Professional Documents

Culture Documents

Well Scrubbed

Uploaded by

ItamarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Well Scrubbed

Uploaded by

ItamarCopyright:

Available Formats

QM March 2007 www.quarrymanagement.

com 19

Well Scrubbed

The selection of washing equipment for processing of clay-contaminated

rock and aggregate

By Mike Burton, managing director, Sepro Mineral Processing Intl Ltd

E

fficient clay removal from as

dug gravel and sand is of

increasing importance in

maximizing product value

and mineral resource utilization.

Similar incentives are driving the

reprocessing of high clay content

scalpings stockpiles in hard rock

quarrying operations.

Four types of process

equipment are typically used for

clay dispersal:

Ore scrubbers: drums that run at

relatively high-speed with heavy-

duty high-lift liners. Their intensive

washing action is characterized by

vigorous turbulence and

cataracting of the charge under

the influence of the speed of

rotation and the form of the

lifters, which are custom designed

for each application.

Washing barrels: drums that run at

relatively low-to-medium speed,

generally with thinner liners and

lower lifters than scrubbers. Their

washing action is characterized by

tumbling and rolling of the

material in the toe and body of

the charge.

Log-washers: usually comprise twin

contra-rotating shafts fitted with

a series of intermeshing angled

blades. Their washing action is

generated by inter-particle

attrition between the blades,

which also transport material

uphill from the feed point to the

discharge point.

Attrition cells: multi-stage tanks,

each fitted with a high-powered

agitator with opposing-flow

blades. Their washing action

involves vigorous inter-particle

attrition at high pulp density.

Attrition cells are only suitable

for sand-size feeds, leaving three

process options to be considered

for new or retrofit aggregate

washing plants. Of these,

traditionally only washing barrels

and log-washers have been

considered for clay removal

applications in UK operations

until

recently.

Washing

barrels have

been widely

used

historically

but their

relatively

low speed

can tend to

agglomerate,

or fail to

disperse clay

masses that occur in some

deposits, leading to the

misconception that rotary-drum

washing equipment is inferior to

log-washers in handling feeds with

high clay contents. Consequently,

log-washers have sometimes been

specified in the expectation of

better performance in

applications with high clay

contents, despite limitations on

feed size and higher maintenance

costs.

Overseas experience with

rotary ore scrubbers in

metallurgical ore washing plants

has led to very different

conclusions. These plants typically

process ores with very high clay

contents. The viability of such

operations depends on the

efficient dispersal of this clay

content for efficient recovery of

the metal ore. The rock and sand

fractions that are rejected must

be super-clean to avoid the loss

of high-value ore minerals, which

typically represent only 0.011.0%

of the plant feed. By using high-

speed scrubbers in these

applications, it has been possible

to obtain a metal recovery rate of

99%, compared with only 6070%

when using washer barrels or log-

washers, which do not fully

disperse the clays or completely

remove clay coatings from the

rock and sand particles.

High-speed scrubbers operating

in washing plants for alluvial

precious metals, nickel/cobalt,

tropical laterites, diamonds and

similar ores, with clay contents

up to 90% in some cases, have

demonstrated that rotary

scrubbing, when properly applied,

can totally disperse the clays to

allow liberation of the very fine

mineral values. Without complete

dispersion, metal recovery levels

rapidly decline, which has driven

the optimization of the washing

equipment used. Performance in

this type of washing plant, in

various countries, has clearly

demonstrated that high-speed

rotary scrubbers offer an effective

solution to efficient clay removal

from rock and sand.

Beneficial features of modern,

well-designed, heavy-duty rotary

scrubbers that are applicable to

the processing of gravel, crushed

rock and sand with significant clay

contamination include:

an ability to efficiently handle

much coarser feeds than log-

washers or washer barrels,

with plants running

successfully that are

processing run-of-mine or

primary crushed feeds up to

500mm. This eliminates the

need to scalp the feed ahead

of the washing process and

removes the risks and

operational problems of

feeding unwashed scalper

oversize to secondary or

tertiary crushers

Log-washer reject

reprocessing plant

20 www.quarrymanagement.com QM March 2007

no de-sanding of feed or

countercurrent operation is

required. Scrubbers operate

efficiently with a simple co-

current flow of solids and

water, irrespective of feed,

clay and fines content

tolerance of wide fluctuations

in feed rate and quality

very low maintenance costs

very high availability, typically

in excess of 95% on

24 hours-per-day, 365 days-

per-year mining operations

disintegration of weathered

mineral, soft siltstone and

similar deleterious

contaminants

very clean product surfaces

due to the vigorous washing

action and absence of dead

areas, which are a particular

characteristic of log-washers.

Two examples of successful ore

scrubber applications are

summarized below:

Bonte Gold Mines,

Ghana

Bonte Gold Mines previously

operated a 3.0m diameter x 8.0m

long washer barrel to process

350 tonnes/h of terrace alluvial

gold ore containing up to 60%

clay interspersed with quartz

boulders up to 600mm in size.

The gold content of

approximately 0.5g/tonne was

intimately associated with the clay

fines. Gold recovery was less than

70% due to a lack of full clay

dispersion and consequent loss of

gold particles tied up in clay ball

agglomerates and residual clay

coatings. This machine was

replaced with a Sepro 3.0m

diameter x 8.0m long heavy-duty

ore scrubber, which immediately

increased the gold recovery rate

to over 95% and subsequently

maintained this level at an

increased feed rate of 700

tonnes/h (figs. 1a and 1b).

Moa Nickel SA,

Cuba

Moa Nickel operated four 72in

log-washers handling up to

700 tonnes/h of extremely sticky

and fine lateritic nickel/cobalt ore

with an inherent as-mined

moisture content of 3540% and

515% serpentine rock content.

The feed was scalped at 120mm

on a wet vibrating grizzly to

protect the log-washers from

oversize rock, leading to metal

losses in lump clay and coated

rock in the grizzly oversize. The

log-washer product was screened

at 0.85mm with large volumes of

sprayed water but undispersed

clays in this material carried 30%

of the nickel content in the ore

to reject.

After several years of fruitless

experimenting with changes to

the log-washer operation, and

tests by various Canadian

manufacturers and consultants to

improve metal recovery, a 1.2m

diameter x 2.1m long Sepro

scrubber was purchased and used

for test work on reprocessing the

log-washer product. These tests

showed that intensive scrubbing

increased recovery from 70% to

98% and, as a result, a 2.5m

diameter x 6.0m long Sepro

scrubber was installed as part of

a 300 tonnes/h log-washer reject

reprocessing facility. This plant

was commissioned in 2003 and

metal recovery has been

maintained above a guaranteed

98% level ever since (figs. 2a and

2b).

This demonstration of the

benefits of high-speed intensive

scrubbing has led to a current

project to replace the log-washers

and expand plant capacity with

the installation of two 3.0m

diameter x 10.0m long scrubbers.

Aggregate

washing

The effectiveness of intensive

scrubbing on typical UK

aggregates has been

demonstrated by two installations

where 2.1m diameter x 5.0m long

high-speed scrubbers have been

installed in preference to larger

conventional washer barrels. The

first scrubber processes heavily

contaminated as-dug gravel and

handles up to 500 tonnes/h,

producing a clean washed

product. A similar scrubber

installed in 2004 processes

300 tonnes/h of granite primary

scalpings with substantial clay

contamination. In both

installations the machines were

selected in preference to larger

conventional washer barrels, and

both have fully vindicated this

decision by their performance,

reliability, spare capacity and

very low maintenance costs.

Conclusion

High-speed intensive ore

scrubbers have been shown

to be extremely effective in fully

dispersing clay coatings and

agglomerates to deliver clean

washed rock products, and

will fully repay their consideration

as the equipment of choice for

new or retrofit stone-washing

applications. T

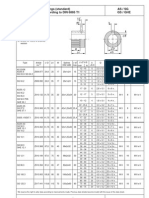

Fig. 1a (above): As

dug gold ore

Fig. 1b (above right):

Clean quartz reject

from the scrubber

Fig. 2a (below): Log-

washer screen oversize

reject feed to a

scrubber

Fig. 2b (below right):

Clean washed reject

from the scrubber

Washing & Filter Pressing

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- XMEye Android User ManualDocument32 pagesXMEye Android User Manualaxelkal ck50% (2)

- Gold Prospecting EquipmentDocument32 pagesGold Prospecting EquipmentItamarNo ratings yet

- Organic Seed Production and Plant Breeding - Strategies, Problems and PerspectivesDocument83 pagesOrganic Seed Production and Plant Breeding - Strategies, Problems and PerspectivesItamarNo ratings yet

- Designing A Cantilever Rack SystemDocument4 pagesDesigning A Cantilever Rack SystemItamarNo ratings yet

- A Review of Gold Particle Size and Recovery Methods WC-97-014 PDFDocument34 pagesA Review of Gold Particle Size and Recovery Methods WC-97-014 PDFItamarNo ratings yet

- Gore DC Tool Replacement Assemblies For George Renault ToolsDocument1 pageGore DC Tool Replacement Assemblies For George Renault ToolsItamarNo ratings yet

- DSC Clamping Catalog 2011 FlyerDocument2 pagesDSC Clamping Catalog 2011 FlyerItamarNo ratings yet

- HD Brown + Clear Low eDocument3 pagesHD Brown + Clear Low eSukhbir SinghNo ratings yet

- Refrence List Middle EastDocument7 pagesRefrence List Middle EastazeemNo ratings yet

- Advanced Simulation Guidebook Volume II - The High Performance Building Process PDFDocument33 pagesAdvanced Simulation Guidebook Volume II - The High Performance Building Process PDFomarNo ratings yet

- 15 Oil Fired Crucible FurnaceDocument2 pages15 Oil Fired Crucible Furnaceudaya kumarNo ratings yet

- As / SG Gs / Ghe Dimensions For Couplings (Standard) Bore With Keyway According To DIN 6885 T1Document1 pageAs / SG Gs / Ghe Dimensions For Couplings (Standard) Bore With Keyway According To DIN 6885 T1hadeNo ratings yet

- Arni AdvertisementDocument2 pagesArni AdvertisementHemanthNo ratings yet

- CE ThesisDocument210 pagesCE ThesisKristin ArgosinoNo ratings yet

- LAB3Document5 pagesLAB3Kaishavi UmrethwalaNo ratings yet

- Case Study of Improving Productivity in Warehouse WorkDocument5 pagesCase Study of Improving Productivity in Warehouse WorkRohan SharmaNo ratings yet

- Mdce InstallDocument67 pagesMdce Installrmehta26No ratings yet

- (BDDJ-2016-0006) Introduction of New Printer NKG-901Document4 pages(BDDJ-2016-0006) Introduction of New Printer NKG-901じゃしゅてぃん ぅうNo ratings yet

- CS-Z25XKEW - 1, Evaporator Specification SheetDocument1 pageCS-Z25XKEW - 1, Evaporator Specification SheetpaulNo ratings yet

- Xpulse200t Manual de PartesDocument92 pagesXpulse200t Manual de PartesAthiq Nehman100% (2)

- Shock Absorber DynamometerDocument19 pagesShock Absorber DynamometerUmanath R Poojary100% (1)

- Assignment Payment 1Document5 pagesAssignment Payment 1Mohamad SafwanNo ratings yet

- DepEd Learner Information System (LIS) PDFDocument36 pagesDepEd Learner Information System (LIS) PDFshasagailNo ratings yet

- Security Officer/GuardDocument2 pagesSecurity Officer/Guardapi-121358674No ratings yet

- Anti Lock Brake Safety PrecautionsDocument1 pageAnti Lock Brake Safety Precautionssonny1234No ratings yet

- ABOUT CV (FLOW COEFFICIENTS)Document1 pageABOUT CV (FLOW COEFFICIENTS)NiksUnglasNo ratings yet

- Building Information Modeling BIM Systems and TheiDocument13 pagesBuilding Information Modeling BIM Systems and Theipurvakul10No ratings yet

- 28L059 PDFDocument9 pages28L059 PDFone_blanche6175No ratings yet

- Revised Syllabus Filipino 2 PAGSASALINDocument8 pagesRevised Syllabus Filipino 2 PAGSASALINErza Scarler100% (4)

- Swot Analysis of PTCLDocument5 pagesSwot Analysis of PTCLM Aqeel Akhtar JajjaNo ratings yet

- Draw 224-1Document8 pagesDraw 224-1Alther Dabon33% (3)

- Shear Strength in The New Eurocode 2. A Step ForwardDocument10 pagesShear Strength in The New Eurocode 2. A Step ForwardChineseAssassinNo ratings yet

- Dynamic Force Analysis (AKJ)Document3 pagesDynamic Force Analysis (AKJ)Sunny BhatiaNo ratings yet

- Project TemplatesDocument64 pagesProject TemplatesMahad AbdiNo ratings yet

- Kirsten Koyle Grade 5 Science and Technology Understanding Matter and EnergyDocument10 pagesKirsten Koyle Grade 5 Science and Technology Understanding Matter and Energyapi-311535995No ratings yet

- Realizing Higher Productivity by Implementing Air Drilling Tech For Drilling Hard Top Hole Sections in Vindhyan FieldsDocument7 pagesRealizing Higher Productivity by Implementing Air Drilling Tech For Drilling Hard Top Hole Sections in Vindhyan FieldsLok Bahadur RanaNo ratings yet