Professional Documents

Culture Documents

Uploaded by

dmsoares19890 ratings0% found this document useful (0 votes)

20 views4 pagesTime-load (static fatigue) testing of fiberglass rods used in non-ceramic insulators has been underway for over 20 years. Results indicate a very flat time-load curve under nominal conditions. Residual strength tests were unable to quantify any significant loss in strength as a result of long-term overload conditions.

Original Description:

Original Title

00756157.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentTime-load (static fatigue) testing of fiberglass rods used in non-ceramic insulators has been underway for over 20 years. Results indicate a very flat time-load curve under nominal conditions. Residual strength tests were unable to quantify any significant loss in strength as a result of long-term overload conditions.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

20 views4 pagesUploaded by

dmsoares1989Time-load (static fatigue) testing of fiberglass rods used in non-ceramic insulators has been underway for over 20 years. Results indicate a very flat time-load curve under nominal conditions. Residual strength tests were unable to quantify any significant loss in strength as a result of long-term overload conditions.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

Time-Load Testing of Non-Ceramic Insulators

With Fiberglass Core Rod - A 20 Year Summary

R. A. Bernstorf

Hubbell Power Systems - Ohio Brass Co.

Abstract: Time-Load (static fatigue) testing of fiberglass rods used

in non-ceramic insulators (NCIs) has been underway for over 20

years. Data collected over that time frame is reported in this paper

for NCIs manufactured with 16 mm ( 5 / 8 ' ) diameter and 22 mm

(7/8") diameter epoxy fiberglass rods. All of the samples tested

utilized crimped steel end fittings for transference of the applied

tensile load to the fiberglass rod and from the rod to the support

structure. Samples with and without a polymer housing covering

the core rod are included.

The data includes time-load test results under constant load to

failure and residual strength evaluations after the removal of a long-

term time-load.

The results indicate a very flat time-load curve under nominal

conditions. The residual strength tests were unable to quantify any

significant loss in strength as a result of long-term overload

conditions.

Over the course of 20 years, the investigation looked into

looked into the characteristics of 16" and 22 mm rod

insulators. In 1998, the test program was terminated, with

this paper reporting the final test results.

11. TIME-LOAD TESTING

Time-Load testing involves applying a constant load to an

insulator for an extended period of time (typically until it

fails). Unless otherwise noted, that is the means of testing

employed for the included data.

Keywords: Non-ceramic Insulators, Time-load.

I. INTRODUCTION

With the introduction of non-ceramic insulators in the late

60s and early 70s came a growing concern for the long term

strength characteristics of the fiberglass rods used as strength

members, as well as the integrity of the end fitting attachment

methods to that rod. These concerns were a product of the

aerospace industry which had been testing composite

materials and their long-term creep characteristics.

Fig. 1 - Typical outdoor load racks - 16 mm samples.

In an effort to address those concerns, a series of long-term

loading tests (time-load) were undertaken. The goal of the

testing program was the development of an understanding of

the long-term load bearing characteristics of the non-ceramic

insulators.

The non-ceramic insulators evaluated in this test program

utilized either a 15.9 mm (nominal 518 inch) Or 22.3"

(nominal 718 inch) diameter fiberglass rod. For the Purposes

of this paper, the two types will be referenced as 16 mm and

22 mm, respectively. The fiberglass rods were an epoxy

resin system with a E-type unidirectional glass fibers.

Fiberglass rod lengths were at least 20X the diameter in order

to minimize end effects.

End fittings were composed of forged steel. These fittings

were crimped to the fiberglass rod using a rolling crimp,

which proceeded from the innermost point of the end fitting

toward the end. The crimp lengths were 63.5 mm(2.5 in)

and 101.6 mm(4 in) for the 16 mmand 22 mm diameter rod

insulators, respectively.

0-7803-5515-6/99/$10.00 0 1999 IEEE

823

The minimum ultimate tensile strength load ratings for the

insulators were 89 kN for the 16 mm rod and 222 kN for the

22 mm rod. The recommended maximum loadings for these

insulators were 44 kN and 11 1 kN for the 16 mm and 22 mm

rod insulators, respectively.

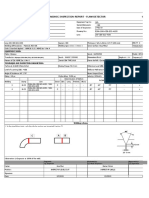

Samples were tested in load frames located both indoors

Samples without weathersheds were only and outdoors.

tested indoors (see fig. 1)

The load frames used lever arms to apply a load to the

insulator. All loads were established by inserting a load cell

(originally hydraulic, later electronic) and measuring the load

during three applications. The error listed for the data

represents the range. Pivot points within the load frames

were lubricated with a high pressure lubricant.

The date and time of loading was recorded exactly. For

newly loaded samples, conditions were checked daily. As

time went by, the samples were checked less frequently.

Sample failure was indicated by mechanical failure and noted

by the load bucket at the free end of the moment arm resting

on the floor. Time to failure was established as an average

time (between checks) and a range.

The data displayed large variations in time to failure as a

function of load. To make sense of the data, it was plotted as

a log-log graph (see fig. 2). The 16 mm rod diameter data

was also analyzed using Chi-Squared analysis. The analysis

was performed in the statistical mode using a logarithmic

equation as shown on the face of the graph. Assumed errors

were 3% for all data.

16" ROD - TIME LOAD DATA

course of the test for the 5/ 8 samples. All of these tests were

performed with the insulator in a vertical position. The solid

line represents the equation derived using the Chi-squared

analysis. Since the samples which did not fail are included,

the curve will be somewhat pessimistic. Had those units been

permitted to remain on test until failure, the curve would

have demonstrated less slope.

With the data for the samples which did not fail removed,

the graph shown in Fig. 3 results.

16" TIME-LOAD FAILURES

o m 1 Owool o w 0 1 owl 001 0 1 I IO I W

,,ME, YE, , , , s Ln(Y)=-O OOor88'Ln(X)+4 414

ChiA2=0 000416

Fig. 3 - Time-load data including only failures.

It should be noted that more than 95% of the samples

which failed during the test sustained a rod failure. The

remainder sustained crimp slips (the crimped fitting slides

from the rod) or hardware failures (the metallic coupling

zone fails).

100

3

2

s

9

U1

Y

0

2

-

4

10

0000001 000001 00001 0001 001 0 1 1 10 100

EUPSED TIME. YEARS

WO=- 000839*Ln(X)+4 3948

Ch1"2=00213

Fig. 4 - Outdoor load racks for 22 mm rod samples.

Fig. 2 - Time-load data including samples which did not fail.

This graph includes all of the data obtained, including the

time to removal for samples which did not fail during the

The test program for the 22 mm insulators was performed

in a similar manner. In this instance, all of the insulators

824

were tested in frames which placed the insulators in a

horizontal position (see fig. 4). All of the tests were

performed outdoors, requiring the use of full insulators.

The data for the 22 mm samples was not run through the

Chi-squared analysis. However, the data is plotted in fig. 5.

22 mm Rod Time-Load Data

10

OOWOl o w 0 1 ow1 001 0 1 1 10

Elapsed Ti m. Yean

Fig. 5 - Time-load data including samples which did not fail.

111. ULTIMATE AND RESIDUAL STRENGTH

The time-load results indicate the ability of the insulator to

sustain a fixed load for a period of time. But that load is

typically well above the loads which would be expected in

the field. The primary concern of most users involves the

residual strength in the design resulting from the insulator's

service history.

Before the time-load tests were begun, control samples

were prepared. These insulators were tested in tension to

determine the ultimate tensile strength. When the test

program was established, every third insulator manufactured

was tested to ascertain the characteristic tensile strength of

the batch. Since no test protocol existed, the load was

applied at a relatively uniform rate until failure occurred. A

typical example of the loading profile (see fig. 6) and the

initial data collected for all of the samples is shown in Fig. 7.

After the termination of the time-load tests, the unfailed

samples which were removed from the loading racks were

subjected to the same ultimate tensile strength test. Those

results are shown in Fig. 8 for the 16 mm test samples.

1m

i m

80

4 60

I

;

40

20

0

1998 - UTS - Time-Load Sample

0 5 4 0 1 5 2 0 2 5 3 0 3 5 4 0 4 5

El.pr.d Thu.

Fig. 6 -Typical Ultimate Tensile Strength load profile.

16mm -CONTROL SAMPLES - UTS

1E-07 O.OOWO1 O.OOW1 0.0001 0.001 0.01 0.1 1

EIAPSED TIME. YEARS

Fig. 7 - Control Samples UTS data.

The data was analyzed using a student's t-test [l]. For the

analysis, a two-tailed distribution was assumed. Details

follow:

1977: Average(l9) =124.25

1998: Average(l1) =120.95

P(T,n) =0.837

o =9.63

o =7.48

2( 1 -P) =.326

The analysis indicates a 32.6% probability that the two

groups of data are from the same general population. That

probability is substantial enough to make doubtful any

supposition that the insulators sustained a measurable loss in

strength as a result of the time under load.

825

16mm RODS - UTS SAMPLES - BEFORE AND AFTER

I

V. CONCLUSIONS

The data collected over 20 years indicates that non-ceramic

insulators exhibit very stable time-load characteristics.

p ; ~ Extrapolations based upon the existing data indicate that the

2-to-1 safety factor applied to this type of insulator, if

properly followed, provides sufficient margin to assure

appropriate long term service.

.S"Z

A comparison of ultimate strength data collected at the

start of the test program with that collected after 20 years of

ODOOOOOI ooowo, Oo wo l oow1 ow1 001 0 1

ELIPSEDIIHE,IEIR~ . 1977 DATi. CONTROLS testing indicates no significant reduction in strength.

SERIES 2 - 1998 DATA - POST LOAD

Fig. 8 - Control samples and post test UTS data

VI. REFERENCES

IV. DISCUSSION

The data collected over 20 years of testing indicates that

the time-load strength reduction for non-ceramic insulators is

minimal. The 2-to-I safety margin normally used for these

insulators is sufficient to permit the insulator to be operated

without fear of failure for any reasonable service life.

The ultimate strength data collected before and after the

time-load test indicates no substantial loss of strength

resulting from the loading. However, since insulators do fail

during time-load testing, there must be strength loss. The

strength loss may be so gradual that it cannot be precisely

determined or it may be non-linear. In either case, the data

implies that evaluations of tensile strength for insulators

removed from service may not be an indicator of their

condition.

[l ] S . L. Meyer, Data Analysis for Scientists and

Engineers, J ohn Wiley and Sons, 1975, pp. 279-

282.

VII. BIOGRAPHIES

R. Allen Bernstorf graduated with a B.A. from Gettysburg

College and an M.S. in physics from the University of Akron.

In his current position as principal engineer, insulators, he is

responsible for the testing and application of insulator

products. He is a member of the IEEE and is active in the

IEEEPES, the ANSI C-29 Committee, the CSA C411

Committee and NEMA HVITC.

826

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- AP Research Survival Guide - RevisedDocument58 pagesAP Research Survival Guide - RevisedBadrEddin IsmailNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- MAS Assessment Exam Answer Key SolutionDocument7 pagesMAS Assessment Exam Answer Key SolutionJonalyn JavierNo ratings yet

- BHEL Ceramic Business Unit Manufactures Composite InsulatorsDocument12 pagesBHEL Ceramic Business Unit Manufactures Composite InsulatorsNikitha ChandrashekarNo ratings yet

- Case Study (DM)Document28 pagesCase Study (DM)Jai - Ho100% (1)

- Maxwell's Equations For Electromagnetic WavesDocument54 pagesMaxwell's Equations For Electromagnetic Wavesdmsoares1989No ratings yet

- Lease of Residential HouseDocument4 pagesLease of Residential HousedenvergamlosenNo ratings yet

- TheSun 2008-11-04 Page16 Asian Stocks Rally Continues On Policy HopesDocument1 pageTheSun 2008-11-04 Page16 Asian Stocks Rally Continues On Policy HopesImpulsive collectorNo ratings yet

- Audit AP TestsDocument3 pagesAudit AP TestsSweet Emme100% (1)

- ABB - Guidelines For Surge Protection of Shunt Capacitors BanksDocument14 pagesABB - Guidelines For Surge Protection of Shunt Capacitors BanksRodolpho SousaNo ratings yet

- A Secret Baby by The Bratva by Lexi AsherDocument184 pagesA Secret Baby by The Bratva by Lexi Asheralisa sanchez100% (1)

- Casio Fx-350MS ManualDocument40 pagesCasio Fx-350MS ManualGarrett Lewis100% (3)

- B D Bonatto PHD ThesisDocument185 pagesB D Bonatto PHD Thesisdmsoares1989100% (1)

- PDFDocument4 pagesPDFdmsoares1989No ratings yet

- Stafford House InternationalDocument24 pagesStafford House Internationaldmsoares1989No ratings yet

- Special Relativity and Maxwells EquationsDocument51 pagesSpecial Relativity and Maxwells EquationslepetitnoirNo ratings yet

- Insulator TestingDocument28 pagesInsulator TestingadnanNo ratings yet

- Characteristic Properties of Silicone Rubber CompoundsDocument16 pagesCharacteristic Properties of Silicone Rubber Compoundslink2u_007No ratings yet

- Intro AC/DC Module MEMS InductorDocument46 pagesIntro AC/DC Module MEMS InductorRafael CoelhoNo ratings yet

- Nema Stdstp2Document34 pagesNema Stdstp2dmsoares1989No ratings yet

- PDFDocument10 pagesPDFdmsoares1989No ratings yet

- Environmental aging of polymeric insulators in PakistanDocument2 pagesEnvironmental aging of polymeric insulators in Pakistandmsoares1989No ratings yet

- COMSOL MetisDocument44 pagesCOMSOL Metisdmsoares1989No ratings yet

- FRP Rods For Brittle Fracture ResistantDocument9 pagesFRP Rods For Brittle Fracture Resistantdmsoares1989No ratings yet

- Upload 1desig N An D Operatio N Perspectiv e o F A Britis H UH V LaboratorDocument21 pagesUpload 1desig N An D Operatio N Perspectiv e o F A Britis H UH V Laboratordmsoares1989No ratings yet

- Corona Ring Design of 800kV DC Composite Insulator Based On Computer AnalysisDocument4 pagesCorona Ring Design of 800kV DC Composite Insulator Based On Computer Analysisdmsoares1989No ratings yet

- PDFDocument7 pagesPDFdmsoares1989No ratings yet

- jgrd14623 PDFDocument8 pagesjgrd14623 PDFdmsoares1989No ratings yet

- PDFDocument6 pagesPDFdmsoares1989No ratings yet

- PDFDocument4 pagesPDFdmsoares1989No ratings yet

- PDFDocument4 pagesPDFdmsoares1989No ratings yet

- Ajas651010 1014 PDFDocument5 pagesAjas651010 1014 PDFdmsoares1989No ratings yet

- Harmonics Transformer de RatingDocument6 pagesHarmonics Transformer de RatingFabricio Dias CoimbraNo ratings yet

- Review of Features of Fog Chamber at The Ohio State University For Polymer Insulator EvaluationDocument4 pagesReview of Features of Fog Chamber at The Ohio State University For Polymer Insulator Evaluationdmsoares1989No ratings yet

- Ajas651010 1014 PDFDocument5 pagesAjas651010 1014 PDFdmsoares1989No ratings yet

- PDFDocument10 pagesPDFdmsoares1989No ratings yet

- PDFDocument4 pagesPDFdmsoares1989No ratings yet

- UEME 1143 - Dynamics: AssignmentDocument4 pagesUEME 1143 - Dynamics: Assignmentshikai towNo ratings yet

- Product 243: Technical Data SheetDocument3 pagesProduct 243: Technical Data SheetRuiNo ratings yet

- Dice Resume CV Narendhar ReddyDocument5 pagesDice Resume CV Narendhar ReddyjaniNo ratings yet

- 3 5 3Document4 pages3 5 3Amr Mohamed RedaNo ratings yet

- Course Code: Hrm353 L1Document26 pagesCourse Code: Hrm353 L1Jaskiran KaurNo ratings yet

- Wicks Angela, Roethlein Christopher - A Satisfaction - Based Definition of QualityDocument1 pageWicks Angela, Roethlein Christopher - A Satisfaction - Based Definition of Qualityalfdjole0% (1)

- Ut ProcedureDocument2 pagesUt ProcedureJJ WeldingNo ratings yet

- Schedule For Semester III, Class of 2021Document7 pagesSchedule For Semester III, Class of 2021Jay PatelNo ratings yet

- 1 FrameworkDocument26 pages1 FrameworkIrenataNo ratings yet

- Electronic Throttle ControlDocument67 pagesElectronic Throttle Controlmkisa70100% (1)

- Ballari City Corporation: Government of KarnatakaDocument37 pagesBallari City Corporation: Government of KarnatakaManish HbNo ratings yet

- GTA Max Profit Bunker Locations Update v1.4Document1 pageGTA Max Profit Bunker Locations Update v1.4Sam FarrelNo ratings yet

- Chapter 5Document11 pagesChapter 5XDXDXDNo ratings yet

- Rieka Fitri Sutrisno-CGK-SXBHSY-BTH-FLIGHT - ORIGINATINGDocument2 pagesRieka Fitri Sutrisno-CGK-SXBHSY-BTH-FLIGHT - ORIGINATINGfairuz fanaNo ratings yet

- Cambridge IGCSE: Computer Science 0478/12Document16 pagesCambridge IGCSE: Computer Science 0478/12Rodolph Smith100% (2)

- Pakistan Affairs Current Affairs 2016 MCQSDocument3 pagesPakistan Affairs Current Affairs 2016 MCQSMuhammad MudassarNo ratings yet

- Chapter 27 Protists I. Evolution of EukaryotesDocument7 pagesChapter 27 Protists I. Evolution of EukaryotesNadeem IqbalNo ratings yet

- Blackmagic RAW Speed TestDocument67 pagesBlackmagic RAW Speed TestLeonardo Terra CravoNo ratings yet

- ReadingDocument6 pagesReadingakhyar sanchiaNo ratings yet

- Gr.10 Music History ModuleDocument45 pagesGr.10 Music History ModuleKyle du PreezNo ratings yet

- A Short Example Presentation On Molecules Slash Molecular Chemistry in LatexDocument8 pagesA Short Example Presentation On Molecules Slash Molecular Chemistry in LatexintangibilidadeNo ratings yet

- Ted Hughes's Crow - An Alternative Theological ParadigmDocument16 pagesTed Hughes's Crow - An Alternative Theological Paradigmsa46851No ratings yet

- CuegisDocument2 pagesCuegisTrishaNo ratings yet