Professional Documents

Culture Documents

No Frost Refrigerator Service Manual

Uploaded by

cinefil700 ratings0% found this document useful (0 votes)

430 views22 pagesService manual

Original Title

Whirpool No Frost Refrigerator Parts and Service Manual

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentService manual

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

430 views22 pagesNo Frost Refrigerator Service Manual

Uploaded by

cinefil70Service manual

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 22

This document is only intended for qualified technicians who are aware of the respective safety regulations.

Revised on 25/03/2003 Subject to modification

Document No. WOI/GNF/2003/003

No Frost Refrigerator

PARTS &

SERVI CE Manual

Models

5622 285L 2G UL 110V QCS - WHITE

5624 285L 2G UL 110V QCS - S.GREY

6670 220L 2G 110V/60 HZ,NARSO-GREY UL Kitting

This document is only intended for qualified technicians who are aware of the respective safety regulations.

Revised on 25/03/2003 Subject to modification

Document No. WOI/GNF/2003/003

Whirlpool of India Limited

Contents

1.0 Safety precautions & warnings 2-3

2.0 Technical Specifications 4-6

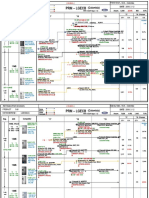

3.0 Circuit diagram 7

4.0 Sealed system schematic layout 8

7.0 Refrigerator does not operate 9

7.0 Trouble shooting -cooling system 10

7.1 Trouble shooting defrosting 11

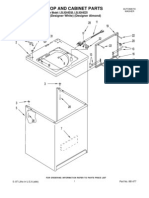

8.10 Cabinet assembly parts diagram 12

8.11 Cabinet assembly parts list 13

8.20 Shelves part diagram 14

8.21 Shelves parts list 15

8.30 Freezer compartment parts diagram 16

8.31 Freezer compartment parts list 17

8.40 Control box parts diagram 18

8.41 Control box parts list 19

8.50 Compressor assembly parts diagram 20

8.51 Compressor assembly parts list 21

8.6 Packing and other parts 22

This document is only intended for qualified technicians who are aware of the respective safety regulations.

Revised on 25/03/2003 Subject to modification

Document No. WOI/GNF/2003/003

Safety precautions and warnings:

Read all instructions before using this appliance in order to

avoid risk of accident or possible damage.

Indicates prohibition

This symbol is intended

to alert the user to the

possible death or injury.

This symbol is intended

to alert the user to the

possible injury or damage.

Warning / Caution Description of symbols

Warning

Warning

Caution

Do not disassemble

Adhere the instruction strictly

Unplug from the electrical outlet

Earth the appliance to avoid the risk

of an electric shock.

This may cause abnormal

heating or fire hazard.

Do not install the

refrigerator in a humid

(with condensation)

location or an

unstable surface.

If earthling is not done, it will

cause break down and electric

shock.

It may cause electric shock

It may cause fire or abnormal

operation which leads to injury. This may cause fire.

Do not plug multiple

electric appliances

into the same outlet.

Check the operating

environment

Be sure to earth. Pull the power plug out for

exchanging the interior

lam of the refrigerator.

Prohibition

Do not disassemble

repair or alter.

Do not bend the power cord

with excessive force or do

not have the power cord

pressure by heavy article.

Do not

disassemble

Do not contact

Earth Unplug

Page 2

This document is only intended for qualified technicians who are aware of the respective safety regulations.

Revised on 25/03/2003 Subject to modification

Document No. WOI/GNF/2003/003

Caution

Bottles may explode

causing personal injury.

Opening or closing the

door may trigger the loose

items to slip & cause injury.

Use of it as it is may cause

fire.

Opening the door may

trigger loose items to slip

& cause injury.

Check the model, rated

voltage, rated current,

operating temperature etc.

of the component.

The service unit should be

resembled & return to its

original assembly state.

Medical supplies, which

need to be under strict

temperature control, should

not be stored in the

refrigerator.

This can protect against the

risk of fire hazard caused by

tracking and short circuit.

When the trace of moisture

penetration is detected,

insulation tapping.

Do not store bottled food

or drinks in the freezing

compartment.

Do not put on top of the

refrigerator.

Please wipe out foreign

materials of the metal

option of power plug

cleanly.

Do not store food in

unstable manner.

When replacing electric

components, be sure to

use rated components.

After servicing the refrigerator

be sure to check the

components are reassembled

in a correct manner.

Do not store anything

other than food in the

refrigerator.

When servicing the

refrigerator completely

remove dust or foreign

substances from the housing,

electric connections etc.

Check electrical ports for

the trace of moisture

penetration.

Prohibition

Prohibition

Prohibition

Prohibition

Unplug

Rated

Components

Page 3

This document is only intended for qualified technicians who are aware of the respective safety regulations.

Revised on 25/03/2003 Subject to modification

Document No. WOI/GNF/2003/003

Technical Specifications for 220L DLX Model

Dimensions Cooling agent

Height 1408mm Type -R134a

Width 550mm Quantity 96Grams

Depth 625mm

Capacity 220L

Refrigerator compartment-150L

Freezer compartment-70L

Thermostat Cooling

Total 220L

Switching values

Cut in Temperature

COLD:-3.9 to -7.3 Deg.Cen,

MID: -2.4 to -0.9 Deg.Cen,

WARM: 0.5 to 3.9 Deg.Cen

Electrical Connection

Switch off Temperature Voltage

Frequency- For every 8 hours. . Max. Voltage- 130V

Power consumption Min. Voltage- 100V

In 24 hours -1.36kwh

*With Control knobs in Mid Position

Compressor

A2111580000

COMPRESSOR

ASSY

Compressor (for service)

Type OIL FILLED

This document is only intended for qualified technicians who are aware of the respective safety regulations.

Revised on 25/03/2003 Subject to modification

Document No. WOI/GNF/2003/003

Technical Specifications for 285L Elite Model

Dimensions Cooling agent

Height: 1725mm

Width: 550mm

Depth: 625mm Type R134a

Quantity 96Grams

Capacity-285L Thermostat Cooling

Refrigerator Compartment: 215L Cut in temperature

Freezer Compartment: 70L COLD:-1.7 to 1.7 Deg.Cen

Total : 285L MID : 2.0 to3.6 Deg.Cen

WARM:2.8 to 6.2 Deg.Cen

Electrical Connection Voltage

Switch off Frequency: For every 8 hours. Maximum: 130V

Minimum: 100V

Power consumption

In 24 hours - 1.4392 Kwh.

*With control knobs in Mid Position

Compressor

A2111580000 COMPRESSOR ASSY

Compressor (for service)

Type OIL FILLED

This document is only intended for qualified technicians who are aware of the respective safety regulations.

Revised on 25/03/2003 Subject to modification

Document No. WOI/GNF/2003/003

Page 4

110-130 V

This document is only intended for qualified technicians who are aware of the respective safety regulations.

Revised on 25/03/2003 Subject to modification

Document No. WOI/GNF/2003/003

Page 8

6. 0 Seal ed System Schemat i c Layout :

Evaporator

Condenser

(Foamed in three sides.)

Heat Loop

(Foamed)

Drier

Compressor

Precooler

This document is only intended for qualified technicians who are aware of the respective safety regulations.

Revised on 25/03/2003 Subject to modification

Document No. WOI/GNF/2003/003

7.0 Trouble shooting method

The refrigerator does not operate

Page 5

Page 6

Is the interior

light on when the door switch

is pushed?

Make sure that the

refrigerator is plugged

in at the wall outlet.

Does the

compressor operate?

Make sure that the

thermostat is

electrically connected

Replace the defective

part

Check the

defrost timer

Check the

PTC relay

Check the

over load

protector

Check the

Condensor

The compressor

is defective

Check for

abnormalities

Check the

electrical connection

The compressor is

defective. The freezing

cycle has a problem.

The compressor

is operated for more

than

30 Min. andthere is no

cooling

If the fan operates

when you push the

door switch,it is

normal(Replace if it is

defective)

Replace the defective

part

This document is only intended for qualified technicians who are aware of the respective safety regulations.

Revised on 25/03/2003 Subject to modification

Document No. WOI/GNF/2003/003

7. 0. Tr oubl e check f or t he cool i ng cycl e :

!

!

! The temperature of the compressor

is high.

The condenser is cold.

The EVAP is not cold.

!

!

! The EVAP does not cool down.

No difference in temperatures

between suction pipe and

discharge pipe.

The temperature of the compressor

is maintained at room temperature.

!

!

! The refrigeration in the EVAP is

not efficient.

Frost on the suction pipe.

The condenser is overheated.

!

!

!

The refrigerator is not easily get

cooled.

The condenser is cold.

The compressor surface

temperature is high.

Moisture in the refrigerant

cause the malfunction.

Foreign substances

hamper the cooling cycle.

The compressor

is defective.

To much refrigerant.

Refrigerant licks

(Slight r

)

efrigerant

leakage causes partial

cooling with

frost on the EVAP

Replace

the compressor.

Replace the refrigerant.

After welding the

licked parts,

replace the refrigerant.

Locate the disturbed

section and

make repairs.

Replace the refrigerant.

Suggestions Cause Symptom

! The EVAP cools down and warms

again.

The condenser warms in

proportion as the EVAP cools

The process continues to repeat.

.

!

!

Page 9

Page 7

This document is only intended for qualified technicians who are aware of the respective safety regulations.

Revised on 25/03/2003 Subject to modification

Document No. WOI/GNF/2003/003

Yes

Yes

7. 1 Def rost i ng mechani sm does not wor k :

7. 2 Def rost i ng mechani sm does not work :

Check that the defrost timer

operates properly

Check the temperature fuse

No

No

No

No

Check the bimetal thermometer

Check the defrost heater

Replace the defrost timer

Replace the temperature fuse

Replace the bimetal thermometer

Replace the defrost heater

Yes

Yes

Yes

No

No

No

No

No

Does not cooling fan operate?

Is the freezer defrosted normally?

Is the door close properly?

Is the door stopper hinge normal?

Is too much food stored in

the freezer compartment?

!

!

cooling fan motor

Check the door switch

Check the

!

!

!

Temperature fuse / Bimetal

thermometer

Defrost heater

Defrost timer

! Check the door gasket is

properly sealed, check for

the damage gasket.

! Correct or readjust the door

stopper hinge.

!

!

!

Tightly cover stored frozen food.

Distribute food evenly in

the compartment.

Tightly cover stored ice cubes.

Yes

Page 10

Page 8

This document is only intended for qualified technicians who are aware of the respective safety regulations.

Revised on 25/03/2003 Subject to modification

Document No. WOI/GNF/2003/003

Page 9

This document is only intended for qualified technicians who are aware of the respective safety regulations.

Revised on 25/03/2003 Subject to modification

Document No. WOI/GNF/2003/003

8.11 CABINET ASSEMBLY PARTS

Loc No Part Code Description 5622 5624 6670

1 A2010870000 SLEEVE- HINGE 2 2 2

1 A201416000J HINGE ASSY TOP - GNF, 2G, 3G 1 1 1

5 A201107200B FILLER- WRAPPER CORNER- WHITE 1

6 21499540000 SWITCH 2 TERM ROCKER ARM 1 1 1

7 A2080630700 DOOR ASSEMBLY FC (FIP) - GREY SLICK 1 1

7 A2080632000 DOOR ASSEMBLY FC (FIP) 2G - WHITE 1

8 A2080452000 END CAP FC-TOP, WHITE 1

9 A2080152000 HANDLE- DOOR, FC- WHITE 1

9 A2080462000 END CAP - FC BOTTOM, WHITE 1

9 A2080150700 HANDLE- DOOR, FC- GREY 1 1

9 A208046070B END CAP - FC BOTTOM, GREY SLICK 1 1

9 A2081330000 RETAINER - FC HANDLE, 2G 1

11 A2080090000 QUICK CHILL LOGO, 2G 1 1 1

11 A208045070B END CAP FC-TOP, GREY 1 1

12 A2035270000 GASKET- FC, DOOR - SERVICE 1 1 1

14 A201156200D STOP - DOOR ,FC- RH SWING- WHITE 1

14 A2011560700 STOP - DOOR, FC- RH SWING- GREY 1 1

16 A201198000A SUPPORT- DOOR 1 1 1

18 9400140000 HOLE PLUG 1 1 1

18 A2016462000 HOLE PLUG, PRESSFIT- WHITE 1

18 A2011070700 FILLER- WRAPPER CORNER, GREY 1 1

18 A201646070A HOLE PLUG, PRESSFIT- GREY 1 1

20 A2080600700 DOOR ASSEMBLY RC (FIP) 220L-GREY SLICK 1

20 A2099630700 DOOR ASSY RC 285, 2G-VCM W/O LOCK-S Grey 1

20 A2099632000 DOOR ASSY RC 285, 2G-HPP W/O LOCK-WHITE 1

21 A2080472000 END CAP - RC TOP, WHITE 1

21 DA20413003E HANDLE M.GREY-190/215L ELITE 1 1 1

21 A208047070B END CAP - RC TOP, GREY SLICK 1 1

22 A2035260000 GASKET- RC, DOOR 285L- SERVICE 1 1

22 A2035770000 GASKET- RC, DOOR 220L- SERVICE 1

25 A2080482000 END CAP - RC BOTTOM, WHITE 1

25 A208048070B END CAP - RC BOTTOM, GREY SLICK 1 1

26 A2017410000 HINGE SUB ASSY, BOTTOM - 2G 1 1 1

26 A2113670000 STOP- DOOR, RC- NYLON6(MoS) 1 1

29 2150304000 ROLLER BACK 1 1 1

41 11153730000 SWITCH 3 TERM ROCKER ARM 1 1 1

This document is only intended for qualified technicians who are aware of the respective safety regulations.

Revised on 25/03/2003 Subject to modification

Document No. WOI/GNF/2003/003

Page 11

This document is only intended for qualified technicians who are aware of the respective safety regulations.

Revised on 25/03/2003 Subject to modification

Document No. WOI/GNF/2003/003

8.21 SHELVES PARTS

Loc No Part Code Description 5622 5624 6670

42 A201012000A PAN CHILLER 285L 1 1

42 A201224000E PAN CHILLER- 220/250L 1

44 A208172000A HALF SHELF - QUICK FREEZE 1 1 1

44 A2083020000 WIRE SHELF ASSY, DOOR COOLING -INTELCOOL 1

45 A201013000G DOOR- CHILLER 1 1

46 A203793000B SHELF- RC (SAN) 2 2 1

47 A2037950000 SHELF BACK- TRIPLE (SAN) 1 1 1

48 A203794000A SHELF FRONT- TRIPLE (SAN) 1 1 1

49 A201036000K COVER -CRISPER 1 1

49 A201207000H COVER -CRISPER 1

50 A201206000H CRISPER PAN 1 1 1

51 A201178000B SLIDE, HUMIDITY CONTROL BLUE 1 1 1

52/57 A201391000C SHELF FLIP UP 65L 1 1 2

54 A201034000E TRIVET, FC 1 1 1

57 A201021000F DOOR BIN 1 1

59 A201008000G TRIVET- RC- DEEP 1 1 1

61 A201001000G TRIVET- RC, SHALLOW 1 1 1

Page 12

This document is only intended for qualified technicians who are aware of the respective safety regulations.

Revised on 25/03/2003 Subject to modification

Document No. WOI/GNF/2003/003

Page 13

This document is only intended for qualified technicians who are aware of the respective safety regulations.

Revised on 25/03/2003 Subject to modification

Document No. WOI/GNF/2003/003

8.31 FREEZER COMP. ASSY. PARTS LIST

Loc No Part Code Description 5622 5624 6670

65 A2016380000 GROMMET SOUND DEADENING- BACK 1 1 1

66 A201637000A GROMMET SOUND DEADENING- FRONT 1 1 1

67 A201476000A WEDGE ,EVAP MOUNTING- LH 1 1 1

68 A201475000D WEDGE ,EVAP MOUNTING- RH 1 1 1

68 A2035710000 FOIL- EVAPORATOR WEDGE 1 1 1

69 A2013780000 SOUND DEADENING- EVAPORATOR 1 1 1

69 A2112900000 EVAPORATOR-SPIROTECH 1 1 1

70 A2036310000 DEFROST HEATER, 110V/60HZ- TAIWAN 1 1 1

72 A201492000B COVER EVAP, BACK 1 1 1

73 A203627000A FAN MOTOR- EXPORT, 110V/60HZ 1 1 1

75 A201493000H COVER EVAP, FRONT 1 1

75 A2036600000 COVER EVAP, FRONT- EXPORT 1

76 A201494000C DAMPER -FREEZER CONTROL 1 1

76 A201495000C KNOB -FREEZER CONTROL 1 1 1

76 A201566000A DAMPER, FREEZER CONTROL- 220/250L 1

78 5319330000 GROMMET FAN MTG 1 1 1

81 A201179000C BLADE -FAN, EVAPORATOR 1 1 1

83 A2036380000 WIRING ASSY- FC 110V/60HZ 1 1 1

87 A201164000A GASKET- EVAP COVER ,SIDE 1 1 1

88 A2011630000 GASKET -EVAP COVER ,TOP 1 1 1

89 A201068000J FREEZER FLOOR-INTEGERATED, HIPS 1 1 1

89 A2012550000 GASKET- EVAPORATOR COVER,BOTTOM 1 1 1

This document is only intended for qualified technicians who are aware of the respective safety regulations.

Revised on 25/03/2003 Subject to modification

Document No. WOI/GNF/2003/003

Page 15

This document is only intended for qualified technicians who are aware of the respective safety regulations.

Revised on 25/03/2003 Subject to modification

Document No. WOI/GNF/2003/003

8.41 CONTROL BOX ASSY. PARTS LIST

Loc No Part Code Description 5622 5624 6670

90 A201617000B THERMOSTAT GE- 220L 1

90 A2016300000 THERMOSTAT WT ASSY -220L 1

90 A2016940000 THERMOSTAT WT ASSY -285L, SIEBE 1 1

91 A2113830000 WIRING ASSY.CONT BOX- PUERTORICO NON BAT 1 1 1

92 A2111090000 DEFROST TIMER, PARAGON - 115V-60HZ 1 1 1

93 A2013960000 BULB- E14, 110V SUNSHINE KOREA 1 1 1

94 A2014490000 SOCKET ASSY- LIGHT 1 1 1

95 A201593000G CONTROL BOX -285L NEW GRAPHICS 1 1

95 A2036980000 CONTROL BOX, 220L, HK- RETAIL 1

96 A201135000D KNOB - THERMOSTAT 1 1

96 A2036590000 KNOB, CONTROL- RC, EXPORT 1

97 A201037000A LIGHT LENS 1 1 1

97 A201616000B SHIELD, ELECTRICAL LIGHT 1 1 1

99 A2017080000 EXTN- BODY AIR DIFFUSER FRONT- 285L (L.C 1 1

99 A208217000A BODY AIR DIFFUSER, REAR - DOOR COOLING 1 1 1

This document is only intended for qualified technicians who are aware of the respective safety regulations.

Revised on 25/03/2003 Subject to modification

Document No. WOI/GNF/2003/003

Page 17

This document is only intended for qualified technicians who are aware of the respective safety regulations.

Revised on 25/03/2003 Subject to modification

Document No. WOI/GNF/2003/003

8.51 COMPRESSOR ASSY. PARTS LIST

Loc No Part Code Description 5622 5624 6670

100 A201039000F COVER - AIR DIFFUSER 1 1 1

100 A201709000B EXTN. COVER AIR DIFFUSER- 285L (L.C) 1 1

100 A208216000A BODY AIR DIFFUSER, FRONT - DOOR COOLING 1 1

100 A2082830000 BODY -AIR DIFFUSER, FRONT - INTELCOOL 1

101 A201042000B DRAIN CUP 1 1 1

113 A2111580000 COMPRESSOR ASSY- DA51C72RBU6 W/O OIL 1 1 1

114 GNF43870190000 SERVICE DRIER 1 1 1

115 A201365000B PLATE -COMPRESSOR MOUNTING 1 1 1

115 A2019930000 ASSY, PLATE - LEVELER - 2G 1 1 1

115 A2113860000 WIRE ASSY UNIT INT.- UL 115V/60Hz 1 1 1

116 A201105000A GROMMET- COMPRESSOR 1 1 1

116 A201435000A CLIP-COMPRESSOR MOUNTING 1 1 1

116 A201441000A SHIM-MOUNTING CLIP COMPRESSOR 1 1 1

122 A2072080000 TRAY- EVAPORATING- QB51 1 1 1

8.6 Packing and Accessories/spares

Part Code Description 5622 5624 6670

2153908000 GROMMET-HEAT EXCH 1 1 1

97918330000 BI-METAL CLIP 1 1 1

A201030000E COVER - UNIT- MTG 1 1 1

A201139000A TRAY - EGG 1 1 1

A2011660000 FOIL- EVAP COVER 1 1 1

A201197000C POST-CORNER, BACK 1 1

A201437000A PUSHNUT 1 1 1

A201458000F POLYBAG, 285L - DOMESTIC 1 1

A201461000E POLYBAG, 220L - DOMESTIC 1

A201466000B GROMMET - DRAIN SEAL 1 1 1

A201471000A FOIL- CONTROL BOX 1 1 1

A2075240000 WASHER HINGE BEARING 1 1 1

A2080820000 WEDGE- HANDLE, FC 1 1 1

A208084000A CORNER POST FRONT, RH 1 1

A208086000D BASE PACKAGING - 2G 1 1

A208089000A BOTTOM CAP FLAT - 2G 1 1

A2080990000 SUPPORT DOOR, FC - EPS 1 1

A208100000A CORNER POST FRONT, LH 1 1

A208106000A EPS TOP - 250, 285L - 2G 1 1

A2111160000 EDGE BOARD, BASE PACKAGING 1

A2112620000 PHILIPS HEAD SCREW M5.5X1.8, DASH BOARD 1 1 1

A2113550000 TUBE RESTRICTOR, OD 1.93 1 1 1

A211405000A CLIP-DEFROST HEATER (SPIROTECH EVAP) 1 1 1

D111404100C TIE CLAMP ALL MODELS 1 1 1

This document is only intended for qualified technicians who are aware of the respective safety regulations.

Revised on 25/03/2003 Subject to modification

Document No. WOI/GNF/2003/003

Part Code Description 5622 5624 6670

A201671000B RETAINER- BOTTLE, 285L BLUE 1 1

A2036320000 USE & CARE GUIDE-Eng/Fren/Arabic 1 1 1

A204131070A Handle cover-grey 310L 1 1

A2041312000 HANDLE COVER- WHITE 1

A208053070D DASH BOARD - BOTTOM, GREY SLICK 1 1

A208053200D DASH BOARD - BOTTOM, WHITE 1

A208054070D DASH BOARD, TOP - GREY SLICK 1 1

A208054200D DASH BOARD, TOP - WHITE 1

A208142000E SLEEVE 4 FLAP, 285L 2G EXPORT,5 PLY 1 1

A2081650000 SUB ASSY, EPS BOTTOM - GNF 2G 1 1

A208168000A BRACKET, ICE TWISTER 1 1 1

A208170000A ICE TRAY 1 1 1

A208171000A ICE COLLECTOR 1 1 1

A2081860000 SUPPORT BUSH, ICE TWISTER 1 1 1

A208203000A CUSHION SHELF PIPE - DOOR COOLING 1

A2082050000 AIR DIRECTOR, ICE TWISTER 1 1 1

A208211000B HOUSING CUSHION - DOOR COOLING 1

A208213000A SHELF DUCT RH - DOOR COOLING 1 1 1

A208214000A SHELF DUCT LH - DOOR COOLING 1 1 1

A208222000A SHELF DUCT PIPE - DOOR COOLING 1 1 1

A2082230000 PLUG SHELF PIPE - DOOR COOLING 1 1 1

A2082240000 VALVE - DOOR COOLING 1 1 1

A2082250000 KNOB, FLOW CONTROL - DOOR COOLING 1 1 1

A2082300000 SUB ASSY, AIR SEPARATOR - DOOR COOLING 2 1 1

A208245000A AIR DEFLECTOR, DOOR COOLING 1 1 1

A2084290000 ICE TWISTER SUB ASSY 1 1 1

A2084300000 ICE BRAKET SUB ASSY 1 1 1

A2110910000 BASE PACKAGING, GNF EXPORTS 1

A2110920000 PAD TOP, GNF EXPORTS 1

A2110930000 CORNER POST-FRONT, GNF EXPORTS 1

A2110940000 CORNER POST-BACK, GNF EXPORTS 1

A2110950000 SLEEVE 220L, GNF EXPORTS (Optimised) 1

A2114310000 ANGLE BOARD - NEW 1 1

You might also like

- Sealed System Service ManualDocument30 pagesSealed System Service ManualBarry BurkanNo ratings yet

- Kenmore Bottom Freezer Refrigerator Stainless Steel 596.71813100 Parts ManualDocument32 pagesKenmore Bottom Freezer Refrigerator Stainless Steel 596.71813100 Parts ManualelvisandmickNo ratings yet

- Maxx Cold Mxx-23f ServiceDocument314 pagesMaxx Cold Mxx-23f Servicedan theman100% (2)

- Refrigerator Frs U20bci U21gaiDocument92 pagesRefrigerator Frs U20bci U21gaiJoão Pedro Almeida100% (1)

- 5Document208 pages5Syed Noman AhmedNo ratings yet

- Tecumseh Guidelines For Utilization of R134aDocument7 pagesTecumseh Guidelines For Utilization of R134aAnibal RiosNo ratings yet

- Service Manual MIH Series Condensing Units Heat Pump: 1.5 Tons To 5 TonsDocument30 pagesService Manual MIH Series Condensing Units Heat Pump: 1.5 Tons To 5 TonsHenry Javier RíosNo ratings yet

- Impact of Altitude On AC SystemsDocument31 pagesImpact of Altitude On AC Systemsjotace469No ratings yet

- Liebert Minimate2 1 1.5 Ton Technical Data Manual 00Document76 pagesLiebert Minimate2 1 1.5 Ton Technical Data Manual 00FernandoNo ratings yet

- KRV93-123EHN XDocument51 pagesKRV93-123EHN Xprr69No ratings yet

- Technical Data & Service Manual: Indoor Unit: As52AlDocument31 pagesTechnical Data & Service Manual: Indoor Unit: As52Alsontuyet82No ratings yet

- Repair Part List - MFI2568AESDocument30 pagesRepair Part List - MFI2568AESAnibal Jose Cruz LarezNo ratings yet

- Whirlpool LSL9244EQ0 Repair Part ListDocument14 pagesWhirlpool LSL9244EQ0 Repair Part ListkenygomezNo ratings yet

- Repair Part List - W10183471Document13 pagesRepair Part List - W10183471celiaNo ratings yet

- DLEX3570W Secadora Colega Tecnico LG de GasDocument64 pagesDLEX3570W Secadora Colega Tecnico LG de GasEdison EspinalNo ratings yet

- Top and Cabinet Parts Guide for LG Washer Models LSQ9500LQ0 and LSQ9500LT0Document14 pagesTop and Cabinet Parts Guide for LG Washer Models LSQ9500LQ0 and LSQ9500LT0jisteeleNo ratings yet

- Install and use your new refrigerator safelyDocument26 pagesInstall and use your new refrigerator safelyAna RodriguezNo ratings yet

- HC-702WE - Service Manual (20-Mar-2013) PDFDocument16 pagesHC-702WE - Service Manual (20-Mar-2013) PDFPaulAbiNasrNo ratings yet

- SJ-A20S/B21S/A34S Service ManualDocument33 pagesSJ-A20S/B21S/A34S Service ManualLuis PapaNo ratings yet

- Manual Lavadora Wla7333jt1 WhirpoolDocument6 pagesManual Lavadora Wla7333jt1 Whirpoolulises zermeñoNo ratings yet

- LG Multi Inverter - Solución de ProblemasDocument87 pagesLG Multi Inverter - Solución de ProblemasJarvin Saenz PavónNo ratings yet

- Dunham Bush - IntroductionDocument3 pagesDunham Bush - Introductionchris110No ratings yet

- American Top Loader Washing Machine + SerialDocument67 pagesAmerican Top Loader Washing Machine + SerialMandragora officinarum100% (1)

- Hisense Corporation: AS-09UR4SVNVG1 AS-12UR4SVNVG1 As-12Ur4Svgvg As-18Ur4Stvvg As-24Ur4SqjvgDocument34 pagesHisense Corporation: AS-09UR4SVNVG1 AS-12UR4SVNVG1 As-12Ur4Svgvg As-18Ur4Stvvg As-24Ur4SqjvgRajesh SoniNo ratings yet

- LG - DW - LDF6810 Service ManualDocument65 pagesLG - DW - LDF6810 Service ManualJames HarpoleNo ratings yet

- Daikin Indoor Unit Manual FTKS50 60 71 FTXSDocument34 pagesDaikin Indoor Unit Manual FTKS50 60 71 FTXSThais G QuinonesNo ratings yet

- Service Manual: Side by Side S20B RSB21-A/GDocument16 pagesService Manual: Side by Side S20B RSB21-A/GjicutuNo ratings yet

- Easy-to-understand guide to Samsung air conditioner models AQV09-12UGEN/UGFEUR and AQV10UG(W)EN/UWFEURDocument167 pagesEasy-to-understand guide to Samsung air conditioner models AQV09-12UGEN/UGFEUR and AQV10UG(W)EN/UWFEURAdriano NascimentoNo ratings yet

- Usa Dishwasher Tech. TrainingDocument68 pagesUsa Dishwasher Tech. TrainingJostin Castillo Hurtado50% (2)

- ProgramaciAn Tarjeta Simplicity Jhonson ControlsDocument22 pagesProgramaciAn Tarjeta Simplicity Jhonson ControlsMario CruzNo ratings yet

- Catalogo Lavadora Amazonas 2009Document10 pagesCatalogo Lavadora Amazonas 2009Ricardo V.No ratings yet

- Whirlpool Repair Part List - 4398122Document10 pagesWhirlpool Repair Part List - 4398122tony_rowe_12100% (1)

- ACDS-R410A-50-60Hz MS0495C 0315 CsDocument40 pagesACDS-R410A-50-60Hz MS0495C 0315 CsMARCOSNo ratings yet

- FW SuperLite Standard Range Catalogue 2012-13Document212 pagesFW SuperLite Standard Range Catalogue 2012-13majortayNo ratings yet

- Coleman Mach 8 Ac ManualDocument12 pagesColeman Mach 8 Ac Manualgcannon3No ratings yet

- Service manual for Sharp refrigerator models SJ-44L and SJ-48LDocument28 pagesService manual for Sharp refrigerator models SJ-44L and SJ-48LJoseph AlbertNo ratings yet

- Compresseur Danfoss Secop sc21cl PDFDocument2 pagesCompresseur Danfoss Secop sc21cl PDFOscar MendozaNo ratings yet

- Daewoo DW-172C DWM161C011Document26 pagesDaewoo DW-172C DWM161C011GIOVANNI VIDAL MORALESNo ratings yet

- EMBRACODocument80 pagesEMBRACOElsa Guéhennec100% (1)

- Isobutane (R600A) DanfosDocument12 pagesIsobutane (R600A) Danfosjob_openings4094No ratings yet

- Floor Standing PDBDocument71 pagesFloor Standing PDBpubudunishanthaNo ratings yet

- TM - MHW - 2010 - 50-60Hz (UMITA)Document21 pagesTM - MHW - 2010 - 50-60Hz (UMITA)Rodrigo Neira De Fino100% (2)

- RACK HussmanDocument147 pagesRACK HussmanOfir LizethNo ratings yet

- Challenger 3000 Parts ManualDocument52 pagesChallenger 3000 Parts ManualCristhian Aguilar100% (1)

- BrochureA53Folds XPower 2 Hi-Wall 112012Document2 pagesBrochureA53Folds XPower 2 Hi-Wall 112012Elaisa KasanNo ratings yet

- Samsung RA20VHSW Service ManualDocument32 pagesSamsung RA20VHSW Service Manualnuk1doe50% (2)

- GTUP270 GE Repair ManualDocument101 pagesGTUP270 GE Repair ManualCarlos RosarioNo ratings yet

- Cat WSCWDC 6Document108 pagesCat WSCWDC 6Emerson PenaforteNo ratings yet

- Chigo Inverters ManualDocument52 pagesChigo Inverters Manualhossimo33No ratings yet

- CS (Cu) - Yc18 24MKV Phaam1101059c3Document51 pagesCS (Cu) - Yc18 24MKV Phaam1101059c3Mukhammad Ken Adi IrwansyahBieberNo ratings yet

- KDocument18 pagesKredaNo ratings yet

- MicrowaveDocument122 pagesMicrowaveBuscad0rNo ratings yet

- Copeland Subcooling CompresorDocument20 pagesCopeland Subcooling CompresorEmmanuel Ayegba100% (1)

- Sam rs2545Document80 pagesSam rs2545vee8power100% (5)

- Chiller Daikin Ed-Ual-160 - 210Document52 pagesChiller Daikin Ed-Ual-160 - 210hector martinezNo ratings yet

- Service Manual: RefrigeratorDocument97 pagesService Manual: RefrigeratorAbdul Sobjan MondolNo ratings yet

- 5081505-02-GB Servicemanual ULUF450 - 490 - 850 - 890 - 750 (G-214)Document60 pages5081505-02-GB Servicemanual ULUF450 - 490 - 850 - 890 - 750 (G-214)Charlie ChannelsNo ratings yet

- Horno Dry Rod Type 300Document6 pagesHorno Dry Rod Type 300rocky_l10No ratings yet

- Samsung Side-By-side Refrigerator - Rs265 SeriesDocument103 pagesSamsung Side-By-side Refrigerator - Rs265 Seriestunet1106100% (5)

- EH Manual EnglishDocument6 pagesEH Manual EnglishHasan CosalevNo ratings yet

- Installation, Operating and Servicing Instructions for ECO, HL and HLE Water HeatersDocument12 pagesInstallation, Operating and Servicing Instructions for ECO, HL and HLE Water HeatersDan FelixNo ratings yet

- HSU-7-9-12-14-18-22 HaerDocument93 pagesHSU-7-9-12-14-18-22 Haerprotek506No ratings yet

- Restoring PH Balance in The BodyDocument6 pagesRestoring PH Balance in The Bodycinefil70No ratings yet

- Digestive EnzymesDocument5 pagesDigestive EnzymesmibosanNo ratings yet

- TS5300ser OnlineManual Win en V01Document465 pagesTS5300ser OnlineManual Win en V01cinefil70No ratings yet

- TS5300ser OnlineManual Win en V01Document465 pagesTS5300ser OnlineManual Win en V01cinefil70No ratings yet

- Fo-Ti and Its Many Health BenefitsDocument4 pagesFo-Ti and Its Many Health Benefitscinefil70No ratings yet

- Bottled Tea Beverages May Contain Fewer Polyphenols Than Brewed TeaDocument3 pagesBottled Tea Beverages May Contain Fewer Polyphenols Than Brewed Teacinefil70No ratings yet

- Processed Foods Linked To Lung CancerDocument2 pagesProcessed Foods Linked To Lung Cancercinefil70No ratings yet

- Quercetin, Skin Issues, and StressDocument1 pageQuercetin, Skin Issues, and Stresscinefil70No ratings yet

- Milk Thistle Benefits & InformationDocument2 pagesMilk Thistle Benefits & Informationcinefil70No ratings yet

- Martial Arts - Bruce Lee's Speed TrainingDocument4 pagesMartial Arts - Bruce Lee's Speed Trainingbrogan97% (33)

- Omega-3 Benefits for All AgesDocument6 pagesOmega-3 Benefits for All Agescinefil70No ratings yet

- Fenugreek Health BenefitsDocument4 pagesFenugreek Health Benefitscinefil70No ratings yet

- Pineapple BromelainDocument2 pagesPineapple Bromelaincinefil70No ratings yet

- A Study On Bisphenol A (BPA)Document3 pagesA Study On Bisphenol A (BPA)EdwardNo ratings yet

- Diet Astrology - Health and Diet For All Zodiac Sun SignsDocument5 pagesDiet Astrology - Health and Diet For All Zodiac Sun Signscinefil70No ratings yet

- Disbelieving Free Will Makes Brain Less FreeDocument2 pagesDisbelieving Free Will Makes Brain Less Freecinefil70No ratings yet

- Mediterranean Diet May Reduce Depression RiskDocument2 pagesMediterranean Diet May Reduce Depression Riskcinefil70No ratings yet

- Colloidal Silver UsesDocument4 pagesColloidal Silver Usescinefil70No ratings yet

- 5 Steps To Kill Hidden Bugs in Your Gut That Make You SickDocument6 pages5 Steps To Kill Hidden Bugs in Your Gut That Make You Sickcinefil70No ratings yet

- High Alpha-Carotene Levels Associated With Longer LifeDocument3 pagesHigh Alpha-Carotene Levels Associated With Longer Lifecinefil70No ratings yet

- 4 Exercises To Sharpen Your BrainDocument3 pages4 Exercises To Sharpen Your BrainMar DeeyaNo ratings yet

- Fasting For HealthDocument8 pagesFasting For Healthcinefil70No ratings yet

- What Can High-Coenzyme Q Foods Do For You?Document5 pagesWhat Can High-Coenzyme Q Foods Do For You?cinefil70No ratings yet

- Chlorella Benefits & InformationDocument2 pagesChlorella Benefits & Informationcinefil70No ratings yet

- Health Benefits of Vitamin C or Ascorbic AcidDocument3 pagesHealth Benefits of Vitamin C or Ascorbic Acidcinefil70No ratings yet

- Evening Primrose Oil Benefits & InformationDocument2 pagesEvening Primrose Oil Benefits & Informationcinefil70No ratings yet

- Health Benefits of A Gluten Free DietDocument2 pagesHealth Benefits of A Gluten Free Dietcinefil70No ratings yet

- Whfoods: Kale: Kale What'S New and Beneficial About KaleDocument16 pagesWhfoods: Kale: Kale What'S New and Beneficial About Kalecinefil70No ratings yet

- How To Feng Shui Your BedroomDocument3 pagesHow To Feng Shui Your Bedroomcinefil70No ratings yet

- Top 10 Resveratrol BenefitsDocument2 pagesTop 10 Resveratrol Benefitscinefil70No ratings yet

- CFM AND AIR CHANGES FOR COMMERCIAL VENTILATIONDocument2 pagesCFM AND AIR CHANGES FOR COMMERCIAL VENTILATIONagchethanNo ratings yet

- Suz-Ka25-71va2 Service Manual (Och472a)Document74 pagesSuz-Ka25-71va2 Service Manual (Och472a)Chi Phạm HồngNo ratings yet

- Study of Psychometry Properties, Chat and Its UseDocument7 pagesStudy of Psychometry Properties, Chat and Its Usesantosh IndulkarNo ratings yet

- Honeywell YTH9421C1002 Install GuideDocument24 pagesHoneywell YTH9421C1002 Install Guidehammy408No ratings yet

- Marine HVAC Systems for Superior Comfort and EfficiencyDocument24 pagesMarine HVAC Systems for Superior Comfort and EfficiencyLucaNo ratings yet

- 01 V5X VRF Service Manual PDFDocument106 pages01 V5X VRF Service Manual PDFcalvin.bloodaxe4478100% (2)

- VMF enDocument4 pagesVMF enroga9610No ratings yet

- Cooling TowerDocument8 pagesCooling TowerMithun MohanNo ratings yet

- Platfrom HVACDocument1 pagePlatfrom HVACaliNo ratings yet

- Remote Control ManualDocument9 pagesRemote Control ManualDirt FilterNo ratings yet

- Nawras CHILLER SUMMARY SHEETDocument2 pagesNawras CHILLER SUMMARY SHEETAhmed BahgatNo ratings yet

- Asl FD 260 - 380 (W)Document11 pagesAsl FD 260 - 380 (W)Comercial BrascomNo ratings yet

- Robertshaw Thermostat Cross Reference (150-2805 - Rev B)Document2 pagesRobertshaw Thermostat Cross Reference (150-2805 - Rev B)Angel NajarroNo ratings yet

- Building Utility System and Fire Protection EngineeringDocument16 pagesBuilding Utility System and Fire Protection EngineeringMohamad SafhireNo ratings yet

- Psych ExercisDocument2 pagesPsych ExercisJohn Jonel CasupananNo ratings yet

- AHRI Groundwater AssessmentDocument30 pagesAHRI Groundwater AssessmentMaxmore KarumamupiyoNo ratings yet

- Haier FlexFit Multi Parts Book 1910Document29 pagesHaier FlexFit Multi Parts Book 1910DELTA T instalacionesNo ratings yet

- AHU-B01-04 All Day Dining-Heating PDFDocument1 pageAHU-B01-04 All Day Dining-Heating PDFNgoc Vũ TrầnNo ratings yet

- Clean radiator finsDocument3 pagesClean radiator finsNeeteshNo ratings yet

- Servicio TaylorDocument136 pagesServicio TaylorMiguelNo ratings yet

- GEA - Pump - NH3 - Data BookDocument69 pagesGEA - Pump - NH3 - Data BookThái Đạo Phạm LêNo ratings yet

- Ijser: Evolution of Domestic Refrigerator by Using LPG As RefrigerantDocument4 pagesIjser: Evolution of Domestic Refrigerator by Using LPG As RefrigerantNaveed MengalNo ratings yet

- Study of solar-powered air conditioning using lithium bromide absorption systemsDocument8 pagesStudy of solar-powered air conditioning using lithium bromide absorption systemsJaime Haro EstropNo ratings yet

- 2018-10-30 - Eurovent - AHU Guidebook - First Edition - EN - WebDocument29 pages2018-10-30 - Eurovent - AHU Guidebook - First Edition - EN - WebJIDUNo ratings yet

- Induction On Central UtilityDocument54 pagesInduction On Central Utilityj.k.kumar100% (1)

- LRC-H Series Dimensions and SpecsDocument3 pagesLRC-H Series Dimensions and Specshashir zamanNo ratings yet