Professional Documents

Culture Documents

Partial Report - Rawan

Uploaded by

Kenny RuizCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Partial Report - Rawan

Uploaded by

Kenny RuizCopyright:

Available Formats

Grasim Cement, Raipur

India

Project No: 10-31017

Case No: 20100035

2010-05-14

Partial Report

FLSmidth A/S

R&D Centre Dania

Daniavej 49

DK-9550 Mariager, Denmark

Tel + 45 3618 1000

Fax + 45 3618 3599

Lab.DK@flsmidth.com

FLSmidth Private Limited

R&D Centre Chennai

34 Egattur, Kelambakkam

Tamil Nadu 603103, India

Tel +91 44 4748 1000

Fax +91 44 2747 0301

R&D.IN@flsmidth.com

LABORATORY REPORT

Grasim Cement, Raipur

India

Case No: 20100035 2010-05-14 Page 1 of 1

LABORATORY REPORT

Ordered by: DKS-IN

Copies to : BLO-IN, SNE-IN, SSA-IN

SAMPLE DESCRIPTION

SAMPLE NAME SAMPLE NUMBER WEIGHT, KG DATE RECEIVED

Limestone 01 1500 2010-01-29

Clay 02 500 2010-01-29

Shale 03 425 2010-01-29

Iron Ore 04 150 2010-01-29

Coal Grade B 05 25 2010-01-29

Coal Grade C 06 25 2010-01-29

Pet Coke 07 25 2010-02-09

Fly Ash 10 60 2010-03-09

Clinker 11 600 2010-03-09

Gypsum 12 35 2010-03-09

Slag 13 150 2010-03-09

CONTENTS OF REPORT (ANALYSES / TESTS)

ENCL. NO. ITEM

1. Material Description

2. Characterization of Materials

3. Analysis of Solid Fuel

4. Raw Mix Calculation

5. Burnability

6. Heat of Reaction

7. ATOX Vertical Roller Mill Test

Grasim Cement, Raipur

India

Encl.: 1.1

Material Description - Sample as received

SAMPLE DESCRIPTION

ID SAMPLE NAME MATERIAL TYPE SAMPLE NUMBER

01 Limestone Limestone 20100035-01

INSPECTION

Received: 2010-02-12

Container: 5 Drum, steel

Weight, kg:

1500

COLOR

Munsell Color: Gray

Color Code: Gley1 6/N

BULK MATERIAL PROPERTIES

PROPERTY OF SAMPLE

MATERIAL CRUSHABILITY

PROPORTION OF FINES GRAIN-SIZE SCALE (mm)

Boulders

Cobbles Top size (mm)

Pebbles 100x50x40

Granules

Sand Average size (mm)

Silt 60x30x30

Clay

MINOR COMPONENTS ADDITIONAL INFORMATION

LABORATORY SUGGESTIONS (MATERIAL CONSIDERATIONS)

Doubleclick here to insert picture

The material smells

Moist

Caking

Dry

Only Plastic/Soft materials

Both fines materials and hard specimen

Only hard specimen

Very Weak - The material can be scratched by thumbnail

Weak - Knife cuts material

Very Strong - Requires many blows by hammer to break into specimens

Strong - Hand held specimens broken by single blow of hammer

None

Low

Medium

High

> 256

64 - 256

4 - 64

2 - 4

0.1 - 2

0.004 - 0.1

< 0.004

Yes No

Flowability Max moisture Load strength Sample contains 10 or more specimens larger that 35 mm

Material wrapped up in Plastic

Case No: 20100035 2010-05-14 Page 1 of 1

Grasim Cement, Raipur

India

Encl.: 1.2

Material Description - Sample as received

SAMPLE DESCRIPTION

ID SAMPLE NAME MATERIAL TYPE SAMPLE NUMBER

02 Clay Clay 20100035-02

INSPECTION

Received: 2010-02-12

Container: 2 Drum, steel

Weight, kg:

500

COLOR

Munsell Color: Yellow

Color Code: 10 YR 7/8

BULK MATERIAL PROPERTIES

PROPERTY OF SAMPLE

MATERIAL CRUSHABILITY

PROPORTION OF FINES GRAIN-SIZE SCALE (mm)

Boulders

Cobbles Top size (mm)

Pebbles 95x80x45

Granules

Sand Average size (mm)

Silt 50x30x25

Clay

MINOR COMPONENTS ADDITIONAL INFORMATION

LABORATORY SUGGESTIONS (MATERIAL CONSIDERATIONS)

Doubleclick here to insert picture

The material smells

Moist

Caking

Dry

Only Plastic/Soft materials

Both fines materials and hard specimen

Only hard specimen

Very Weak - The material can be scratched by thumbnail

Weak - Knife cuts material

Very Strong - Requires many blows by hammer to break into specimens

Strong - Hand held specimens broken by single blow of hammer

None

Low

Medium

High

> 256

64 - 256

4 - 64

2 - 4

0.1 - 2

0.004 - 0.1

< 0.004

Yes No

Flowability Max moisture Load strength Sample contains 10 or more specimens larger that 35 mm

Material wrapped up in Plastic

Case No: 20100035 2010-05-14 Page 1 of 1

Grasim Cement, Raipur

India

Encl.: 1.3

Material Description - Sample as received

SAMPLE DESCRIPTION

ID SAMPLE NAME MATERIAL TYPE SAMPLE NUMBER

03 Shale Shale 20100035-03

INSPECTION

Received: 2010-02-12

Container: 2 Drum, steel

Weight, kg:

425

COLOR

Munsell Color: Pink

Color Code: 5YR 7/4

BULK MATERIAL PROPERTIES

PROPERTY OF SAMPLE

MATERIAL CRUSHABILITY

PROPORTION OF FINES GRAIN-SIZE SCALE (mm)

Boulders

Cobbles Top size (mm)

Pebbles 110x60x25

Granules

Sand Average size (mm)

Silt 60x30x15

Clay

MINOR COMPONENTS ADDITIONAL INFORMATION

LABORATORY SUGGESTIONS (MATERIAL CONSIDERATIONS)

We Observed 3 Types of color Material Pink ,Yellow &White

Doubleclick here to insert picture

The material smells

Moist

Caking

Dry

Only Plastic/Soft materials

Both fines materials and hard specimen

Only hard specimen

Very Weak - The material can be scratched by thumbnail

Weak - Knife cuts material

Very Strong - Requires many blows by hammer to break into specimens

Strong - Hand held specimens broken by single blow of hammer

None

Low

Medium

High

> 256

64 - 256

4 - 64

2 - 4

0.1 - 2

0.004 - 0.1

< 0.004

Yes No

Flowability Max moisture Load strength Sample contains 10 or more specimens larger that 35 mm

Material wrapped up in Plastic

Case No: 20100035 2010-05-14 Page 1 of 1

Grasim Cement, Raipur

India

Encl.: 1.4

Material Description - Sample as received

SAMPLE DESCRIPTION

ID SAMPLE NAME MATERIAL TYPE SAMPLE NUMBER

04 Iron Ore Iron Ore 20100035-04

INSPECTION

Received: 2010-02-12

Container: 4 Bag, plastic

Weight, kg:

150

COLOR

Munsell Color: Brown

Color Code: 7.5YR 4/3

BULK MATERIAL PROPERTIES

PROPERTY OF SAMPLE

MATERIAL CRUSHABILITY

PROPORTION OF FINES GRAIN-SIZE SCALE (mm)

Boulders

Cobbles Top size (mm)

Pebbles 50x25x15

Granules

Sand Average size (mm)

Silt 20x15x10

Clay

MINOR COMPONENTS ADDITIONAL INFORMATION

LABORATORY SUGGESTIONS (MATERIAL CONSIDERATIONS)

Doubleclick here to insert picture

The material smells

Moist

Caking

Dry

Only Plastic/Soft materials

Both fines materials and hard specimen

Only hard specimen

Very Weak - The material can be scratched by thumbnail

Weak - Knife cuts material

Very Strong - Requires many blows by hammer to break into specimens

Strong - Hand held specimens broken by single blow of hammer

None

Low

Medium

High

> 256

64 - 256

4 - 64

2 - 4

0.1 - 2

0.004 - 0.1

< 0.004

Yes No

Flowability Max moisture Load strength Sample contains 10 or more specimens larger that 35 mm

Material wrapped up in Plastic

Case No: 20100035 2010-05-14 Page 1 of 1

Grasim Cement, Raipur

India

Encl.: 1.5

Material Description - Sample as received

SAMPLE DESCRIPTION

ID SAMPLE NAME MATERIAL TYPE SAMPLE NUMBER

05 Coal Grade B Coal 20100035-05

INSPECTION

Received: 2010-02-12

Container: 1 Bag, plastic

Weight, kg:

25

COLOR

Munsell Color: Black

Color Code: 7.5YR 2.5/1

BULK MATERIAL PROPERTIES

PROPERTY OF SAMPLE

MATERIAL CRUSHABILITY

PROPORTION OF FINES GRAIN-SIZE SCALE (mm)

Boulders

Cobbles Top size (mm)

Pebbles 60x50x30

Granules

Sand Average size (mm)

Silt 30x15x10

Clay

MINOR COMPONENTS ADDITIONAL INFORMATION

LABORATORY SUGGESTIONS (MATERIAL CONSIDERATIONS)

Doubleclick here to insert picture

The material smells

Moist

Caking

Dry

Only Plastic/Soft materials

Both fines materials and hard specimen

Only hard specimen

Very Weak - The material can be scratched by thumbnail

Weak - Knife cuts material

Very Strong - Requires many blows by hammer to break into specimens

Strong - Hand held specimens broken by single blow of hammer

None

Low

Medium

High

> 256

64 - 256

4 - 64

2 - 4

0.1 - 2

0.004 - 0.1

< 0.004

Yes No

Flowability Max moisture Load strength Sample contains 10 or more specimens larger that 35 mm

Material wrapped up in Plastic

Case No: 20100035 2010-05-14 Page 1 of 1

Grasim Cement, Raipur

India

Encl.: 1.6

Material Description - Sample as received

SAMPLE DESCRIPTION

ID SAMPLE NAME MATERIAL TYPE SAMPLE NUMBER

06 Coal Grade C Coal 20100035-06

INSPECTION

Received: 2010-02-12

Container: 1 Bag, plastic

Weight, kg:

25

COLOR

Munsell Color: Black

Color Code: 7.5YR 2.5/1

BULK MATERIAL PROPERTIES

PROPERTY OF SAMPLE

MATERIAL CRUSHABILITY

PROPORTION OF FINES GRAIN-SIZE SCALE (mm)

Boulders

Cobbles Top size (mm)

Pebbles 70x50x25

Granules

Sand Average size (mm)

Silt 30x25x15

Clay

MINOR COMPONENTS ADDITIONAL INFORMATION

LABORATORY SUGGESTIONS (MATERIAL CONSIDERATIONS)

Doubleclick here to insert picture

The material smells

Moist

Caking

Dry

Only Plastic/Soft materials

Both fines materials and hard specimen

Only hard specimen

Very Weak - The material can be scratched by thumbnail

Weak - Knife cuts material

Very Strong - Requires many blows by hammer to break into specimens

Strong - Hand held specimens broken by single blow of hammer

None

Low

Medium

High

> 256

64 - 256

4 - 64

2 - 4

0.1 - 2

0.004 - 0.1

< 0.004

Yes No

Flowability Max moisture Load strength Sample contains 10 or more specimens larger that 35 mm

Material wrapped up in Plastic

Case No: 20100035 2010-05-14 Page 1 of 1

Grasim Cement, Raipur

India

Encl.: 1.7

Material Description - Sample as received

SAMPLE DESCRIPTION

ID SAMPLE NAME MATERIAL TYPE SAMPLE NUMBER

07 Pet Coke Petcoke 20100035-07

INSPECTION

Received: 2010-02-12

Container:

Weight, kg:

25

COLOR

Munsell Color: Black

Color Code: 7.5YR 2.5/1

BULK MATERIAL PROPERTIES

PROPERTY OF SAMPLE

MATERIAL CRUSHABILITY

PROPORTION OF FINES GRAIN-SIZE SCALE (mm)

Boulders

Cobbles Top size (mm)

Pebbles 45x40x20

Granules

Sand Average size (mm)

Silt 4mm

Clay

MINOR COMPONENTS ADDITIONAL INFORMATION

LABORATORY SUGGESTIONS (MATERIAL CONSIDERATIONS)

Doubleclick here to insert picture

1 Drum, steel small

The material smells

Moist

Caking

Dry

Only Plastic/Soft materials

Both fines materials and hard specimen

Only hard specimen

Very Weak - The material can be scratched by thumbnail

Weak - Knife cuts material

Very Strong - Requires many blows by hammer to break into specimens

Strong - Hand held specimens broken by single blow of hammer

None

Low

Medium

High

> 256

64 - 256

4 - 64

2 - 4

0.1 - 2

0.004 - 0.1

< 0.004

Yes No

Flowability Max moisture Load strength Sample contains 10 or more specimens larger that 35 mm

Material wrapped up in Plastic

Case No: 20100035 2010-05-14 Page 1 of 1

Grasim Cement, Raipur

India

Encl.: 2.1

ID SAMPLE NAME MATERIAL TYPE SAMPLE NUMBER

01 Limestone Limestone 20100035-01

02 Clay Clay 20100035-02

03 Shale Shale 20100035-03

04 Iron Ore Iron Ore 20100035-04

PARAMETER METHOD UNIT 01 02 03 04

Moisture Content (105C) FLS-B21 % 0.1 5.1 1.0 1.8

SiO

2

FLS-D03 % 11.47 40.76 61.85 5.07

Al

2

O

3

FLS-D03 % 2.68 15.17 14.43 5.74

Fe

2

O

3

FLS-D03 % 1.25 28.47 7.02 82.66

CaO FLS-D03 % 45.24 4.12 2.98 0.55

MgO FLS-D03 % 1.13 0.79 2.42 0.17

Mn

2

O

3

FLS-D03 % 0.03 0.23 0.02 0.06

TiO

2

FLS-D03 % 0.17 0.82 0.90 0.36

P

2

O

5

FLS-D03 % 0.04 0.05 0.11 0.20

K

2

O FLS-D03 % 0.67 1.57 3.79 0.10

Na

2

O FLS-D03 % 0.16 0.63

SrO FLS-D03 % 0.01 0.01

LOI, 975 C FLS-D00 % 36.72 10.30 5.28 6.10

TOTAL FLS-D03 % 99.57 102.28 99.44 101.01

Sulphur, total FLS-D08 % 0.02 0.01 0.26 0.04

Organic Carbon FLS-D27 % 0.05 0.23 0.08 0.10

Chloride FLS-D07 % 0.006 0.001 0.002 0.002

Lime saturation factor (LSF) FLS-D03 % 125 3 2 1

Silica modulus (MS) FLS-D03 - 2.9 0.9 2.9 0.1

Iron modulus (MA) FLS-D03 - 2.1 0.5 2.1 0.1

Characterization of Materials

SAMPLE DESCRIPTION

Moisture

Chemical analyses

Case No: 20100035 2010-05-14 Page 1 of 1

Grasim Cement, Raipur

India

Encl.: 3.1

ID SAMPLE NAME MATERIAL TYPE SAMPLE NUMBER

05 Coal Grade B Coal 20100035-05

05.01 Coal Ash Coal Ash 20100035-05.01

PARAMETER METHOD UNIT

As analysed

(air dried)

As received Dry

Dry,

ash free

Dry, mineral

matter free

Analysis

Free moisture FLS-B21BS

% 0.3

Moisture in air-dried sample FLS-E03BS

% 6.6

Total moisture CALC-BS

% 6.9

Volatile matter FLS-E03BS

% 30.2 30.1 32.3 46.5 42.8

Ash FLS-E03BS

% 28.5 28.4 30.5

Fixed Carbon CALC-BS

% 34.7 34.6 37.2 53.5 57.2

Carbon FLS-E10

% 51.5 51.3 55.1 79.4 82.6

Hydrogen FLS-E10

% 3.11 3.10 3.33 4.79 4.36

Sulphur FLS-E09BS

% 0.48 0.48 0.51 0.74 0.86

Nitrogen FLS-E10

% 1.14

Oxygen CALC

% 8.67

CO

2

FLS-D27

%

Mineral matter CALC-BS

% 31.0 31.0

Gross calorific value FLS-E08ISO

kJ/kg 20559 20497 22012 31678 32994

FLS-E08ISO

kcal/kg 4910 4896 5257 7566 7881

Net calorific value FLS-E08ISO

kJ/kg 19731 19665 21298 30651

FLS-E08ISO

kcal/kg 4713 4697 5087 7321

K

2

O FLS-D13

% 0.31

Na

2

O FLS-D13

% 0.02

Chloride FLS-D07BS

% 0.007

Hardgrove grindability index FLS-I08ISO

Wear Index FLS-I12BS

mg/kg

(total hydrogen - hidden) % 3.85

Safety index CALC 1

PARAMETER METHOD UNIT PARAMETER METHOD UNIT

Fineness (sieve openings) Analyses of ash

Residue on 40 mm Machine %

SiO

2 XRF % 65.06

Residue on 25 mm Machine %

Al

2

O

3 XRF % 23.09

Residue on 16 mm Machine %

Fe

2

O

3 XRF % 4.84

Residue on 8 mm Machine % CaO XRF % 1.54

Residue on 4 mm Machine % MgO XRF % 0.68

Residue on 2 mm Machine %

Mn

2

O

3 XRF % 0.07

Residue on 1 mm Machine %

TiO

2 XRF % 1.65

Residue on 500 m Machine %

P

2

O

5 XRF % 0.16

Residue on 250 m Alpine % SrO XRF % 0.02

Residue on 200 m Alpine % LOI, 975 C % 0.74

Residue on 90 m Alpine % TOTAL % 99.06

Residue on 45 m Alpine %

1.07

1

1.54

1.6

Analysis of solid fuel

SAMPLE DESCRIPTION

Case No: 20100035 2010-05-14 Page 1 of 1

Grasim Cement, Raipur

India

Encl.: 3.2

ID SAMPLE NAME MATERIAL TYPE SAMPLE NUMBER

06 Coal Grade C Coal 20100035-06

06.01 Coal Ash Coal Ash 20100035-06.01

PARAMETER METHOD UNIT

As analysed

(air dried)

As received Dry

Dry,

ash free

Dry, mineral

matter free

Analysis

Free moisture FLS-B21BS

% 0.3

Moisture in air-dried sample FLS-E03BS

% 6.1

Total moisture CALC-BS

% 6.4

Volatile matter FLS-E03BS

% 29.2 29.1 31.1 45.7 41.7

Ash FLS-E03BS

% 30.0 29.9 31.9

Fixed Carbon CALC-BS

% 34.7 34.6 37.0 54.3 58.3

Carbon FLS-E10

% 52.5 52.3 55.9 82.2 85.7

Hydrogen FLS-E10

% 3.19 3.18 3.39 4.99 4.53

Sulphur FLS-E09BS

% 0.47 0.47 0.50 0.74 0.86

Nitrogen FLS-E10

% 1.16

Oxygen CALC

% 6.58

CO

2

FLS-D27

%

Mineral matter CALC-BS

% 32.7 32.6

Gross calorific value FLS-E08ISO

kJ/kg 20520 20458 21853 32113 33533

FLS-E08ISO

kcal/kg 4901 4886 5220 7670 8009

Net calorific value FLS-E08ISO

kJ/kg 19690 19623 21128 31047

FLS-E08ISO

kcal/kg 4703 4687 5046 7415

K

2

O FLS-D13

% 0.39

Na

2

O FLS-D13

% 0.03

Chloride FLS-D07BS

% 0.011

Hardgrove grindability index FLS-I08ISO

Wear Index FLS-I12BS

mg/kg

(total hydrogen - hidden) % 3.87

Safety index CALC 1

PARAMETER METHOD UNIT PARAMETER METHOD UNIT

Fineness (sieve openings) Analyses of ash

Residue on 40 mm Machine %

SiO

2 XRF % 65.26

Residue on 25 mm Machine %

Al

2

O

3 XRF % 22.93

Residue on 16 mm Machine %

Fe

2

O

3 XRF % 4.92

Residue on 8 mm Machine % CaO XRF % 1.29

Residue on 4 mm Machine % MgO XRF % 0.69

Residue on 2 mm Machine %

Mn

2

O

3 XRF % 0.07

Residue on 1 mm Machine %

TiO

2 XRF % 1.51

Residue on 500 m Machine %

P

2

O

5 XRF % 0.16

Residue on 250 m Alpine % SrO XRF % 0.03

Residue on 200 m Alpine % LOI, 975 C % 0.74

Residue on 90 m Alpine % TOTAL % 99.05

Residue on 45 m Alpine %

1.06

1

1.56

1.63

Analysis of solid fuel

SAMPLE DESCRIPTION

Case No: 20100035 2010-05-14 Page 1 of 1

Grasim Cement, Raipur

India

Encl.: 3.3

ID SAMPLE NAME MATERIAL TYPE SAMPLE NUMBER

07 Pet Coke Petcoke 20100035-07

PARAMETER METHOD UNIT

As analysed

(air dried)

As received Dry

Dry,

ash free

Dry, mineral

matter free

Analysis

Free moisture FLS-B21BS

% 0.6

Moisture in air-dried sample FLS-E03BS

% 0.9

Total moisture CALC-BS

% 1.5

Volatile matter FLS-E03BS

% 10.7 10.6 10.8 10.8 10.4

Ash FLS-E03BS

% 0.2 0.2 0.2

Fixed Carbon CALC-BS

% 88.2 87.7 89.0 89.2 89.6

Carbon FLS-E10

% 87.2 86.7 88.0 88.2 90.6

Hydrogen FLS-E10

% 3.65 3.63 3.68 3.69 3.86

Sulphur FLS-E09BS

% 4.87 4.84 4.91 4.92 1.43

Nitrogen FLS-E10

% 1.79

Oxygen CALC

% 1.39

CO

2

FLS-D27

%

Mineral matter CALC-BS

% 2.9 2.9

Gross calorific value FLS-E08ISO

kJ/kg 35483 35270 35805 35878 36451

FLS-E08ISO

kcal/kg 8475 8424 8552 8569 8706

Net calorific value FLS-E08ISO

kJ/kg 34686 34463 35023 35094

FLS-E08ISO

kcal/kg 8285 8231 8365 8382

K

2

O FLS-D13

%

Na

2

O FLS-D13

%

Chloride FLS-D07BS

% 0.001

Hardgrove grindability index FLS-I08ISO

Wear Index FLS-I12BS

mg/kg

(total hydrogen - hidden) % 3.75

Safety index CALC 8

PARAMETER METHOD UNIT PARAMETER METHOD UNIT

Fineness (sieve openings) Analyses of ash

Residue on 40 mm Machine %

SiO

2 XRF %

Residue on 25 mm Machine %

Al

2

O

3 XRF %

Residue on 16 mm Machine %

Fe

2

O

3 XRF %

Residue on 8 mm Machine % CaO XRF %

Residue on 4 mm Machine % MgO XRF %

Residue on 2 mm Machine %

Mn

2

O

3 XRF %

Residue on 1 mm Machine %

TiO

2 XRF %

Residue on 500 m Machine %

P

2

O

5 XRF %

Residue on 250 m Alpine % SrO XRF %

Residue on 200 m Alpine % LOI, 975 C %

Residue on 90 m Alpine % TOTAL %

Residue on 45 m Alpine %

1.01

0.99

1.01

1.04

Analysis of solid fuel

SAMPLE DESCRIPTION

Case No: 20100035 2010-05-14 Page 1 of 1

RAW MIX CALCULATION

PLANT: Grasim Cement, Raipur Encl.: 4.1

CASE.NO.: Date:

Raw Mix Calculation Mix 1

Ed. 1, 29-03-2010 by DKS Clinker Mix M01 M02 M03 M04 F01 A01 F02 A02

Mix [% dry] 100.00 96.29 1.00 1.61 1.10 100.00 0.00 100.00

Mix [as analysed % wet] 100.00 96.29 1.00 1.61 1.10 100.00 0.00 100.00

Mix [as fired % wet] 100.00 0.00 100.00

H

2

O (analysed) [% (wb)]

0.00 0.00 0.00 0.00 0.00 6.10 6.60 6.10

H

2

O (as fired) [% (wb)]

1.00 1.00 1.00

SiO

2

[%]

21.44 12.51 11.47 40.76 61.85 5.07 65.26 65.06 65.26

Al

2

O

3

[%]

5.51 3.03 2.68 15.17 14.43 5.74 22.93 23.09 22.93

Fe

2

O

3

[%]

3.94 2.51 1.25 28.47 7.02 82.66 4.92 4.84 4.92

CaO [%] 64.77 43.65 45.24 4.12 2.98 0.55 1.29 1.54 1.29

MgO [%] 1.72 1.14 1.13 0.79 2.42 0.17 0.69 0.68 0.69

Mn

2

O

3

[%]

0.05 0.03 0.03 0.23 0.02 0.06 0.07 0.07 0.07

TiO

2

[%]

0.35 0.19 0.17 0.82 0.90 0.36 1.51 1.65 1.51

P

2

O

5

[%]

0.07 0.04 0.04 0.05 0.11 0.20 0.16 0.16 0.16

K

2

O [%]

1.13 0.72 0.67 1.57 3.79 0.10 0.39 0.31 0.39

Na

2

O [%]

0.25 0.16 0.16 0.63 0.03 0.02 0.03

SrO [%] 0.02 0.01 0.01 0.01 0.03 0.02 0.03

SO

3

[%]

0.26 0.00

LOI [%] 35.61 36.72 10.30 5.28 6.10 0.74 0.74 0.74

Total [%] 99.51 99.61 99.57 102.28 99.44 101.01 97.60 97.85 97.60

S Total [%] 0.11 0.02 0.02 0.01 0.26 0.04 0.47 0.48 0.47

S Pyrite [%] 0.00

Cl

-

[%] 0.010 0.006 0.006 0.001 0.002 0.002 0.011 0.007 0.011

F

-

[%] 0.00 0.00 0.00

Cr

2

O

3

[ppm]

0 0 0

Ash [%] 4.55 30.00 28.50 30.00

Hi (analysed) [kcal/kg] 4703 4713 4703

Exp. kiln heat cons. [kcal/kg] 702.0

LSF [%] 93.7 108.5 125.4 2.7 1.5 0.7

MS 2.27 2.26 2.92 0.93 2.88 0.06

MA 1.40 1.21 2.14 0.53 2.06 0.07

Na

2

O eq. [%]

0.99 0.64 0.60 1.03 3.12 0.07

K

2

O eq. [%]

1.51 0.97 0.91 1.57 4.75 0.10

C3S [%] 52.00 M01: Limestone

C2S [%] 22.24 M02: Clay

C3A [%] 7.93 M03: Shale

C4AF [%] 11.99 M04: Iron ore

C2F [%] 0.00 F01: Coal B

Free CaO [%] 1.50 F02: Coal C

Liq. Ph. 1450 C [%] 28.75

Liq. Ph. 1338 C [%] 27.96

M SO

3 0.23

Exc. SO

3

[g/100 kg]

0

Calc. rev. 08-01 / May 29, 2008 / CBMI

20100035

Total fuel+ash

2010-05-14

Case No.20100035 2010-05-14 Page 1 of 1

Grasim Cement, Raipur

India

Encl.: 5.1

ID SAMPLE NAME MATERIAL TYPE SAMPLE NUMBER

09 Raw Mix for Burnability Raw Mix

06.01 Coal Ash Coal Ash

PARAMETER METHOD UNIT 09

SiO

2

FLS-D03 % 13.99

Al

2

O

3

FLS-D03 % 3.61

Fe

2

O

3

FLS-D03 % 2.59

CaO FLS-D03 % 42.42

MgO FLS-D03 % 1.12

Mn

2

O

3

FLS-D03 % 0.03

TiO

2

FLS-D03 % 0.23

P

2

O

5

FLS-D03 % 0.05

K

2

O FLS-D03 % 0.73

Na

2

O FLS-D03 % 0.10

SrO FLS-D03 % 0.01

LOI, 975 C FLS-D00 % 34.81

TOTAL FLS-D03 % 99.69

Fluoride FLS-D34 % 0.03

C

3

S in Clinker (Free CaO=0) FLS-D03 % 59

Lime saturation factor (LSF) FLS-D03 % 94

Silica modulus (MS) FLS-D03 - 2.3

Iron modulus (MA) FLS-D03 - 1.4

PARAMETER METHOD UNIT Coarse Medium Fine

Residue, 200 m, wet WET % 2.0 0.3 0.1

Residue, 125 m, wet WET % 3.0

Residue, 90 m, wet WET % 19.8 13.8 9.9

Residue, 90 m, alpine ALPINE % 20.2 14.3 10.0

Residue, 45 m, wet WET % 30.7

Free CaO after burning at 1400 C FLS-D23 % 1.1 0.8 0.7

Free CaO after burning at 1450 C FLS-D23 % 0.7 0.6 0.6

Free CaO after burning at 1500 C FLS-D23 % 0.5 0.5 0.5

Burnability Index FLS-D23 - 30 27 24

Burnability Classification FLS-D23 - EASY EASY EASY

Burnability test on Raw Mix with Coal Ash

Burnability Test

SAMPLE DESCRIPTION

Characterization of Raw Mix with Coal Ash (Coal Grade C)

Fineness on Raw Mix

20100035-06.01

20100035-09

Case No: 20100035 2010-05-14 Page 1 of 1

Grasim Cement, Raipur

India

Encl.: 6.1

SAMPLE DESCRIPTION

ID SAMPLE NAME MATERIAL TYPE SAMPLE NUMBER

09 Raw Mix

06 Coal

06.01 Coal Ash

PARAMETER UNIT * RESULT PARAMETER UNIT RESULT

Raw mix Fuel: Coal

SiO

2

% 12.51 Fuel in percentage of clinker % 14.9

Al

2

O

3

% 3.03 Sulphur, total % 0.47

Fe

2

O

3

% 2.51 Ash in percentage of fuel % 30.0

CaO % 43.65 Net calorific value ( Q

net,p

) kJ/kg 19690

MgO % 1.14 kcal/kg 4703

SO

3

% * 0.01 Heat consumption, clinker kJ/kg 2939

Loss on ignition (LOI) % 35.61 kcal/kg 702

TOTAL % 98.46 Analysis of ash

CO

2

% * 34.86 SiO

2

% 65.26

K

2

O % 0.72 Al

2

O

3

% 22.93

Na

2

O % 0.16 Fe

2

O

3

% 4.92

Sulphur, total % 0.02 CaO % 1.29

Water of crystallisation % * 0.86 MgO % 0.69

Carbon

1)

% * 0.05 K

2

O

2)

% 1.30

Na

2

O

2)

% 0.10

CaCO

3

% 77.93 CaSO

4

% 0.02

MgCO

3

% 1.09 Silica-combined CaO % 0.00

Sulphur in pyrites % 0.02

RAW MIX ADJ USTMENT

PARAMETER UNIT RAW MIX ADJUSTMENT FUEL

SiO

2

% 12.51 1.97 14.48

Al

2

O

3

% 3.03 0.69 3.72

Fe

2

O

3

% 2.51 0.15 2.66

CaO % 43.65 0.04 43.69

MgO % 1.14 0.02 1.16

SO

3

(total) % 0.05 0.12 0.17

K

2

O % 0.72 0.04 0.76

Na

2

O % 0.16 0.00 0.16

TOTAL % 63.77 3.03 T = 66.80

SULPHUR BALANCE AND RAW MIX / CLINKER RATIO

Adjusted raw mix, total : T : 66.80

Volatilised : U = 50 U : 0.02

SO

3

in clinker (calculated) : 0.22

Raw mix / clinker ratio F : 1.50

Remarks:

* Analytical results

1) Carbon as CO

2

is not included. 2) Calculated from analysis of solid fuel.

(loss of dust = 0 %) : F = 100 / ( T U ) :

% of sulphur in pyrites as SO

3

CALCULATED VALUES

Heat of reaction

ADJUSTED RAW MIX

20100035-09 Raw Mix for Burnability

Coal Grade C

Coal Ash

20100035-06

20100035-06.01

Case No: 20100035 2010-05-14 Page 1 of 2

Grasim Cement, Raipur

India

CALCULATIONS

Content

%

Conversion factors

kJ / kg / %

RAWMIX

kJ / kg

CLINKER

kJ / kg

RAWMIX

CaCO

3

77.93 -17.78 -1386

MgCO

3

1.09 -15.10 -16

Water of crystallisation 0.86 -42.70 -37

Silica-combined CaO 0.00 -17.00 0

Alkali silicates (K

2

O + Na

2

O) 0.88 -14.80 -13

-1452 xF: -2174

Heat of formation

Property Component Adj. RAWMIX

C

3

S CaO

43.69 -0.46 -20

C

2

S SiO

2 14.48 21.43 310

C

3

A Al

2

O

3 3.72 1.21 5

C

4

AF Fe

2

O

3 2.66 2.46 7

SO

3

from fuel and pyrites 0.14 59.60 8

309 xF: 463

Heat of combustion

Carbon 0.05 327.86 16

Sulphur in pyrites 0.02 129.14 2

18 xF: 28

Heat of reaction

HEAT OF REACTION (A + B + C): -1683

-402

HEAT OF REACTION excl. HEAT OF COMBUSTION (A + B): -1711

-409 ( kcal / kg clinker )

Heat of combustion (C):

( kJ / kg clinker )

( kJ / kg clinker )

( kcal / kg clinker )

Heat of reaction

Heat of decomposition

Heat of decomposition (A):

Heat of formation (B):

Encl.: 6.1

Case No: 20100035 2010-05-14 Page 2 of 2

Encl.: 7.1 Page 1

PLANT : Grasim Cement, Raipur Case. No.:

MATERIAL : Rawmix Date :

PROJECT : VRM No. :

MILL FEED, COMPOSITION

M1 : 96.29%

M2 : 1.00%

M3 : 1.61%

M4: 1.10%

SIEVE ANALYSIS - MOISTURE DETERMINATION :

Sample Id. : M1 M2 M3 M4 M5 M6 M7 M8 MIX

AS RECEIVED

Moisture : (%)

Sieve Residues :

: (%)

: (%)

40 mm : (%)

25 mm : (%)

16 mm : (%)

8 mm : (%)

4 mm : (%)

2 mm : (%)

1 mm : (%)

500 m : (%)

250 m : (%)

200 m : (%)

90 m : (%)

45 m : (%)

32 m : (%)

AFTER PRECRUSHING, -25mm

Moisture :

+4 mm : (%)

+4mm, max : (%)

-4 mm : (%)

-4 mm, max : (%)

Sieve Residues :

16 mm : (%)

8 mm : (%)

4 mm : (%)

2 mm : (%)

1 mm : (%)

500 m : (%)

250 m : (%)

200 m : (%)

90 m : (%)

45 m : (%)

32 m : (%)

AFTER PRECRUSHING, -16 mm Mill Feed

Sieve Residues :

8 mm : (%) 8.42

4 mm : (%) 49.94

2 mm : (%) 73.52

1 mm : (%) 85.42

500 m : (%) 91.91

250 m : (%) 95.16

200 m : (%) 95.54

90 m : (%) 96.97

45 m : (%)

32 m : (%)

Wet sieving :

90 m : (%)

45 m : (%)

Spec. Surf. (m/kg)

20100035

2010-04-14

ATOXIN10-11

Limestone

Clay

Shale

Iron ore

LABORATORY REPORT

F.L.Smidth Research Center - Chennai, India

VERTICAL MILL

Mill feed composition and Sieve analysis

Encl.: 7.1 Page 2

PLANT : Grasim Cement, Raipur Case. No. :

MATERIAL : Rawmix Date :

PROJECT : VRM No. :

MILL FEED, COMPOSITION

M1 : 96.29%

M2 : 1.00%

M3 : 1.61%

M4: 1.10%

TEST PARAMETERS

Mill : Moisture :

Revolutions : (rpm) 100 Mill feed : (%) 2.44

Grind. pres. : (bar) 90 Product : (%) 0.17

Grind. force : (kN) 26

(kN/m) 596

Gas :

Quantity : (m/h) 996

Temp out : (C) 91

TEST RESULTS

Period 1 2 3 4 5 6 7

Separator : Static () 39 30 25 22

Dyn. press. (mmWg) 238 238 239 238

Grinding bed:

Average for rollers: (mm)

Power consumption :

Mean : (kW) 4.46 4.56 4.65 4.77

Total (spec.) : (kWh/t) 10.39 9.27 8.78 8.66

Production :

Total : (kg) 26.7 21.9 34.1 35.5

Rate : (t/h) 0.429 0.492 0.530 0.550

Sieve residue :

90 m : (%) 7.2 14.2 21.0 26.0

200 m : (%) 0.9 1.3 3.3 5.0

Grinding constants :

90 m : (kWh/t) 9.21 11.12 13.20 15.15

200 m : (kWh/t) 5.10 4.94 6.02 6.77

- Factor : 0.116 0.118 0.121 0.124

ABRASION TEST

Wear parts : Abrasion :

Table : Cromin 15 Table : (g) 0.3

Rollers : Cromin 15 Roller 1 : (g) 0.1

Roller 2 : (g) 0.1

Test time (h) 1.37 Roller 3 : (g) 0.2

Average (net) (kW) 4.61 Total : (g) 0.7

Ground mat. (t) 0.662

Fineness, average : Table : (g/t) 0.5

90 m (%) 18.1 Rollers : (g/t) 0.6

TOTAL ABRASION 1.1 (g/t)

0.5 (g/h)

0.1 (g/kWh)

20100035

2010-04-14

ATOXIN10-11

Limestone

Clay

Shale

Iron ore

LABORATORY REPORT.

F.L.Smidth Research Center - Chennai, India

VERTICAL MILL

Encl.: 7.1 Page 3

PLANT : Grasim Cement, Raipur Case.No. :

MATERIAL : Rawmix VRM No.: Date :

PROJECT :

20100035

2010-04-14 ATOXIN10-11

y = 0.0059Ln(x) + 0.1036

R

2

= 0.9261

0.000

0.010

0.020

0.030

0.040

0.050

0.060

0.070

0.080

0.090

0.100

0.110

0.120

0.130

0.140

0.150

0.0 5.0 10.0 15.0 20.0 25.0

Sieve residue 90 mm, Alpine (%)

-

F

a

c

t

o

r

Rawmix Log. (Rawmix)

LABORATORY REPORT

F.L.Smidth Research Center - Chennai, India

VERTICAL MILL

m-factor vs. Sieve residue on 90mm

Encl.: 7.1 Page 4

PLANT : Grasim Cement, Raipur Case.No. :

MATERIAL : Rawmix VRM No.: Date :

PROJECT :

20100035

2010-04-14 ATOXIN10-11

y = 10.922e

-0.0097x

R

2

= 0.9167

0.00

1.00

2.00

3.00

4.00

5.00

6.00

7.00

8.00

9.00

10.00

11.00

12.00

0.0 5.0 10.0 15.0 20.0 25.0

Sieve residue 90 mm, Alpine (%)

S

p

e

c

i

f

i

c

p

o

w

e

r

c

o

n

s

u

m

p

t

i

o

n

(

k

W

h

/

t

)

Rawmix Expon. (Rawmix)

LABORATORY REPORT

F.L.Smidth Research Center - Chennai, India

VERTICAL MILL

Specific power consumption rate vs. Sieve residue on 90mm

Encl.: 7.1 Page 5

PLANT : Grasim Cement, Raipur Case.No. :

MATERIAL : Rawmix VRM No.: Date :

PROJECT :

20100035

2010-04-14 ATOXIN10-11

y = 0.3975e

0.0132x

R

2

= 0.9609

0.00

0.10

0.20

0.30

0.40

0.50

0.60

0.70

0.80

0.90

1.00

1.10

1.20

1.30

1.40

0.0 5.0 10.0 15.0 20.0 25.0

Sieve residue 90 mm, Alpine (%)

P

r

o

d

u

c

t

i

o

n

(

t

/

h

)

Rawmix Expon. (Rawmix)

LABORATORY REPORT

F.L.Smidth Research Center - Chennai, India

VERTICAL MILL

Production rate vs. Sieve residue on 90mm

Grasim Cement, Raipur

India

Case No: 20100035 2010-05-14 Page 1 of 1

Disclaimer

This report is based on material, samples and information which FLSmidth has received from you, and

FLSmidth is only liable and responsible for the accuracy and correctness of this report and the information

set out herein to the extent that such material and/or information is correct, true and representative. Such

liability shall in any event be limited to the direct loss suffered by you as a consequence of FLSmidths error

or negligence. Neither FLSmidth nor any person or company associated with FLSmidth shall be liable for

any loss or damage resulting from your or any third party's use of this report or the information provided

herein as a result of use of the report and/or any of the information set out herein contrary to the purpose

for which it was intended.

FLSmidths liability for this report shall in any event never exceed the liability that FLSmidth has accepted in

any contract signed between FLSmidth and yourselves.

Copyrights

The copyright of this report is owned by the FLSmidth Group. No part of this report may be reproduced,

used or transmitted inconsistent with the specific purpose for which the testing was completed without

written permission. The following terms are either registered trademarks or trademark of the FLSmidth

Group: FLSmidth, FLS, .

Other product names mentioned herein may be trademarks of their respective companies and reference

herein to any specific product, process, or service of a third party by trade name, trademark, manufacturer,

or otherwise does not necessarily constitute or imply its endorsement by FLSmidth.

You might also like

- Cement Separator & Ball Mill OptimizationDocument29 pagesCement Separator & Ball Mill OptimizationAdelezzat OmranNo ratings yet

- Baghouse Options For Kiln BHDocument1 pageBaghouse Options For Kiln BHKenny RuizNo ratings yet

- Plain Mixture Design with Internal CuringDocument2 pagesPlain Mixture Design with Internal CuringBùi Hắc HảiNo ratings yet

- VB 29 - 10Document5 pagesVB 29 - 10Kenny RuizNo ratings yet

- VRM Fan ..Document2 pagesVRM Fan ..harikrushnaNo ratings yet

- Typical Cement Mill Bag Filter Capital Cost CamparisonDocument1 pageTypical Cement Mill Bag Filter Capital Cost CamparisonKenny RuizNo ratings yet

- Ball Mills - Guidelines For Sample Amount and Ball ChargeDocument4 pagesBall Mills - Guidelines For Sample Amount and Ball ChargeAndrejs AndrejsNo ratings yet

- Study of The Grinding Balls Distribution Inside The MillDocument2 pagesStudy of The Grinding Balls Distribution Inside The Millsempatik721No ratings yet

- Description Kiln Size Project Doc - No DateDocument2 pagesDescription Kiln Size Project Doc - No DateRaji SuriNo ratings yet

- Technical Specification of VSK PDFDocument28 pagesTechnical Specification of VSK PDFmaran.suguNo ratings yet

- Ball Mill GrindingDocument6 pagesBall Mill GrindingShyanu Udeshika WijerathnaNo ratings yet

- MBT CalculatorDocument2 pagesMBT Calculatorsempatik721100% (1)

- Dimension Mills - UploadDocument5 pagesDimension Mills - UploadTIRIANTONo ratings yet

- Rawmix DesignDocument3 pagesRawmix DesignavisgopNo ratings yet

- Evaluasi % Moisture Terhadap GHV & Harga: Serbuk GergajiDocument6 pagesEvaluasi % Moisture Terhadap GHV & Harga: Serbuk GergajiTIRIANTONo ratings yet

- 4 MPDocument33 pages4 MPSyed Shahzaib ShahNo ratings yet

- Bits Ps-II Eos FDBK I Sem 2012-13Document1 pageBits Ps-II Eos FDBK I Sem 2012-13Sai Sricharan ReddyNo ratings yet

- Pengukuran New Coal Mill Tuban I (Atox)Document2 pagesPengukuran New Coal Mill Tuban I (Atox)TIRIANTONo ratings yet

- (J-1) Burner TypesDocument1 page(J-1) Burner Typesgie pradanaNo ratings yet

- Dust RM Particle Size AnalysisDocument13 pagesDust RM Particle Size AnalysisTIRIANTONo ratings yet

- Ball Top Size Diameter CalculationDocument1 pageBall Top Size Diameter Calculationsempatik721100% (1)

- BELT FEEDER Preliminary Dimension IngDocument29 pagesBELT FEEDER Preliminary Dimension IngoscarjofkNo ratings yet

- Annexure 1 Mass Flow RajashreeDocument3 pagesAnnexure 1 Mass Flow RajashreeKenny RuizNo ratings yet

- High Air To Cloth Ratio Bag FilterDocument2 pagesHigh Air To Cloth Ratio Bag Filterayaskant751001No ratings yet

- Optimize cement kiln grate speed productionDocument3 pagesOptimize cement kiln grate speed productionrudye kardunNo ratings yet

- V SK VSK: Focus On EfficiencyDocument8 pagesV SK VSK: Focus On EfficiencyGerman Gabriel Anaya VegaNo ratings yet

- Filling Degree: 1St ChamberDocument6 pagesFilling Degree: 1St ChamberIrfan AhmedNo ratings yet

- Optimization of A Fully Air Swept Dry Grinding Cement Raw Meal Ball Mill Closed Circuit Capacity With The Aid PDFDocument10 pagesOptimization of A Fully Air Swept Dry Grinding Cement Raw Meal Ball Mill Closed Circuit Capacity With The Aid PDFJunaid MazharNo ratings yet

- Presep Air Separator VTP enDocument6 pagesPresep Air Separator VTP enBrunoNo ratings yet

- 76 Mbar - 91 Mbar: CO - InertizationDocument1 page76 Mbar - 91 Mbar: CO - InertizationKenny RuizNo ratings yet

- Coal Mill Ball Interlocks-V0.0Document11 pagesCoal Mill Ball Interlocks-V0.0Junaid MazharNo ratings yet

- Ball-Cement-Mill-Monitoring-Inspection-Evaluation PerformanceDocument7 pagesBall-Cement-Mill-Monitoring-Inspection-Evaluation PerformanceMin MCLNo ratings yet

- ATC Report on Dynamic Separator Gap IssuesDocument4 pagesATC Report on Dynamic Separator Gap IssuesDilnesa EjiguNo ratings yet

- White Paper - HolcimIEEE - AirDocument11 pagesWhite Paper - HolcimIEEE - AirKenny RuizNo ratings yet

- Cooler Balance 1Document17 pagesCooler Balance 1Tamer Fathy100% (1)

- Kiln Heavy Build Ups Details: Cimenterie Report On Rings Formation in KilnDocument12 pagesKiln Heavy Build Ups Details: Cimenterie Report On Rings Formation in KilnirfanNo ratings yet

- The Cement Grinding Office: Home About Us Services Mining AreaDocument3 pagesThe Cement Grinding Office: Home About Us Services Mining AreaVisnu SankarNo ratings yet

- 2012 - Design, Fabrication and Commissioning of RDF PDFDocument72 pages2012 - Design, Fabrication and Commissioning of RDF PDFHilmi Gazali TvkNo ratings yet

- Ecway Technologies: Design and Fabrication of Cyclone Seperator Using Vane PumpDocument9 pagesEcway Technologies: Design and Fabrication of Cyclone Seperator Using Vane Pumpieee4mybusinessonly100% (1)

- International Bag FilterDocument4 pagesInternational Bag FilterRAJAMANICKAMNo ratings yet

- FLSPfister IB05000 I GBTRWSD0216 MailDocument26 pagesFLSPfister IB05000 I GBTRWSD0216 MailLuis Angel BusturiaNo ratings yet

- Training PODFA: Prepol - Preheater - DesignDocument53 pagesTraining PODFA: Prepol - Preheater - DesignДен СтаднікNo ratings yet

- 3 Strategies For Reducing Cement KilnDocument14 pages3 Strategies For Reducing Cement Kilnorientanjali7066100% (1)

- Preheater Cyclone Dsigns: Tube Dia X EntryDocument6 pagesPreheater Cyclone Dsigns: Tube Dia X EntrynileshNo ratings yet

- Ball - Mill - Finish Mill Ball Charge CalculationDocument3 pagesBall - Mill - Finish Mill Ball Charge CalculationVijay Bhan50% (2)

- FLS - Ball Mill Liners Brochure - DIGITALDocument9 pagesFLS - Ball Mill Liners Brochure - DIGITALaliNo ratings yet

- Roller Press (High Pressure Grinding Rolls) : V Naga KumarDocument24 pagesRoller Press (High Pressure Grinding Rolls) : V Naga KumarApril ReynoldsNo ratings yet

- How to remove scrap from ball millDocument5 pagesHow to remove scrap from ball millsafwat hassanNo ratings yet

- Monitoring and optimizing cement mill performanceDocument5 pagesMonitoring and optimizing cement mill performanceMin MCLNo ratings yet

- ZeiselDocument98 pagesZeiselGirne100% (1)

- BM TrompcurveDocument1 pageBM Trompcurveniladri.jagatyNo ratings yet

- Hydroulik Roll CrusherDocument15 pagesHydroulik Roll CrusherTIRIANTONo ratings yet

- Impact of Process Parameters On QualityDocument25 pagesImpact of Process Parameters On QualityDineshNo ratings yet

- Dokumen - Tips - Vertical Raw Mill Heat Balance SolutionDocument3 pagesDokumen - Tips - Vertical Raw Mill Heat Balance SolutionRamadhani AhdiyakaNo ratings yet

- Graphic Symbol 39701-01-2.2: Instruction ManualDocument17 pagesGraphic Symbol 39701-01-2.2: Instruction ManualmkpqNo ratings yet

- Filler (Materials) : Filler Materials Are Particles Added To Resin or Binders (Document9 pagesFiller (Materials) : Filler Materials Are Particles Added To Resin or Binders (YitayewNo ratings yet

- Kolomstruktur: 25 X 45 Balok: 25 X 70 Pondasisetempat 1.35 M X 1.35M X 0.25mDocument5 pagesKolomstruktur: 25 X 45 Balok: 25 X 70 Pondasisetempat 1.35 M X 1.35M X 0.25mRio Rangga IriantoNo ratings yet

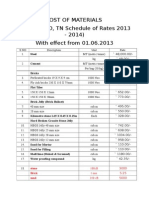

- Cost of MaterialsDocument2 pagesCost of MaterialsambipathiNo ratings yet

- Bulk Oil Storage Aliaabad, Daulatpur.Document17 pagesBulk Oil Storage Aliaabad, Daulatpur.sameerpecNo ratings yet

- Shaft DesignDocument1 pageShaft DesignKenny RuizNo ratings yet

- SketchsDocument1 pageSketchsKenny RuizNo ratings yet

- Electrical Steels For Rotating MachinesDocument334 pagesElectrical Steels For Rotating Machinesgraziellina83% (6)

- Book-I Chapter 1: Input DataDocument3 pagesBook-I Chapter 1: Input DataKenny RuizNo ratings yet

- AppleDocument1 pageAppleKenny RuizNo ratings yet

- Condmaster Ruby 2012 User GuideDocument238 pagesCondmaster Ruby 2012 User GuideKenny Ruiz67% (6)

- Successful Solution: To The Challenge ofDocument2 pagesSuccessful Solution: To The Challenge ofKenny RuizNo ratings yet

- Bulk Materials Handling in The Mining IndustryDocument12 pagesBulk Materials Handling in The Mining IndustrypabulumzengNo ratings yet

- Electrical Properties of Solar CellsDocument8 pagesElectrical Properties of Solar CellsKenny RuizNo ratings yet

- Piped 3Document32 pagesPiped 3Paraskevi_Kark_3983No ratings yet

- Quant Methods: Stats & OR Techniques for Business DecisionsDocument4 pagesQuant Methods: Stats & OR Techniques for Business DecisionsKenny RuizNo ratings yet

- Fly AcDocument7 pagesFly AcKenny RuizNo ratings yet

- Test Report 10034-1 Raw Material Grasim Rawan IndiaDocument6 pagesTest Report 10034-1 Raw Material Grasim Rawan IndiaKenny RuizNo ratings yet

- Comment From GrasimDocument1 pageComment From GrasimKenny RuizNo ratings yet

- Cement Plant Saves Energy with Online Air Flow MeasurementDocument3 pagesCement Plant Saves Energy with Online Air Flow MeasurementKenny RuizNo ratings yet

- VB 32 - 10Document8 pagesVB 32 - 10Kenny RuizNo ratings yet

- Annexure 1 Mass Flow RajashreeDocument3 pagesAnnexure 1 Mass Flow RajashreeKenny RuizNo ratings yet

- Equipment Dossier R0Document50 pagesEquipment Dossier R0Kenny RuizNo ratings yet

- Test Report 10032 Raw Material Grasim South Karur IndienDocument7 pagesTest Report 10032 Raw Material Grasim South Karur IndienKenny RuizNo ratings yet

- VB 32 - 10Document8 pagesVB 32 - 10Kenny RuizNo ratings yet

- Annexure 2 - Project ActivitiesDocument2 pagesAnnexure 2 - Project ActivitiesKenny RuizNo ratings yet

- WE 12742 Grasim Rawan Table: Mixing Calculation Mixture With Coal B As FuelDocument1 pageWE 12742 Grasim Rawan Table: Mixing Calculation Mixture With Coal B As FuelKenny RuizNo ratings yet

- List of DOE - Unaided Schools (1278) : S.No District Zone School ID School NameDocument2 pagesList of DOE - Unaided Schools (1278) : S.No District Zone School ID School NameKenny RuizNo ratings yet

- cdk1 Coal B-EDocument1 pagecdk1 Coal B-EKenny RuizNo ratings yet

- 141 EaDocument3 pages141 EaKenny RuizNo ratings yet

- cdk1 Coal B-EDocument1 pagecdk1 Coal B-EKenny RuizNo ratings yet

- 140 EaDocument3 pages140 EaKenny RuizNo ratings yet

- 139 FPDocument7 pages139 FPKenny RuizNo ratings yet

- Breadtalk AR 2011Document158 pagesBreadtalk AR 2011Wong ZieNo ratings yet

- AirROC T35 D45 D50 Tech SpecDocument4 pagesAirROC T35 D45 D50 Tech SpecmdelvallevNo ratings yet

- PW Trail Beaver Valley Oct 25Document63 pagesPW Trail Beaver Valley Oct 25Pennywise PublishingNo ratings yet

- What Is International Business?: Educator Resource PPT To AccompanyDocument41 pagesWhat Is International Business?: Educator Resource PPT To AccompanyArif Raza100% (1)

- CBP Form 434Document2 pagesCBP Form 434Heather SoraparuNo ratings yet

- Advance NewsletterDocument14 pagesAdvance Newsletterapi-206881299No ratings yet

- Responsibility and Transfer Pricing Solving: Answer: PDocument3 pagesResponsibility and Transfer Pricing Solving: Answer: PPhielle MarilenNo ratings yet

- Theory of Elinor OstromDocument5 pagesTheory of Elinor OstromSanjana KrishnakumarNo ratings yet

- HE Vibration AnalysisDocument8 pagesHE Vibration AnalysisWade ColemanNo ratings yet

- The Strategy of IB: International Business - Chapter 13Document20 pagesThe Strategy of IB: International Business - Chapter 13Yến Ngô HoàngNo ratings yet

- Noam Chomsky Propaganda Modela Critical EvaluationDocument24 pagesNoam Chomsky Propaganda Modela Critical Evaluationsatyanarayana vuyyapuNo ratings yet

- Vda. de Consuegra v. Government Service Insurance System (1971)Document1 pageVda. de Consuegra v. Government Service Insurance System (1971)Andre Philippe RamosNo ratings yet

- Module 2 - Introduction To A Web-AppDocument17 pagesModule 2 - Introduction To A Web-AppJASPER WESSLYNo ratings yet

- DigitalForensics 05 NOV2010Document84 pagesDigitalForensics 05 NOV2010hhhzineNo ratings yet

- Essay 5 Practice Activities - DBS IntroductionsDocument6 pagesEssay 5 Practice Activities - DBS IntroductionsLeyla IsayevaNo ratings yet

- Strict Liability - ProjectDocument7 pagesStrict Liability - ProjectRushabh Lalan100% (1)

- Diploma Engineer Question Paper-1Document1 pageDiploma Engineer Question Paper-1Nahid RahmanNo ratings yet

- Chapter 5Document30 pagesChapter 5فاطمه حسينNo ratings yet

- Phyton para Sujetar HerramientasDocument21 pagesPhyton para Sujetar HerramientasAlex D H RuizNo ratings yet

- BEE 027 Microcontroller Based System DesignDocument83 pagesBEE 027 Microcontroller Based System DesignBen StarkNo ratings yet

- Cereal Partners World Wide (Case Presentation)Document42 pagesCereal Partners World Wide (Case Presentation)Misbah JamilNo ratings yet

- Bus 102 QuestionsDocument4 pagesBus 102 Questionsali2aliyuNo ratings yet

- Globalization of Religion Chapter SummaryDocument2 pagesGlobalization of Religion Chapter SummaryKaye KateNo ratings yet

- 17th Edition OverviewDocument108 pages17th Edition OverviewJeremie Rameau100% (2)

- Ramdump Modem 2021-06-26 00-06-27 PropsDocument15 pagesRamdump Modem 2021-06-26 00-06-27 PropsKoikoiNo ratings yet

- AeroCRS 5.95-Premier AirlinesDocument1 pageAeroCRS 5.95-Premier AirlinesmohamedNo ratings yet

- 2021-2022 Reopening Plan 2.0Document22 pages2021-2022 Reopening Plan 2.0Dan LehrNo ratings yet

- Practical Approach To Practice 5SDocument4 pagesPractical Approach To Practice 5SNikola DjorovicNo ratings yet

- LG Mini Split ManualDocument38 pagesLG Mini Split ManualMark ChaplinNo ratings yet

- Container Stowage Plans ExplainedDocument24 pagesContainer Stowage Plans ExplainedMohd akifNo ratings yet