4 - TENDON PROFILE

4.2 Datum Line

4.3 CGS Distance [ in]

4.5 Force

3.25 1.75 5.25

[201.2ki ps]

5.25 1.25 5.25

[201.5 ki ps]

5.25 1.75 3.25

[201.2 kips]

5 - BOTTOM REBAR

5.1 User selected

5.2 User selected

5.3 ADAPT selected

5.4 ADAPT selected

4 2#6X9'6"

5 1#6X7'0"

6 - REQUIRED & PROVIDED BARS

6.1 Top Bars

[ in

2

]

required

provided

6.2 Bot tom Bars

max

max

0.0

0.6

1.2

1.8

2.4

0.7

1.4

1.23

0.00

1.89

1.00

1.23

0.00

7 - PUNCHING SHEAR

OK=Acceptable

NG=No Good

*=not applicable

or not perf ormed

.64

OK

1. 15

NG

1.15

NG

7.1 Stress Ratio

7.2 Status

8 - LEGEND

Stressing End Dead End

9 - DESIGN PARAMETERS

9.1 Code: ACI-02 f'c = 4 ksi fy = 60 ksi (longitudinal) fy = 60 ksi (shear) fpu = 270 ksi

9.2 Rebar Cov er: Top = 1 in Bot tom = 1 in Rebar Table: ASTM - US Cust omary bars (Non-redist ributed Moments)

9.3 Stressing: fpj = .8 fpu

9.4 Strand Area = .153 in

2

10 - DESIGNER'S NOTES

FIGURE 5.2.3-7

To view the graphs, either click Show Graphs button from the program tool bar or

select the Graphs item on the View menu on the menu bar. You can choose the graph to

display from the Graphs item on the view Menu.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Lead Funnels On Funnel Swipe File - TrelloDocument5 pagesLead Funnels On Funnel Swipe File - TrelloKatherie BriersNo ratings yet

- American With Disabilities Act AdaDocument16 pagesAmerican With Disabilities Act Adaapi-376186426No ratings yet

- Electronics Today 1977 10Document84 pagesElectronics Today 1977 10cornel_24100% (3)

- 6907 6 52 0040Document35 pages6907 6 52 0040amitkumar8946No ratings yet

- Planning Dirty FrameworkDocument62 pagesPlanning Dirty FrameworkHoàng Hoa Dương100% (1)

- Strut and Tie CalculationDocument8 pagesStrut and Tie Calculationgmazzucco100% (4)

- Drive Test For BeginnerDocument88 pagesDrive Test For Beginnerahwaz96100% (1)

- Katja Kruckeberg, Wolfgang Amann, Mike Green-Leadership and Personal Development - A Toolbox For The 21st Century Professional-Information Age Publishing (2011)Document383 pagesKatja Kruckeberg, Wolfgang Amann, Mike Green-Leadership and Personal Development - A Toolbox For The 21st Century Professional-Information Age Publishing (2011)MariaIoanaTelecan100% (1)

- Tan Tan 1 Cos: Bishop's Simplified MethodDocument10 pagesTan Tan 1 Cos: Bishop's Simplified MethodLie FangNo ratings yet

- Truss DepthDocument1 pageTruss DepthLie FangNo ratings yet

- Purlin DesignDocument1 pagePurlin DesignjanethNo ratings yet

- Wind Calculation: Project Job RefDocument1 pageWind Calculation: Project Job RefjanethNo ratings yet

- K ColumnDocument5 pagesK ColumnjanethNo ratings yet

- Punching Shear CheckDocument2 pagesPunching Shear CheckLie FangNo ratings yet

- ASCEDocument6 pagesASCELie FangNo ratings yet

- CHS ConnectionDocument1 pageCHS ConnectionLie FangNo ratings yet

- Composite BeamDocument9 pagesComposite BeamLie FangNo ratings yet

- Design Momen BaseDocument3 pagesDesign Momen BaseLie FangNo ratings yet

- v2 Result (Multi Layer Bar) - Sect 8Document34 pagesv2 Result (Multi Layer Bar) - Sect 8Lie FangNo ratings yet

- 2 Way SlabDocument6 pages2 Way SlabLie FangNo ratings yet

- InertiaDocument2 pagesInertiaLie FangNo ratings yet

- Respon Spektra DisainDocument10 pagesRespon Spektra DisainLie FangNo ratings yet

- Design Momen BaseDocument3 pagesDesign Momen BaseLie FangNo ratings yet

- ASCEDocument6 pagesASCELie FangNo ratings yet

- Beam Design ACIDocument1 pageBeam Design ACILie FangNo ratings yet

- CorbelDocument1 pageCorbelLie FangNo ratings yet

- 2 Way SlabDocument6 pages2 Way SlabLie FangNo ratings yet

- Titik BeratDocument7 pagesTitik BeratLie FangNo ratings yet

- Hilti HSL3Document6 pagesHilti HSL3Lie FangNo ratings yet

- Purlin CapacityDocument4 pagesPurlin CapacityLie FangNo ratings yet

- Purlin CapacityDocument4 pagesPurlin CapacityLie FangNo ratings yet

- InersiaDocument8 pagesInersiaLie FangNo ratings yet

- Hilti HSL3Document6 pagesHilti HSL3Lie FangNo ratings yet

- ConnectionDocument1 pageConnectionLie FangNo ratings yet

- CorbelDocument1 pageCorbelLie FangNo ratings yet

- GempaDocument3 pagesGempaLie FangNo ratings yet

- Bolt CapacityDocument2 pagesBolt CapacityLie FangNo ratings yet

- Finimpianti Power EngDocument2 pagesFinimpianti Power EngJosip GrlicaNo ratings yet

- Educ 1301 Field Experience 1 ThielenDocument4 pagesEduc 1301 Field Experience 1 Thielenapi-610903961No ratings yet

- PC 4 Product List 2019 - Pc4Document28 pagesPC 4 Product List 2019 - Pc4ShNo ratings yet

- FMBXXX Quick Manual v3.5Document18 pagesFMBXXX Quick Manual v3.5AMNo ratings yet

- Cartoon Network, Boomerang & TCM TV Rate Card July - SeptemberDocument11 pagesCartoon Network, Boomerang & TCM TV Rate Card July - SeptemberR RizalNo ratings yet

- Report Card of Army Public School StudentDocument2 pagesReport Card of Army Public School StudentRama KrishnaNo ratings yet

- Explosive Ordnance DisposalDocument13 pagesExplosive Ordnance DisposalZelwisNo ratings yet

- A Comparative Study of Different Image Denoising Methods: Afreen Mulla, A.G.Patil, Sneha Pethkar, Nishigandha DeshmukhDocument6 pagesA Comparative Study of Different Image Denoising Methods: Afreen Mulla, A.G.Patil, Sneha Pethkar, Nishigandha DeshmukherpublicationNo ratings yet

- Chem 361 Separation Methods IntroDocument8 pagesChem 361 Separation Methods IntroTwum SomoahNo ratings yet

- 1 Clock Domain CrossingDocument35 pages1 Clock Domain CrossingRamakrishnaRao SoogooriNo ratings yet

- Detect and Diagnose HVAC Equipment ErrorsDocument1 pageDetect and Diagnose HVAC Equipment ErrorsCatalin DragomirNo ratings yet

- CM Group Marketing To Gen Z ReportDocument20 pagesCM Group Marketing To Gen Z Reportroni21No ratings yet

- Kompres Panas Dingin Dapat Mengurangi Nyeri Kala I Persalinan Di Rumah Sakit Pertamina Bintang AminDocument9 pagesKompres Panas Dingin Dapat Mengurangi Nyeri Kala I Persalinan Di Rumah Sakit Pertamina Bintang AminHendrayana RamdanNo ratings yet

- Acer Veriton S480G Service ManualDocument90 pagesAcer Veriton S480G Service ManualAndreea Georgiana ChirilaNo ratings yet

- Keynote Proficient End-Of-Course Test BDocument7 pagesKeynote Proficient End-Of-Course Test Bana maria csalinasNo ratings yet

- Zeal Institute of Manangement and Computer ApplicationDocument4 pagesZeal Institute of Manangement and Computer ApplicationSONAL UTTARKARNo ratings yet

- Risk and Risk ManagementDocument8 pagesRisk and Risk ManagementMARY JUSTINE PAQUIBOTNo ratings yet

- Sigmund Freud and His Main TheoriesDocument5 pagesSigmund Freud and His Main TheoriesNguyen HarryNo ratings yet

- Caring Seedlings TLE Weekly PlanDocument3 pagesCaring Seedlings TLE Weekly PlanMarjorie RaymundoNo ratings yet

- An Overview On Recognition of State in International LawDocument17 pagesAn Overview On Recognition of State in International LawRamanah VNo ratings yet

- PLC SCADA ASSIGNMENT SsDocument10 pagesPLC SCADA ASSIGNMENT SsShadab AhmadNo ratings yet

- 611k01 Kicatalog C Ka Us 1Document8 pages611k01 Kicatalog C Ka Us 1Ean LeeNo ratings yet

- Flap System RiginDocument12 pagesFlap System RiginHarold Reyes100% (1)