Professional Documents

Culture Documents

CCB82C3Cd01 PDF

Uploaded by

Italo ChiarellaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CCB82C3Cd01 PDF

Uploaded by

Italo ChiarellaCopyright:

Available Formats

New Challenges with Substations utilizing

Communication Networks

Dr. Fred Steinhauser

Dr. Fred Steinhauser is with OMICRON electronics, A-6833 Klaus, Austria.

Abstract--The new series of standards IEC 61850 about

Communication Networks and Systems in Substations is on its

way. By applying these communication systems in substations,

totally new challenges arise for the planning, commissioning and

operation of those installations. This paper addresses some of

these challenges and anticipates how the solutions could look like.

Index Terms--Substation Communications, IEC 61850,

Substation Network, Intelligent Electronic Device, Configuration,

Testing.

I. NOMENCLATURE

ASN.1 Abstract Syntax Notation One

CT Current Transformer

GOOSE Generic Object Oriented Substation Event

IEC International Electrotechnical Commission

IED Intelligent Electronic Device

IPSec IP Security

MMS Manufacturing Messaging Specification

OSI Open System Interconnection

PT Potential Transformer

SV Sampled Value

SCL Substation Configuration description Language

SSL Secure Sockets Layer

TC57 Technical Committee No. 57 of the IEC, Power

System Control and Associated Communications

TCP/IP Transmission Control Protocol / Internet Protocol

XML Extensible Markup Language

II. INTRODUCTION

The common name of the IEC 61850 series of standards is

Communications Networks and Systems in Substations. It

consists of several parts and sections, focussing on distinct

issues. Most parts are finalized ore were already issued as

standards, while others ([3], [5]) approach the final phase. The

working groups intend to have the standard complete until end

of 2003. Some prominent device vendors have already

announced first compatible devices for 2004 [1].

The application of the IEC 61850 in real installations will

have effects on many aspects during the whole lifecycle of a

substation installation. Communication equipment will become

an integral part of the substation installation.

In the planning phase, suitable equipment has to be

selected, appropriate communication architectures have to be

chosen, and the logical device interconnections have to be

configured.

During commissioning, the network infrastructure has to be

put in place, the communication parameters, such as IP

addresses, have to be set up before the actual function

parameters are configured into the devices. Testing the

installation requires the use of protocol aware testing tools to

analyze the data streams on the network.

For operation, maintenance and routine testing, a subset of

the tasks performed during commissioning may be performed,

requiring similar skills and tools.

This might look frightening on the first view, but smart

tools will support the engineers in their work, allowing them to

exploit the benefits which are offered by the new technology.

III. COMMUNICATION INFRASTRUCTURE

A. Substation Networks

The communication infrastructure is guided by the choice

of Ethernet for the network layers. There have been concerns

because of the non-deterministic nature of Ethernet, but in the

meanwhile it is widely accepted that this technology can be

used for this purpose. One important benefit of using this

established technology is the instant availability of a wide

range of products.

Components for the communication system like cables,

connectors, hubs, switches, and routers have to be selected.

For the cabling, the optical fiber is an obvious choice. It

avoids galvanic couplings and provides excellent noise

immunity.

To guide the data streams effectively and to utilize the

present bandwidth in the best possible way, the use of network

switches instead of simple hubs will be imposed. Different

priorities will be assigned to distinct types of messages on the

network. The established feature of priority tagging is

proposed to perform this, so the network devices must support

this.

Paper accepted for presentation at 2003 IEEE Bologna Power Tech Conference, June 23th-26th, Bologna, Italy

0-7803-7967-5/03/$17.00 2003 IEEE

Reliability is very important for components in a substation.

The communication network becomes the backbone of the

substation, being a "mission critical" component. One way to

achieve this is redundancy. The standard does not impose

redundancy, but the system integrator may choose such

networking topologies. On the other hand, network

technologies offer supervision functions to check also inactive

connections for availability, while a broken wire in a classical,

hard wired binary I/O loop would remain undetected.

B. Communication Capabilities for Substation Devices

Developing a communication unit to make an IED "speak"

IEC 61850 can be a challenging task. For the first generation

of devices, adding a communication unit to existing, well

proven protective relays, RTUs, transducers, etc. will be the

most common choice. Some large vendors will have several

reasons to start their own developments. They aim to higher

volumes and have the development resources and expertise in

house. Other vendors will find it more difficult to spend

resources for developing a communication hardware and to

port the protocol stack on it. Modeling the device functions in

logical nodes according to the standard and mapping the data

items is another task to be performed. Purchasing such

components and services from specialized suppliers can be a

faster and more efficient way to obtain an IEC 61850

compliant product.

IV. PROTOCOLS

A. Application Protocols

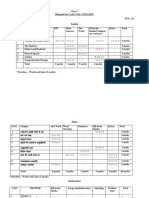

Depending on the application, purpose, and nature of the

transmitted data, different services and application protocols

are defined (see Fig. 1).

Reading and writing the functions parameters (the logical

node data), logging, and reporting are implemented as client-

server services. These services need not to be handled in real

time and can have lower priority.

Status information, like trip commands, is transmitted via

GOOSE messages. From this, the high priority of these

messages becomes obvious. Nevertheless, the GOOSE

mechanism is designed to be robust. The system will not fail if

a GOOSE gets lost for whatever reason. Beside this, the

content of a GOOSE is configurable, e.g. it could also contain

measurands.

The sampled values (SV) from CTs and PTs contain the

instantaneous values of the primary quantities and have to be

transferred in a fixed time frame and without any losses.

Sufficient bandwidth has to be provided to assure this.

B. Transport Protocols

Different transport mechanisms are used for the application

protocols. For the client-server services, MMS over TCP/IP

(and also OSI transport) will be used. For transmitting the real

time services GOOSE and SV, some layers of the OSI model

will be skipped to increase performance (see Fig. 1).

The device vendors will undertake measures to keep these

layers and the related problems away from the users.

Conformance tests at the vendor's laboratories or at

independent test institutes should ensure compatibility of the

transport layers and interoperability for the applications.

IEC 61850-10 [5] gives guidance how these conformance tests

have to be performed. This is not a new topic. Already during

the introduction of the IEC 60870-5 protocols, communication

problems have showed up. The vendors resolved these

problems to be able to deliver interoperable products. In the

meanwhile, the link layer implementations are so mature that

problems on this level have almost disappeared.

C. Security

For the data inside the substation, restricting physical

access to the substation and network components will be the

most effective security measure. An intruder in the substation

can easily cause much more damage with very simple means

than by forging data packets on the substation networks, which

requires high sophisticated tools and skills. But at least when

the data get in or out of the substation, data security becomes a

topic. Cryptography is the keyword to address this issue.

WG15 of TC57 works on security solutions for the substation

protocols. Standard internet security solutions like SSL and

IPSec seem to be applicable for use in substation

communication as well.

Client-Server-

Services

IEC 61850-8-1

GOOSE

IEC 61850-

8-1

SV

IEC 61850-

9-2

MMS

ASN.1

TCP/

IP

OSI

Ethernet

Fig. 1. Simplified diagram of IEC 61850 protocols and communication layers

V. APPLICATIONS

A. Skills

Of course, substation engineers will acquire more and more

networking skills in the future, but it must not be a necessary

precondition that a substation engineer is a communications

expert to perform his work in a IEC 61850 equipped

substation. The same applies for the engineering of a

substation.

New tools will be needed to handle these issues. One focus

will be to maintain the established procedures. For example,

the planning system has to serve the IED database with

configuration data as defined in the SCL. Where new

procedures and tools must be introduced to account for the

new nature of certain components, they must be implemented

in the language of the utility engineer. To continue the above

example, during commissioning the IEDs can be initialized

using the data from the IED database.

The network related issues must be clearly separated from

application issues, so the utility engineer can focus on his main

tasks.

B. Profiling

To make efficient use of the data communication features

and to gain a competitive advantage out of it, any user must

make a useful selection how he will apply the features

provided by the standard in his systems. This experience had

already been made with IEC 60870-5-101, which also provides

a wide variety of options how the features can be used. Re-

inventing addressing schemes and mappings for any new

substation is for sure ineffective, so users have generally set up

rules to use the same features in the same way in all their

installations. These rules are called a profile of the protocol.

The application specific protocol IEC 60870-5-103 is a profile

of the IEC 60870-5-101 which has become even a standard by

itself. Such a profiling for restricting variety to a reasonable

level will be also necessary for IEC 61850. The size of the

group joining the profiling process has essential effect on the

outcome. A larger group will most likely bring in more

different requirements, leaving more variance in the resulting

profile or having the need for many detailed, sparsely used

conventions. On the other hand, most commercial benefits can

be expected when a profile applies to a large group of users

and many applications. Again, the restriction of variety is the

key for commercial benefits. The room for utility specific

protection philosophies is getting narrower in order to achieve

effectiveness.

C. Common Data Repository

IEC 61850-6 [3] defines how the IED configuration and

substation configuration information has to be structured. It

uses XML for the configuration description.

The different configuration tools from the different vendors

produce a variety of configuration information for the devices,

from which only a part is aggregated in the substation

configuration file. Other configuration data, like logical

function programming, marshalling, etc., is not covered by

IEC 61850. Nevertheless, there is a natural need to integrate

also these data on the substation level. IEC 61850-6 provides

options for this in the SCL, the so called private data. Inside

these entities, vendors can pack their own, proprietary data that

they need for their proprietary functions. It should be an easy

task to provide plug-ins for vendor independent tools to view

or manipulate these proprietary data. The schema awareness of

the SCL supports this. The need for vendor specific setting

tools would be significantly reduced, which is not only an

advantage for the user of substation equipment. Also relay

manufacturers who have different setting programs for any

relay model or family could benefit from this. In the long run,

the vendors could get rid of maintaining their setting software

and concentrate on their core competences in protection.

Substation

Configuration

Database

IEDs

Device

Models

Engineering

Tools

Testing

Tools

Device Setting

Tools

(legacy)

Device

Browser

(generic)

Self Description

Fig. 2. Vision of the central data repository serving multiple applications

D. Interoperability and Interchangeability

Users of substation equipment have a natural desire for

interchangeability of the devices, and there were hopes that

IEC 61850 could serve this need. Despite this, it has been

emphasized that IEC 61850 provides interoperability, but not

interchangeability. This is obvious since the logical nodes hold

the actual parameters of the device functions. Interoperability

means that any logical node has to issue and accept the same

parameters in the same format, but it does not assure that two

devices would have the same parameter values when they are

set for the same protection task. This is because the actual

implementation of a function is not part of IEC 61850, the

vendors will still use their individual algorithms, which they

regard as best suited to perform a certain task. The setting

rules for different relays will most likely lead to different

setting values when applied for the same protection task. For

instance, two distance relays from different vendors will have

different settings for the resistive and reactive reach for

covering the same percentage of the line length or providing

comparable arc resistance tolerance.

When interchanging devices, it must be made sure that the

function parameters match the protection task. In the worst

case, the whole setting rules must be applied again for the new

relay. There are more straightforward cases, like interchanging

a IDMT overcurrent relay or a "classical" Mho-relay by

another, since most of these have identical function principles,

independent of the vendor.

VI. PRACTICAL EXPERIENCES

Although many parts of the standard are not published yet,

there have already been several demonstrations of prototypes.

From this prototype work, very essential experience and

knowledge for the implementation of released products could

be gained.

The first demonstration of this kind was a setup utilizing

GOOSE messaging, which was presented at the UCA

Substation Interoperability Demonstration in Vancouver in

May 2001. The demonstration setup consisted of a protection

test set, two protective relays, and a CB-simulator. All

components communicated via GOOSE. The test simulated a

power system fault and one relay issued a trip command. The

other relay performed the autoreclosure function and issued a

CB-on command. The CB-simulator operated on the

commands and signaled the actual breaker position. All events

involved were recorded and visualized by the test set.

Fig. 3. GOOSE Demonstration setup in Vancouver 2001

The prototype hardware used in this early stage was not

optimized. There is considerably processing involved for the

GOOSE handling, as ASN.1 coding and decoding of the

messages, but even with this simple equipment, a satisfactory

timing performance could be achieved. The trip command was

also monitored in parallel via a conventional, hard-wired

binary I/O circuit. It appeared that the GOOSE arrived faster

than the output contact of the relay, so the delay through the

communication stacks was less than the mechanical delay of a

binary output contact. The network was an unswitched

Ethernet running on 10Mbit/s, while the standard proposes the

use of network switches and 100Mbit/s. Of course, the

configuration was still rudimentary at this stage; it was done

via XML files which had to be copied manually. Taking all the

aspects into account, this demonstration was a clear proof of

the concept.

In 2002, a setup with the protocol for SVs according to

IEC 61850-9-1 was demonstrated at several occasions. Each

participating vendor supplied a merging unit and a protective

relay; an energy meter was involved as well. To prove the

interoperability, the merging unit of one vendor supplied the

relay / meter of the other vendor with the SVs from the

process. Also the feature of concatenating multiple samples

into one Ethernet packet was already used in this

implementation. This method is provided for keeping packet

rate and network load low while using an increased sampling

rate for the data. Four samples were concatenated together at a

packet rate of 1kHz, giving the signal processing system a

sample rate of 4kHz for the process values.

At the CIGR 2002 exhibition in Paris, a complete process

bus implementation, utilizing both SVs and GOOSE signaling

was demonstrated. The system consisted of a compact

switchgear with non-conventional CT and PT, a feeder

controller, and a feeder protection. The whole signaling was

done over the Ethernet without conventional hard-wired

connections between the devices.

VII. CONCLUSIONS

IEC 61850 offers many new options and benefits. To

exploit the benefits, some preconditions have to be met.

Certain new skills will have to be acquired, but new tools

will support the users on their application level.

Although not yet fully defined and finished, the SCL

concept promises many advantages, such as consistent

description of the device and substation configuration and the

possibility to use vendor independent software tools.

Profiling to reduce variety is crucial for the efficient use of

the features. Experiences already made with IEC 60870-5-101

can be re-used in this process.

With these preconditions in place, the utility engineer can

again concentrate on his main task: to use the equipment in an

optimized way for the reliable and economical generation,

transmission, and distribution of electric energy.

VIII. REFERENCES

Conference Proceedings (Published):

[1] Proceedings of FGH/VDN Fachtagung Kommunikationsnormung fr

die Schutz- und Stationsleittechnik IEC 61850 - Der Weg in die Praxis,

March 2003, Mannheim.

Standards:

[2] Final Draft for International Standard IEC 61850-5. Part 5:

Communication Requirements for Functions and Device Models. IEC

document number 57/604/RVC.

[3] Committee Draft for Vote for IEC 61850-6. Part 6: Substation

Automation System Configuration Description Language. IEC

document number 57/614/CDV.

[4] Committee Draft for Vote for IEC 61850-8-1. Part 8-1: Specific

Communication Service Mapping (SCSM) - Mapping to MMS

(ISO/IEC 9506 Part 1 and Part 2) over ISO 8802-3. IEC document

number 57/617/CDV.

[5] Committee Draft for IEC 61850-10. Part 10: Conformance Testing. IEC

document number 57/634/CD.

IX. BIOGRAPHIES

Fred Steinhauser was born in Feldkirch, Austria, in 1960. He studied at the

Technical University of Vienna, where he obtained his diploma in 1986 and

received a Dr. of Technical Sciences in 1991.

From 1990 to 1998 he worked for SCAPA Group plc, specializing in

process control and automation for the production of forming fabrics.

In 1998 he joined OMICRON as project engineer, where he worked on

several aspects of testing power system protection. Since 2000 he works as a

product manager with a focus on applications and new technologies, includ-

ing substation communication issues. Fred Steinhauser is a member of the

WG12 in the TC57 of the IEC working on the standard IEC 61850.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The IT System That Couldn't Deliver SummaryDocument3 pagesThe IT System That Couldn't Deliver SummaryWnsyuhada Ismail100% (1)

- Fis-Opf Ach PaymentsDocument5 pagesFis-Opf Ach PaymentscrazytrainNo ratings yet

- Mean Deviation of Grouped Data - LPDocument4 pagesMean Deviation of Grouped Data - LPKishi Nissi Dela CruzNo ratings yet

- Yi Ming 2003Document7 pagesYi Ming 2003Italo ChiarellaNo ratings yet

- Observation of Frequency Oscillation in Western Japan 60Hz Power System Based On Multiple Synchronized Phasor MeasurementsDocument6 pagesObservation of Frequency Oscillation in Western Japan 60Hz Power System Based On Multiple Synchronized Phasor MeasurementsItalo ChiarellaNo ratings yet

- A Fast and Efficient Method For Frequency Deviation Measurement Based On Genetic Algorithms Using A FPGA ApproachDocument6 pagesA Fast and Efficient Method For Frequency Deviation Measurement Based On Genetic Algorithms Using A FPGA ApproachItalo ChiarellaNo ratings yet

- Synchronous MachineDocument10 pagesSynchronous MachineItalo ChiarellaNo ratings yet

- A Fast Electric Load Forecasting UsingDocument6 pagesA Fast Electric Load Forecasting UsingItalo ChiarellaNo ratings yet

- 0 FF349 BEd 01Document6 pages0 FF349 BEd 01Italo ChiarellaNo ratings yet

- 0 AE549 BEd 01Document6 pages0 AE549 BEd 01Italo ChiarellaNo ratings yet

- A Uniform Line Model For Non-Uniform Single-Phase Lines With Frequency Dependent Electrical ParametersDocument6 pagesA Uniform Line Model For Non-Uniform Single-Phase Lines With Frequency Dependent Electrical ParametersItalo ChiarellaNo ratings yet

- 5 A58243 FD 01Document8 pages5 A58243 FD 01Italo ChiarellaNo ratings yet

- Simulation of The Impact of Wind Power On The Transient Fault BehaviorDocument10 pagesSimulation of The Impact of Wind Power On The Transient Fault Behaviormanigopal123No ratings yet

- Abdel Akher2014Document6 pagesAbdel Akher2014Italo ChiarellaNo ratings yet

- 141020131617446117500Document8 pages141020131617446117500Italo ChiarellaNo ratings yet

- Operating Stationary Fuel Cells On Power System and Micro-GridsDocument6 pagesOperating Stationary Fuel Cells On Power System and Micro-GridsItalo ChiarellaNo ratings yet

- Street Light by Using ZigbeeDocument5 pagesStreet Light by Using ZigbeeRohit Khodke100% (1)

- CD2 B2 C3 CD 01Document4 pagesCD2 B2 C3 CD 01Italo ChiarellaNo ratings yet

- Stochastic Assessment of Unbalanced Voltage Dips in Large Transmission SystemsDocument8 pagesStochastic Assessment of Unbalanced Voltage Dips in Large Transmission SystemsItalo ChiarellaNo ratings yet

- Replicating Interruptible Supply Contracts For Security Constrained Transmission ManagementDocument7 pagesReplicating Interruptible Supply Contracts For Security Constrained Transmission ManagementItalo ChiarellaNo ratings yet

- Applications of Optical Current and Voltage Sensors in High-Voltage SystemsDocument4 pagesApplications of Optical Current and Voltage Sensors in High-Voltage SystemsItalo ChiarellaNo ratings yet

- Analysing Negative Skewness of Spot Returns in The Australian Electricity MarketDocument7 pagesAnalysing Negative Skewness of Spot Returns in The Australian Electricity MarketItalo ChiarellaNo ratings yet

- A6 E733 C1 D 01Document7 pagesA6 E733 C1 D 01Italo ChiarellaNo ratings yet

- Technological Evolution of MV Equipment and Structure NetworkDocument5 pagesTechnological Evolution of MV Equipment and Structure NetworkItalo ChiarellaNo ratings yet

- Direct Load Control As A Market-Based Program in Deregulated Power IndustriesDocument4 pagesDirect Load Control As A Market-Based Program in Deregulated Power IndustriesItalo ChiarellaNo ratings yet

- An Efficient Multi-Objective Meta-Heuristic Method For Distribution Network Expansion PlanningDocument6 pagesAn Efficient Multi-Objective Meta-Heuristic Method For Distribution Network Expansion PlanningItalo ChiarellaNo ratings yet

- Power System Stability Improvement by Energy Storage Type STATCOMDocument7 pagesPower System Stability Improvement by Energy Storage Type STATCOMItalo ChiarellaNo ratings yet

- ACEE3 D87 D 01Document6 pagesACEE3 D87 D 01Italo ChiarellaNo ratings yet

- CA3 C2 C3 CD 01Document7 pagesCA3 C2 C3 CD 01Italo ChiarellaNo ratings yet

- CD9 C2 C3 CD 01Document8 pagesCD9 C2 C3 CD 01Italo ChiarellaNo ratings yet

- An Integrated Machine Learning Model For Day-Ahead Electricity Price ForecastingDocument7 pagesAn Integrated Machine Learning Model For Day-Ahead Electricity Price ForecastingItalo ChiarellaNo ratings yet

- A Dynamic SecurityDocument8 pagesA Dynamic SecurityItalo ChiarellaNo ratings yet

- 5 - Blueprint Cycle I UT - I (2022-23)Document4 pages5 - Blueprint Cycle I UT - I (2022-23)Monia PunyaniNo ratings yet

- MOCK Exams Submission TestDocument7 pagesMOCK Exams Submission TestPam MshweshweNo ratings yet

- Asus HS 1000W ManualDocument13 pagesAsus HS 1000W Manualbmmanuals0% (1)

- Land Surface TemperatureDocument10 pagesLand Surface Temperatureimane100% (1)

- TukacadDocument17 pagesTukacadajay kalangiNo ratings yet

- Introduction To IOTDocument8 pagesIntroduction To IOTAKASH S RNo ratings yet

- Advanced High-Capacity Synchronization Solution: Your BenefitsDocument6 pagesAdvanced High-Capacity Synchronization Solution: Your BenefitsTuan MANo ratings yet

- MVC Interview Questions AnswersDocument12 pagesMVC Interview Questions AnswersKapil SharmaNo ratings yet

- Classification Tree - Utkarsh Kulshrestha: Earn in G Is in Learnin G - Utkarsh KulshresthaDocument33 pagesClassification Tree - Utkarsh Kulshrestha: Earn in G Is in Learnin G - Utkarsh KulshresthaN MaheshNo ratings yet

- Endterm Exam Answers:jimenea PDFDocument5 pagesEndterm Exam Answers:jimenea PDFGilianne JimeneaNo ratings yet

- Assignment 4 CSE 205Document8 pagesAssignment 4 CSE 205Dewank SainiNo ratings yet

- Seminar Report On CyberneticsDocument67 pagesSeminar Report On CyberneticsSimmi JoshiNo ratings yet

- It Is Vital To Good Project Management To Be Meticulously Honest in Estimat Ing The Time Required To Complete Each of The Various Tasks Included in The Project. Note ThatDocument16 pagesIt Is Vital To Good Project Management To Be Meticulously Honest in Estimat Ing The Time Required To Complete Each of The Various Tasks Included in The Project. Note ThatSuraj SinghalNo ratings yet

- X6060520doss-OE OXYTOME 30E HPC HP125-N2W - JOSE SCHOIHET-CL.Document26 pagesX6060520doss-OE OXYTOME 30E HPC HP125-N2W - JOSE SCHOIHET-CL.Juan LopezNo ratings yet

- SecASC - M02 - Azure Security Center Setup and ConfigurationDocument53 pagesSecASC - M02 - Azure Security Center Setup and ConfigurationGustavo WehdekingNo ratings yet

- Vision: Electricity Bill Management SystemDocument25 pagesVision: Electricity Bill Management SystemDiyaN IrfaN sketcher and cartooning artNo ratings yet

- ResumeDocument1 pageResumeKevin Shui HuNo ratings yet

- Script-For-Library-Tour. 7.13.22Document1 pageScript-For-Library-Tour. 7.13.22Cyrus CorpuzNo ratings yet

- Auto Power ManualDocument97 pagesAuto Power ManualAngel100% (1)

- DBMSDocument28 pagesDBMSPratik JainNo ratings yet

- 300G Im 20121214Document4 pages300G Im 20121214Josue Vieira OliveiraNo ratings yet

- OMD-425 O2 AnalyzerDocument1 pageOMD-425 O2 Analyzerindra irawanNo ratings yet

- Punching Report - Unikl MsiDocument9 pagesPunching Report - Unikl MsiRudyee FaiezahNo ratings yet

- Computer Security EITA25: Final Exam inDocument6 pagesComputer Security EITA25: Final Exam inGeorges karamNo ratings yet

- Growth Marketing Final PresentationDocument17 pagesGrowth Marketing Final PresentationAmna AhmedNo ratings yet

- Chapters 1 - 6: - Chapter 6Document51 pagesChapters 1 - 6: - Chapter 6Delasdriana WiharjaNo ratings yet

- Alpha MaxDocument36 pagesAlpha Maxpezamarillo2No ratings yet