Professional Documents

Culture Documents

Industrial Laser Compliance Guide

Uploaded by

VonLoutsos0 ratings0% found this document useful (0 votes)

29 views14 pagesdfbfsgsdfg esgs dfg fgsdfg

Original Title

wsh_cetsp39_272060_7

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentdfbfsgsdfg esgs dfg fgsdfg

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

29 views14 pagesIndustrial Laser Compliance Guide

Uploaded by

VonLoutsosdfbfsgsdfg esgs dfg fgsdfg

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 14

Consultation Education and Training Division

Michigan Occupational Safety & Health Administration

Michigan Department of Licensing and Regulatory Affairs

7150 Harris Drive, P.O. Box 30643

Lansing, MI 48909-8143

(517) 322-1809

INDUSTRIAL LASER

COMPLIANCE

GUIDE

Table of Contents

Topic Page Number

Sample Written Program............................................................................ 1

Standard Operating Procedures (SOP)(Sample)...5

Laser Inspection Tips.. ............................................................................... 6

Shall & Required from the OSHA Instruction Pub 8-1.7........................ 7

Laser Related Websites........................................................................10

Laser Hazard Evaluation Form..11

MIOSHA MTDS 51 Disease Report Form12

STATE OF MICHIGAN

MIOSHA CET DIVISION

SAMPLE

(Insert company name)

INDUSTRIAL LASER SAFETY

WRITTEN PROGRAM

SCOPE

This document provides for the safe use of high powered lasers in industrial applications (e.g. where woods,

metals, aggregates and plastics are cut or shaped using a class 3B or 4 lasers) and for employee protection

related to the use of these lasers. The intent of this program is to provide safe guidelines for our facility, the

Laser Safety Officer (LSO) and any other Authorized employee user of Class 3B and 4 lasers.

LASER SAFETY OFFICER (LSO)

The LSO for this facility is ______________________.

LSO SPECIFIC DUTIES

The LSO has the authority to monitor and enforce the control of laser hazards and effect the knowledgeable

evaluation and control of laser hazards. The LSO administers the overall laser safety program where the duties

include, but are not limited to: confirming the classification of lasers, conducting a hazard evaluation (e.g.

Nominal Hazard Zone (NHZ) evaluation), assuring proper control measures are in place, approving substitute

controls, approving Standard Operating Procedures (SOP's), recommending and/or approving protective

eyewear and other protective equipment, assuring appropriate signage and labels, approving overall facility

controls, assuring adequate laser safety training for affected personnel (e.g. maintenance and operators), and

determining personnel categories requiring medical surveillance if appropriate.

Classification of Lasers

The LSO shall classify or verify the classifications of lasers or laser systems. The laser hazard class is based

on the lasers capability of injuring personnel. Any laser or laser system shall be classified according to its

accessible radiation during operation (Note: Class 1 systems containing imbedded Class 3B or 4 lasers, where

employees have access to the laser, would be included in this program. For example, maintenance or alignment

activities associated with a Class 3B or 4 imbedded laser).

Our site laser inventory is shown in the table below (Complete with site specific information. A sample entry

has been provided).

Laser Inventory Table

Class Type

Manf. And Model

#

Serial # Power

(W)

Hazard

Analysis

Completed

and on-file?

(Y/N)

SOP(s) has

been

developed?

(Y/N/NA)

Affected

employees

trained?

(Y/N)

4 CO2 Mazak XYZ 11000 2000 Y Y Y

Page 1

Hazard Evaluation

The LSO shall assure that hazard evaluations are conducted for the lasers used. The hazard evaluation

process shall consider the laser or laser systems ability to injure personnel, the environment in which the laser

is used (including the beam path) and any personnel who may be directly or indirectly exposed to laser

radiation; such as maintenance or operators.

Hazard evaluations will be conducted for all of our Class 3B and 4 lasers (See Laser Hazard Evaluation form

included in the compliance guide).

Standard Operating Procedures (SOPs) Procedure Approvals

A SOP is a written description of the safety procedures and administrative controls to be followed when

performing a specific task; such as alignment. Any SOPs or laser procedures developed shall be approved by

the LSO or his/her authorized designee. The SOPs shall address both beam and non-beam hazards.

The SOPs developed for this facility can be found attached to this program (Attach site specific laser

related SOPs. A sample SOP is attached).

Personal Protective Equipment (PPE)

Hazard analyses conducted by the LSO will determine what PPE is required (e.g. laser eyewear, skin

protection, natural fiber/non-flammable clothing, etc.). The LSO will assure that any optical density (OD)

calculated during a hazard analysis is rounded up to the next highest number when selecting eyewear. As an

example, if the calculated OD =5.2, eyewear rated with an OD=6 shall be selected. OD information may be

found in the Laser manufacturers manual.

Signs and Labels

The LSO shall assure any applicable area signage and equipment labels are in place and legible. The purpose

of a laser area warning sign is to convey a rapid visual hazard-alerting message. The three types of signs are

DANGER, CAUTION and NOTICE. DANGER signs and labels shall be used for Class 3R, 3B and 4 lasers.

CAUTION signs and labels shall be used for Class 2 and 2M lasers. A NOTICE sign is to be used for facility

area control (e.g. an outside temporary laser controlled area during periods of service).

Equipment labels for Class 3B lasers and laser systems shall say, Laser Radiation Avoid Direct Exposure to

Beam. Equipment labels for Class 4 lasers and laser systems shall say, Laser Radiation Avoid Eye or Skin

Exposure to Direct or Scattered Radiation.

Signage and labels shall be displayed in locations where they best serve to warn onlookers.

Equipment

The LSO shall approve the purchase of new laser equipment, regardless of class. The LSO shall review the

modification, installation and facilities associated with laser equipment, prior to use.

The use of protective barrier curtains and screens to protect against laser exposure will be approved by the LSO

to assure they are appropriate. Standard welding curtains have not been rated to serve as a means of laser

beam protection.

Training

Education may be provided to users of Class 1M, Class 2, Class 2M or Class 3R lasers. Laser safety training

must be provided to users of Class 3B or Class 4 lasers.

Laser Safety Officer (LSO) training is required for the facility LSO and will be documented. The LSO should

have a comprehensive understanding of the key laser safety issues associated with the lasers they manage.

Page 2

The LSO shall be trained on the following:

1. Operational laser characteristics (e.g. operation, definitions, applications, manufacturers

requirements)

2. Laser hazards (e.g. hazard assessment, eye and skin hazards)

3. Laser safety standards (e.g. OSHA Pub 8-1, ANSI Z136.1)

4. Laser controls (e.g. Engineering, Administrative and Procedural)

5. Safety Methods and Procedures (e.g. alignments, barriers, warning signs and labels, control of

unauthorized personnel, audits and laser worker training)

Maintenance Personnel

The LSO shall insure that all employees assigned to service, maintain, install, adjust, and operate laser

equipment be qualified and trained. The training program should be designed appropriate to the class of laser

and radiation accessible during the performance of required task(s). Laser area supervisors shall maintain the

names of all persons trained and date of training and inform the LSO of training completions and

requirements.

Operator Training

Training will include all of the following as appropriate:

(a) Capabilities of equipment and attachments or fixtures.

(b) Purpose, use, and limitation of controls & safeguards.

(c) How to make daily visual inspections of all safety devices.

(d) Practice in operating assigned equipment through its functions necessary to perform

the required job tasks.

(e) A review of applicable state standards.

Training shall be provided for employees working with Class 3B and Class 4 lasers (e.g. including operators,

maintenance personnel, service persons, technical support staff, technicians, etc.) The training will provide a

complete understanding of the requirements of a safe laser environment and include discussion of the hazards,

safety devices required, procedures related to operating the equipment, warning sign requirements and

description of any applicable medical surveillance practices. Emphasis should be placed on practical, safe laser

techniques and procedures as well as safety devices that provide an overall safe environment.

The content of the laser safety training should be tailored to each different group that uses lasers. Often the type

of laser(s) and locations will impact the content of the training program. For example, the hazards and controls

recommended for far-infrared CO(2) lasers may be different than those for a near-infrared Nd:YAG laser or a

visible Argon Ion laser.

Training records should be reviewed periodically to assure that training is up to date and potentially exposed

personnel have been trained.

Unauthorized Personnel

No unauthorized personnel may enter an identified laser area, when a laser is in operation, unless accompanied

by an authorized user. All visitors must be briefed on proper safety protocol and wear appropriate laser safety

eyewear.

Medical Surveillance

A medical exam will be performed as soon as practical (usually within 48 hours) of when a suspected injury or

adverse effect from a laser exposure occurs. A baseline ocular exam may be useful to have to compare to a

post incident ocular exam. Also, a baseline ocular exam may identify certain workers who might be at special

risk from chronic exposure to selected lasers.

Audits

An annual laser equipment audit is recommended to assure that effective safeguards and controls are still

appropriate and in place.

Page 3

Accidents

Notifications or incidents (e.g. near miss, recordable injury and/or equipment damage) of actual or suspected

exposure, to potentially harmful laser radiation, should be reported to management. At this site, the contact

person to report such an incident is ________________________. Employees are encouraged to report

laser related incidents. Incidents will be investigated to determine the root cause and appropriate corrective

actions to be taken.

The Michigan Public Health Code P. A. 368 of 1978 requires reporting of laser injuries on the MIOSHA Form

MTSD 51 attached in this compliance guide.

Attachments

Laser Hazard Analysis Form

MIOSHA Form MTSD 51

Page 4

SAMPLE SOP

This standard operating procedure (SOP) applies to beam alignment for Laser #2 (See

equipment manual specifics associated with beam alignment procedure). Only trained and

authorized employees are permitted to perform alignment activities.

1. System Description.

Model 1000 Nd:YAG laser marker system manufactured by the XYZ Company. This is

a class 1 laser system with an embedded class 4 laser.

Wavelength: 1.064m

Pulse Duration: 100 ns

Pulse Repetition Rate: 5,000-20,000 Hz

Average Power: 30 W

Beam Diameter: 4 mm

Beam Divergence: 2 mrad

2. Hazards.

Eye hazard from direct, reflected or scattered beam.

Skin hazard and fire hazard.

Electrical hazard inside power supply.

Laser Generated Air Contaminants (LGACs).

3. Control Measures.

Exclude unnecessary personnel from the laser area.

Establish a Laser Controlled Area using laser barrier screens and warning signs.

Personnel in the laser controlled area shall wear approved laser safety eyewear

with O. D. 5.0 @ 1064nm and protective clothing.

Use a low power visible laser for path simulation of higher power invisible lasers.

Use the lowest possible power level while performing alignment tasks.

When aligning invisible laser beams, use beam display devices such as image

converter viewers or phosphor cards to locate beams.

Utilize diffuse reflecting beam blocks under these conditions:

o At source when not needed

o To terminate beams down range

o Where alignment beams could stray

o To terminate beams that might miss mirrors

Locate and block stray reflections before proceeding to the next optical component

or section.

Be sure all beams and reflections are properly terminated before high-power

operation.

Keep all combustibles, tool, and reflective surfaces away from the beam path.

Make sure you know where the beam is and stay clear.

Work involving access to the power supply normally will be conducted with the

system locked out. Access to the energized power supply must be done only by

qualified personnel using the buddy system. Workers are directed to review the

electrical safety and power supply sections of the manual before any activities

involving access to high voltage.

Assure the exhaust system in on to remove LGACs, even with the protective

housing open.

Page 5

LASER INSPECTION TIPS

1. Is there a designated Laser Safety Officer (LSO)?

Is the LSO trained?

Required for Class 3B and Class 4

Application dependent for Class1M and Class 2M

2. Does the operator utilize protective eyewear?

Does the eyewear match the laser manufacturers requirements?

Required for Class 4

Recommended for Class 3B

3. Are reflective objects in or near the beam path of the laser kept to a minimum?

Required for Class 3B and Class 4

4. Is egress clear of obstructions?

Required for all laser classes

5. Are the warning signs and labels legible and adequately located?

Required for Class 3B and Class 4

Recommended for Class 3R, Class 2M and Class 2

6. Are the interlocks intact and functioning?

For Class 3B and Class 4, including enclosed Class 3B and Class 4, interlocks

are required for protective housings and service access panels

7. For fully open and limited open beam paths: Does the beam appear to be as

close to the work piece as possible?

Is the beam above or below eye level? (These Lasers cannot operate at eye level)

Required for Class 3B and Class 4

8. Did the person in charge of the area authorize the presence of all personnel in

the area?

Required for Class 3B and Class 4

9. Is the area well lit?

Required for all laser classes

10. Alignment/Adjustment procedures

Beam off- is the power on. Do additional safeguards appear adequate?

(contact with live parts)

Beam off- the power is not on. Do additional safeguards appear adequate?

Beam on- Service function as delineated in product manual

Required for Class 3B and Class 4, including enclosed Class 3B and Class 4

Page 6

SHALL AND REQUIRED

From OSHA Instruction PUB 8-1.7

PROCEDURAL and ADMINISTRATIVE CONTROLS

The LSO shall have the authority and responsibility to monitor and enforce the control of laser

hazards, and to effect the knowledgeable evaluation and control of laser hazards.

This shall be done at each location or administrative area where Class 3 or 4 laser or laser

systems are used or manufactured.

If service is performed on a laser product having an embedded Class 3A, 3B or 4, there shall

be a designated LSO.

Employees who service, maintain, install, adjust and operate laser equipment shall be

trained.

An alignment SOP is required for all Class 2, 3A, 3B and 4 lasers.

The Nominal Hazard Zone (NHZ) associated with Class 3B and 4 lasers shall also be

determined.

Control measures shall be devised to reduce the possibility of exposure to the eye and skin to

hazardous laser radiation and to other hazards associated with the operation of lasers and

laser systems.

Access during operations must require authorization of the person responsible for the area. In

conditions where the beam path is not completely enclosed, access shall be limited.

Designs for lasers, laser systems and the associated work areas shall be predicated upon the

classification of the laser or laser system used.

The beams shall not, under any circumstances, be transmitted from an indoor laser controlled

area unless for specific purposes (such as testing).

The LSO shall be notified of the purchase of any laser regardless of class.

No attempt shall be made to place any shiny or glossy object into the laser beam other than

that for which the equipment is specifically designed.

Eye protection devices designed for protection against radiation from a specific laser system

shall be used when engineering controls are inadequate to eliminate the possibility of

potentially hazardous eye exposure.

All laser protective eyewear shall be clearly labeled with optical density values and

wavelengths for which protection is afforded.

Page 7

SHALL AND REQUIRED

From OSHA Instruction PUB 8-1.7

PROCEDURAL and ADMINISTRATIVE CONTROLS

Class 3B Lasers:

Laser beams shall be contained whenever possible.

When uncontained beams are used, the following precautions shall be taken:

1. A Class 3B warning sign shall be placed at the entrances to the area when the laser

beam is operating and access must require authorization by persons responsible for

the area.

2. The laser beam shall be terminated at the limit of its useful distance.

3. Specularly reflecting surfaces in or around the beam path shall be minimized.

4. The area shall be well lighted to restrict pupils.

5. The laser shall be positioned and the beam contained such that the beam does not

exit the immediate area of use.

Class 4 Lasers:

In addition to the requirements for Class 3B lasers the following are required:

1. A total hazards review shall be conducted before a high-powered laser is used.

2. Devices shall be located in an area designated specifically for laser operations.

3. An entryway control shall be used. Control measures shall permit rapid egress and

admittance to the area under emergency conditions.

4. A control disconnect switch or equivalent shall be available near the exit for

deactivating the laser.

5. The beam shall be terminated by a highly absorbent beam trap of fire resistant

material.

6. For infrared lasers, areas which are exposed to reflections of the beam shall be

protected by fully enclosing the beam and target area

7. Ultra violet laser beam radiation shall require a beam shield.

8. A countdown procedure shall be used to signify the firing of single pulse laser types

(Q-switch).

Page 8

SHALL AND REQUIRED

From OSHA Instruction PUB 8-1.7

ENGINEERING CONTROLS

Protective Housing- Shall be provided for all classes of laser.

Housing Interlocks- Shall be provided for both Class 3A,3B and 4.

Beam enclosures:

1. Enclosed Beam Path- When properly labeled and safeguarded with a

protective housing, the laser may be operated with no additional controls for

the operator.

2. Limited Open Beam Path - Enclosure surrounding the laser focusing optics

and immediate area of the workstation almost completely, procedural

controls will be sufficient for both Class 3B and 4.

3. Totally Unenclosed Beam Path - Complete Hazard Analysis and NHZ

assessment is required. Additional controls which may be required are:

PPE, barriers, and entryway interlock for both Class 3B and 4.

4. When the entire beam path from a Class 3B or 4 laser is not sufficiently

enclosed and/or baffled such that access to radiation above the MPE is

possible, a laser-controlled area is required.

Beam Shutter or Attenuator - Should for Class 3B, Shall for Class 4

Remote Interlock Connector - Should for Class 3B, Shall for Class 4

Key Switch Master Control - Should for Class 3B, Shall for Class 4

Viewing Optics and Windows - Shall for both Class 3B and 4

When viewing optics and windows are utilized in the laser, optical filter

interlocks are required.

Service Panels - Shall for both Class 3B and 4, be interlocked or require a tool for

removal.

Warning System - Should for Class 3B, Shall for Class 4

Controlled Areas:

1. Indoor - Shall for both Class 3B and 4

2. Outdoor - Shall for both Class 3B and 4

Page 9

Laser Related Websites

MIOSHA www.michigan.gov/miosha

State of Michigan - Consultation Education Training (CET)

Michigan Occupational Safety & Health Administration

Several links to current MIOSHA standards, publications, sample written programs, the

MIOSHA Training Institute (MTI) and current MIOSHA initiatives.

Laser-Professionals www.laser-professionals.com

Sample Micro Laser Safety training course, speakers notes, SOP template and example,

laser related DVDs (show 2 free 5 min video clips), EASY- Haz free laser hazard calculator.

ANSI electronic Standards Store www.webstore.ansi.org

The American National Standards Institute (ANSI) coordinates development and use

of voluntary consensus standards in the United States.

Rockwell Laser Industries (RLI) www.rli.com

Rockwell Laser Industries pledges to continue its heritage of delivering outstanding quality,

service and support to the worldwide community of laser users.

Laser Institute of America (LIA) www.laserinstitute.org

Federal OSHA and LIA have an Alliance that focuses on providing the organization's

members and others, including small businesses with information, guidance, and access to

training resources that will help them protect employees' health and safety, particularly in

reducing and preventing exposure to laser beam and non-beam hazards in industrial and

medical workplaces.

Federal OSHA www.osha.gov

STD 01-05-001 - PUB 8-1.7 - Guidelines for Laser Safety and Hazard Assessment

This publication is free to download, is over 100 pages, and covers use of lasers, laser

hazards, and laser training.

Page 10

STATE OF MICHIGAN

MIOSHA CONSULTATION EDUCATION & TRAINING MIOSHA

SAFETY LASER HAZARD EVALUATION FORM HEALTH

EMPLOYER NAME

.LASER SYSTEM LOCATION

NAME OF LASER SAFETY OFFICER (LSO)

LASER TYPE

LASER MANUFACTURER

MODEL NO.

SERIAL NO.

WAVE LENGTH (nm)

MAX POWER (W)

PULSED PULSE RATE (HZ) PULSE DURATION (S) PULSE POWER(1)

YES

NO

BEAM DIAMETER OR DIMENSIONS AT THE APERTURE (mm) BEAM DIVERGENCE, FULL ANGLE (mrad)

LASER HAZARD ANALYSIS

WAVELENGTH (nm) EXPOSURE DURATION (s)

MPE (W/cm

2

)

OPTICAL DENSITY (OD)

NOMINAL HAZARD DISTANCE (m)

DIFFUSE HAZARD DISTANCE (m)

CHEMICAL HAZARDS OPTICAL HAZARDS LASER GENERATED HAZARDS

COOLANTS DISCHARGE TUBES AIR CONTAMINANTS

SOLVENTS UV / WELDING CHEMICAL FUMES

GASES VISIBLE METALLIC FUMES

OTHER ____________________ IR METALLIC DUSTS

OTHER ____________________ OTHER ____________________

VENTILATION PROVIDED NOISE ISSUES FIRE HAZARDS

LOCAL EXHAUST YES IMPROPER BEAM ENCLOSURES

GENERAL VENTILATION NO COMBUSTIBLE MATERIALS

OTHER________________________ KNOWN dBA __________ GAS / VAPOR IGNITION

ELECTRICAL CIRCUITS

ELECTRICAL HAZARDS IS LOCKOUT REQUIRED COMPRESSED GAS CYLINDERS

POWER SOURCES YES NO PROPERLY STORED

EXPOSED WIRING RESTRAINED

MISSING COVERS PROCEDURES ESTABLISHED REQUIRED SIGNAGE

STORED ENERGY (CAPACITORS, ETC) NO MISSING CAPS

YES NO

LASER HAZARD CONTROL MEASURES

SIGNAGE REQUIRED

DANGER

CAUTION

NOTICE

PROTECTIVE DEVICES FOR STRAY BEAMS

OR REFLECTIONS

BEAM BLOCKS PATH COVERS

BARRIERS CURTAINS

LASERS IN AREA

ONE

TWO

THREE

EYE PROTECTION

(OD RATING)

OTHER PPE

TRAINING PROVIDED

LSO

OPERATOR

MAINTENANCE

ALIGNMENT PROCEDURES

ESTABLISHED

YES NO

STANDARD OPERATING

PROCEDURES ESTABLISHED

YES NO

LAST TIME LASER INSPECTED

FORM COMPLETED

BY:________________________________________________________________________________DATE:_______________________________

CET LASER EVALUATION FORM rev 11/12

Page 11

Michigan Department of Licensing and Regulatory Affairs Management and Technical Services Division

Known or Suspected Occupational Disease Report

(Information will be held confidential asprescribed in Act.)

EMPLOYEE AFFECTED

Name (Last, First, Middle) Age Sex Race: White Black Hispanic

M F Other

Street City State Zip

Home Phone Number Last Four Digits of Social Security Number (Optional)

CURRENT EMPLOYER

Current Employer Name Worksite County

Worksite Address City State Zip

Business Phone If Known, Indicate Business Type (products manufactured or work done)

Number of Employees

<25 25-100 100-500 >500

Employee's Work Unit/Department Dates of Employment

From: ____________________ To:____________________

Mo Day Year Mo Day Year

Employee's Job Title or Description of Work

ILLNESS INFORMATION

Nature of Illness or Health Condition (Examples: Headache, Nausea, Difficulty Breathing, Cough, etc.) Date of Diagnosis

___________________

Mo Day Year

Suspected Causative Agents (Chemicals, Physical Agents, Conditions) Did Employee Die? If Yes, Date of Death

Yes No ___________________

Mo Day Year

If Physician, Indicate Clinical Impression for Suspected Occupational Disease, or Diagnosis of Confirmed Occupational Disease

ADDITIONAL COMMENTS

________________________________________________________________________________________________________________________________________

________________________________________________________________________________________________________________________________________

REPORT SUBMITTED BY

If Report Submitted by Non-Physician, Did Employee See a Physician?

If yes, record information below. Yes No Don't Know

Physician's Name Phone

Office Address City State Zip

Name of Person Submitting Report

Physician Non-Physician

Address City State Zip

Signature Phone Date

The Michigan Department of Licensing Regulatory Affairs isan equal opportunity, affirmative action employer, service provider and buyer.

Return completed formto:

Michigan Department of Licensing and Regulatory Affairs

Michigan Occupational Safety and Health Administration

Management and Technical Services Division

7150 Harris Drive, P.O. Box 30649

Lansing, MI 48909-8149

MIOSHA-MTSD-51 (02/09)

Authority: P.A. 368 of 1978

Completion: Required

Penalty: Misdemeanor

Page 12

You might also like

- Aircraft System Safety: Assessments for Initial Airworthiness CertificationFrom EverandAircraft System Safety: Assessments for Initial Airworthiness CertificationNo ratings yet

- Security Controls Evaluation, Testing, and Assessment HandbookFrom EverandSecurity Controls Evaluation, Testing, and Assessment HandbookRating: 5 out of 5 stars5/5 (2)

- Industrial Laser Compliance Guide: SP-39 (Revised 11/29/17)Document14 pagesIndustrial Laser Compliance Guide: SP-39 (Revised 11/29/17)Mohamad GhosenNo ratings yet

- Laser Safety HandbookDocument20 pagesLaser Safety Handbookgfit100No ratings yet

- ProgramDocument15 pagesProgramMIKENo ratings yet

- Laser Safety ManualDocument34 pagesLaser Safety ManualNiranjanNo ratings yet

- Laser Control Measures 2018Document3 pagesLaser Control Measures 2018Mediatrix DevianiNo ratings yet

- Laser Safe Operation ProtocolDocument4 pagesLaser Safe Operation Protocolchaitra rNo ratings yet

- Laser Safety Manual UTHealth Houston 2023Document29 pagesLaser Safety Manual UTHealth Houston 2023Firdaus Mohd IdrisNo ratings yet

- OSUlaser Safety ManualDocument14 pagesOSUlaser Safety ManualUrología GinecológicaNo ratings yet

- Laser Safety Manual 9-1-2017Document36 pagesLaser Safety Manual 9-1-2017Urología GinecológicaNo ratings yet

- Laser Safety JSP-392 - CH - 34 - Web - VersionDocument2 pagesLaser Safety JSP-392 - CH - 34 - Web - VersionFirdaus Mohd IdrisNo ratings yet

- DSA 03 JSP 390-Final-OCT 19 V2Document23 pagesDSA 03 JSP 390-Final-OCT 19 V2MostafaNo ratings yet

- Lasers OpDocument6 pagesLasers OpAndrian PrimadyaNo ratings yet

- LaserguideDocument33 pagesLaserguideUrología GinecológicaNo ratings yet

- Cmlso Exam RefDocument9 pagesCmlso Exam RefUrología GinecológicaNo ratings yet

- Saftyguide - Laser - e Amada JapanDocument11 pagesSaftyguide - Laser - e Amada JapanHLNo ratings yet

- Laser Safety Policy ManualDocument45 pagesLaser Safety Policy Manual3oo14 NileshNo ratings yet

- Ionizing Radiation Audit ChecklistDocument25 pagesIonizing Radiation Audit Checklistaden72No ratings yet

- Quick Start Summary: Radiological SafetyDocument50 pagesQuick Start Summary: Radiological SafetyMahmoud Nouh MohamedNo ratings yet

- NRRC SG 013Document17 pagesNRRC SG 013Ahmed shabanNo ratings yet

- Duties and Responsibilities of Industrial RPODocument40 pagesDuties and Responsibilities of Industrial RPOJie DVNo ratings yet

- AERB Safety Guide 2018Document206 pagesAERB Safety Guide 2018sudhir kumarNo ratings yet

- Raycus C6600SDocument52 pagesRaycus C6600SLeandro PotrinoNo ratings yet

- V-500iA ManualDocument229 pagesV-500iA ManualKien Nguyen TrungNo ratings yet

- Laser Safety ManualDocument80 pagesLaser Safety Manualburcin.unlu161No ratings yet

- Laser Registration Form - 121619Document7 pagesLaser Registration Form - 121619BIO HPNo ratings yet

- LaserSelfDiagnostic32 35Document40 pagesLaserSelfDiagnostic32 35AnamikaGiNo ratings yet

- Laser Safety Beam PDFDocument3 pagesLaser Safety Beam PDFKomkep MHJSNo ratings yet

- 7 10 General IndustrialDocument6 pages7 10 General IndustrialFazle Riaz KhanNo ratings yet

- Clso Exam Ref 19Document39 pagesClso Exam Ref 19Urología GinecológicaNo ratings yet

- Radiation Safety and AlaraDocument2 pagesRadiation Safety and AlarawesmorangaNo ratings yet

- 64-Laser Safety ManualDocument12 pages64-Laser Safety ManualROSSINo ratings yet

- ICFO Slides Part 2Document33 pagesICFO Slides Part 2Bhavesh ChauhanNo ratings yet

- NHMSFAP As X Ray and Radiation SafetyDocument16 pagesNHMSFAP As X Ray and Radiation Safetymohadese EstajiNo ratings yet

- CS S 14WeldingandGrindingSafety - Rev1 PDFDocument9 pagesCS S 14WeldingandGrindingSafety - Rev1 PDFnqh2009No ratings yet

- Oil Gas Offshore Safety Case (Risk Assessment) : August 2016Document44 pagesOil Gas Offshore Safety Case (Risk Assessment) : August 2016Andi SuntoroNo ratings yet

- Aerb DX 2016Document52 pagesAerb DX 2016hiteshNo ratings yet

- Process Safety ManagementDocument5 pagesProcess Safety Managementpatrickandreas77100% (2)

- Personnel Monitoring in Radiation Facilities FINAL JUNE 2020Document20 pagesPersonnel Monitoring in Radiation Facilities FINAL JUNE 2020L SILPANo ratings yet

- Radiation Protection ProgramDocument13 pagesRadiation Protection ProgramShane RequiermeNo ratings yet

- Laser Module 5Document25 pagesLaser Module 5Luis Enrique B GNo ratings yet

- LaserSafety Medical&ClinicalAppsDocument12 pagesLaserSafety Medical&ClinicalAppsRavish BangreNo ratings yet

- VJA 3330 3130 Lesson 1 SafetyDocument42 pagesVJA 3330 3130 Lesson 1 Safetyjohn smithNo ratings yet

- 5 1 9-Breathing-ApparatusDocument13 pages5 1 9-Breathing-ApparatusRafael Barbosa MeloNo ratings yet

- Oil Gas Offshore Safety Case (Risk Assessment) : Pbt750@mun - CaDocument43 pagesOil Gas Offshore Safety Case (Risk Assessment) : Pbt750@mun - CaUlviyye ElesgerovaNo ratings yet

- Oil Gas Offshore Safety Case (Risk Assessment) : Pbt750@mun - CaDocument43 pagesOil Gas Offshore Safety Case (Risk Assessment) : Pbt750@mun - CaUlviyye ElesgerovaNo ratings yet

- 3.1 - Vibration v3.1 EnglishDocument16 pages3.1 - Vibration v3.1 EnglisheliezerNo ratings yet

- NISP-RP-009, RadiographyDocument22 pagesNISP-RP-009, RadiographyRafael MercadoNo ratings yet

- Rockwell Laser Industries - Laser Safety Training and Consulting BrochureDocument16 pagesRockwell Laser Industries - Laser Safety Training and Consulting Brochurer_paura100% (1)

- Laser Safety PDFDocument39 pagesLaser Safety PDFcarlos_eqn100% (1)

- Risk Assessment Lift PDFDocument36 pagesRisk Assessment Lift PDFnsadnanNo ratings yet

- XRay RPP v8Document9 pagesXRay RPP v8Kirito-sanRyuukaNo ratings yet

- Certified Radiation Protection Officer (RPO) FinalDocument3 pagesCertified Radiation Protection Officer (RPO) FinalأحمدآلزهوNo ratings yet

- Procedure - Hazard Identification and Risks AssesmentDocument4 pagesProcedure - Hazard Identification and Risks AssesmentMarjorie Dulay Dumol0% (1)

- Vdoc - Pub Radiation Safety Officer Survival HandbookDocument60 pagesVdoc - Pub Radiation Safety Officer Survival HandbookESTSS TrainingNo ratings yet

- Radiation Safety ProgramDocument40 pagesRadiation Safety ProgramKhalid AbeedNo ratings yet

- XL80 Training Manual (Part 3)Document48 pagesXL80 Training Manual (Part 3)Anonymous swGC2IGNo ratings yet

- Ionising Radiations Code of Practice and Guidance Controlled AreasDocument7 pagesIonising Radiations Code of Practice and Guidance Controlled AreasLenaj EbronNo ratings yet

- The Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsFrom EverandThe Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsRating: 3.5 out of 5 stars3.5/5 (14)

- Bmus Safety Guidelines 2009 Revision Final Nov 2009Document17 pagesBmus Safety Guidelines 2009 Revision Final Nov 2009VonLoutsosNo ratings yet

- Opinion: Ultrasound Is Not Unsound, But Safety Is An IssueDocument4 pagesOpinion: Ultrasound Is Not Unsound, But Safety Is An IssueVonLoutsosNo ratings yet

- 11h00 Olsson MR 21 Saturday Session 2Document6 pages11h00 Olsson MR 21 Saturday Session 2VonLoutsosNo ratings yet

- Ni Hms 517878Document16 pagesNi Hms 517878VonLoutsosNo ratings yet

- Laser Safe ManDocument45 pagesLaser Safe ManVonLoutsosNo ratings yet

- RPT 73Document70 pagesRPT 73VonLoutsosNo ratings yet

- Laser Safety Is orDocument5 pagesLaser Safety Is orVonLoutsosNo ratings yet

- Media 287686 enDocument44 pagesMedia 287686 enVonLoutsosNo ratings yet

- Laser PolicyDocument33 pagesLaser PolicyVonLoutsosNo ratings yet

- Lenovo Y50Document2 pagesLenovo Y50VonLoutsosNo ratings yet

- Laser Safety ManualDocument30 pagesLaser Safety ManualVonLoutsosNo ratings yet

- B&G Quantum XM 50 Owners ManualDocument0 pagesB&G Quantum XM 50 Owners ManualVonLoutsosNo ratings yet

- Lenovo Y50Document2 pagesLenovo Y50VonLoutsosNo ratings yet

- Case Analysis: Beth OwensDocument8 pagesCase Analysis: Beth OwensPhillip CookNo ratings yet

- Date SissyDocument5 pagesDate SissyFletcher Irvine50% (2)

- C50SCR PLC Complete ManualDocument286 pagesC50SCR PLC Complete ManualthuanNo ratings yet

- (Jill E. Thistlethwaite) Values-Based Interprofess (B-Ok - CC)Document192 pages(Jill E. Thistlethwaite) Values-Based Interprofess (B-Ok - CC)Ria Qadariah AriefNo ratings yet

- Damasco - Cpi - Activity No. 10Document18 pagesDamasco - Cpi - Activity No. 10LDCU - Damasco, Erge Iris M.No ratings yet

- Microporous WikiDocument2 pagesMicroporous WikiIris BalcarceNo ratings yet

- Mock Test MCQ 2017Document18 pagesMock Test MCQ 2017Alisha ChopraNo ratings yet

- Quiz BowlDocument36 pagesQuiz BowlSherry GonzagaNo ratings yet

- Kernberg, O. (1991) - A Contemporary Reading of On Narcissism in Freud's On Narcissism An IntroductionDocument10 pagesKernberg, O. (1991) - A Contemporary Reading of On Narcissism in Freud's On Narcissism An IntroductionAngelina Anastasova100% (2)

- PC110R 1 S N 2265000001 Up PDFDocument330 pagesPC110R 1 S N 2265000001 Up PDFLuis Gustavo Escobar MachadoNo ratings yet

- TextDocument3 pagesTextKristineNo ratings yet

- Pentacon Six-02Document28 pagesPentacon Six-02Melissa Moreira TYNo ratings yet

- E4-E5 - Text - Chapter 2. ISO 9001-2015 QUALITY MANAGEMENT SYSTEMDocument17 pagesE4-E5 - Text - Chapter 2. ISO 9001-2015 QUALITY MANAGEMENT SYSTEMAGM S&M-CMNo ratings yet

- 9 - 1 H Wood Cabinet Spec Options NelDocument8 pages9 - 1 H Wood Cabinet Spec Options NelinformalitybyusNo ratings yet

- Review Dynamic Earth CoreScienceDocument3 pagesReview Dynamic Earth CoreScienceVikram BologaneshNo ratings yet

- Technician's Instructions Estetica E30Document142 pagesTechnician's Instructions Estetica E30виктор100% (1)

- Harvard Referencing GuideDocument6 pagesHarvard Referencing GuideKhánh Nguyên VõNo ratings yet

- 18-MCE-49 Lab Session 01Document5 pages18-MCE-49 Lab Session 01Waqar IbrahimNo ratings yet

- Tropical Fruit CHAPTER-3Document32 pagesTropical Fruit CHAPTER-3Jeylan FekiNo ratings yet

- Air Compressors: Instruction, Use and Maintenance ManualDocument66 pagesAir Compressors: Instruction, Use and Maintenance ManualYebrail Mojica RuizNo ratings yet

- Research Essay Final Draft 1Document4 pagesResearch Essay Final Draft 1api-614550036No ratings yet

- ReclosersDocument28 pagesReclosersSteven BeharryNo ratings yet

- 27nov12 PA Task Force On Child Protection ReportDocument445 pages27nov12 PA Task Force On Child Protection ReportDefendAChildNo ratings yet

- Keith UrbanDocument2 pagesKeith UrbanAsh EnterinaNo ratings yet

- தமிழ் உணவு வகைகள் (Tamil Cuisine) (Archive) - SkyscraperCityDocument37 pagesதமிழ் உணவு வகைகள் (Tamil Cuisine) (Archive) - SkyscraperCityAsantony Raj0% (1)

- EASA Ops ProceduresDocument11 pagesEASA Ops ProceduresMoslem Grimaldi100% (4)

- Protein Metabolism and Urea Recycling in Rodent HibernatorsDocument5 pagesProtein Metabolism and Urea Recycling in Rodent HibernatorsBud Marvin LeRoy RiedeselNo ratings yet

- Bsbfia401 3Document2 pagesBsbfia401 3nattyNo ratings yet

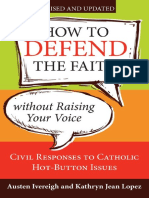

- How To Defend The Faith Without Raising Your VoiceDocument139 pagesHow To Defend The Faith Without Raising Your VoiceCleber De Souza Cunha100% (2)

- Executive SummaryDocument2 pagesExecutive Summarykulsoomalam100% (1)