Professional Documents

Culture Documents

PV Elite

Uploaded by

vikrantgulhane0 ratings0% found this document useful (0 votes)

182 views6 pagesDesign Of Horizontal Pressure Vessel Using PVElite Software

Original Title

PV ELITE

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentDesign Of Horizontal Pressure Vessel Using PVElite Software

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

182 views6 pagesPV Elite

Uploaded by

vikrantgulhaneDesign Of Horizontal Pressure Vessel Using PVElite Software

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

I J I RSTI nternational J ournal for I nnovative Research in Science & Technology| Vol.

1, I ssue 1, J une 2014| I SSN(online): 2349-6010

All rights reserved by www.ijirst.org

58

Design Of Horizontal Pressure Vessel Using

PVElite Software

Shyam R. Gupta Ashish Desai

PG Student Asst. Professor

Kalol Institute Of Technology And Research Centre, Kalol,

Gujarat

LDRP engineering college ,Gandhinagar, Gujarat

Abstract

Pressure vessels are widely used in various industries. A Horizontal pressure vessel has been designed using graphical based software

named PVElite. For designing of nozzle, saddle supported pressure vessel some input parameters like volume, inside diameter,

design pressure (either inside pressure or external pressure), temperature, material, processing fluid. Etc. is required. PVElite gives

thickness of shell, thickness of head, height of head, thickness of nozzle,. The high stresses at intersections are caused by

discontinuity shear stresses and moments which exist to maintain compatibility at the junctions. PVElite calculate this local stresses

according to welding research council (WRC) 107.

Keywords: Horizontal Pressure Vessel, Design using PVElite, Local stress analysis using PVElite.

_________________________________________________________________________________________________________

I. INTRODUCTION

Pressure vessels are the container for fluid and gases under high pressure. Due to high pressure, stresses are induced in pressure

vessel, if this stresses are more than the permissible stresses then the failure of pressure vessel occurs. So it is necessary to

manufacture pressure vessels under standard codes. A code is a standard that has been adopted by one or more governmental bodies

and has the force of law, or when it has been incorporated into a business contract. Codes specify requirements of design, fabrication,

inspection and testing of pressure vessels. A detailed study of various parts of pressure vessels like shell, head support, flanges,

nozzles etc. Is carried out according to rules of ASME code section VIII, Division I. Due to mathematical calculation designing of

pressure vessel becomes tedious but by using software like PVElite designing of pressure vessel can be done easily. In the case of

shell, opening requiring reinforcement in vessel under internal pressure the metal removed must be replaced by the metal of

reinforcement. In addition to providing the area of reinforcement, adequate welds must be provided to attach the metal of

reinforcement and the induced stresses must be evaluated.

II. ANALYSIS OF PRESSURE VESSEL USING PVELITE AND DISCUSSION

A. DESI GN CONDI TI ON

Design pressure: 439.46 psi

Design temperature: 122 F

Material: SA-516 70

Corrosion allowance: D M water (non-lethal)

Process fluid sp. Gravity: 1.00

Wind load/snow load: not applicable

B. RESULT AND DI SCUSSI ON

In PVElite software we have to enter input data that is required for pressure vessel element and then we have to select its components

like head, shell, pipe and legs etc. And its calculate its o/p value like thickness, shell/head height and all other result as shown in

bellow. Pressure vessel contains fluid so while designing we have to also consider static pressure due to fluid. Static pressure is equal

* g * h. Where, = density of fluid, g= gravity and h= height up to which vessel contain fluid. PVElite also show analyzes as

follows:

1) Result of head:

Thickness Due to Internal Pressure [Tr]:

Design Of Horizontal Pressure Vessel Using PVElite Software

(IJIRST/ Volume 01 / Issue 01 / 010)

All rights reserved by www.ijirst.org

59

= (P*(D+2*CA)*K)/(2*S*E-0.2*P) Appendix 1-4(c)

=(439.460*(84.0000+2*0.0000)*1.00)/(2*20000.00*1.00-0.2*439.460)

= 0.9249 + 0.0000 = 0.9249 in.

Max. All. Working Pressure at Given Thickness [MAWP]:

= (2*S*E*(T-Ca))/(K*(D+2*Ca)+0.2*(T-Ca)) per Appendix 1-4 (c)

=(2*20000.00*1.00*(1.0000))/(1.00*(84.0000+2*0.0000)+0.2*(1.0000))

= 475.059 psig

Fig. 1: research flow chart:

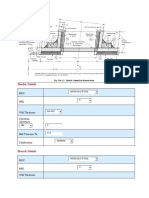

Fig. 2: Head Of Pressure Vessel And Input Data Screen

Maximum Allowable Pressure, New and Cold [MAPNC]:

Design Of Horizontal Pressure Vessel Using PVElite Software

(IJIRST/ Volume 01 / Issue 01 / 010)

All rights reserved by www.ijirst.org

60

= (2*Sa*E*T)/(K*D+0.2*T) per Appendix 1-4 (c)

=(2*20000.00*1.00*1.0000)/(1.00*84.0000+0.2*1.0000)

= 475.059 psig

Actual stress at given pressure and thickness [Sact]:

= (P*(K*(D+2*CA)+0.2*(T-CA)))/(2*E*(T-CA))

=(439.460*(1.00*(84.0000+2*0.0000)+0.2*(1.0000)))/(2*1.00*(1.0000))

= 18501.266 psi

Required Thickness of Straight Flange = 0.935 in.

Percent Elongation per UCS-79 (75*tnom/Rf)*(1-Rf/Ro) 5.190 %

Generally industry used mm unit system but we can change it into other system because soft ware provide this facility and also

design code are given so can use any of it. For pressure vessel we used ASME SEC VIII division I and also material can change and

according to material software used materials all data like max. Allowable stress etc.

2) Cylindrical Shell SA-516 70:

Fig. 3: Shell Of Pressure Vessel And Input Data Screen

Thickness Due to Internal Pressure [Tr]:

= (P*(D/2+Ca))/(S*E-0.6*P) per UG-27 (c)(1)

= (439.460*(84.0000/2+0.0000))/(20000.00*1.00-0.6*439.460)

= 0.9352 + 0.0000 = 0.9352 in.

Max. All. Working Pressure at Given Thickness [MAWP]:

= (S*E*(T-Ca))/((D/2+Ca)+0.6*(T-Ca)) per UG-27 (c)(1)

=(20000.00*1.00*(1.0000))/((84.0000/2+0.0000)+0.6*1.0000)

= 469.484 psig

Maximum Allowable Pressure, New and Cold [MAPNC]:

= (SA*E*T)/(D/2+0.6*T) per UG-27 (c)(1)

= (20000.00*1.00*1.0000)/(84.0000/2+0.6*1.0000)

= 469.484 psig

Actual stress at given pressure and thickness [Sact]:

= (P*((D/2+CA)+0.6*(T-CA)))/(E*(T-CA))

=(439.460*((84.0000/2+0.0000)+0.6*(1.0000)))/(1.00*(1.0000))

= 18720.996 psi

Percent Elongation per UCS-79 (50*tnom/ Rf)*(1-Rf/Ro) 1.176 %

In this pressure vessel there is one nozzle I showed and Input parameter and its calculation given by PVElite. Here I selectee nozzle

with RF pad and input all parameter including nozzle orientation

3) Nozzle description:

NOZZLE CALCULATION, Description: Noz N1 Fr20

ASME Code, Section VIII, Division 1, 2007, UG-37 to UG-45

Actual Nozzle Inside Diameter Used in Calculation 12.126 in.

Actual Nozzle Thickness Used in Calculation 0.937 in.

Design Of Horizontal Pressure Vessel Using PVElite Software

(IJIRST/ Volume 01 / Issue 01 / 010)

All rights reserved by www.ijirst.org

61

Fig. 4: nozzle input data screen

Nozzle input data check completed without errors.

Reqd thk per UG-37(a)of Cylindrical Shell, Tr [Int. Press]

= (P*(D/2+CA))/(S*E-0.6*P) per UG-27 (c)(1)

= (439.46*(84.0000/2+0.0000))/(20000*1.00-0.6*439.46)

= 0.9352 in.

Reqd thk per UG-37(a)of Nozzle Wall, Trn [Int. Press]

= (P*(D/2+CA))/(S*E-0.6*P) per UG-27 (c)(1)

= (439.46*(12.1260/2+0.0000))/(17100*1.00-0.6*439.46)

= 0.1583 in.

4) UG-40, Thickness and Diameter Limit Results: [Int. Press]

Effective material diameter limit, Dl 24.2520 in.

Effective material thickness limit, no pad Tlnp 2.3425 in.

Effective material thickness limit, pad side Tlwp 2.5000 in.

5) Results of Nozzle Reinforcement Area Calculations:

AREA AVAILABLE, A1 to A5 Design

Area Required Ar 11.340

Area in Shell A1 0.786

Area in Nozzle Wall A2 3.329

Area in Inward Nozzle A3 0.000

Area in Welds A4 0.238

Area in Pad A5 7.500

TOTAL AREA AVAILABLE Atot 11.853

The Internal Pressure Case Governs the Analysis.

Nozzle Angle Used in Area Calculations 90.00 Degs.

The area available without a pad is Insufficient.

The area available with the given pad is Sufficient.

Reinforcement Area Required for Nozzle [Ar]:

= (Dlr*Tr+2*Thk*Tr*(1-fr1)) UG-37(c)

= (12.1260*0.9352+2*(0.9370-0.0000)*0.9352*(1-1.0000))

= 11.340 in

Areas per UG-37.1 but with DL = Diameter Limit, DLR = Corroded ID:

Area Available in Shell [A1]:

= (DL-Dlr)*(ES*(T-Cas)-Tr)-2*(Thk-Can)*(ES*(T-Cas)-Tr)*(1-fr1)

= (24.252-12.126)*(1.00*(1.0000-0.000)-0.935)-2*(0.937-0.000) *(1.00*(1.0000-0.0000)-0.9352)*(1-1.0000)

= 0.786 in

Area Available in Nozzle Wall, no Pad [A2np]:

= ( 2 * min(Tlnp,ho) ) * ( Thk - Can - Trn ) * fr2

Design Of Horizontal Pressure Vessel Using PVElite Software

(IJIRST/ Volume 01 / Issue 01 / 010)

All rights reserved by www.ijirst.org

62

= ( 2 * min(2.342 ,12.000 ) ) * ( 0.9370 - 0.0000 - 0.1583 ) * 0.8550 )

= 3.119 in

Area Available in Nozzle Wall, with Pad [A2wp]:

= ( 2 * Tlwp)*( Thk - Can - Trn )* fr2

= ( 2 * 2.5000 ) * ( 0.9370 - 0.0000 - 0.1583 ) * 0.8550 )

= 3.329 in

Area Available in Welds, no Pad [A4np]:

= Wo * fr2 + ( Wi-Can/0.707 ) * fr2

= 0.3750 * 0.8550 + ( 0.0000 ) * 0.8550

= 0.120 in

Area Available in Welds, with Pad [A4wp]:

= (Wo - Ar Lost)*Fr3+((Wi-Can/0.707) - Ar Lost)*Fr2 + TrapFr4

= (0.1406 ) * 0.86 + (0.0000 ) * 0.86 + 0.1179 * 1.00

= 0.238 in

Area Available in Pad [A5]:

=(min(Dp,DL)-(NozzleOD))*(min(Tp,Tlwp,Te))*fr4

= ( 24.0000 - 14.0000 ) * 0.7500 * 1.00

= 7.500 in

6) UG-45 Minimum Nozzle Neck Thickness Requirement: [Int. Press.]

Wall Thickness per UG45(a), tra = 0.1583 in.

Wall Thickness per UG16(b), tr16b = 0.0625 in.

Wall Thickness per UG45(b)(1), trb1 = 0.9352 in.

Check UG16(b) Min. Thickness, trb1 = Max(trb1, tr16b) = 0.9352 in.

Std. Wall Pipe per UG45(b)(4), trb4 = 0.3281 in.

Wall Thickness per UG45(b), trb = Min(trb1, trb4) = 0.3281 in.

Final Required Thickness, tr45 = Max(tra, trb) = 0.3281 in.

Available Nozzle Neck Thickness = .875 * 0.9370 = 0.8199 in.

M.A.W.P. Results for this Nozzle (Based on Areas) at this Location

Approximate M.A.W.P. for given geometry 449.111 psig

7) Result of saddle support:

Longitudinal Bending (+-) at Midspan

= ( 3 * Q * L * K.2 / ( pi * R * ( Ts - Ca )))

= ( 3 * 12938 * 19.50 * 0.5431 ) / ( 3.141 * 42.0000 * 42.0000 * ( 1.0000 - 0.0000 )))

= 74.18 psi

Compute the area ratio [K]:

= Pi * (Sin(Delta)/Delta - Cos(Delta) ) / (Delta + Sin(Delta) * Cos(Delta) - (Delta + Sin(Delta) * Cos(Delta) - 2 * Sin(Delta) *

Sin(Delta)/Delta)

= Pi * (Sin(1.396 ) / 1.396 - Cos(1.396 )) / ( 1.396 + Sin(1.396 ) * Cos(1.396 ) - 2 * Sin(1.396 ) * Sin(1.396 )/ 1.396)

= 9.3799

Compute the moment fraction [X]:

= 1 - (1 - A/L + ( R - H )/(2 * A*L ) )/(1 + (4*H )/( 3 * L ) )

= 1 - (1 - 1.917 /19.500 + (42.000 - 1.750)/( 2 * 1.917 * 19.500 ) )(1 + (4 * 1.750 )/(3 * 19.500 ) )

= 0.0849

Intermediate Product [K.1]:

= K * X * 4 * A / L

= 9.380 * 0.085 * 4 * 1.917 / 19.500 = 0.3130

Longitudinal Bending (+-) at Saddle

= ( 3 * Q * L * K.1 / ( pi * R * ( Ts - Ca )))

= ( 3 * 12938 * 19.50 * 0.3130 ) / ( 3.141 * 42.0000 * 42.0000 * ( 1.0000 - 0.0000 )))

= 42.75 psi

Tangential Shear in Shell near Saddle

= Q * K.4 * (( L-H-2A )/( L+H ))/( R*(Ts-Ca))

= 12938 * 1.1707 * (( 19.50 - 1.75 - 2 * 1.92 )/ ( 19.50 + 1.75 ))/( 42.0000 * ( 1.0000 - 0.0000 ))

= 236.18 psi

Circumferential Stress at Tip of the Wear Plate

= -Q/(4*(TS-CA)*(SADWTH+1.56*Sqrt(R*(TS-CA))))-12*Q*R*K13/(L*(TS-CA))

Design Of Horizontal Pressure Vessel Using PVElite Software

(IJIRST/ Volume 01 / Issue 01 / 010)

All rights reserved by www.ijirst.org

63

= -12938 /( 4 * 1.0000 * (8.00 + 1.56 * Sqrt(42.0000 *1.0000 )))-12.0 * 12938 * 3.50 * 0.0142 / ( 19.5000 *1.0000)

= -575.38 psi

Note: Wear Plate thk. could Not be considered in this formula because:

Saddle-Tangent Distance A (1.92 ) is > R/2 (1.75 ft.)

Circumferential Stress at Horn of Saddle

= -Q/(4*TEM*(SADWTH+1.56*sqrt(R*TCA)))-12*Q*R*K.7/(L*TEB)

= -12938 /( 4 * 1.0000 * (8.00 + 1.56 * sqrt(42.0000 *1.0000 ))) -12.0 * 12938 * 3.50 * 0.0168 / ( 19.5000 * 1.0000 )

= -647.04 psi

Circumferential Compression at Bottom of Shell

= (Q*( K.9/( TEM9 * WPDWTH ) ) )

= ( 12938 *( 0.7603 /( 1.3750 * 12.000 ) ) )

= -596.15 psi

III. DISCUSSION

Design of pressure vessel can be finished quickly by applying numerous calculations in software. the drawing process was simpler

associated to other software. this research only investigated a part of parameter design. There are other parameters that are not

considered such as thermal loads, wind loads, earthquake, transportation, erection, fabrication methods, etc. however this

insufficiency can be overcome by mastering software.

IV. CONCLUSION

Design of pressure vessel by using pvelite gives accurate analysis and also reduces time. Mechanical design of pressure vessel of

horizontal type had been done using graphical based software. Drawing process was very easy and input parameter can be entered in

the same screen. The result fully complied with standard code and had been employed on practical design of pressure vessel.

selection material referring to ASME standard can also been developed. The behaviors of pressure vessels in case of fluctuating load

could be a challenging matter for future research. Further research need to explore environmental parameter such as earthquake,

thermal load, fluctuation load, and so on. High stresses occurred at intersection of head and nozzle welding research council (WRC)

bulletin gives formulation for calculating this stresses.

REFERENCE

[1] Stress analysis of torispherical shell with radial nozzle by Arman ayob faculty of mechanical engineering, university technology Malaysia

[2] Megasy Eugene F, pressure vessel handbook, eleventh edition, pressure vessel publishing Inc. Tulsa, Oklahoma, 2001

[3] Moss dennis, pressure vessel design manual, third edition, Gulf professional publishing Inc,Burlington, 2004

[4] ASME boiler & pressure vessel code: Rules for construction of pressure vessel, (ASME VIII), Division 1, 2007

[5] Pvelite and PV codeCalc 2008

[6] PVElite users guide

You might also like

- Engineering Example CalculationDocument78 pagesEngineering Example Calculationkae kaeNo ratings yet

- Stress in ASME Pressure Vessels, Boilers, and Nuclear ComponentsFrom EverandStress in ASME Pressure Vessels, Boilers, and Nuclear ComponentsNo ratings yet

- Asme Viii CalcsDocument20 pagesAsme Viii CalcsSriram VjNo ratings yet

- Design, Analysis and Optimization of Non Standard Weld Neck Body Flange in Small Pressure VesselDocument7 pagesDesign, Analysis and Optimization of Non Standard Weld Neck Body Flange in Small Pressure VesselGRD JournalsNo ratings yet

- 4.1 Rerating Piping and Pressure Vessels: Major Piping Inspection CodesDocument23 pages4.1 Rerating Piping and Pressure Vessels: Major Piping Inspection CodesMahmoud samahaNo ratings yet

- E.1.1) Nozzle Neck Thickness For Cyl. Shell Nozzles As Per UG-45Document2 pagesE.1.1) Nozzle Neck Thickness For Cyl. Shell Nozzles As Per UG-45Rajesh KumarNo ratings yet

- Training ASME-VIII-Division-1-2-Pressure-Vessel-Series PDFDocument6 pagesTraining ASME-VIII-Division-1-2-Pressure-Vessel-Series PDFumeshNo ratings yet

- Pvelite OutputDocument44 pagesPvelite OutputRam MurtyNo ratings yet

- Training Manual For PVelite Basic LevelDocument41 pagesTraining Manual For PVelite Basic LevelRajaram100% (1)

- Manual Design Validation CalculationDocument21 pagesManual Design Validation CalculationToniNo ratings yet

- TBE-Pressure Vessel Standard TemplateDocument4 pagesTBE-Pressure Vessel Standard TemplateSiva baalanNo ratings yet

- How To Review PV Elite Design Report PDFDocument9 pagesHow To Review PV Elite Design Report PDFprocess process100% (1)

- Ccopps WebinarDocument36 pagesCcopps WebinarAkenathon71No ratings yet

- ΔL, SIF, Hoop Stress, API StandardsDocument3 pagesΔL, SIF, Hoop Stress, API StandardsVijay KumarNo ratings yet

- Design Calculation of Nozzle Junction Based On ASME Pressure Vessel Design CodeDocument8 pagesDesign Calculation of Nozzle Junction Based On ASME Pressure Vessel Design CodeYakubu100% (1)

- Lethal Service - Quick Guide - Pressure Vessel EngineeringDocument4 pagesLethal Service - Quick Guide - Pressure Vessel EngineeringVilas AndhaleNo ratings yet

- On The Design of The Tubesheet and Tubesheet-To-Shell Junction of A Fixed Tubesheet Heat ExchangerDocument7 pagesOn The Design of The Tubesheet and Tubesheet-To-Shell Junction of A Fixed Tubesheet Heat ExchangerEdgardo Chavez BelloNo ratings yet

- Calculation of Pipe Thickness For External PressureDocument3 pagesCalculation of Pipe Thickness For External Pressurereach_arindomNo ratings yet

- MDMT Calculations For A Pressure Vessel - Abdel Halim GalalaDocument12 pagesMDMT Calculations For A Pressure Vessel - Abdel Halim Galalabego00No ratings yet

- Whats Different in B31.1 PDFDocument30 pagesWhats Different in B31.1 PDFhirenkumar patel100% (2)

- Design of Saddle Support For Horizontal Pressure Vessel PDFDocument5 pagesDesign of Saddle Support For Horizontal Pressure Vessel PDFnizam1372100% (3)

- FVCDocument0 pagesFVCsmileya_vpNo ratings yet

- Welding of Pressure VesselsDocument2 pagesWelding of Pressure VesselsDvida PleasureNo ratings yet

- Process Industry Basket StrainersDocument27 pagesProcess Industry Basket StrainersmartinnovelNo ratings yet

- ASME Pressure Vessel Joint EfficienciesDocument4 pagesASME Pressure Vessel Joint EfficienciesliamcsNo ratings yet

- A Comparison Study of Pressure Vessel Design Using Different Standards PDFDocument319 pagesA Comparison Study of Pressure Vessel Design Using Different Standards PDFJM100% (1)

- Flange Leakage Test As Per Asme Boiler & Pressure Vessel CodeDocument12 pagesFlange Leakage Test As Per Asme Boiler & Pressure Vessel CoderssambhiNo ratings yet

- B31 3 (Mygaz) - 1Document1 pageB31 3 (Mygaz) - 1Nasrul AdliNo ratings yet

- Pressure Design Straight Pipe (Run Pipe)Document6 pagesPressure Design Straight Pipe (Run Pipe)gembirasekaliNo ratings yet

- PV Elite WebinarDocument24 pagesPV Elite WebinarAndrea Hank LattanzioNo ratings yet

- Equipment SizingDocument9 pagesEquipment SizingAnonymous Hy5Ir9QXNo ratings yet

- Calcu Nozzle NeckDocument15 pagesCalcu Nozzle Necksachmaya0% (1)

- ASME BPVC Section VIII Division 2: Responsibilities and Duties ParagraphDocument3 pagesASME BPVC Section VIII Division 2: Responsibilities and Duties ParagraphSubrata PatraNo ratings yet

- Pressure Relief Device Inspection: Review of NBIC Part 2, Par. 2.5/ Jurisdictional IssuesDocument37 pagesPressure Relief Device Inspection: Review of NBIC Part 2, Par. 2.5/ Jurisdictional IssuesPham LanphuongNo ratings yet

- WRC Check List CriteriaDocument1 pageWRC Check List CriteriaAlvin Smith100% (1)

- Fatigue Analysis in PV EliteDocument3 pagesFatigue Analysis in PV EliteCostynhaNo ratings yet

- ASME VIII Div 1 ReportDocument12 pagesASME VIII Div 1 ReportAmir Zamri100% (2)

- ASMEDocument27 pagesASMERoy DreinaNo ratings yet

- Static Equipment Group-Facebook Posts Binder Format-eBook-1st EditionDocument397 pagesStatic Equipment Group-Facebook Posts Binder Format-eBook-1st EditionDivyesh PatelNo ratings yet

- Design Calculation of Nozzle Junction Based On ASME Pressure Vessel Design CodeDocument8 pagesDesign Calculation of Nozzle Junction Based On ASME Pressure Vessel Design CodeAndres Rodriguez HerreraNo ratings yet

- How to Use Code Case 2695 in PV Elite for ASME Section VIII Division 1 DesignDocument2 pagesHow to Use Code Case 2695 in PV Elite for ASME Section VIII Division 1 DesignMukeshChopraNo ratings yet

- Balaji S - Static Equipment Design - 7 Years - Resume - NEWDocument5 pagesBalaji S - Static Equipment Design - 7 Years - Resume - NEWkanchanabalajiNo ratings yet

- Flange calculation as per ASME Section VIIIDocument9 pagesFlange calculation as per ASME Section VIIIDarshan PanchalNo ratings yet

- ASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound GasketsDocument5 pagesASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound Gasketserik aranaNo ratings yet

- Brance Pipe CALDocument6 pagesBrance Pipe CALKlaikangwol AnuwarnNo ratings yet

- ASME e - Learn - Final - Sec VIII-2 PDFDocument282 pagesASME e - Learn - Final - Sec VIII-2 PDFSantoshNo ratings yet

- Design Horizontal Pressure Vessel - 2Document2 pagesDesign Horizontal Pressure Vessel - 2evrim77No ratings yet

- Design Horizontal Pressure Vessel - 3Document2 pagesDesign Horizontal Pressure Vessel - 3evrim770% (1)

- PV Elite Vessel Analysis Program: Input DataDocument9 pagesPV Elite Vessel Analysis Program: Input DataAhmed Ammar YasserNo ratings yet

- E4.5 Flange Cover CalcDocument10 pagesE4.5 Flange Cover CalcTanCM100% (1)

- Element Thickness 3Document24 pagesElement Thickness 3Vipul GandhiNo ratings yet

- Element Thickness 2Document20 pagesElement Thickness 2Vipul GandhiNo ratings yet

- Hemispherical HeadDocument4 pagesHemispherical HeadAscanio BarbosaNo ratings yet

- Nozzle Calculation - Auxiliary Boiler Stack-R0Document13 pagesNozzle Calculation - Auxiliary Boiler Stack-R0Aditya JainNo ratings yet

- Studding Outlet Calculation - PV Elite 2016Document8 pagesStudding Outlet Calculation - PV Elite 2016Liu YangtzeNo ratings yet

- Asme Viii Shell & Se HeadDocument5 pagesAsme Viii Shell & Se HeadSnr George RaczNo ratings yet

- Nozzle Calculation - Primary Reformer Stack-R0Document22 pagesNozzle Calculation - Primary Reformer Stack-R0Aditya Jain100% (1)

- Torisperical - Element ThicknessDocument6 pagesTorisperical - Element ThicknessVipul GandhiNo ratings yet

- 620Document33 pages620ccricaNo ratings yet

- Stress AnalysisDocument249 pagesStress Analysisvikrantgulhane100% (2)

- Marine SystemsDocument44 pagesMarine Systemsvikrantgulhane83% (6)

- New Microsoft Word DocumentDocument7 pagesNew Microsoft Word DocumentvikrantgulhaneNo ratings yet

- Refrigeration CycleDocument15 pagesRefrigeration CycleshahkkrishNo ratings yet

- Variable Geometry Turbine Technology For Marine Gas Turbines-Springer (2022)Document227 pagesVariable Geometry Turbine Technology For Marine Gas Turbines-Springer (2022)miladNo ratings yet

- SteelKote EP ZN HS: High-Build Zinc-Rich Epoxy PrimerDocument3 pagesSteelKote EP ZN HS: High-Build Zinc-Rich Epoxy Primerprasanth cp100% (1)

- Roebuck 1942Document12 pagesRoebuck 1942Imam Saja DechNo ratings yet

- Dimensions of Physical Quantities DensityDocument100 pagesDimensions of Physical Quantities DensityGerman Rincon UrregoNo ratings yet

- Strength of Pressure Vessels With Ellipsoidal HeadsDocument8 pagesStrength of Pressure Vessels With Ellipsoidal Headsنصرالدين ادريسNo ratings yet

- Batch Profile - 2017Document57 pagesBatch Profile - 2017Praneet TNo ratings yet

- Lg938l - Operation & Maintenance ManualDocument114 pagesLg938l - Operation & Maintenance ManualMuhammad Nadim MakhlufNo ratings yet

- Equilibrium of A Particle, The Free-Body Diagram & Coplanar Force SystemsDocument24 pagesEquilibrium of A Particle, The Free-Body Diagram & Coplanar Force SystemsAtef NazNo ratings yet

- Asme B36.10M-2018Document36 pagesAsme B36.10M-2018امينNo ratings yet

- Analysis, Specification and Estimate On Road WorksDocument71 pagesAnalysis, Specification and Estimate On Road WorksAnonymous BACdUNvPZ280% (5)

- Crompton Greaves LimitedDocument3 pagesCrompton Greaves LimitedNitish SinghNo ratings yet

- 3RInternational Tetzner Model Based Pipeline LDS 07-2003 PDFDocument6 pages3RInternational Tetzner Model Based Pipeline LDS 07-2003 PDFRene ParedesNo ratings yet

- Sru Flow DiagramDocument1 pageSru Flow Diagrampppppp5No ratings yet

- Previews AGA XQ9902 PreDocument6 pagesPreviews AGA XQ9902 PreAldrin HernandezNo ratings yet

- AMS Thread Size ChartDocument4 pagesAMS Thread Size Chartarunvelu_1250% (2)

- Models - Rf.bowtie Antenna OptimizationDocument14 pagesModels - Rf.bowtie Antenna OptimizationbkmmizanNo ratings yet

- NUSTian Final July SeptDocument36 pagesNUSTian Final July SeptAdeel KhanNo ratings yet

- List of Linkages2016Document74 pagesList of Linkages2016engrwho0% (1)

- BS 1400 - 1973Document38 pagesBS 1400 - 1973Metal dept100% (1)

- 13 - Principles of Flight - QuestionsDocument80 pages13 - Principles of Flight - QuestionsEdgar Muñoz Fernández50% (4)

- FH400 73158464 Pca-6.140Document431 pagesFH400 73158464 Pca-6.140IgorGorduz100% (1)

- Duet CE-3301 Geotechnical Engineering - IDocument37 pagesDuet CE-3301 Geotechnical Engineering - IShekh Muhsen Uddin AhmedNo ratings yet

- How To Install GmtsarDocument24 pagesHow To Install GmtsardedetmixNo ratings yet

- 95 - 737-General-InformationDocument3 pages95 - 737-General-InformationffontanaNo ratings yet

- Customer Targeted E-CommerceDocument4 pagesCustomer Targeted E-CommercepriyaNo ratings yet

- Application of PLC and SCADA in Auto-Control Systems For Silo Grain HandlingDocument4 pagesApplication of PLC and SCADA in Auto-Control Systems For Silo Grain Handlingshahid_scribdNo ratings yet

- Foundation LayoutDocument1 pageFoundation LayoutrendaninNo ratings yet

- JLG Lighting Tower 6308AN Series II 20150907Document2 pagesJLG Lighting Tower 6308AN Series II 20150907DwiSulistyo09No ratings yet

- Michelson Interferometer Na Lamp-1Document11 pagesMichelson Interferometer Na Lamp-1SOHINI KAYALNo ratings yet

- Manual Service Aoc - E943fwskDocument51 pagesManual Service Aoc - E943fwskEduardo BentoNo ratings yet

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionFrom EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionRating: 4.5 out of 5 stars4.5/5 (3)

- Handbook of Mechanical and Materials EngineeringFrom EverandHandbook of Mechanical and Materials EngineeringRating: 5 out of 5 stars5/5 (4)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseFrom EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseRating: 4.5 out of 5 stars4.5/5 (50)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- Quantum Mechanics 4: Spin, Lasers, Pauli Exclusion & Barrier PenetrationFrom EverandQuantum Mechanics 4: Spin, Lasers, Pauli Exclusion & Barrier PenetrationRating: 1 out of 5 stars1/5 (1)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- The Laws of Thermodynamics: A Very Short IntroductionFrom EverandThe Laws of Thermodynamics: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (10)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- Introduction to Applied Thermodynamics: The Commonwealth and International Library: Mechanical Engineering DivisionFrom EverandIntroduction to Applied Thermodynamics: The Commonwealth and International Library: Mechanical Engineering DivisionRating: 2.5 out of 5 stars2.5/5 (3)

- Control of Power Electronic Converters and Systems: Volume 1From EverandControl of Power Electronic Converters and Systems: Volume 1Rating: 5 out of 5 stars5/5 (1)

- Machinery Failure Analysis Handbook: Sustain Your Operations and Maximize UptimeFrom EverandMachinery Failure Analysis Handbook: Sustain Your Operations and Maximize UptimeRating: 3.5 out of 5 stars3.5/5 (4)

- Rolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsFrom EverandRolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsNo ratings yet

- Design of Foundations for Offshore Wind TurbinesFrom EverandDesign of Foundations for Offshore Wind TurbinesRating: 5 out of 5 stars5/5 (3)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideFrom Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideRating: 3.5 out of 5 stars3.5/5 (7)

- Operational Amplifier Circuits: Analysis and DesignFrom EverandOperational Amplifier Circuits: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (2)

- Three Laws of Nature: A Little Book on ThermodynamicsFrom EverandThree Laws of Nature: A Little Book on ThermodynamicsRating: 4.5 out of 5 stars4.5/5 (10)