Professional Documents

Culture Documents

Taier TD

Uploaded by

MrDarera0 ratings0% found this document useful (0 votes)

420 views2 pagesRate of heat transfer between the turbogenerator and its surroundings is related to the surface temperature Tb and the lower ambient temperature T0. An inventor claims that at steady state the device shown in Fig. P6. Develops power from entering and exiting streams of water at a rate of 1174. KW. Kinetic and potential energy effects are negligible. Evaluate the inventor's claim.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentRate of heat transfer between the turbogenerator and its surroundings is related to the surface temperature Tb and the lower ambient temperature T0. An inventor claims that at steady state the device shown in Fig. P6. Develops power from entering and exiting streams of water at a rate of 1174. KW. Kinetic and potential energy effects are negligible. Evaluate the inventor's claim.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

420 views2 pagesTaier TD

Uploaded by

MrDareraRate of heat transfer between the turbogenerator and its surroundings is related to the surface temperature Tb and the lower ambient temperature T0. An inventor claims that at steady state the device shown in Fig. P6. Develops power from entering and exiting streams of water at a rate of 1174. KW. Kinetic and potential energy effects are negligible. Evaluate the inventor's claim.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

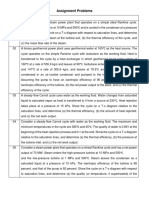

6.

59 A power plant has a turbogenerator, shown in

Fig. P6.59, operating at steady state with an input

shaft rotating at 1800 RPM with a torque of 16,700

Nm. The turbogenerator produces current at 230

amp with a voltage of 13,000 V. The rate of heat

transfer between the turbogenerator and its

surroundings is related to the surface temperature

Tb and the lower ambient temperature T0, and is

given by:

Q = - h A (Tb - T0)

where h=110 W/m2*K; A=32 m2, and T0=298 K.

(a) Determine the temperature Tb, in K. (b) For the

turbogenerator as the system, determine the rate

of entropy production, in kW/K. (c) If the system

boundary is located to take in enough of the

nearby surroundings for heat transfer to take place

at temperature T0, determine the rate of entropy

production, in kW/K, for the enlarged system.

6.87 An inventor claims that at steady state the

device shown in Fig. P6.87 develops power from

entering and exiting streams of water at a rate of

1174.9 kW. The accompanying table provides data

for inlet 1 and exits 3 and 4. The pressure at inlet 2

is 1 bar. Stray heat transfer and kinetic and

potential energy effects are negligible. Evaluate the

inventors claim.

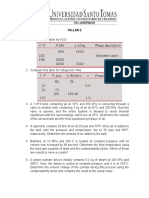

6.135 Figure P6.135 shows a simple vapor power

cycle operating at steady state with water as the

working fluid. Data at key locations are given on

the figure. Flow through the turbine and pump

occurs isentropically. Flow through the steam

generator and condenser occurs at constant

pressure. Stray heat transfer and kinetic and

potential energy effects are negligible. Sketch the

four processes of this cycle in series on a Ts

diagram. Determine the thermal efficiency.

.

6.167 As shown in Fig. P6.167, a well-insulated

turbine operating at steady state has two stages in

series. Steam enters the first stage at 800F, 600

lbf/in.2 and exits at 250 lbf/in.2 The steam then

enters the second stage and exits at 14.7 lbf/in.2

The isentropic efficiencies of the stages are 85%

and 91%, respectively. Show the principal states on

a Ts diagram. At the exit of the second stage,

determine the temperature, in F, if superheated

vapor exits or the quality if a two-phase liquid

vapor mixture exits. Also determine the work

developed by each stage, in Btu per lb of steam

flowing.

You might also like

- Principles of Thermodynamics NotesDocument12 pagesPrinciples of Thermodynamics NotesSaniya SohailNo ratings yet

- Ejercicios TermodinamicaDocument7 pagesEjercicios TermodinamicaJavier Lopez VegaNo ratings yet

- Problemario MFCDocument80 pagesProblemario MFCBassaldua AlfreedNo ratings yet

- Problemario MFCDocument31 pagesProblemario MFCPonce MrlnNo ratings yet

- Homework #10 PDFDocument3 pagesHomework #10 PDFAnonymous nHya4Z4No ratings yet

- Thermodynamics II Assignment 3: C R I H H I R H HDocument2 pagesThermodynamics II Assignment 3: C R I H H I R H HPriyanshuNo ratings yet

- Adv Therm Week 10Document16 pagesAdv Therm Week 10Tegin Berkay BudakNo ratings yet

- Ejercicios TermodinamicaDocument3 pagesEjercicios TermodinamicaJavier Lopez VegaNo ratings yet

- Tarea 10 TermodinamicaDocument5 pagesTarea 10 TermodinamicaMario GonzalezNo ratings yet

- Home WorkDocument3 pagesHome WorkMalik Ahsan MahotaNo ratings yet

- ETD - Question BankDocument6 pagesETD - Question BankGopinath VNo ratings yet

- Me2202 - EtDocument7 pagesMe2202 - EtAnonymous mRBbdopMKfNo ratings yet

- PPE AssignmentDocument3 pagesPPE AssignmentAshish Kumar SahuNo ratings yet

- TutorialDocument12 pagesTutorialJohnson MangumaNo ratings yet

- Assignment-4 ModDocument2 pagesAssignment-4 ModSai naveenNo ratings yet

- 3.feb 321 - Assignment Sheet 3Document1 page3.feb 321 - Assignment Sheet 3Timothy SimirenNo ratings yet

- Assignment No 2Document4 pagesAssignment No 2Ravi DuttaNo ratings yet

- Assignment ProblemsDocument2 pagesAssignment ProblemsRam SharmaNo ratings yet

- Tutorial Problem: Entropy: T T S MC TTDocument1 pageTutorial Problem: Entropy: T T S MC TTAditya TiwariNo ratings yet

- Homework #7Document3 pagesHomework #7Sebastián SantarrosaNo ratings yet

- Soal Latihan Termodinamika IIDocument5 pagesSoal Latihan Termodinamika IIPur NomoNo ratings yet

- Assignment and Its Solution - Airstandardcycle and VapourcycleDocument24 pagesAssignment and Its Solution - Airstandardcycle and VapourcycleMatthias100% (1)

- Applications of First LawDocument12 pagesApplications of First LawHarminder SinghNo ratings yet

- β= T T T T E T Q Q: Tutorial Sheet 5 (Document6 pagesβ= T T T T E T Q Q: Tutorial Sheet 5 (deshrajNo ratings yet

- QUESTION BANK ThermodynamicsDocument6 pagesQUESTION BANK Thermodynamicsvikas_1989No ratings yet

- Kevon JohnsonDocument11 pagesKevon JohnsonCharlotte BNo ratings yet

- 4 - Gas Power CycleDocument4 pages4 - Gas Power CycleMohamed MohamedNo ratings yet

- Assign - Engg. ThermodynamicsDocument8 pagesAssign - Engg. ThermodynamicsSagarZopeNo ratings yet

- BookDocument2 pagesBookaref GhorbaniNo ratings yet

- AssimentDocument3 pagesAssimentSantosh SharmaNo ratings yet

- GP CycleDocument11 pagesGP Cyclerajasekar KNo ratings yet

- ThermoDocument3 pagesThermopranavNo ratings yet

- Channabasaveshwara Institute of Technology: (NAAC Accredited & An ISO 9001:2015 Certified Institution)Document2 pagesChannabasaveshwara Institute of Technology: (NAAC Accredited & An ISO 9001:2015 Certified Institution)cenu 1999No ratings yet

- Faculty of Engineering Department of Mechanical and Marine Engineering Thermodynamics (TDN620S)Document4 pagesFaculty of Engineering Department of Mechanical and Marine Engineering Thermodynamics (TDN620S)Wilbard IitulaNo ratings yet

- AdsorptionDocument3 pagesAdsorptionali105No ratings yet

- Latihan Soal-Soal Sistem Tenaga GasDocument6 pagesLatihan Soal-Soal Sistem Tenaga GasDhira GunawanNo ratings yet

- Contoh Soal TermodinamikaDocument24 pagesContoh Soal TermodinamikaDea FarhaniNo ratings yet

- Problemas Sugeridos EntropíaDocument1 pageProblemas Sugeridos EntropíaMercedes VidalNo ratings yet

- Thermo of MechDocument2 pagesThermo of MecheyobNo ratings yet

- Midterm Exam Me 322aDocument1 pageMidterm Exam Me 322aStephanie ParkNo ratings yet

- Assig1-Due On Feb 1,2018Document3 pagesAssig1-Due On Feb 1,2018Graeme KendallNo ratings yet

- Agricultural Engg Thermodynamics Final Exam Fall 2016 Che 212Document2 pagesAgricultural Engg Thermodynamics Final Exam Fall 2016 Che 212falmubaddelNo ratings yet

- Tarea de CiclosDocument6 pagesTarea de CiclosSebastiánGarcía100% (1)

- Tutorial Vapor and Combined Power CyclesDocument3 pagesTutorial Vapor and Combined Power CyclesShariff Mohamad Fairuz0% (1)

- Exercise PyeqDocument2 pagesExercise PyeqNaufal SyafiqNo ratings yet

- Exercise of Thermodynamics - Sept292016Document4 pagesExercise of Thermodynamics - Sept292016bro0% (1)

- Tutorial Sheet 02 2014Document11 pagesTutorial Sheet 02 2014checkmeout803No ratings yet

- Introduction To Chemical Engineering ThermodynamicDocument3 pagesIntroduction To Chemical Engineering ThermodynamicR SuyaoNo ratings yet

- AET Question Bank For AUC R2013 - SDocument5 pagesAET Question Bank For AUC R2013 - SGurunath AeroNo ratings yet

- Qbank 18me32 BTDDocument6 pagesQbank 18me32 BTDAmaresh Movies ASNo ratings yet

- Addis Ababa UniversityDocument2 pagesAddis Ababa Universitydeni ebit nugroho100% (1)

- Assignment 3Document2 pagesAssignment 3api-3802845No ratings yet

- Problem Sheet-03 ME201 1st LawDocument2 pagesProblem Sheet-03 ME201 1st LawPratyusha SatpathyNo ratings yet

- Assignment 1Document1 pageAssignment 1Billy LimNo ratings yet

- Taller 2 2023-1Document8 pagesTaller 2 2023-1anderson ortizNo ratings yet

- Wor ShopDocument4 pagesWor ShopDavid Santiago Ayala RodriguezNo ratings yet

- Worksheet Thermo I PDF 1Document13 pagesWorksheet Thermo I PDF 1roba angasuNo ratings yet

- HW3 (2) Thermo UEM Aerospace 2021Document1 pageHW3 (2) Thermo UEM Aerospace 2021Marina Gil JimenezNo ratings yet

- 32 Article 5Document10 pages32 Article 5MrDareraNo ratings yet

- A Couple Problems SolutionDocument3 pagesA Couple Problems SolutionMrDareraNo ratings yet

- DOC316.53.01153 8ed PDFDocument6 pagesDOC316.53.01153 8ed PDFHugo Armando Iral MaldonadoNo ratings yet

- Medición Del Manganeso Por El Método PANDocument6 pagesMedición Del Manganeso Por El Método PANMrDareraNo ratings yet

- Pat 1-4 PDFDocument17 pagesPat 1-4 PDFMrDareraNo ratings yet

- IEM c3-1 PDFDocument62 pagesIEM c3-1 PDFdinamo1948No ratings yet

- Generator EdcDocument77 pagesGenerator EdcAJAY KUMAR100% (1)

- Aruna Biomass-Company-ProfileDocument8 pagesAruna Biomass-Company-ProfileAdhavan ThamizhanNo ratings yet

- Rakesh Kumar: BHEL HaridwarDocument25 pagesRakesh Kumar: BHEL Haridwarparth038No ratings yet

- Solutions For Nuclear Power IndustryDocument9 pagesSolutions For Nuclear Power IndustryАлександр ВишняковNo ratings yet

- Transient Thermal VibrationDocument18 pagesTransient Thermal VibrationJarot PrakosoNo ratings yet

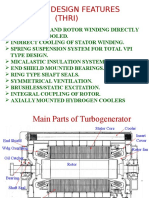

- Turbogenerators Gyanendra Sharma NPTI DelhiDocument36 pagesTurbogenerators Gyanendra Sharma NPTI DelhiNPTINo ratings yet

- Hy Turbo Generator enDocument18 pagesHy Turbo Generator enHeri SetyantoNo ratings yet

- Nuclear Power Plant Hydrogen CoolingDocument7 pagesNuclear Power Plant Hydrogen Coolingrizky kateNo ratings yet

- BHEL Reference Manuals S.No Manual DescriptionDocument4 pagesBHEL Reference Manuals S.No Manual DescriptionShubhamPrinceNo ratings yet

- O&M Manual 500 MW TurboGeneratorDocument448 pagesO&M Manual 500 MW TurboGeneratorAnubhav Srivastav100% (9)

- Operation and Mainetance Manual of Dongfang 300mw Steam Turbine Generator Unit-1Document728 pagesOperation and Mainetance Manual of Dongfang 300mw Steam Turbine Generator Unit-1Adeta GitaNo ratings yet

- WEG Turbogenerator 10174576 Manual English PDFDocument58 pagesWEG Turbogenerator 10174576 Manual English PDFShivaShankarNo ratings yet

- Training Module BHELDocument97 pagesTraining Module BHELMouryaChakradharNageshNo ratings yet

- Electrical ResumeDocument4 pagesElectrical Resumerasakatla jaswanthNo ratings yet

- Gigatop 4 Pole Hydrogen and Water Cooled Turbogenerator PDFDocument8 pagesGigatop 4 Pole Hydrogen and Water Cooled Turbogenerator PDFJiHoon Lee100% (1)

- Type Testing of Generator TransformerDocument6 pagesType Testing of Generator TransformerAnonymous BBX2E87aHNo ratings yet

- Pages From Electrical Insulation For Rotating Machines - Design, Evaluation, Aging, Testing, and Repair-7Document5 pagesPages From Electrical Insulation For Rotating Machines - Design, Evaluation, Aging, Testing, and Repair-7Muhammad AsimNo ratings yet

- IEM c3 PDFDocument62 pagesIEM c3 PDFdinamo1948No ratings yet

- Services For Turbogenerator Rotor Rewinds: NEC's Full-Service Rewind Facility Competes With The OEMDocument1 pageServices For Turbogenerator Rotor Rewinds: NEC's Full-Service Rewind Facility Competes With The OEMShanjiNo ratings yet

- BHELDocument51 pagesBHELanuboraNo ratings yet

- Sketch ThriDocument35 pagesSketch ThrisahilNo ratings yet

- Optimal Scheme For Structural Design of Large Turbogenerator Stator End WindingDocument10 pagesOptimal Scheme For Structural Design of Large Turbogenerator Stator End WindingmanojkumarNo ratings yet

- Designing TurbogeneratorDocument6 pagesDesigning TurbogeneratorMadhan GopalNo ratings yet

- 220089enb Generator DesignDocument58 pages220089enb Generator DesignMahmoud ElboraeNo ratings yet

- SNPP2019 EngDocument16 pagesSNPP2019 EngShanon RustoffNo ratings yet

- Siemens AG: Generator Load LimitsDocument1 pageSiemens AG: Generator Load LimitsArnab PalNo ratings yet

- My - Project EzejiDocument13 pagesMy - Project EzejiJoseph IsraelNo ratings yet

- AHVISITCTGDocument5 pagesAHVISITCTGVamshi RajNo ratings yet

- Brush Dax Generadores Dax - 2 - PoleDocument4 pagesBrush Dax Generadores Dax - 2 - PoleHernan GirautNo ratings yet