Professional Documents

Culture Documents

Bukling Lab Report

Uploaded by

kenjosroy1Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bukling Lab Report

Uploaded by

kenjosroy1Copyright:

Available Formats

Aim:-

To determine critical buckling loads for the given material with different kinds of

support and to examination the Euler theory of buckling.

Theory:-

If a rod is subjected to longitudinal forces it can fail in two ways. On the one hand,

it can be plasticized and flattened if its admissible compressive strain is exceeded.

On the other hand, it is possible that it will suddenly shift to one side and buckle

before attaining the admissible compressive strain. This effect is called buckling.

The shape of the rod is the factor determines which of the two cases of failure will

occur. A slender, thin rod is more likely to buckle than a thick, stout rod.

Euler Formula

Buckling occurs suddenly and without warning when a certain limit load is

attained. It is therefore an extremely dangerous type of failure, which must be

avoided by all means. As, soon as a rod begins to buckle, it will become deformed

to the point of total destruction. This is typical unstable behavior. Buckling is a

stability problem. The critical limit load Fcrit, above which buckling can occur, is

dependent on both the slenderness of the rod, i.e. influence of length and

diameter, and the material used. In order to define slenderness the slenderness

ratio will be introduced here.

= lk/i

In this case lk is the characteristic length of the rod. It takes both the actual length

of the rod and the mounting conditions into consideration. For example, clamping

the ends of the odds causes rigidity. The buckling length decisive for slenderness

is shorter than the actual length of the rod. Altogether, a differentiation is made

between four types of mountings, each having a different buckling length. The

influence of diameter in the slenderness ratio is expressed by the inertia radius i.

It is calculated using the minimum geometrical moment of inertia ly and the cross-

sectional area A.

i = (ly /A )^(1/2)

The influence of material is taken into consideration by the longitudinal rigidity of

the rod EA. Here, E is the modulus of elasticity of the respective material and A is

the cross-sectional area. The influence of various factors on the critical load are

summarized in the so-called Euler formula":

Fcrit = (Pie)*(Pie)*E*Iy/A

Influencing Factors

Below the influence of various characteristic values such as the E modulus,

geometric moment of inertia, length and the type of mounting on buckling

behavior will be examined using the Euler formula.

E modulus

The E modulus is a measure of the rigidity of a material. A stiff material is sensible

for high resistance to buckling. Since strength has no influence on buckling,

materials with as high an E modulus as possible should be used.

Geometric moment of inertia

The geometric moment of inertia indicates the resistance against deflection

resulting from the cross-sectional shape of the rod. Since a rod buckles in the

direction of least resistance, the minimum geometric moment of inertia is the

decisive factor.

Buckling length

The length of the rod as well as the type of mounting determines the buckling

length 1k. The influence of the length is quadratic. At twice the length the

admissible load is only one-fourth the original value.

Description of Apparatus:-

The test device mainly consists of a basic frame, the guide columns and the load

cross bar.

The basic frame contains the bottom mounting for the rod specimen, consisting

of a force-measuring device for measuring the testing force and an attachment

socket which can hold different pressure pieces for realizing various storage

conditions.

The height of the load cross bar can be adjusted along the guide columns and it

can be clamped in position. This allows rod specimens with different buckling

lengths to be examined. The load cross bar features a load spindle for generating

the test force. Using the load nut, the test force is applied to the rod specimen via

guided thrust pieces. An axial mounting between the load nut and the thrust

piece prevents torsional stresses from being applied to the rod specimen.

Experimental Procedure:-

1. Insert thrust piece with V notch into attachment socket and fasten with

clamping screw

2. Insert long thrust piece with V notch into the guide bush of the load cross-bar

and hold it firmly

3. Insert the first specimen with edges in the V notch.

4. Fix it properly on both ends

5. Slowly subject the specimen to load using the load nut.

6. Record the reading when the buckling load reaches a constant value

7. Repeat the experiment for other specimen

8. Do it for Fixed-Fixed and Fixed-Pin case

9. Pre-tighten the specimen with some tensile load in Fixed-Fixed case

Results:-

You might also like

- Charpy Test: Aim:-To Determine The Amount of Energy Absorbed During FractureDocument4 pagesCharpy Test: Aim:-To Determine The Amount of Energy Absorbed During Fracturekenjosroy1No ratings yet

- Impact of JetDocument7 pagesImpact of Jetkenjosroy1No ratings yet

- IC Engine LabDocument5 pagesIC Engine Labkenjosroy1No ratings yet

- Flow MeasurementDocument9 pagesFlow Measurementkenjosroy1No ratings yet

- Capillary Rise Experiment ReportDocument2 pagesCapillary Rise Experiment Reportkenjosroy157% (7)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Sliding Contact Bearings - DmeDocument47 pagesSliding Contact Bearings - DmeSumitNo ratings yet

- Physical Chemistry II (Quantum Mechanics) Spring Semester 2006Document8 pagesPhysical Chemistry II (Quantum Mechanics) Spring Semester 2006Bhavesh AroraNo ratings yet

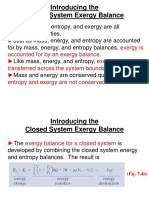

- Closed System Exergy BalanceDocument14 pagesClosed System Exergy BalanceJamshidNo ratings yet

- Linear Momentum: Question Paper 2Document13 pagesLinear Momentum: Question Paper 2Mulei KithyaNo ratings yet

- Wellplan: Ypfb ChacoDocument18 pagesWellplan: Ypfb ChacobeymarNo ratings yet

- Tutorial With Solution - DiffractionDocument5 pagesTutorial With Solution - DiffractionKiran KumarNo ratings yet

- Previous Year Questions - EM WAVESDocument11 pagesPrevious Year Questions - EM WAVESYuvrajNo ratings yet

- SPX Curve BookDocument38 pagesSPX Curve BookCarlos Alberto Ramirez GarciaNo ratings yet

- Simulation of Gas Flow in Microchannels With A SuddenDocument11 pagesSimulation of Gas Flow in Microchannels With A SuddenAyoub HaranjaNo ratings yet

- JUJ 08 BAHAN SEMINAR GURU FizikDocument86 pagesJUJ 08 BAHAN SEMINAR GURU Fizikalianabila_79No ratings yet

- LCT Deck Strength Check (Simulation Only)Document17 pagesLCT Deck Strength Check (Simulation Only)SanieBurhanNo ratings yet

- SPIRE 206-Railway Tower-FOS2.0-5.4SQM - Trunkate To 15mDocument147 pagesSPIRE 206-Railway Tower-FOS2.0-5.4SQM - Trunkate To 15mmithunNo ratings yet

- MSE 2103 - Lec 12 (7 Files Merged)Document118 pagesMSE 2103 - Lec 12 (7 Files Merged)md akibhossainNo ratings yet

- HW5 PracticexDocument6 pagesHW5 PracticexMehran ShahNo ratings yet

- BalancingDocument2 pagesBalancingV DhinakaranNo ratings yet

- Pipe Ut TelDocument16 pagesPipe Ut TelS N satyanarayanaNo ratings yet

- MMM336 - Compute Fluid DynamicsDocument119 pagesMMM336 - Compute Fluid DynamicsSam Wang Chern PengNo ratings yet

- FEA Assignment No 1 Shivaji UniversityDocument8 pagesFEA Assignment No 1 Shivaji Universityashutosh khanvilkarNo ratings yet

- Course Outline in General Physics 1Document5 pagesCourse Outline in General Physics 1Jin SenpaiNo ratings yet

- Aakash Physics Study Package 5 SolutionsDocument134 pagesAakash Physics Study Package 5 SolutionsfociweNo ratings yet

- Elements JointsDocument52 pagesElements JointssdsdsdnNo ratings yet

- SPE/IADC-190008-MS Advancing The Mud Gas Separator Sizing Calculation: The MPD PerspectiveDocument11 pagesSPE/IADC-190008-MS Advancing The Mud Gas Separator Sizing Calculation: The MPD PerspectiveDiego AraqueNo ratings yet

- PPDocument12 pagesPPsanto_r05No ratings yet

- 6.1 Angles & Their MeasureDocument6 pages6.1 Angles & Their MeasureMiles BaldersNo ratings yet

- LG - PSHSCVC - Grade10 - Physics2 - Potential DifferenceDocument8 pagesLG - PSHSCVC - Grade10 - Physics2 - Potential DifferenceqwertyNo ratings yet

- Phase RuleDocument3 pagesPhase Rulekalyanivishal777No ratings yet

- Automotive Connecting RodDocument6 pagesAutomotive Connecting Rodlukasz199567No ratings yet

- Sea Pressure Loads Calculation Based On DNV RulesDocument6 pagesSea Pressure Loads Calculation Based On DNV RulesMarian LazarNo ratings yet

- Chemistry Notes Class 11 Chapter 6 ThermodynamicsDocument16 pagesChemistry Notes Class 11 Chapter 6 ThermodynamicsFazrin Fadzili43% (7)

- Centripetal Force Multiple Choice QuestionsDocument3 pagesCentripetal Force Multiple Choice QuestionsMalaika ChaudharyNo ratings yet