Professional Documents

Culture Documents

Cambio Shimano

Uploaded by

ourthingOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cambio Shimano

Uploaded by

ourthingCopyright:

Available Formats

General Safety Information Specifications Chain length Inserting the inner cable

Insert the inner cable into the outer casing from the end with the marking on it. Apply

Add 2 links (with the chain on both the largest grease from the end with the marking in order to

Largest sprocket Largest chainring

WARNING Rear Derailleur maintain cable operating efficiency.

sprocket and the largest chainring)

• Check that the wheels are fastened securely before riding the bicycle. If the wheels are loose in any Model number RD-M530

Marking

way, they may come off the bicycle and serious injury may result. Type SGS

• Use neutral detergent to clean the chain. Do not use alkali-based or acid based detergent such as Cutting the outer casing

Gears 8

rust cleaners as it may result in damage and/or failure of the chain. Chain When cutting the outer casing, cut the opposite end to the end

• Use the reinforced connecting pin only for connecting the narrow type of chain. Total capacity 45T with the marking. After cutting the outer casing, make the end

• There are two different types of reinforced connecting pins available. Be sure to check the table below Largest sprocket 34T

round so that the inside of the hole has a uniform diameter.

before selecting which pin to use. If connecting pins other than reinforced connecting pins are used,

or if a reinforced connecting pin or tool which is not suitable for the type of chain is used, sufficient Smallest sprocket 11T Installation of the lever Attach the same outer end cap to the cut end

connection force may not be obtained, which could cause the chain to break or fall off. of the outer casing. Outer end cap

Front chainwheel tooth difference 22T

Use a handlebar grip with a maximum outer diameter of 32 mm.

Reinforced

Chain Chain tool

connecting pin Cassette sprocket tooth combination SL-M410 ST-M410

9-speed super narrow chain Gears Group name Tooth combination

such as Silver TL-CN32/TL-CN23

CN-7701 / CN-HG93 an 11, 13, 15, 17, 20, 23, 26, 30T Be careful not to bend

6.5mm

The sealed cap with tongue and the rubber shield Rubber shield

8- / 7- / 6-speed narrow 8 ao 11, 13, 15, 17, 20, 23, 26, 34T should be installed to the outer casing stopper of

chain such as Black TL-CN32/TL-CN23 the frame.

CN-HG50 / CN-IG51 7.1mm aw 11, 13, 15, 18, 21, 24, 28, 32T Sealed cap with tongue

• If it is necessary to adjust the length of the chain due to a change in Reinforced Connecting Pin

the number of sprocket teeth, make the cut at some other place than Rapidfire Plus

the place where the chain has been joined using a reinforced Model number ST-M410 / SL-M410

connecting pin or an end pin. The chain will be damaged if it is cut at 5 mm Allen key 5 mm Allen key

Gears 8 Rubber shield

a place where it has been joined with a reinforced connecting pin or End Pin Link Pin

an end pin. Tightening torque : Tightening torque :

• Check that the tension of the chain is correct and that the chain is not damaged. If the tension is too Freehub 5 N·m 6 - 8 N·m

weak or the chain is damaged, the chain should be replaced. If this is not done, the chain may break {44 in lbs.} {53 - 69 in. lbs.} 4. How to use the B-tension adjustment screw

Model number FH-MC18 / FH-RM40-8 Mount the chain on the smallest chainring and Largest sprocket

and cause serious injury. SL-M410 Smallest sprocket

the largest sprocket, and turn the crank arm 2

• Obtain and read the service instructions carefully prior to installing the parts. Loose, worn, or Gears 8 2

damaged parts may cause injury to the rider. Install the brake lever in a position where it will not obstruct brake operation. Do not use in backward. Then turn the B-tension adjustment

No. of spoke holes 36 / 32 a combination which causes brake operation to be obstructed. screw to adjust the guide pulley as close to the

We strongly recommend only using genuine Shimano replacement parts.

• Read these Technical Service Instructions carefully, and keep them in a safe place for later reference. sprocket as possible but not so close that it

touches. Next, set the chain to the smallest

SIS Adjustment sprocket and repeat the above to make sure that 1 2

Note the pulley does not touch the sprocket. 1

B-tension

• Adjust the RD-M530 reverse spring type rear derailleur from the low side.

• If gear shifting operations do not feel smooth, wash the derailleur and lubricate all moving parts.

Gear shifting operation Installation of the chain 1 adjustment screw

Install the chain with the Pro-Set alignment block still

• If the amount of looseness in the links is so great that adjustment is not possible, you should replace Both lever (A) and lever (B) always return to the initial position when they are released after

attached.

the derailleur. shifting. When operating one of the levers, always be sure to turn the crank arm at the same time. 5. SIS Adjustment

After installing, remove the Pro-Set alignment block.

• You should periodically clean the derailleur and lubricate all moving parts (mechanism and pulleys). Push lever (B) while turning the crank arm to move the derailleur to the largest

• If gear shifting adjustment cannot be carried out, check the degree of parallelism at the rear end of sprocket. Then operate lever (A) once to move the derailleur to the 2nd-gear sprocket.

the bicycle. Also check if the cable is lubricated and if the outer casing is too long or too short.

To shift from a large sprocket to a To shift from a small sprocket to a larger Turn the crank arm to set the derailleur to the low

smaller sprocket (Lever A) sprocket (Lever B) After this, operate lever (A) just as far as the extent of play, and then turn the crank

• If you hear abnormal noise as a result of looseness in a pulley, you should replace the pulley. position.

arm.

• If the wheel becomes stiff and difficult to turn, you should lubricate it with grease. To shift one step only, press lever (A) to the (1) Press lever (B) once to shift one step from a Pro-Set alignment block

• Do not apply any oil to the inside of the hub, otherwise the grease will come out. position. To shift two steps at one time, press smaller to a larger sprocket. When changing to 3rd 23 When no noise is heard 23

• You should periodically wash the sprockets in a neutral detergent and then lubricate them again. In to the (2) position. at all

addition, cleaning the chain with neutral detergent and lubricating it can be a effective way of 1. Low adjustment

extending the useful life of the sprockets and the chain. Turn the low adjustment screw so that the

Lever (A) initial position

• If the chain keeps coming off the sprockets during use, replace the sprockets and the chain. guide pulley moves to a position directly in

1 line with the largest sprocket.

• Always be sure to use the sprocket set bearing the same group marks. Never Group marks

Largest

sprocket

use in combination with a sprocket bearing a different group mark.

• Use a frame with internal cable routing is strongly discouraged as it has Guide pulley

1 2 Adjustment bolt 23 Adjustment bolt 23

ag - 18T 2

tendencies to impair the SIS shifting function due to its high cable resistance. ag -15

T Low adjustment

ag

-1

3T 2 1 screw

• Use an outer casing which still has some length to spare even when the

handlebars are turned all the way to both sides. Furthermore, check that the

shifting lever does not touch the bicycle frame when the handlebars are turned Lever (B)

SH

all the way. 2. Top adjustment

IM

Outer line of

AN

O

HYPERGL I DE - C

smallest sprocket Turn the cable adjustment bolt Turn the cable adjustment bolt

• Grease the inner cable and the inside of the outer casing before use to ensure Turn the crank arm while pulling the derailleur with

1 2 clockwise to tighten it until the chain counterclockwise to loosen it until the

that they slide properly. your hand to move the derailleur to the top position, returns to the 2nd sprocket. chain touches a sprocket and

• For smooth operation, use the specified outer casing and the bottom bracket cable guide. and then turn the top adjustment screw to adjust so * Turn the adjustment bolt together with the generates noise.

• Operation of the levers related to gear shifting should be made only when the front chainwheel is that the guide pulley is in line with the outer line of outer casing adjustment barrel cover. * Turn the adjustment bolt together with the

turning.

• Parts are not guaranteed against natural wear or deterioration resulting from normal use.

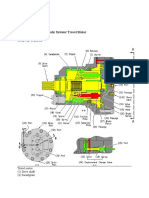

Installation of the rear derailleur the smallest sprocket when looking from the rear.

Guide pulley 1 2 outer casing adjustment barrel cover.

Turn the crank arm to set the derailleur to the low

• For maximum performance we highly recommend Shimano lubricants and maintenance products. When installing, be careful not to position. Top adjustment

screw

• For any questions regarding methods of installation, adjustment, maintenance or operation, please let the B-tension adjustment screw 5 mm Allen key

contact a professional bicycle dealer. come into contact with the dropout Best setting

tab, otherwise deformation may B-tension The best setting is when the cable adjustment bolt is tightened (turned clockwise) until

result. adjustment

screw

3. Connecting and securing the inner cable Lever (B)

noise occurs without lever (A) being operated, and then loosened (turned

Do not remove the Pro-Set Operate lever (B) 7 times or more, and check on the counterclockwise) 90 - 180 degrees from that point.

alignment block at this time. indicator that the lever is at the lowest position. Then

remove the inner hole cover and connect the inner cable. Operate lever (A) to change gears, and check that no noise occurs in any of the gear

positions.

Bracket spindle tightening torque: Dropout tab

8 - 10 N·m {70 - 86 in. lbs.}

Inner cable

Inner hole cover

For the best SIS performance, periodically lubricate all power-transmission parts.

Install the inner hole cover by turning it as shown in the Replacement of the freewheel body

Installation of the sprockets illustration until it stops.

Technical Service Instructions SI-0026B Do not turn it any further than this, otherwise it may After removing the hub axle, remove the FH-MC18 / FH-RM40-8

U mark damage the screw thread. freewheel body fixing bolt (inside the

A Freewheel body Freewheel body fixing bolt

For each sprocket, the surface that has the group mark ac -14T freewheel body), and then replace the

should face outward and be positioned so that the triangle Tightening torque :

freewheel body. Disassembly

0.3 - 0.5 N·m {3 - 4 in. lbs.}

(U) mark on each sprocket and the A part (where the Note:

Rear Drive System groove width is wide) of the freewheel body are aligned.

The groove is wide

at one place only.

Inner hole cover

Do not attempt to disassemble

the freewheel body, because it may result

Connect the inner cable to Assembly

the derailleur as shown in in a malfunction.

Note: Be sure that the cable is Freewheel body washer

the illustration. securely in the groove.

ab

11T

IM

A NO

HYP

ER

G

Tightening torque: 10 mm Allen key (TL-WR37)

35 - 50 N·m {305 - 434 in. lbs.}

H

S

L I

m

DE

4 0 0 kg /c

- C

J AP

CK

Groove

In order to realize the best performance, we recommend that the following combination be used.

LO

AN

9 U

25 .S

. PA

T 4268

Series Alivio

This service instruction explains how to use and maintain the Shimano bicycle parts

Rapidfire Plus ST-M410 / SL-M410 The 6 sprockets are secured by which have been used on your new bicycle. For any questions regarding your bicycle or

means of rivets.

Outer casing SP40 Lock ring other matters which are not related to Shimano parts, please contact the place of

purchase or the bicycle manufacturer.

Rear derailleur RD-M530

For installation of the HG sprockets, use the special tool

Type SGS (TL-LR15) to tighten the lock ring.

Freehub FH-MC18 / FH-RM40-8 Lock ring Connect the cable to the rear derailleur and, after taking up the initial

Tightening torque:

Gears 8 30 - 50 N·m {261 - 434 in. lbs.} slack in the cable, re-secure to the rear derailleur as shown in the

illustration. One Holland, Irvine, California 92618, U.S.A. Phone: +1-949-951-5003

Cassette sprocket CS-HG50-8I

To replace the HG sprockets, use the special tool (TL-LR15) Pull

Tool

Chain CN-HG50 / CN-HG40 and TL-SR21 to remove the lock ring. TL-LR15 (TL-SR21) Industrieweg 24, 8071 CT Nunspeet, The Netherlands Phone: +31-341-272222 3-77 Oimatsu-cho Sakai-ku, Sakai, Osaka 590-8577, Japan

Tightening torque :

Bottom bracket cable guide SM-SP17 / SM-BT17 / SM-SP18 / SM-BT18 Disassembly 5 - 7 N·m {44 - 60 in. lbs.} Please note: specifications are subject to change for improvement without notice. (English)

© Feb. 2006 by Shimano Inc. XBC SZK Printed in Singapore

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 2009 3560ton Lowboys Web PDFDocument55 pages2009 3560ton Lowboys Web PDFFelipe Pan Iturra Ramirez100% (2)

- Tyre Stock RegisterDocument35 pagesTyre Stock RegisterSalman KhanNo ratings yet

- VOLVO XC70 2006 Wiring Diag.Document328 pagesVOLVO XC70 2006 Wiring Diag.Florentin Manea100% (4)

- Volvo MD2002 OnderdelenDocument2 pagesVolvo MD2002 OnderdelenFrank ReusenNo ratings yet

- SACAA ATPL ATG SyllabusDocument12 pagesSACAA ATPL ATG SyllabusOsa Aig100% (1)

- Schematics (Engine Controlsfuel - 1.0L - 1.19L - or 1.2L)Document9 pagesSchematics (Engine Controlsfuel - 1.0L - 1.19L - or 1.2L)Data TécnicaNo ratings yet

- SD XLS Unit 6172 To TBD 2015 OctDocument36 pagesSD XLS Unit 6172 To TBD 2015 OctMark RitcheyNo ratings yet

- Deutz F4L912 engine specifications and componentsDocument9 pagesDeutz F4L912 engine specifications and componentsnemoneoNo ratings yet

- Optra 2006 ECM Connector PDFDocument3 pagesOptra 2006 ECM Connector PDFYulys Teresa Diaz Freites100% (1)

- CRV WiringDocument308 pagesCRV WiringJATC100% (3)

- Tadano Faun GR - 700EXDocument21 pagesTadano Faun GR - 700EXForomaquinas100% (1)

- Automatic Transmission - F4A42 PDFDocument100 pagesAutomatic Transmission - F4A42 PDFSyed Mustaqim Al-Shahabudin100% (7)

- N61 1491 000 000 TPE331 10TurbopropEngine BroDocument2 pagesN61 1491 000 000 TPE331 10TurbopropEngine BroDima George100% (1)

- Diesel Smoke Diagnostic InformationDocument1 pageDiesel Smoke Diagnostic InformationLuis JesusNo ratings yet

- Canyon MTB PLDocument64 pagesCanyon MTB PLgrazka20No ratings yet

- PropellerDocument25 pagesPropellerNima ConquistadorNo ratings yet

- Ajusa Tip14 IngDocument6 pagesAjusa Tip14 IngLeito vilaNo ratings yet

- SM - VOLVO L180F WHEEL LOADER Service Repair ManualDocument8 pagesSM - VOLVO L180F WHEEL LOADER Service Repair ManualEng-AhmedRashad0% (3)

- 330C Excavator Hydraulic System/ Travel MotorDocument4 pages330C Excavator Hydraulic System/ Travel Motorjohn ayengahNo ratings yet

- GAZELLE Brochure UK OptDocument97 pagesGAZELLE Brochure UK Optboblenaze0% (1)

- Certificate III Light Vehicle Mechanic CourseDocument2 pagesCertificate III Light Vehicle Mechanic Coursesai kumar reddyNo ratings yet

- Caterpillar 3412 Marine Engine Details, Specs, Features & ExtrasDocument5 pagesCaterpillar 3412 Marine Engine Details, Specs, Features & ExtrasTobias BengtsenNo ratings yet

- (IRFCA) Brake Systems Used by IRDocument4 pages(IRFCA) Brake Systems Used by IREr Rajesh BuraNo ratings yet

- All-New CAPTUR BrochureDocument40 pagesAll-New CAPTUR BrochureLuke AustinNo ratings yet

- Magura HS 11/33Document16 pagesMagura HS 11/33Nebojša TepićNo ratings yet

- Project ReportDocument65 pagesProject ReportMusical world100% (1)

- Yanmar L100v6ej1chas1 PLDocument18 pagesYanmar L100v6ej1chas1 PLHolleeNo ratings yet

- Lash Valve SB213023 (E7)Document2 pagesLash Valve SB213023 (E7)Carlos Enrique Vega OrtegaNo ratings yet

- DDFP Detroit 12 SER V71 PDFDocument92 pagesDDFP Detroit 12 SER V71 PDFzona amrullohNo ratings yet

- TM 5-2420-222-34P John Deere JD 410 Backhoe LoaderDocument701 pagesTM 5-2420-222-34P John Deere JD 410 Backhoe LoaderAdvocate100% (4)