Professional Documents

Culture Documents

Aeroblock Installation Procedure

Uploaded by

ari_prasCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aeroblock Installation Procedure

Uploaded by

ari_prasCopyright:

Available Formats

PP IMECO Consortium

AEROBLOCK WALL

PROCEDURE

DOCUMENT NO. :

781102-0000-38QA-0019

PROJECT NAME:

KDL 120 MW COMBINED CYCLE

POWER PLANT

DATE REVISION :

-

UNIT ISSUING:

QA/QC

APPROVED BY:

PROJECT MANAGER

PAGE :

0 of 5

REVISION :

00

0

AEROBLOCKWALL

PROCEDURE

00 19/11/12 FOR APPROVAL WIN MTS SBY

REV DATE DESCRIPTION PREPARED CHECKED APPD PM

APPD BY

KDL

PP IMECO Consortium

AEROBLOCK WALL

PROCEDURE

DOCUMENT NO. :

781102-0000-38QA-0019

PROJECT NAME:

KDL 120 MW COMBINED CYCLE

POWER PLANT

DATE REVISION :

-

UNIT ISSUING:

QA/QC

APPROVED BY:

PROJECT MANAGER

PAGE :

1 of 5

REVISION :

00

1

TABLE OF CONTENTS

1. Description of Work ....................................................................................2

2. Document & Drawing Reference .....................................................................2

3. General ....................................................................................2

3.1. Material .........................................................................................3

3.2. Installation .........................................................................................3

PP IMECO Consortium

AEROBLOCK WALL

PROCEDURE

DOCUMENT NO. :

781102-0000-38QA-0019

PROJECT NAME:

KDL 120 MW COMBINED CYCLE

POWER PLANT

DATE REVISION :

-

UNIT ISSUING:

QA/QC

APPROVED BY:

PROJECT MANAGER

PAGE :

2 of 5

REVISION :

00

2

1. Description of Work

The following procedure is covering of work scope, the general requirement for

aeroblock installation.

2. Document & Drawing Reference

1. Material finish schedule for Electrical, Admin and Control Building; Warehouse

and workshop Building; Electrical Switchyard Building (781102-0000-44D0-

0014, 781102-0000-44D1-0014)

2. Standar Detail Wall Installation Detail (781102-0000-44D0-0012).

3. General

3.1. Material

3.1.1. Avoid stacking aeroblock contact with ground directly.

3.1.2. Protect aeroblock sheet and keep away from dirt, dust and rain water.

3.1.3. Bonding material for aeroblock will use Prime Mortar 110.

3.1.4. Plaster and finish mortar (acian) material for wall will use Prime Mortar

200 and Prime Mortar 310.

3.2. Installation and Sequence

3.2.1. RC Post

Install/pour RC post for every edge of column, corner of wall, opening for

door, every 3000 max spacing. For steel structure building, RC post and

bond beam rebar will be welded to steel structure every 600 mm.

PP IMECO Consortium

AEROBLOCK WALL

PROCEDURE

DOCUMENT NO. :

781102-0000-38QA-0019

PROJECT NAME:

KDL 120 MW COMBINED CYCLE

POWER PLANT

DATE REVISION :

-

UNIT ISSUING:

QA/QC

APPROVED BY:

PROJECT MANAGER

PAGE :

3 of 5

REVISION :

00

3

3.2.2. Aeroblock installation

1. Marking position for sloof and wall. This will use waterpass and string for

marking every elevation of aeroblok.

2. Base layers

3. Install and adjust aeroblock

4. Sticking vertical of aeroblok with prime mortar

PP IMECO Consortium

AEROBLOCK WALL

PROCEDURE

DOCUMENT NO. :

781102-0000-38QA-0019

PROJECT NAME:

KDL 120 MW COMBINED CYCLE

POWER PLANT

DATE REVISION :

-

UNIT ISSUING:

QA/QC

APPROVED BY:

PROJECT MANAGER

PAGE :

4 of 5

REVISION :

00

4

5. Install aeroblock each edge and check with waterpass

6. Clean surface of aeroblock everytime when start install new aeroblok.

7. Continue install aeroblock until reach the final elevation.

3.2.3. Plastered and Mortar Finish (Acian)

Before plastered, all coordinat for mechanical/electrical already follow shop

drawing.

1. Cleaning all surface of aeroblock from dirt .

2. Prepare place for mixing the mortar. Make a guidline for thickness of

plaster at aeroblock wall.

3. Pour PM-200 gradually into the water. Stir for 2 minutes to produce a

uniform mixture, wait 10 minutes for additives soluble. Stir again before

use.

4. Plaster work can be done using roskam.

5. Installation of plastering done at least 24 hours after installation

aeroblock.

PP IMECO Consortium

AEROBLOCK WALL

PROCEDURE

DOCUMENT NO. :

781102-0000-38QA-0019

PROJECT NAME:

KDL 120 MW COMBINED CYCLE

POWER PLANT

DATE REVISION :

-

UNIT ISSUING:

QA/QC

APPROVED BY:

PROJECT MANAGER

PAGE :

5 of 5

REVISION :

00

5

6. Continue with mortar finish (acian) PM-310. Sequence for mortar finish

follow Primer Mortar 310 procedure.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Brosur KatodikDocument6 pagesBrosur Katodikari_pras0% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Tools & Instruments For GISDocument1 pageTools & Instruments For GISari_prasNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- SS3.16-01 (00) Customer Information Form-CetakDocument2 pagesSS3.16-01 (00) Customer Information Form-Cetakari_prasNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- GA Vant Stack REV.0Document1 pageGA Vant Stack REV.0ari_prasNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- (PDS) Nitoproof 30Document4 pages(PDS) Nitoproof 30ari_prasNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Temperature Measurement TS500Document4 pagesTemperature Measurement TS500ari_prasNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- TM Network TopologyDocument1 pageTM Network Topologyari_prasNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Tightening Torque For UNC Grade 8 Bolts: Wellington City Porirua CityDocument1 pageTightening Torque For UNC Grade 8 Bolts: Wellington City Porirua Cityari_prasNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Sample Download 2Document1 pageSample Download 2ari_prasNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- SurfacePrepGuide PDFDocument2 pagesSurfacePrepGuide PDFPercyFloresNo ratings yet

- G 2004-Qcri-0101Document1 pageG 2004-Qcri-0101ari_prasNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- G 2004-Qcri-071Document1 pageG 2004-Qcri-071ari_prasNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Rfi 0232Document3 pagesRfi 0232ari_prasNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Data Laboratory The Soil Test ResultsDocument9 pagesData Laboratory The Soil Test Resultsari_prasNo ratings yet

- No. Name of Equipment Type Serial No. Capacity Expired Date Date of CalibrationDocument2 pagesNo. Name of Equipment Type Serial No. Capacity Expired Date Date of Calibrationari_prasNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- OracleDocument23 pagesOracleari_prasNo ratings yet

- Drawing 1022Document5 pagesDrawing 1022ari_prasNo ratings yet

- Safety Plan For Erection Steel BuildingDocument8 pagesSafety Plan For Erection Steel Buildingari_prasNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- 26 418Document6 pages26 418ari_prasNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- TighteningofStructuralBolts 31-35Document5 pagesTighteningofStructuralBolts 31-35masaud akhtarNo ratings yet

- Test Point 1 DataDocument4 pagesTest Point 1 Dataari_prasNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- DC Hi Pot TestDocument2 pagesDC Hi Pot TestVictor Jr QuijanoNo ratings yet

- Valve Material ApplicationDocument16 pagesValve Material Applicationari_prasNo ratings yet

- SurfacePrepGuide PDFDocument2 pagesSurfacePrepGuide PDFPercyFloresNo ratings yet

- Specifications For Installation of Grounding Rods For Lightning Protection of Electronic Scale SystemsDocument2 pagesSpecifications For Installation of Grounding Rods For Lightning Protection of Electronic Scale SystemsAbu Hanif Al KabumainyNo ratings yet

- Metric Class 8-8Document1 pageMetric Class 8-8ari_prasNo ratings yet

- QCP e 11 Hipot TestDocument4 pagesQCP e 11 Hipot Testari_prasNo ratings yet

- Vacuum Test BottomDocument1 pageVacuum Test Bottomari_prasNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- 3E AND 110H/210H SERIES Canned Motor Pumps: R S P W C I MDocument16 pages3E AND 110H/210H SERIES Canned Motor Pumps: R S P W C I Mari_prasNo ratings yet

- ABAO (NN) Literary Paper 1Document4 pagesABAO (NN) Literary Paper 1Trisha Abao100% (1)

- Progress Test Version A: Choose The Correct Answer. Write A, B, or C in The BoxDocument2 pagesProgress Test Version A: Choose The Correct Answer. Write A, B, or C in The BoxHector MarzanaNo ratings yet

- Annabel LeeDocument4 pagesAnnabel LeeMaricon DomingoNo ratings yet

- 12 Angry Men Unit - Play PiecesDocument19 pages12 Angry Men Unit - Play PiecesEithan HayimNo ratings yet

- ENGLISHDocument2 pagesENGLISHblack stalkerNo ratings yet

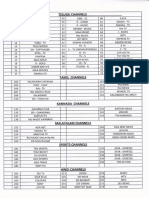

- Channels ListDocument2 pagesChannels Listphani raja kumarNo ratings yet

- Proofs of A Conspiracy by John RobisonDocument239 pagesProofs of A Conspiracy by John Robisonhasangetinya100% (6)

- Daria TV ScriptsDocument1,018 pagesDaria TV ScriptsFrater Bier100% (5)

- Thoughts & Life of A LegendDocument213 pagesThoughts & Life of A LegendDrDaniel Victory100% (2)

- Unit 8: Focus On Time Analysis: - Before You ReadDocument5 pagesUnit 8: Focus On Time Analysis: - Before You ReadScribd0ProfileNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- G1 HinduismDocument40 pagesG1 HinduismJulie-Ar Espiel SibalaNo ratings yet

- Government of West Bengal: Finance (Audit) DepartmentDocument2 pagesGovernment of West Bengal: Finance (Audit) DepartmentSamrat MukherjeeNo ratings yet

- Mapeh 8 Prelim ExamDocument5 pagesMapeh 8 Prelim ExamRonald EscabalNo ratings yet

- Proiectare Pregatitoare English For Kids, BookletDocument8 pagesProiectare Pregatitoare English For Kids, BookletCristina M.No ratings yet

- 100 Must-Read Fantasy Novels PDFDocument208 pages100 Must-Read Fantasy Novels PDFJoel100% (1)

- MODULE 1 Art - HumanitiesDocument96 pagesMODULE 1 Art - HumanitiesRejaelSenoro67% (9)

- Unit 4 TestDocument4 pagesUnit 4 TestJuanJesusOcañaAponteNo ratings yet

- Annotated Bibliography For House Made of DawnDocument6 pagesAnnotated Bibliography For House Made of DawnRam GoliNo ratings yet

- High Impact CopywritingDocument17 pagesHigh Impact CopywritingdurvalmartinsNo ratings yet

- Borderlands 2 How To Use Github ModsDocument4 pagesBorderlands 2 How To Use Github ModsMcneilKoenig3No ratings yet

- Michael V Pisani - Imagining Native America in Music PDFDocument439 pagesMichael V Pisani - Imagining Native America in Music PDFPaulo Jorge Pessoa100% (1)

- 3rd Edition Dragon Lance Source BooksDocument5 pages3rd Edition Dragon Lance Source BooksJoshua Laferriere100% (1)

- Curriculum Map ENGLISH 2 Edited PRINTED 1-4Document11 pagesCurriculum Map ENGLISH 2 Edited PRINTED 1-4Jo MeiNo ratings yet

- Booklet FROM MY BIBLE How To Sermons May 2014Document23 pagesBooklet FROM MY BIBLE How To Sermons May 2014cruzNo ratings yet

- 17 Paket Grammar PDFDocument72 pages17 Paket Grammar PDFSyekhmundu jambukarangNo ratings yet

- Characterization of Madam Loisel From The NecklaceDocument2 pagesCharacterization of Madam Loisel From The NecklaceNita SafitriNo ratings yet

- Clarinet SongsDocument5 pagesClarinet SongsJose Claudio da Silva100% (1)

- 20 Windows Keyboard Shortcuts You Might Not KnowDocument4 pages20 Windows Keyboard Shortcuts You Might Not KnowjackieNo ratings yet

- DeskTop LAA6E84Document164 pagesDeskTop LAA6E84Muhammad AbubakarNo ratings yet

- Pecdc Materials ElizaDocument16 pagesPecdc Materials ElizaLorelyn Buscagan EliveraNo ratings yet