Professional Documents

Culture Documents

Laser Policy

Uploaded by

VonLoutsosOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Laser Policy

Uploaded by

VonLoutsosCopyright:

Available Formats

DUKE UNIVERSITY

DUKE UNIVERSITY MEDICAL CENTER

Laser Safety Policy

Date Rev: 10/2011

CONTENTS

SECTION PAGE

1. Laser Safety Program Elements ... 1

1.1 Abbreviations Used . 1

1.2 Purpose ... 1

1.3 Roles and Responsibilities ... 2

1.3.1 Laser Safety Program Oversight Organizational Chart 2

1.3.2 Laser Safety Committees . 2

1.3.3 Radiation Safety Officer .. 2

1.3.4 Laser Safety Manager .. 3

1.3.5 Principal Laser User . 3

1.3.6 Laser Operators 4

1.3.7 Escalated Enforcement Policy . 5

2. Laser Classification ... 7

2.1 Class 1 (IEC Class 1)... 7

2.2 Class 2 (IEC Class 2) .. 7

2.3 Class 3a (IEC Class 1M, 2M, 3R)... 7

2.4 Class 3b (IEC Class 3B) ..... 7

2.5 Class 4 (IEC Class 4) . 8

2.6 Embedded Lasers 8

2.7 IEC Classification Scheme . 8

3. Laser Acquisition, Transfer, and Disposal .. 9

4. Laser Hazard Control Measures .. 10

4.1 Controls for Class 1, 2, and 3a (IEC Class 1, 1M, 2, 2M and 3R) Lasers .. 10

4.2 Controls for Class 3b and 4 (IEC Class 3R and 4) Lasers ...... 10

4.2.1 Posting . 10

4.2.2 Authorization ... 10

4.2.3 Beam Stop 10

4.2.4 Eye Protection .. 11

4.2.5 Light Containment ... 11

4.3 Additional Controls for Class 4 Lasers ... 12

4.3.1 Rapid Egress and Emergency Access .. 12

4.3.2 Laser Activation Warning Systems and Entry Controls .. 12

4.3.3 Key Switches ... 12

4.4 Temporary Control Areas ... 12

4.5 Special Requirements for Invisible Beam Lasers ... 13

4.5.1 Infrared Lasers . 13

4.5.2 Ultraviolet Lasers . 13

4.6 Substitution of Alternate Control Measures ... 13

5. Laser Safety Training 14

5.1 Initial Laser Safety Training ... 14

5.2 Visitors 14

5.3 Laser-specific Training ... 14

5.4 Update Training .. 14

6. Laser Related Non-Beam Hazards & Control Measures ... 15

6.1 Electrical Hazards ... 15

6.2 Laser Dyes .. 15

6.3 Compressed Gases and Cryogenics 15

6.4 Laser Generated Air Contaminants (LGAC) .. 16

6.5 Plasma Emissions ... 16

6.6 UV and Visible-Radiation .. 16

6.7 Explosion Hazards .. 16

6.8 Ionizing Radiation (X-rays) 16

7. Medical Surveillance .. 17

8. Laser Accidents .. 18

8.1 Immediate Response and General Procedures

8.1.1 General Laser Accident Reporting ..

8.1.2 Known or Suspected Laser Overexposure ...

18

18

18

8.2 Laser Accidents in Duke University Hospital 18

8.2.1 Occurrence Reports .. 18

8.2.2 Follow-up Procedures by the Laser Safety Manager ... 19

9. Standard Operating Procedure (SOP) . 21

10. Resources .. 22

10.1 Glossary 22

10.2 SOP Template ... 22

11. References . 23

APPENDIX A Use of Lasers Outside the Clinical or Laboratory Setting .... 24

APPENDIX B Summary of Laser Hazard Classification Schemes ... 27

APPENDIX C Additional Considerations for Outdoor Laser Use 28

APPENDIX D Protective Eyewear for Ultrashort Pulsed Lasers . 29

1

1. Laser Safety Program Elements

1.1 Abbreviations Used

ANSI Z136.1 American National Standards Institute Z136.1-2000 (or latest version thereof)

Standard for the Safe Use of Lasers

ANSI Z136.3 American National Standards Institute Z136.3-2005 (or latest version thereof) Safe

Use of Lasers in Health Care Facilities

CFR Code of Federal Regulations

CW Continuous wave laser (laser operating with continuous output for more than 0.25 seconds)

DU Duke University

DUMC Duke University Medical Center

GCFI Ground Fault Circuit Interrupter

IEC International Electrotechnical Commission. This group establishes standards for the safe use

of lasers that are similar to the ANSI Z136 series of standards and which, like the ANSI standards,

are recognized by the various U.S. government agencies regulating laser use in this country

IR Infrared light (> 760 nm wavelength)

LO Laser Operator

LSC Laser Safety Committee.

LSM Laser Safety Manager

MPE Maximum Permissible Exposure, i.e. the laser radiation level to which a person can be

exposed without hazardous effect or adverse biological changes in the eye or skin.

MSDS Material Safety Data Sheet

OESO Duke Occupational and Environmental Safety Office

OSHA Occupational Safety and Health Administration

PLU Principal Laser User

RSO Radiation Safety Officer and Director of the OESO Radiation Safety Division

SOP Standard Operating Procedure

UV Ultraviolet light (100 400 nm wavelength)

1.2 Purpose

The Duke University laser safety policy is based on the recommendations of ANSI Z136.1 and the

applicable federal and state regulations. The laser safety programs primary objective is to ensure

that no laser radiation in excess of the MPE reaches the human eye or skin. This program is also

intended to ensure adequate protection against laser-related non-beam hazards.

2

1.3 Roles and Responsibilities

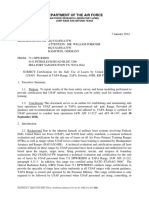

1.3 .1 Laser Safety Program Oversight Organizational Chart

1.3 .2 Laser Safety Committees (LSC)

While the two institutional Radiation Safety Committees are ultimately responsible for laser safety

oversight, two LSCs, one for Clinical Use and another for Research Use, directly oversee the laser

safety programs at Duke. Each LSC is a subcommittee of the corresponding Radiation Safety

Committee (see the Radiation Safety Manual for Duke University and Duke University Medical

Center). Each LSC consists of the Committee Chairman, the LSM, laser users, management

representatives, persons knowledgeable in laser safety and/or laser technology, and others as

needed. The LSCs responsibilities include:

(a) Establish and maintain internal policies/procedures to ensure they comply with applicable

regulations and standards.

(b) Resolve conflicts or issues identified by the LSM, laser users, or other parties.

(c) Perform annual program reviews.

(d) Maintain an awareness of all applicable new or revised laser safety standards.

1.3.3. Radiation Safety Officer (RSO)

The RSO has the responsibility to establish, monitor, and enforce control of laser hazards and is

responsible to the Radiation Safety Committee and LSC for the laser safety programs

management and administration. The RSO designates the LSM.

Duke University Administration

Duke MC Administration

Chair &

MC/Univ RSC

Director (RSO)

Radiation Safety Division

Laser Safety Manager (LSM)

Radiation Safety Division

Chair &

MC/Univ

Laser Safety Committee

Operational Unit

Policy implementation/Safety Oversight

Policy Making Unit

Advisory role to RSO/LSM

3

1.3.4 Laser Safety Manager (LSM)

The LSM is designated by the RSO. The LSMs responsibilities include:

(a) Administer the day-to-day operation of the Laser Safety Program.

(b) Maintain a current inventory of Class 3b and 4 lasers.

(c) Function as liaison between PLUs and the LSCs.

(d) Accompany outside inspectors/regulators on laser safety inspections.

(e) Perform laser hazard analyses and audits; ensure, by follow up and additional audits as

necessary, that all laser safety deficiencies are addressed and resolved.

(f) Make recommendations to improve laser safety.

(g) Restrict or terminate use of lasers that present an imminent danger or excessive hazard.

(h) Ensure the availability of proper laser safety training.

(i) Make recommendations for selection of proper personnel protective equipment.

(j) Investigate laser accidents and near misses.

(k) Update laser safety policy and procedures as needed.

(l) Review, approve, and maintain a copy on file of all laser SOPs.

(m) Review, approve, and maintain a copy on file of all Non-Clinical Laser Laboratory Pre-

Operational Checklists; coordinate with the responsible PLU to ensure compliance prior to

approval.

(n) Review, approve, and maintain a copy on file of all Non-Clinical Laser Laboratory

Authorizations; coordinate with the responsible PLU to ensure compliance prior to

approval.

(o) Ensure maintenance of laser users most recent laser safety training records until that user

is no longer involved with laser use at Duke.

(p) Provide periodic reports on the status of laser safety to the LSC and RSO, and promptly

inform the RSO of any serious laser safety concerns.

1.3.5 Principal Laser User (PLU)

Every Class 3b or 4 (IEC Class 3B or 4) laser system on site must be assigned to a PLU. If no

PLU has been formally identified for a particular laser/laser system, the Departmental Chairman

may designate a PLU, and inform the LSM of the designation. The PLUs responsibilities include:

(a) Planning and implementation of all safety measures required for safe laser operation for all

lasers under their control, and prior to introducing additional laser equipment to their area.

(b) Complete a Laser Registration Form for each Class 3b or 4 (IEC Class 3B or 4) laser and

send the form(s) to the LSM.

(c) Prior to non-clinical use of a Class 3b or 4 (IEC Class 3B or 4) laser, complete and obtain

the LSMs approval signature on a Laser Laboratory Pre-Operational Checklist. This

checklist is available on the OESO Laser Safety Web Site.

4

(d) For every non-clinical area using Class 3b and 4 (IEC Class 3B or 4) lasers under the

PLUs control, complete and submit to the LSM a Non-Clinical Laser Laboratory

Authorization form (available on the OESO web site). Coordinate with the LSM to obtain

approval of the Non-Clinical Laser Laboratory Authorization before operating a Class 3b

or 4 (IEC Class 3B or 4) lasers for non-clinical applications. Resubmit each Non-Clinical

Laser Laboratory Authorization to the LSM for renewal every four years, or upon major

changes (e.g. room relocation, different laser types, etc.) to the laser laboratory.

(e) Post a written SOP (as described in section 9 of this Policy) in a location readily available

to laser operators, for all unenclosed Class 3b and 4 (IEC Class 3B or 4) lasers; ensure

compliance with the SOP. Provide a current copy of the SOP to the LSM and obtain LSM

approval for the SOP before operation of the laser.

(f) Supervise the safe use of lasers in the laser environment.

(g) Ensure that all lasers under his/her control are properly classified and labeled.

(h) Establish and maintain a current list of those personnel approved to operate specific types

of Class 3b or 4 lasers under their supervision and provide a copy of the list to the LSM.

(i) Complete the applicable OESO Laser Safety course at the interval specified in this Manual.

(j) Immediately notify OESO in the event of a suspected overexposure to the output beam

from a Class 3b or 4 (IEC Class 3B or 4) laser.

(k) Ensure that safety controls are not disabled, removed, or modified without written

authorization from the PLU, and notify the LSM immediately of any changes in the status

of safety controls.

(l) Notify the LSM of any OEM lasers (i.e. lasers that do not comply with all requirements of

the Federal Laser Product Performance Standard, e.g., warning labels, interlock shutter, etc.

because they are designed for incorporation into larger devices) that the PLU is using in an

open beam configuration.

(m) Ensure the safe and responsible disposition of their unneeded, but potentially hazardous,

Class 3b or 4 (IEC Class 3B or 4) lasers and laser components. See chapter 3 for a list of

appropriate disposal options.

1.3.6 Laser Operator (LO)

Only a PLU or an LO may operate a Class 3b or 4 (IEC Class 3B or 4) laser. Each LO must work

under the supervision of a PLU. LO responsibilities include:

(a) Complete the applicable OESO Laser Safety course, before operating a Class 3b or 4 (IEC

Class 3B or 4) laser and again at the interval specified in this Policy manual.

(b) Use lasers safely.

(c) Comply with established policy, SOPs and other procedural requirements.

(d) Promptly report to the PLU any malfunctions, problems, accidents, or injuries, which may

have an impact on safety.

(e) Do not disable, remove, or modify any safety control systems without prior written

approval from the PLU.

5

1.3.7 Escalated Enforcement Policy

(a) Purpose

This section specifies the actions of the Radiation Safety Officer (RSO) and the Research

Use Laser Safety Committee to correct specific items of non-compliance, ensuring that

laser users work with the RSO and the Committee to maintain safety and compliance. This

enforcement policy does not apply to patient care areas. Instead, for these areas, the RSO

will work with the Division Director or Departmental Chair to resolve any uncorrected

compliance issues.

(b) Enforcement Process

i. Radiation Safety staff will provide the PLU with written notification of any items of non-

compliance discovered in that PLU's area of responsibility. If appropriate, Radiation

Safety staff may request a written response from the PLU regarding corrective measures

for any items of non-compliance discovered during routine laser laboratory audits. Any

such written response shall be provided by the PLU to the auditor on or before the date

specified in the written notification.

ii. Documented compliance issues should be resolved between the PLU and the RSO or

his/her designee.

iii. If routine Radiation Safety staff surveys show a repeat violation (i.e. same item cited on

last inspection) or other pattern of multiple violations, the PLU must, within one week of

notification, send the Radiation Safety Officer a brief written explanation of:

what caused the item(s) of non-compliance,

steps taken to date by the PLU to correct the item(s),

further steps to be taken by the PLU, and

measures the PLU took or will take to prevent recurrence.

iv. If the PLU has not achieved compliance to the Radiation Safety Officer's satisfaction

within one week of notification, the Radiation Safety Officer and the PLU will discuss

the matter with the PLU's Departmental Chair or Faculty Dean, or other representative of

the Institutional Administration as appropriate.

v. If satisfactory resolution still cannot be obtained, the matter will be escalated to the

Research Use Laser Safety Committee and, if necessary, senior Institutional

Administration.

(c) Enforcement Options

i. Radiation Safety Intervention

The RSO is authorized to immediately order the termination or limitation of any

procedure or other laboratory activity that in his/her professional opinion constitutes an

immediate danger to life, health, property, or the environment. The RSO is also

authorized to order the termination or limitation of any procedure or laboratory activity of

a PLU who willfully violates the Duke Laser Safety Policy. Such intervention may

include, but is not necessarily limited to, the suspension of laser use, the withholding of

pending deliveries of lasers and the disabling of lasers (e.g. by confiscation of the laser

6

on/off switch key). The RSO will notify the PLU, the chair of the Research Use Laser

Safety Committee and appropriate senior management.

ii. Restriction and Revocation

The Chairman of the Research Use Laser Safety Committee may, upon the RSO's

recommendation, restrict the authority of a PLU as a result of repeated or serious

violations of Duke University/Medical Center policy. Radiation Safety staff must

immediately notify the PLU, the PLU's Departmental Chair or Faculty Dean, and the

appropriate Institutional Administrators of any restriction and of the reason for that

restriction.

Such restriction remains in effect until review by the Research Use Laser Safety

Committee either reinstates, modifies, or revokes the restricted privileges by a

majority vote.

7

2. Laser Classification

All lasers and laser systems in the U.S. are categorized into one of several hazard classes.

Corresponding labels affixed to the laser or laser system positively identify the class. These laser

classifications are detailed in ANSI Z136.1, ANSI Z136.3; the Federal Laser Products

Performance Standard, 21 CFR 1040.10 and 1040.11; and the International Electrotechnical

Commission (IEC). See Appendix B for a summary of the classification schemes of these three

organizations. The manufacturer provides the classification for most lasers. For custom-built and

modified lasers, the LSM can assist with classification.

2.1 Class 1 (IEC Class 1)

Do not emit harmful levels of radiation during normal operation.

Also includes higher class lasers completely enclosed and interlocked to prevent beam

access, allowing a Class 1 laser system designation; any time the higher class laser is

accessible (e.g. during alignment or servicing), the higher laser class controls must be

observed.

Can be used without restriction in the manner intended by the manufacturer and without

special operator training or qualification.

2.2 Class 2 (IEC Class 2)

Emit accessible laser light in the visible wavelength region.

Capable of creating eye damage through chronic exposure.

In general, the human eye will blink within 0.25 second when exposed to Class 2 laser

light; this blink reflex provides adequate protection.

Can be used without restriction in the manner intended by the manufacturer and without

special operator training or qualification.

2.3 Class 3a (IEC Class 1M, 2M, 3R)

Normally not hazardous when viewed momentarily with the unaided eye, but may pose

severe eye hazards when viewed through collecting optics (e.g., microscopes and

binoculars).

Power levels 1-5 milliwatt (mW).

Same controls as Class 1 and Class 2 lasers for normal operations; if viewed through

optical instruments (e.g., binoculars, telescopes, or microscopes), contact the LSM for a

hazard review.

2.4 Class 3b (IEC Class 3B)

Will cause injury upon direct viewing of the beam and specular reflections.

Power output 5-500 mW for CW or less than 0.03 joule (J) for a pulsed system (i.e. pulse

width less than 0.25 second).

Must implement specific control measures covered in this chapter.

8

2.5 Class 4 (IEC Class 4)

Includes all laser systems with power levels greater than 500 mW CW or greater than 0.03

J for a pulsed system.

Pose eye hazards, skin hazards, and fire hazards. Viewing the beam or specular reflections

or exposure to diffuse reflections can cause eye and skin injuries.

All control measures explained in this document must be implemented.

2.6 Embedded Lasers

Lasers are often embedded in laser products or systems with a lower hazard class. When the laser

system is used as intended, the controls for the system's class apply. When the system is opened

(e.g. for service or alignment) and the embedded laser beam is accessible, a temporary control area

must be established. The controls for the temporary control area must be based on the

classification of the embedded laser. The user and LSM must determine adequate controls.

Confirmation of a system classification is the responsibility of the LSM, and therefore necessitates

registering the system. An abbreviated SOP may be required, as in the case of such commercially

available enclosed laser systems as a laser scanning confocal microscope.

2.7 IEC Classification Scheme

The IEC has established a hazard classification scheme similar to that described in this section, but

with some minor differences. Laser products encountered at Duke may be labeled using this

alternate system. Laser systems bearing the IEC 1M, 2M, or 3R classification require the same

control measures as Class 3a lasers. See Appendix B [Summary of Laser Hazard Classification

Schemes] for further information regarding these laser classification schemes

9

3. Laser Acquisition, Transfer, and Disposal

Notify the LSM of any decision to purchase, fabricate, or otherwise acquire a Class 3b (3B) or

Class 4 laser. The LSM will review with the user the hazards of the proposed operation and make

recommendations regarding the specific safety requirements that pertain to the proposed use,

including requirements for SOPs, laser control areas, training, and personnel protective equipment.

Also notify the LSM of any Class 3b (3B) or 4 laser or laser system relocated, transferred to

another PLU or institution, or sent offsite as surplus equipment.

Laser users have an obligation to ensure safe and responsible disposition of their unneeded, but

potentially hazardous, Class 3b (3B) or 4 lasers and laser components. Appropriate means of laser

disposal include:

Donate the laser to an organization (e.g. school, industrial company, hospital) with a need

for such a device. The donor should ensure that the donated laser system complies with all

applicable product safety standards, such as the Federal Laser Product Performance

Standard, and is provided with adequate safety instructions for operations and maintenance.

The donor should also verify that the receiving organization has a viable laser safety

program.

Return the laser to the manufacturer, or to a vendor specializing in re-selling used laser

equipment.

Eliminate the possibility of activating the laser by removing all means by which it can be

electrically activated. Once this has happened the laser could then be discarded.

Destroy the laser.

The last two methods also require proper disposal of any hazardous materials found inside the laser

components, such as mercury switches, oils, dyes, etc. Users should contact the LSM if they need

further information or assistance with proper disposal.

10

4. Laser Hazard Control Measures

4.1 Controls for Class 1, 2, and 3a (IEC Class 1, 1M, 2, 2M and 3R) Lasers

Class 1, 2, and 3a (IEC 1, 1M, 2, 2M or 3R) laser beams may not be intentionally directed

at a law enforcement officer or the head or face of another person, except for:

- law enforcement purposes by police, or

- medical use by authorized medical personnel.

Class 3a (IEC 1M, 2M or 3R) laser beams must not be viewed with collecting optics (e.g.

microscopes) unless the optical system is specifically designed and constructed to prevent

eye exposure exceeding the applicable MPE.

Otherwise, no other specific laser safety requirements apply to Class 1, 2, and 3a (IEC 1,

1M, 2, 2M or 3R) lasers.

4.2 Controls for Class 3b and 4 (IEC Class 3B and 4) Lasers

Class 3b (3B) and Class 4 lasers may be operated only in designated laser control areas, including

operative suites, patient treatment rooms and patient examination rooms, or in other laser control

areas approved by the LSM. The purpose of laser control areas is to confine laser hazards to well-

defined spaces that are under the control of the laser user, thereby preventing injury to those

visiting and working near the control area. All personnel authorized to enter a Class 3b (3B) or

Class 4 laser controlled area shall be appropriately trained, and must follow all applicable

administrative and operational controls.

4.2.1 Posting

The area must be posted with appropriate warning signs that indicate the nature of the hazard. The

wording on the signs will be specified by the LSM and conform to the ANSI Z136.1 guidelines.

Such signs shall be posted at all entrances to the laser control area during the time a procedure

utilizing the active beam is in progress, and shall be removed when the procedure is completed. In

addition, an SOP approved by the LSM must be posted in a location readily available to laser

operators.

4.2.2 Authorization

Only personnel who have been authorized by the PLU may operate the laser. Personnel may be

authorized upon completing the applicable OESO laser safety training. The PLU may stipulate

additional authorization requirements. For Non-Clinical Applications, Class 3b (3B) and 4 lasers

may only be operated upon the LSMs approval of the responsible PLUs applicable Non-Clinical

Laser Laboratory Authorization.

4.2.3 Beam Stop

All laser beams, other than those applied to tissue for surgical or therapeutic purposes, must be

terminated at the end of their useful paths by a material that is non-reflective and (for class 4

lasers) fire resistant.

11

4.2.4 Eye Protection

Laser protective eyewear of adequate optical density and threshold limit for the beams under

manipulation must be provided and worn at any point where laser exposure could exceed the MPE.

This includes provision and use of M-rated eyewear in labs using unenclosed Class 3b (3B)

or 4 laser systems capable of <1 ns pulses, and R-rated eyewear in labs using unenclosed Class

3b (3B) or 4 Q-switched laser systems (see Appendix D for further information). In addition:

(a) Procedures and practices must ensure that optical systems and power levels are not adjusted

upstream during critical open beam operations, such as beam alignment.

(b) In clinical use, patients must also be provided with eye protection. If the patient is

conscious or under conscious sedation, appropriate protective eyewear is to be used. If the

patient is under general anesthesia, the eyes are to be protected with wet gauze pads or

similar non-flammable material.

(c) The need for laser eye protection must be balanced by the need for adequate visible light

transmission. It is the responsibility of the PLU to obtain appropriate laser protective

eyewear. For assistance in selecting laser eye protection, contact the LSM. The LSM can

assist the user in determining the proper parameters of such eyewear, and can provide

contact numbers for vendors.

(d) Laser eye protection should be inspected periodically to ensure that it is in good condition.

Damaged or faded eyewear must be removed from service.

4.2.5 Light Containment

Laser light levels in excess of the MPE must not pass the boundaries of the control area. All

windows, doorways, open portals, and other openings through which light might escape from a

laser control area must be covered or shielded in such a manner as to preclude the transmission of

laser light. Where feasible, the laser user is required to keep all laser beams within the operating

field, on the optical table or within the experimental envelope at all times. To maintain this control

it is essential to be aware of all beams, including stray beams and/or reflections, and to terminate

them with beam stops at the end of their useful paths. When a beam traverses to other tables or

across aisles, the beam must be enclosed or the access to the aisle must be blocked to prevent

personnel from exposure to the beam. Lasers should be mounted so that the beam path is not at eye

level for standing or seated personnel. Special rules apply for outdoor use and laser control areas

that do not provide complete containment. Contact the LSM for details.

12

4.3 Additional Controls for Class 4 Lasers

Only appropriately trained personnel may enter a Class 4 laser controlled area during the time a

procedure utilizing the active beam is in progress. All personnel within the control area must be

provided with appropriate protective equipment and are required to follow all applicable

administrative controls. Class 4 laser control areas must meet all of the requirements that apply to

Class 3b (3B) control areas and also the following requirements:

4.3.1 Rapid Egress and Emergency Access

There must be provisions for rapid egress from a laser control area under all normal and

emergency conditions. Any control area interlock system must not interfere with emergency

egress. In addition, access control measures must not interfere with the ability of emergency

response personnel (fire, paramedical, police) to enter the laser control area in the event operating

personnel become injured or incapacitated.

4.3.2 Laser Activation Warning Systems and Entry Controls

Procedural area or entryway controls must be in place to prevent inadvertent entry into a laser

control area, or inadvertent exposure to the active laser beam. These measures should include:

(a) a visible sign or audible warning sign or signal must be at the entrance to the control area to

indicate when the laser is energized and operating;

(b) provision of personnel with proper training and laser protective eyewear;

(c) doors or blocking curtains/barriers that attenuate the laser beam to below the MPE at the

entranceway.

(d) Entryway control (e.g. interlocks, shutters, illuminated Laser On warning signs, barrier

curtains) shall be checked periodically to verify proper operation

(e) If entryway controls must be disabled for any reason, administrative and procedural

controls providing the same level of protection must be instituted prior to the operation of

the laser or laser system. Any such changes to entryway controls and alternate control

measures must be pre-approved in writing by the PLU and communicated to all personnel

working in the laser area. The PLU and all personnel in the laser area must also be notified

upon restoration of the entryway controls.

The results of a formal hazard evaluation by the LSM may require more rigorous entryway

controls to be put into place, depending upon the level of the hazard. These may include door

interlocks or other entryway safety controls.

Locking entryway doors as a means of access control is not acceptable, because it is contrary to the

principle of permitting rapid egress or emergency access (see 2.2.1 above).

4.3.3 Key Switches

For those laser systems equipped with a key switch to prevent unauthorized use, the key must not

be left in the switch when the laser system is unattended.

13

4.4 Temporary Laser Control Areas

Temporary laser control areas can be created for the servicing and alignment of embedded lasers,

enclosed lasers, and in special cases where permanent laser control areas cannot be provided. They

are subject to the normal SOP approval process.

4.5 Special Requirements for Invisible Laser Beams

Since IR and UV laser beams are not within the boundaries of normal human vision, they possess a

higher hazard potential than visible light lasers. Because of the invisible nature of the optical

radiation, the use of laser eyewear that will protect against worst-case exposures is required at all

times.

4.5.1 Infrared Lasers

Infrared laser beams (> 700 nm), other than those applied to tissue for surgical or therapeutic

purposes, must be terminated by a highly absorbent, non-specular backstop. Note that many

surfaces that appear dull are excellent IR reflectors and would not be suitable for this purpose.

Class 4 IR laser beam terminators must be made of a fire-retardant material, or of a material which

has been treated to be fire-retardant.

4.5.2 Ultraviolet Lasers

UV radiation causes photochemical reaction in the eyes and the skin, as well as in materials that

are found in laboratories. The latter may cause hazardous by-products such as ozone and skin-

sensitizing agents. The direct beam and scattered radiation should be shielded to the practical

maximum extent to avoid such problems. The use of long-sleeved coats, gloves, and face

protectors is recommended. Some medications, including tetracycline, doxycycline, tricyclic

antidepressants, and methotrexate, can increase a persons risk to UV radiation. Contact the LSM

for more information about this subject.

4.6 Substitution of Alternate Control Measures

Upon documented review by the LSM, the engineering control measures recommended by ANSI

Z136.1 for Class 3b (3B) and Class 4 lasers or laser systems may be replaced by administrative or

other alternate engineering controls that provide equivalent protection. Approvals of these controls

are subject to the same review procedure as described in this chapter.

14

5. Laser Safety Training

5.1 Initial Training

All employees who use Class 3b (3B) or Class 4 lasers must complete the appropriate OESO Laser

Safety course. Non-Medical laser users must complete the Laser Safety Non Clinical Use

course. Healthcare laser users and those nursing and ancillary personnel working in operative or

treatment areas during healthcare laser use must complete the appropriate application-specific laser

safety course. All of these laser safety courses are available on-line on the OESO Web site or,

upon request, by classroom instruction through the LSM.

5.2 Visitors

Guests of DU/DUMC requesting to use or observe Class 3b (3B) or Class 4 lasers must contact the

LSM regarding the training requirement for non-Duke personnel. New employees and guests may

use lasers under the direct supervision of a PLU until completing the training requirement.

5.3 Laser-specific Training

Laser users are also responsible for knowing the safety requirements that apply to their specific

laser or laser system and for knowing the contents of the applicable SOP.

5.4 Update Training

Laser users must periodically retake the applicable OESO laser safety course.

(a) Research (non-medical) users: retraining interval not to exceed two years

(b) Healthcare laser users:

- Physicians with Laser Privileges: comply with applicable Credentialing training requirements

- All others: annual retraining interval

15

6. Laser Related Non-Beam Hazards & Control Measures

While beam hazards are the most prominent laser hazards, other hazards pose equal or possibly

greater risk of injury or death. These hazards must be reviewed by the LSM and addressed by the

PLU in the SOP for the laser operation where applicable.

6.1 Electrical Hazards

Some lasers use high-voltage power supplies, large capacitors, or capacitor banks that present a

lethal shock hazard. Additional hazards of electrical equipment include resistive heating and

ignition source. Electrical safety controls include:

(a) OSHA [29 CFR 1910 S] requires additional controls and training for work on live circuits

operating a more than 50 volts; note also that capacitors maintain a lethal charge even in

de-energized and unplugged equipment. Use extreme caution if servicing laser power

supplies.

(b) Review and comply with the Electrical Safety chapter of the Duke University Safety

Manual.

(c) Check the condition of electrical insulation and ensure that electrical terminals are covered;

repair or replace damaged equipment.

(d) Ensure good equipment grounding (i.e. chassis/frame resistance to ground limited to a few

ohms).

(e) Follow good wiring practices (e.g. use GFCI outlets, no wires on the floor, no overloaded

circuits, etc.).

(f) Use equipment only for its intended/designed purpose.

(g) Keep equipment power up warning lights clearly visible.

6.2 Laser Dyes

Dyes used as the optically active medium in some laser are often toxic and/or carcinogenic

chemicals dissolved in flammable solvents. This creates the potential for personnel exposures

above permissible limits, fires, and chemical spills. For each dye used, the PLU must have the

MSDS available for staff review and in general ensure compliance with applicable Duke policies

governing hazardous chemical use and disposal (see the DU Laboratory Safety Manual).

6.3 Compressed Gases and Cryogenics

Hazardous gases may be used in laser applications; i.e. excimer lasers (fluorine, hydrogen

chloride). Cryogenic fluids are used in cooling systems of some lasers. The SOP should contain

references for the safe handling of compressed gases. See the applicable section of the Duke

Laboratory Safety Manual for further guidance.

16

6.4 Laser Generated Air Contaminants

Air contaminants may be generated when Class 3b (3B) and Class 4 laser beams interact with

matter. When target irradiance reaches a threshold of about 10

7

W/cm

2

, target materials including

plastics, composites, metals, and tissues may liberate toxic and noxious airborne contaminants.

Generally, the PLU must ensure that any laser operation that creates visible smoke or plume has

adequate local exhaust ventilation in place and included in the SOP; respiratory protection is not an

acceptable alternative to local exhaust ventilation. If, in addition to local exhaust ventilation,

respiratory protection is required or worn voluntarily, consult the Duke Respiratory Protection

Policy in the Duke University Safety Manual.

6.5 Plasma Radiation

Interactions between very high power (~10

12

W/cm) laser beams and target materials may produce

a plasma, which in turn generates "blue light" and UV emissions that pose an eye and skin hazard.

Similarly, targets heated to very high temperatures (e.g. in laser welding and cutting) emit an

intense light. The PLU must ensure adequate control measures are in place and addressed in the

SOP for such operations.

6.6 UV and Visible Radiation

Laser discharge tubes and pump lamps may generate sufficient UV and visible radiation to pose an

eye and skin hazard. To address this issue, maintain the integrity of the laser housing and avoid

operating any laser with the housing removed.

6.7 Explosion Hazards

High-pressure arc lamps, filament lamps, and capacitors may explode if they fail during operation.

Keep these components enclosed in the laser housing, which will withstand the maximum

explosive forces that may be produced. Laser targets and some optical components also may

shatter if heat cannot be dissipated quickly enough. Ensure adequate mechanical shielding when

exposing brittle materials to high intensity lasers.

6.8 Ionizing Radiation (X-rays)

X-rays could be produced from two main sources: high voltage vacuum tubes of laser power

supplies such as rectifiers and thyratrons and electric discharge lasers. Any power supplies that

require more than 15 kilovolts may produce enough x-rays to be a health concern. Consult

Radiation Safety for review and control of such hazards.

17

7. Medical Surveillance

Personnel working with Class 3b (3B) and/or Class 4 lasers or laser systems are not required to

obtain either a pre- or post-employment medical examination specific to laser use. Following any

suspected laser injury, employees must report to a supervisor and the Employee Occupational

Health & Wellness if they believe that they have been injured.

18

8. Laser Accidents

8.1 Immediate Response and General Procedures

8.1.1 General Laser Accident Reporting

Laser users must report all laser accidents on site, no matter how minimal, to the PLU responsible

for the laser system involved. The PLU must report any accidents causing injury or property

damage to the LSM. If immediate assistance from the LSM is required, dial 911 (on DU &

DUMC sites), indicate to the Duke Police that a laser accident has occurred, and direct them to

notify the Radiation Safety On Call contact person, who will contact the LSM to respond to the

situation.

8.1.2. Known or Suspected Laser Overexposure

If a known or suspected overexposure to laser radiation occurs within DU or DUMC:

(a) Seek medical care for the individual(s) exposed without delay from Employee

Occupational Health and Wellness (EOHW), located in Duke Hospital South and open

between the hours of 8:00 AM and 5:00 PM. If an incident occurs outside the operating

hours of EOHW, seek assistance from the Emergency Department. Take all seriously

injured persons directly to the Emergency Department.

(b) Notify the supervisor of the injured individual(s) to ensure action is taken to prevent any

further injury to other personnel. The supervisor shall notify the LSM within 24 hours after

the initial reporting of the incident. The LSM will inform OESO and other relevant

personnel of actions being taken or required as part of the medical investigation.

(c) Complete an injury report form (AO-16).

8.2 Laser Accidents in Duke University Hospital

In addition to the general procedures outlined in Section 8.1, the following actions will also be

undertaken if a laser accident occurs in Duke University Hospital.

8.2.1 Occurrence Reporting

(a) Notify Risk Management immediately of any incident involving serious injury (i.e. life

threatening, resulting in permanent impairment of a body function or permanent damage to

a body structure, or necessitating medical or surgical intervention to preclude such

impairment or damage) to a patient or visitor. Contact Risk Management at:

Telephone: 684-3277 (8 AM - 5 PM, Monday - Friday)

Risk Manager on-call pager: 970-2404 (evenings, nights, weekends, & holidays)

(b) If laser equipment is involved, maintain all control settings, if possible, when discontinuing

use of the equipment and notify Clinical Engineering and OESO Radiation Safety Division

for assistance with equipment evaluation. If settings cannot be maintained, document the

settings prior to discontinuing use (if possible within safety limits) and include those

settings in the occurrence report.

(c) Risk Management will coordinate regulatory reporting and root cause analysis, with the

assistance and at the direction of Counsel's office, and in concert with the Office of

Accreditation and Patient Safety.

19

(d) Report any other occurrence (event not consistent with the standard of care of a patient or

safety of a patient, visitor, or volunteer, whether or not injuries are sustained) to the

supervisor responsible for the laser system involved.

(e) For assistance or directions concerning incident documentation, call Risk Management at

684-3277 (8 AM - 5 PM, Monday - Friday) or page the risk manager on-call at 970-2404

(evenings, nights, weekends, and holidays).

8.2.2 Follow-up Procedures by the Laser Safety Manager

The following guidelines describe the initial procedure to be followed by the LSM in the event of a

laser accident or incident:

If indicated, the LSM will respond on-site to the department reporting the incident.

The LSM will document the following information for future review:

(a) Date and time of call.

(b) Name and department of caller.

(c) Name of reporting person's immediate supervisor

(d) Model, serial number, Duke lot number, manufacturer, and nomenclature of device.

The LSM will contact the caller's supervisor to ensure that he/she is informed, and to remind

him/her to report incidents to Risk Management via report or telephone (if indicated).

If the accident occurred in Duke Hospital, the LSM will contact Clinical Engineering and instruct

them to sequester equipment involved in the incident.

The LSM will notify Risk Management and provide them with complete documentation (if

indicated). Risk Management will provide further guidance to the LSM if any is necessary.

After the LSM has verified that the exposed individual(s) have received the appropriate medical

care, and that the appropriate administrative personnel have been notified of the incident, the LSM

will continue to investigate the circumstances of the accident by obtaining the following

information:

(a) Name(s) of individual(s) alleged or suspected to have been overexposed.

(b) Laser nomenclature, characteristics and operating parameters at the time of the incident

(wavelength, peak and average power, pulse width and frequency, beam diameter and

divergence, etc.).

(c) Date, location, and time of the incident, as well as the duration of the exposure and the

individuals position relative to the laser.

(d) Description of what happened. If possible, obtain a signed brief description from all

individuals who have first-hand knowledge of the incident.

(e) Protective equipment / clothing in use at the time of the accident, and eyewear transmission

characteristics at the wavelength of the laser.

(f) Facility configuration at the time of the event.

(g) The name and telephone number of the attending physician.

20

Following the initial reporting of the alleged or suspected overexposure, the LSM will coordinate

with appropriate organizations to prepare a detailed report of the incident. This report shall consist

of a summary of the estimated exposure, timetable of medical evaluations, recommendations to

prevent recurrence of the incident, and discussion of further medical follow-up recommendations.

When requested by Risk Management/Counsels Office, the LSM shall provide consulting services

on laser incident investigations. When investigation services are requested the investigating

individual shall adhere to the following procedures:

(a) Interview the person reporting the incident using the necessary documentation forms.

(b) Provide all copies of investigation documentation to Risk Management.

(c) Obtain signature of Risk Management official who receives the information.

21

9. Standard Operating Procedure (SOP)

The PLU must provide written SOP, approved by the LSM prior to laser use, for all Class 3b (3B)

and Class 4 laser systems. This SOP must be posted near the laser(s) and include:

hazard identification and mitigation;

manufacturers start up and shut down procedures;

safe alignment procedures;

safety procedures;

protective equipment; and

emergency procedures.

A general laser SOP template is available via the Duke Laser Safety web site. The use of the

template is highly recommended. The template provides a guide for the laser user in identifying

the characteristics of the laser operation and collateral hazards, and in formulating set-up and

alignment procedures. Clinical and research laser users can also use an interactive "application-

specific" on-line template on the OESO Web site. Contact the LSM for assistance in developing

control measures and completing the SOP.

In the case of enclosed systems (e.g. laser scanning confocal microscopy) the requirement for an

SOP may be reduced or waived entirely after a review by the LSM, who will then determine if

which if any SOP sections are required.

All SOPs should be reviewed annually by personnel working with lasers to ensure the accuracy of

the procedure(s). If no new hazards have been added to the system, the users can perform the

review without notifying the LSM. If new hazards (use of a sub-nanosecond laser system, for

example) have been added to the experiment, a review by the LSM is necessary to assure all

applicable safeguards have been implemented.

22

10. Additional Resources

10.1 Glossary (available on line via the OESO web site)

10.2 Standard Operating Procedure (SOP) Template (available on line via the OESO web site)

23

11. References

(1) American National Standards Institute (ANSI) Z136.1-2007, American National

Standard for the Safe Use of Lasers (or later revision)

(2) American National Standards Institute (ANSI) Z136.3-2005, American National

Standard for the Safe Use of Lasers in Health Care Facilities (or later revision)

(3) U.S. Department of Labor, Occupational Safety and Health Administration Instruction

Publication 8-1.7, "Guidelines for Laser Safety and Hazard Assessment"

24

APPENDIX A

Use of Lasers Outside of the Clinical or Laboratory Setting

A.1 Introduction

The use of a laser outside of a controlled area can present special hazards. This appendix addresses

the control of any Class 3a, 3b, or 4 (IEC Class 3R, 3B, or 4) laser used outside the normal

research laboratory or clinical environment. These applications may include; lasers used for

telecommunications, laser research being performed outdoors, and lasers used for entertainment or

public viewing.

A.2 General Requirements

Any Class 3b, or 4 laser used for entertainment, displays, demonstrations, or any related use

intended for public viewing (indoors or outdoors) shall be operated in accordance with federal,

state, local, and campus regulations and requirements.*

Any Class 3b (3B), or 4 laser used outdoors for telecommunication applications or for research

projects shall be registered with the Laser Safety Manager per the requirements of the Duke Laser

Safety Policy.*

The operators of laser systems used for entertainment are required by law to file a Report on

Laser Light Show Display (or a variance document), with the Food and Drug Administrations

Center for Devices and Radiological Health (FDA/CDRH). No laser light show, display, or device

may vary from compliance with 21CFR1040.11(c) in design or use unless an approved

Application for a Variance from 21CFR1040.11(c) for a Laser Light Show, Display, or Device has

been issued by the FDA per 21CFR1010.4. If the venue is outdoors and the beam(s) may

terminate in navigable airspace, then the operators are also required to file a report with the

Regional Federal Aviation Administration (FAA) office.

All Class 3a (3R), 3b (3B), or 4 laser systems being used on Duke University property must be

used in accordance with the Duke Laser Safety Policy. The Laser Safety Committees must

approve any variation from the Laser Safety Policy.

A.3 Procedures

A.3.1 Laser Light Shows (Indoor or Outdoor)

Duke organizations, departments, or campus affiliated groups (student or otherwise) shall

coordinate with Corporate Risk Management on the contracting of outside companies to conduct

any laser light show (indoor or outdoor) to be performed on Duke property. Corporate Risk

Management will contact the LSM for technical support as needed.

The FAA specifies several levels of irradiance; it is not necessary to injure a pilot to disrupt a

flight. See App. C for further discussion of outdoor laser use.

25

For any light show (indoor or outdoor) conducted by a Duke affiliated entity, that entity must

coordinate with the LSM. The LSM will request from the light show operators a copy of the

required Report on Laser Light Show Display (or variance document) prior to the show. Upon

receipt, the LSM shall review the description of the show and the operators safety procedures. The

LSM may require additional safety measures to assure the safety of the operators, performers, or

audience. Specific requirements for laser light shows include:

A.3.1.1 The CDRH and ANSI requirements specified by the LSM must be met.

A.3.1.2 Any audience exposure to laser radiation must not exceed the ANSI Class 1 limit.

A.3.1.3 Operators, performers, and employees must be able to perform their duties without having

to directly view laser radiation exceeding the ANSI Class 1 limit, and without being exposed to

laser radiation exceeding the ANSI Class 2 limit.

A.3.1.4 All laser scanners (including mirror balls) must incorporate proper scanning safeguards.

A.3.1.5 If the laser is not under continuous operator control, any Class 3b, or 4 level of laser

radiation cannot be closer than 6 m vertically or 2.5 m horizontally from any standing surface or

standing position where the audience may be located.

A.3.1.6 If the laser is under continuous operator control, any Class 3a, 3b, or 4 level of laser

radiation cannot be closer than 3 m vertically or 2.5 m horizontally from any standing surface or

standing position where the audience may be located.

A.3.1.7 An operator with an accessible control to terminate the beam must be available if

conditions become unsafe.

A.3.1.8 FAA notification is required (for Class 3a/3R, 3b/3B, and 4 lasers) if the display is being

used in navigable airspace.

A.3.1.9 Additional safety requirements may be needed as specified by the LSM.

A.3.1.10 The CDRH Report on Laser Light Show Display forms are available from the LSM.

NOTE: An SOP is not normally required for laser light shows.

A.3.2 Research Projects Involving Outdoor Laser Use

The PLU shall inform the LSM of any lasers used outdoors for research projects. Such laser uses

will need to be covered under an SOP approved by the LSM as specified in the Duke Laser Safety

Policy. The department will be responsible for informing the LSM of any indoor or outdoor

telecommunication applications being pursued by that department. In both cases, the application

and operation of the laser system(s) shall be evaluated by the LSM to ensure that appropriate

safety measures are in place prior to operation. Specific laser safety requirements for (non-light

show) uses of lasers include:

A3.2.1 The PLU must create a written SOP and meet the specified SOP safety requirements.

A.3.2.2 The LSM will establish a Nominal Hazard Zone (any area where the maximum

permissible exposure (MPE) is exceeded).

26

A.3.2.3 The NHZ must be posted and/or restricted as directed by the LSM.

A.3.2.5 The PLU must ensure that only trained personnel enter the NHZ, and that appropriate PPE

(personal protective equipment) is issued and used.

A.3.2.6 The PLU must ensure users are properly trained and meet the campus laser safety training

requirements.

A.3.2.7 The PLU must ensure only authorized personnel are allowed to operate the laser.

A.3.2.8 The PLU must ensure the use of any required administrative/engineering controls.

A.3.2.9 Laser beams shall not be directed toward structures, automobiles, aircraft, or other vehicles

within the NHZ unless adequate training and protective equipment is provided and used by all

personnel within these structures/vehicles.

A.3.2.10 The laser beam path shall not be maintained at eye level without LSM approval.

A.3.2.11 FAA notification is required (for Class 3a/3R, 3b/3B, or 4 lasers) if the laser is being used

in navigable airspace.

A.3.2.12 Additional safety requirements may be needed as specified by the LSM.

A.4 Emergencies

The potential for injuries from a laser light show/display is minimal if the operators observe the

CDRH requirements. In the event that an individual suspects an eye injury, the operators of the

laser system shall be notified immediately so that the laser beam(s) can be terminated. The event

staff shall also be notified and medical attention shall be provided to the injured individual if

needed. The LSM shall be informed as soon as possible should any laser injury be suspected. The

LSM or his alternate can be contacted at any time by calling 911 and asking for the Duke

Radiation Safety Office.

27

APPENDIX B

Summary of Laser Hazard Classification Schemes

FDA/CDRH

21CFR1040.10

ANSI Z136 IEC/EN 80625

Class I - levels of laser radiation are not

considered hazardous

Class 1 no hazard; exempt from all

control measures

Class 1 no risk, even with viewing

instruments

Class 1M

a

no risk except perhaps to eye

when viewed through viewing instruments

(eye loupes or binoculars)

Class IIa - levels of laser (applies to

visible only) radiation are not considered

hazardous if viewed 1,000 seconds but

are considered a chronic viewing hazard

for any period of time >1,000 seconds

Class 2 visible (0.4 0.7 m) lasers not

considered hazardous for momentary

viewing (<0.25 seconds), but for which

the Class 1 accessible emission limit may

be exceeded for longer exposure

durations; avoid prolonged staring

Class 2 no eye risk for short term

exposures, even with viewing instruments;

no risk to skin (applies to visible lasers

only)

Class II - levels of (visible only) laser

radiation considered a chronic viewing

hazard

Class 2M

a

no eye risk for short term

exposures, except perhaps with viewing

instruments; no risk to skin (visible only)

Class IIIa - levels of laser radiation are

considered,

depending upon the irradiance, either an

acute intrabeam viewing hazard or chronic

viewing hazard, and an acute viewing

hazard if viewed directly with optical

instruments

Class 3a

- with Caution label: does not exceed

the appropriate irradiance MPE, except

perhaps when viewed through collecting

optics (e.g. microscopes, telescopes)

- with Danger label: may exceed the

appropriate irradiance MPE

Class 3R

b

low risk to eyes, no risk to

skin

Class IIIb - levels of laser radiation are

considered to be an

acute hazard to the skin and eyes from

direct radiation

Class 3b emit greater than Class 3a

limits and pose an acute eye hazard; more

rigorous controls are required to prevent

exposure of the unprotected eye

Class 3B medium to high risk to eyes,

low risk to skin

Class 4 - levels of laser radiation are

considered an acute hazard to the skin and

eyes from direct and scattered radiation

Class 4 acute eye and skin hazard, plus

ignition source (fire) and laser-generated

airborne contaminants hazards; strict

control measures required

Class 4 high risk to eyes and skin

a. The M designation in the IEC classification scheme is derived from magnifying optical

viewing instruments.

b. The R designation in the IEC classification scheme is derived from reduced or relaxed

requirements for manufacturers (no key switch or interlock connector required) and users

(usually no eye protection required).

28

APPENDIX C

Additional Considerations for Outdoor Laser Use

A laser need not cause a pilot eye injury to disrupt the normal operation of an aircraft. The FAA

identifies three (non-injury) categories of air crew visual impairment:

Glare: dazzling sensation induced by relatively bright light, producing unpleasantness,

discomfort, or interference with optimal vision; generally ceases once stimulus removed,

but residual effects (spatial disorientation, loss of situational awareness) can persist;

Flash blindness: visual loss during & following exposure to high intensity light flash; may

last a few seconds to several minutes; and

Afterimage: persisting sensation or image after stimulus removed.

An FAA study of flight crews in simulators exposed to various levels of laser radiation found that

exposure to 0.5 W/cm causes visual impairment (FAA, 2004). Landing approach is the most

critical time, and in fact distractions during this crucial period are limited by law (49CFR121.542,

125.311 &135.100). To prevent distractions associated with pilot laser exposure, the FAAs Order

7400.2 (Part 6 Chapter 29 Outdoor Laser Operations) long ago established maximum allowable

irradiance levels (flight safe exposure limits) in the area around airports, as follows:

Laser Free Zone 2 nautical miles (3.7 km) from runway centerline in all directions, plus

additional 3 NM along flight path, to 2,000 ft; 50 nW/cm (distraction)

Critical Flight Zone 10 NM (18.5 km) from airport center point; 5 W/cm (glare)

Sensitive Flight Zone (distance established on case by case basis) 100 W/cm (level for

significant flash blindness & afterimage)

Normal Flight Zone 2.5 mW/cm (exposure <MPE)

Table C.1 indicates the approximate range within which a typical 5 mW red (~680 nm) diode laser

pointer (~1 mrad divergence) will exceed the specified FAA exposure limits [based on ANSI

Z136.1-2000 NOHD Eq 50].

Table C.1: Approximate Laser Pointer Hazard Distance D (neglecting atmospheric attenuation)

Exposure Limit D (m)

MPE (2.5 mW/cm) ~16

SFZ (100 W/cm) ~80

CFZ (5 W/cm) ~356

LFZ (50 nW/cm) ~3560

Operators of any laser must ensure that the beam is not directed into navigable airspace.

29

APPENDIX D

Protective Eyewear for Ultrashort Pulsed Lasers

D.1 Executive Summary

Researchers (e.g. Koschinski et al, 1998) some years ago observed induced transmittance in

protective filter materials upon exposure to very high irradiances from ns, ps and fs pulsed lasers.

This temporary loss of filter material attenuation can negate the protective capability of eyewear

and thereby place laser users at risk of injury due to excessive laser radiation exposure. In

response, the European Laser Protective Eyewear Standard EN207 has established additional

eyewear testing and marking protocols to address this potential hazard. This Standard adds a pulse

duration rating to the previously-established L attenuation number (which corresponds to the OD

of the eyewear) and wavelength, as follows:

- D: rated for continuous wave lasers

- I: rated for long pulse lasers (>100 ns)

- R: rated for Q-switched lasers (1 ns to 100 ns)

- M: rated for ps and fs lasers (< 1 ns)

M-rated eyewear recently became commercially available. In addition to meeting the

wavelength and OD (L number) requirements specified by Duke Laser Safety, provision and use

of M-rated eyewear should be mandated for all laboratories using unenclosed class 3b or 4 ps

and fs pulsed laser systems.

D.2 Technical Basis

Koschinski et al (1998) reported dramatic decreases in the attenuation provided by some

glass and polycarbonate laser protective eyewear filter materials exposed to very high irradiances,

although the filter material appeared physically undamaged. Increased transmittance was observed

for polycarbonate material exposed to irradiances in excess of 4x10

9

W/cm from a 1064 nm Q-

switched (~15 ns pulse duration) Nd:YAG laser. The filter materials OD dropped by over six

orders of magnitude as the irradiance was increased from 4x10

9

W/cm to 4x10

11

W/cm, with

ablation of filter material beginning around 10

12

W/cm. Similarly the transmittance of semi-

conductor doped glass filter material increased upon exposures to 800 nm 250 fs pulse Ti:Sapphire

irradiances in excess of 10

11

W/cm. The OD dropped by five orders of magnitude as the

irradiance increased to 10

12

W/cm. The authors propose an absorption center model that

accurately predicts this increased transmittance as a function of irradiance for the materials tested.

Several other researchers have confirmed and extended these findings to other wavelengths

and filter materials. For example, Schirmacher et al (2005) compared induced transmittance in 11

types of polycarbonate filter materials and three types of glass filters exposed to 50 ns and 200 fs

pulses in the 70-800 nm range, finding temporary induced transmittance at irradiances below those

that caused any visible damage to the eyewear. These effects are real and have serious

implications for users of ultra short pulsed laser systems.

30

Although US laser safety standards have been slow to react, the European laser safety community

has responded to this issue by specifying improved testing and marking requirements for laser

protective eyewear. The European Laser Protective Eyewear Standard EN207 adds a D, I,

R or M pulse duration rating to the previously-established L attenuation number (which

corresponds to the OD of the eyewear) and wavelength, as noted in section I above.

D.3 References

Koschinski W, Schirmer A, Sutter E. Induced transmittance of eye-protective filters. J. Laser

Appl., 10:126-130 (1998).

Schirmacher A, Sutter E, Werhhahn O, Siegner U, Nevenjina-Sturhan A. Investigation of the

irradiance-dependent spectral transmittance of laser filters in the nanosecond- and femtosecond-

pulse regime in the wavelength range between 700 and 800 nm. J. Laser Appl., 17:191-197

(2005).

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Honeywell Laser SafetyDocument28 pagesHoneywell Laser SafetyRogier van der Heide100% (1)

- Spectralis Hardware Operating ManualDocument27 pagesSpectralis Hardware Operating ManualgdoctorNo ratings yet

- Icon I-1010 / I-1030: User ManualDocument132 pagesIcon I-1010 / I-1030: User ManualCAO DATNo ratings yet

- 76 - 8271423M - B FGTM-MDocument32 pages76 - 8271423M - B FGTM-MHamza_yakan967No ratings yet

- Fs19 Soldadura LaserDocument3 pagesFs19 Soldadura LaserAntonio AntezanaNo ratings yet

- 323-1851-545.r1.2 - OME6500 Module Replacement ProcedureDocument114 pages323-1851-545.r1.2 - OME6500 Module Replacement ProcedureJonatn SilvaNo ratings yet

- Opinion: Ultrasound Is Not Unsound, But Safety Is An IssueDocument4 pagesOpinion: Ultrasound Is Not Unsound, But Safety Is An IssueVonLoutsosNo ratings yet

- Ultrasound Safety Review Current TrendsDocument6 pagesUltrasound Safety Review Current TrendsVonLoutsosNo ratings yet

- RPT 73Document70 pagesRPT 73VonLoutsosNo ratings yet

- Industrial Laser Compliance GuideDocument14 pagesIndustrial Laser Compliance GuideVonLoutsosNo ratings yet

- Bmus Safety Guidelines 2009 Revision Final Nov 2009Document17 pagesBmus Safety Guidelines 2009 Revision Final Nov 2009VonLoutsosNo ratings yet

- Media 287686 enDocument44 pagesMedia 287686 enVonLoutsosNo ratings yet

- Ni Hms 517878Document16 pagesNi Hms 517878VonLoutsosNo ratings yet

- Laser Safe ManDocument45 pagesLaser Safe ManVonLoutsosNo ratings yet

- Laser Safety Is orDocument5 pagesLaser Safety Is orVonLoutsosNo ratings yet

- Laser Safety ManualDocument30 pagesLaser Safety ManualVonLoutsosNo ratings yet

- Lenovo Y50Document2 pagesLenovo Y50VonLoutsosNo ratings yet

- Lenovo Y50Document2 pagesLenovo Y50VonLoutsosNo ratings yet

- B&G Quantum XM 50 Owners ManualDocument0 pagesB&G Quantum XM 50 Owners ManualVonLoutsosNo ratings yet

- Operator's Manual Diamond Series OEM/Industrial Diamond C-70™ Liquid-Cooled LaserDocument70 pagesOperator's Manual Diamond Series OEM/Industrial Diamond C-70™ Liquid-Cooled LaserErrol Llacer Manago100% (1)

- Laser Safety Test !Document5 pagesLaser Safety Test !shabeer hassimNo ratings yet

- 3fe-56068-Aaaa-Tczza-03-7356 Isam FTTB 7360 Isam FX Ansi Safety Manual r5 XDocument46 pages3fe-56068-Aaaa-Tczza-03-7356 Isam FTTB 7360 Isam FX Ansi Safety Manual r5 XThuan Nguyen100% (1)

- Monarch PLT200 Tachometer User InstructionsDocument14 pagesMonarch PLT200 Tachometer User InstructionsHakkı YılmazNo ratings yet

- Honeywell-Xenon-1900 Manual PDFDocument312 pagesHoneywell-Xenon-1900 Manual PDFGatoNo ratings yet

- Focus 30 Maintenance Manual - 1.0Document353 pagesFocus 30 Maintenance Manual - 1.0pablox86No ratings yet

- FAX2000L: Operator's ManualDocument194 pagesFAX2000L: Operator's Manualhans_johns1No ratings yet

- What Is Laser Diode Sanyo - Databook PDFDocument22 pagesWhat Is Laser Diode Sanyo - Databook PDFnaupas007No ratings yet

- Mako Series: Operator GuideDocument52 pagesMako Series: Operator GuideAnthonyNo ratings yet

- LMC2010 Fiber Laser Control Board User ManualDocument19 pagesLMC2010 Fiber Laser Control Board User ManualZeljko Krivokuca100% (1)

- Service Manual Rev 2.1: MF5900/MF6100/D1300 SeriesDocument176 pagesService Manual Rev 2.1: MF5900/MF6100/D1300 Seriestraminer0% (1)

- WLS7 UserManual 01rev01 PDFDocument44 pagesWLS7 UserManual 01rev01 PDFilham gozaliNo ratings yet

- A5 Series Engraver Installation Manual V2.1Document52 pagesA5 Series Engraver Installation Manual V2.1torettoindumentariaNo ratings yet

- UM158 - User's Manual - PEFL-K, PYFL-K - PK5xA, PK5xD - Rev.4Document28 pagesUM158 - User's Manual - PEFL-K, PYFL-K - PK5xA, PK5xD - Rev.4李旭No ratings yet

- Leica Disto X310 ManualDocument22 pagesLeica Disto X310 ManualDian RushdianaNo ratings yet

- Tapa AGR Reg App BDocument35 pagesTapa AGR Reg App Bfoxbat05No ratings yet

- Manual Epilog Laser Mod 8000Document228 pagesManual Epilog Laser Mod 8000damarcrazyNo ratings yet

- HGC 1030Document4 pagesHGC 1030Régis RenanNo ratings yet

- IMZ9782 Rev C FTPA2000-200 Series Users GuideDocument98 pagesIMZ9782 Rev C FTPA2000-200 Series Users GuideTito Bojone LubisNo ratings yet

- LIGHT HardcoverDocument366 pagesLIGHT HardcoverMaxwell100% (1)

- Kyocera KM1620 enDocument124 pagesKyocera KM1620 enVVhiskyFourlegNo ratings yet

- 6409 ManualDocument219 pages6409 Manualharis harisNo ratings yet

- Operator'S Manual Coherent Stingray Diode Laser ProductsDocument58 pagesOperator'S Manual Coherent Stingray Diode Laser ProductsMaria TzagarakiNo ratings yet

- Quickstart Dx35 de en FR Es PT ZH Ja It Ru Im0044955Document2 pagesQuickstart Dx35 de en FR Es PT ZH Ja It Ru Im0044955ROSSNo ratings yet