Professional Documents

Culture Documents

Spring Hanger & Piping Support Inspection

Uploaded by

Anibal Quezada100%(3)100% found this document useful (3 votes)

622 views20 pagesThe document provides technical specifications for conducting a spring hanger and piping support inspection at the Chilca Uno Combined Cycle Power Plant in Lima, Peru. It outlines the scope of inspecting hangers and supports for condition, design, installation, load settings, and compliance with standards. Documentation of the plant's piping systems will be provided to the winning bidder. The suggested schedule is for the inspection to occur in two phases - during plant operation from October 27-31 for hot settings, and during the November plant outage from November 20-25 for cold settings.

Original Description:

Original Title

TECHNICAL SPECIFICATIONS FOR SPRING HANGER AND PIPING SUPPORT INSPECTION FOR CHILCA UNO CCPP (REV8).docx

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides technical specifications for conducting a spring hanger and piping support inspection at the Chilca Uno Combined Cycle Power Plant in Lima, Peru. It outlines the scope of inspecting hangers and supports for condition, design, installation, load settings, and compliance with standards. Documentation of the plant's piping systems will be provided to the winning bidder. The suggested schedule is for the inspection to occur in two phases - during plant operation from October 27-31 for hot settings, and during the November plant outage from November 20-25 for cold settings.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

100%(3)100% found this document useful (3 votes)

622 views20 pagesSpring Hanger & Piping Support Inspection

Uploaded by

Anibal QuezadaThe document provides technical specifications for conducting a spring hanger and piping support inspection at the Chilca Uno Combined Cycle Power Plant in Lima, Peru. It outlines the scope of inspecting hangers and supports for condition, design, installation, load settings, and compliance with standards. Documentation of the plant's piping systems will be provided to the winning bidder. The suggested schedule is for the inspection to occur in two phases - during plant operation from October 27-31 for hot settings, and during the November plant outage from November 20-25 for cold settings.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 20

TECHNICAL SPECIFICATIONS FOR CONDUCTING SPRING HANGER & PIPING

SUPPORT INSPECTION FOR CHILCA UNO COMBINED CYCLE POWER PLANT

BACKGROUND

Our plant site is located in Lima, Peru. However most of the industrial components used

during plant erection were brought from the US, Europe and South Korea, and following this

lead, we have privileged since then direct contact with the OEM or its authorized distributors

therein...

As of now, we are interested in solely performing a spring hanger & pipe support inspection

that uncovers any problems or help us out in identifying options for improving our current

configuration.

From our standpoint it is clear that a hanger and support inspection must be implemented

the sooner the better. EnerSur has finally gathered as much information as readily available

at plant site project documentation library regarding pipe hangers and supports, it is almost

215 MB in size

Bearing in mind our HRSG units were built and erected as per ASME Section VIII 2007

Edition with 2009 Addenda & HEI, we will request that winner bidding company be certified

accordingly for performing this tasks. On this regard, EnerSur will appraise the most to

bidding companies whose personnel exhibit a technical background in excess of 5 years in

performing this task.

All tools and equipment to be used in these activities must have an updated certification for

conducting the tests as per ASME, NB, or MSS SP regulations applicable hereinwe will

apply the most stringent criteria whenever decision-making must be done.

PLANT AND ACC LIFE STATISTICS

a. Commercial Operation Date for HRSG Units # 11, #12 and #21 including Deaerator

and ACC was Thursday, November 15

th

2012.

b. Since then, our national grid coordinator, COES for short, has dispatched our plant

either partial or base load.

c. So far, our Operation and Maintenance logbooks have recorded some unit forced

outages and trips that are available upon request for further revision.

d. Our 3 X 1 combined cycle configuration encompasses three topping cycles and one

bottoming cycle.

The topping cycles include the following machines: two Siemens V84.3a2

combustion turbine units (SGT6-4000F) and one SGT6-5000F unit, also

coded as W501FD3

The bottoming cycle comprises three BHI heat recovery steam generators,

one GE D11 steam turbine unit, an SPX air cooled condenser and four

Hyundai boiler feedwater pumps plus a Deaerator vessel

SCOPE

Following Good Industry Practices, the appointed specialist company will conduct an

inspection of as-built, as-found support components for the power piping as laid out at plant

site premises to identify current problems and defects affecting them. It is our understanding

so far that they comply and conform with ASME B31.1, MSS SP 58 & MSS SP 127. If

additional standards, recommended practices or regulations are found to be applicable for

the purpose, both the winning bidder company and EnerSur will meet together for analyzing

pros and cons for the Chilca Uno project.

Hangers & supports are to be investigated for the following:

General condition of pipe supports and hangers and their components.

Poor support design.

Faulty installation.

Incorrect load settings.

Inappropriate instructions.

Deficient quality of support components

Proper hanger type selection.

Proper loading & movements.

Possible interfering edges which may hamper the piping expansions.

Attached herein, the winning bidder company will receive the following documentation:

Complete listing of both constant-load and variable-load supporting devices as laid

out at plant site (when finally they are confirmed to be as-built and ready/available for

submittal)

Hot & Cold Temperature Settings for all pipe supports & hangers as laid out at plant

site (when finally they are confirmed to be as-built and ready/available for submittal)

Technical drawings as per listing below.

If additional information is deemed necessary and this is not available at the time, the

winner bidding company is entitled to apply best industry practices and criteria in

agreement with EnerSur in order to correct, repair, and modify existing configuration

for the good.

Main goal for this activity is to increase reliability figures for

Power Piping System running along HRSG Units # 11, # 21 & # 31 and into Steam

Turbine Unit # 270T818 including both ACC & Deaerator facilities

TECHNICAL INFORMATION & DOCUMENTATION:

0-WD385-EP146-0001_HP STEAM SYSTEM.pdf

0-WD385-EP146-0002_COLD REHEAT SYSTEM.pdf

0-WD385-EP146-0003_HOT REHEAT SYSTEM.pdf

0-WD385-EP146-0004_FEED WATER SYSTEM.pdf

0-WD385-EP146-0005_LP STEAM SYSTEM.pdf

0-WD385-EP146-0006_AUX STEAM SYSTEM.pdf

0-WD385-EP146-0007_CONDENSATE SYSTEM.pdf

0-WD385-EP146-0008_STEAM DRAIN & EXHAUST HOOD WATER SPRAY SYSTEM.pdf

0-WD385-EP146-0009_STEAM SEAL SYSTEM.pdf

0-WD385-EP146-0010_BLOWDOWN WATER TRANSF SYSTEM.pdf

0-WD385-EP146-0011_FLASH BOX DRAIN SYSTEM.pdf

0-WD385-EP146-0012_FLASH TANK DRAIN SYSTEM.pdf

0-WD385-EP146-0013_BFP FW TANK AREA.pdf

0-WD385-EP146-0014_BYPASS VALUE STATION AREA.pdf

0-WD385-EP146-0016_CONDENSATE TANK PUMP AREA.pdf

0-WD385-EP146-0017_FIN FAN COOLER AREA.pdf

0-WD385-EP146-0018_HRSG AREA.pdf

0-WD385-EP146-0019_MAIN PIPE RACK AREA.pdf

0-WD385-EP146-0021_STG AREA.pdf

0-WD385-EP146-0022_WATER TREATMENT AREA.pdf

0-WD385-EP146-0023_STEAM BLOWING OUT SYSTEM.pdf

0-WD385-EP146-0024_CLOSED COOLING WATER SYSTEM.pdf

0-WD385-EP146-0025_SMALL BORE TYPICAL DRAWING.pdf

0-WD385-EP146-0026_SERVICE DEMI WATER SYSTEM.pdf

0-WD385-EP146-0027_ST INTERONECTING PIPING.pdf

0-WD385-EP244-00001_Painting Procedure.pdf

0-WD385-EP290-00001_Rev AB_AS BULT.pdf

0-WD385-EZ261-00001_WPS&PQR&CWL Procedure.pdf

0-WD385-EZ670-00001_Rev AB_AS BULT.pdf

0-WD385-EZ731-00002_Packing Procedure.pdf

0-WD385-EZ731-00003_Heat Treatment Procedure.pdf

0-WD385-EZ731-00004_Rev AB-AS BULT.pdf

\\ENERPECHISFSP01\Base de Datos\Base de Datos CC_Chilca Ciclo combinado\400

Engineering\402 HB HRSG\7.Piping

\\ENERPECHISFSP01\Base de Datos\Base de Datos CC_Chilca Ciclo combinado\400

Engineering\402 HB HRSG\7.Piping\[1&2-WD170-EP146-C0001] Pipe Support Drawings

\\ENERPECHISFSP01\Base de Datos\Base de Datos CC_Chilca Ciclo combinado\400

Engineering\402 HB HRSG\7.Piping\[3-WD170-EP146-C0001] Pipe Support Drawings

\\ENERPECHISFSP01\Base de Datos\Base de Datos CC_Chilca Ciclo combinado\400

Engineering\402 HB HRSG\7.Piping\[3-WD170-EP146-C0001] Pipe Support

Drawings\Rev.0\pdf

\\ENERPECHISFSP01\Base de Datos\Base de Datos CC_Chilca Ciclo combinado\400

Engineering\402 HB HRSG\7.Piping\[3-WD170-EP146-C0001] Pipe Support

Drawings\Rev.a\PDF

\\ENERPECHISFSP01\Base de Datos\Base de Datos CC_Chilca Ciclo combinado\400

Engineering\402 HB HRSG\7.Piping\[3-WD170-EP146-C0001] Pipe Support

Drawings\Rev.b\pdf

\\ENERPECHISFSP01\Base de Datos\Base de Datos CC_Chilca Ciclo combinado\400

Engineering\PIPING - PIPE RACK

\\ENERPECHISFSP01\CT_Chilca\30 Proyecto Comb Cycle\04. Informacion Tecnica\2.

Manuales O&M\Appendix (Vendor's OM Manual)

\\ENERPECHISFSP01\CT_Chilca\30 Proyecto Comb Cycle\04. Informacion Tecnica\2.

Manuales O&M\Appendix (Vendor's OM Manual)\35.Pipe Hanger&Support

F:\NO.49_385_PHS_Pipe Hanger & Support_Seonghwa

\\ENERPECHISFSP01\CT_Chilca\30 Proyecto Comb Cycle\04. Informacion Tecnica\2.

Manuales O&M\Appendix (Vendor's OM Manual)\35.Pipe Hanger&Support

NO.49_385_PHS_Pipe Hanger & Support_Seonghwa

SUGGESTED SCHEDULE FOR SERVICE

Having into consideration that we are running out of time for appropriately addressing this

issue, our best suggested time frame and program for conducting this inspection within plant

site installation premises is as follows:

a. EnerSur Chilca Uno Combined Cycle Power Plant is currently dispatching to the grid

and spring hangers and piping supports can be considered to be operating in hot

condition and they will stay that way until November 17

th

, 2014 when its scheduled

outage will start.

b. As per last walk-down inspection, all spring hangers and pipe supports are easily and

safely accessible either by handrails, platforms, catwalks, scaffolding and/or ladders

for the purpose.

c. For the hot-condition inspection, the winner bidding company will be scheduled to

perform its duties within the timeframe period going from October 27

th

onwards and

no later than October 31

st

, 2014. EnerSur and the winner bidding company will meet

each other upon finishing the hot-settings spring hanger and pipe support inspection

on a daily basis. The winner bidding company will release a preliminary report

immediately afterwards and will issue a final report within the next five (5) working

days for review.

d. For the cold-condition inspection, the winner bidding company will be scheduled to

perform its duties within the timeframe period going from November 20

th

onwards

and no later than November 25

th

, 2014. The winner bidding company will release a

preliminary report immediately afterwards and will issue a final report within the next

ten (10) working days for review.

e. The winner bidding company may suggest a work schedule in advance so that all

activities run smoothly.

SPECIAL TOOLING NEEDED FOR PERFORMING THE SERVICE

a. As per EnerSur best understanding, no special tools will be deemed necessary other

than those used by the winner bidding company. HRSG and deaerator units are

provisioned with ladders and handrails for safely getting access to equipment. If need

be, EnerSur will take care of temporary scaffolding for hard-to-reach areas, manlift

equipment and loader cranes fit for the purpose.

b. Updated calibration certificates are mandatory for all tools and instrumentation used

in this inspection.

MATERIALS, CONSUMABLES & SPARE PARTS

a. EnerSur will not provide special materials, consumables that are not supplied via

local vendors in Peru, so the winning bidder company must account for these and the

logistic support that may be needed for having them available at plant site. EnerSur

may assist the winning bidder in getting contact credentials for approved and certified

local vendors.

b. EnerSur will supply industrial-grade water (desalinated and deionized water),

electricity (480 VAC, 220 VAC, 60 Hz, single-phase, three-phase), compressed air

(100 psig) and any means deemed necessary to make them available at specific

areas near the ACC installation.

SAFETY REGULATIONS

EnerSur is an ISO compliant company and is currently certified at ISO 9001, ISO 14001 and

ISO 18001 so we promote quality and safety at work alongside environmental stewardship.

On this regard, all employees and people working inside the plant site must follow safety

regulations that will prevent any accidents from occurring anytime, anywhere.

a. All winning bidder company inspectors will attend a health and safety induction

training session (no longer than 2 hours)

b. The winning bidder company will prepare a risk assessment matrix / environmental

impact assessment for the job being carried out

c. The winning bidder company inspectors will have documentation updated for

labor/life insurance.

d. The winning bidder company inspectors will generate a short form for describing the

job to be performed at plant site so that EnerSur can help in implementing a lock-out

/ tag-out procedure to suit their needs, having in mind there will be other contract

companies doing different activities and performing other jobs at the same time.

e. Even though EnerSur knows that above-mentioned ISO standards can not

completely equate to OSHA regulations, we understand that the core business for

the latter is also employee life- and health preservation. On this regard, EnerSur will

accept them as a valid and added aid and will help us during safety training sessions.

DELIVERABLES

a. Following the SPRING HANGER & PIPE SUPPORT INSPECTION, both the winning

bidder company inspectors and EnerSur interested parties will meet together for a

preliminary report of activities accomplished so far and for identifying findings that

may entail prompt action to circumvent near-future problems.

b. If further documentation is needed for circumscribing scope of conclusions and

recommendations, the winning bidder company is entitled to issue timely inquiries

within 5 DAYS before the final report is submitted for a last revision and discussion.

c. Final report must be issued in one hard paper copy and in digital format, CD-ROM or

DVD media, depending on how much resolution the video or picture material does

have or how hefty the documentation may be.

d. The winning bidder company will issue an updated listing of spring hangers and pipe

support components in an illustrated Excel sheet as per the recommended format

attached herein in Annex # 08A & 08B.

REFERENCE STANDARDS

ASME BPVC 2013, Section V, Nondestructive Examination

ASME BPVC 2013, Section VIII, Rules for Construction of Pressure Vessels, Division

1

National Board Inspection Code (NBIC), 2013 Edition

ASME B31.1 (2012) Power Piping (Annex # 4)

MSS SP 58 (2009) Pipe Hangers and Supports - Materials, Design, Manufacture,

Selection, Application, and Installation (Annex # 5)

MSS SP 127 (2014) Bracing for Piping Systems: Seismic-Wind-Dynamic Design,

Selection, Application (Annex # 6)

ANNEX # 01 : SAMPLE AFFECTED COMPONENTS DUE TO DEFICIENT

HANGER AND SUPPORT INSTALLATION ALONG POWER PIPING SYSTEM

ANNEX # 02 : REFERENCE STANDARDS AS CLAIMED BY KOREAN OEM

ANNEX # 3 CONTACT CREDENTIALS FOR PIPE HANGER & SUPPORT OEM

SEONGHWA

http://www.seonghwa.co.kr/

ANNEX # 4 : ASME B31.1 2012 Power Piping

https://www.asme.org/products/codes-standards/b311-2012-power-piping

http://files.asme.org/Catalog/Codes/PrintBook/34984.pdf

ANNEX # 5 : MSS SP-58-2009 Pipe Hangers and Supports - Materials, Design,

Manufacture, Selection, Application, and Installation

ANNEX # 6 : MSS SP-127-2014 Bracing for Piping Systems: Seismic-Wind-Dynamic

Design, Selection, Application

ANNEX # 07 : REFERENCE STANDARDS AS OUTLINED BY DIFFERENT OEMS

FOLLOWING OUR FIRST INQUIRIES:

ANNEX # 08A : HANGER RECORD SHEET AS OUTLINED BY DIFFERENT OEMS

FOLLOWING OUR FIRST INQUIRIES:

ANNEX # 08B : HANGER RECORD SHEET AS OUTLINED BY DIFFERENT OEMS

FOLLOWING OUR FIRST INQUIRIES:

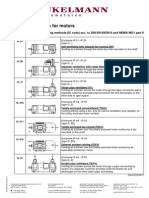

System Code Location Type Photograph

Hot

Reheat

HR-1 Top of HRSG,

under pipe,

near

LHSW, over

UC1

front wall.

Variable

Type T

Cold

Reheat

CR-4 Near LHSW,

~12 m

above grade,

hung

from pipe

bridge

Constant

Load

Hanger

Pair

Type CDS

HP Steam HP-1 Adjacent to

front

wall of UC1,

upstream of

desuperheater,

near LHSW

Fixed

Hanger

Rod

You might also like

- Cambridge Primary Computing: Mulit-Component SampleDocument28 pagesCambridge Primary Computing: Mulit-Component SampleMuhammed Muhammed0% (1)

- Procedure For SPRING HANGER INSPECTION PDFDocument11 pagesProcedure For SPRING HANGER INSPECTION PDFAnonymous yCpjZF1rF100% (3)

- Rotating Machines Erection GuidelinesDocument18 pagesRotating Machines Erection Guidelinessbmmla50% (4)

- Valves: Types, Functions, Uses, Maintenance & TroubleshootingDocument68 pagesValves: Types, Functions, Uses, Maintenance & TroubleshootingToniNo ratings yet

- BFBP Maintenance Instruction For HZB200-430 PDFDocument30 pagesBFBP Maintenance Instruction For HZB200-430 PDFJuan Jose Mendez GarciaNo ratings yet

- Saudi Aramco Motor Inspection RequirementsDocument2 pagesSaudi Aramco Motor Inspection RequirementsVijay BhaleraoNo ratings yet

- SAIC-G-2022 Rev 2Document25 pagesSAIC-G-2022 Rev 2faisal hussainNo ratings yet

- Inspection and Testing of Piping Systems ES-14-602-02Document44 pagesInspection and Testing of Piping Systems ES-14-602-02Edmund MoraldeNo ratings yet

- STS QAC SOP 016 Spring Hanger InspectionDocument6 pagesSTS QAC SOP 016 Spring Hanger Inspectionmohd as shahiddin jafriNo ratings yet

- Parameter Boiler Drum HRSGDocument7 pagesParameter Boiler Drum HRSGDwi Mulyanti DwimulyantishopNo ratings yet

- Process Equipment, Plant Layout and Piping Design – Part 4 Rotating Equipment DesignDocument34 pagesProcess Equipment, Plant Layout and Piping Design – Part 4 Rotating Equipment DesignJohn Lexmar LeynesNo ratings yet

- Steam TurbineDocument5 pagesSteam Turbinerashm006ranjanNo ratings yet

- Alignment of Shaft For Pump and Motor Using DTIDocument2 pagesAlignment of Shaft For Pump and Motor Using DTIRAMALINGUM BRIAN RUNGEN100% (1)

- TURBINESDocument44 pagesTURBINESESWARANM91No ratings yet

- Safety ValveDocument56 pagesSafety ValveAbhishek KumarNo ratings yet

- 660MW Air Cooled CondenserDocument26 pages660MW Air Cooled CondenserRaj_Jai030% (1)

- RWPL TG Capital Overhauling Scope of JobDocument8 pagesRWPL TG Capital Overhauling Scope of JobSreekanthMylavarapuNo ratings yet

- Technical Bulletin: AudcoDocument12 pagesTechnical Bulletin: AudcoHrushikesh ReddyNo ratings yet

- 31-SAMSS-010 - Nov. 12, 2013Document9 pages31-SAMSS-010 - Nov. 12, 2013Lainhatanh100% (1)

- Rotating Machinery EngineerDocument15 pagesRotating Machinery EngineerJose Luis RattiaNo ratings yet

- ENGINEERING REFERENCE CHECKSDocument2 pagesENGINEERING REFERENCE CHECKSMVSEETARAMANNo ratings yet

- Sec-Visual Inspection Report For Boiler Pressure Parts Lower Panels (Unit - #6)Document5 pagesSec-Visual Inspection Report For Boiler Pressure Parts Lower Panels (Unit - #6)حمودي معز100% (2)

- A2. Equipment Criticality RatingDocument3 pagesA2. Equipment Criticality RatingPeter IyereNo ratings yet

- InstallationOperationMaintenance 3600 enDocument110 pagesInstallationOperationMaintenance 3600 enStaman1988No ratings yet

- SEALDocument6 pagesSEALkishorsinghNo ratings yet

- Booster Pump Agiba PDFDocument518 pagesBooster Pump Agiba PDFhamadaNo ratings yet

- 02 Samss 012 PDFDocument10 pages02 Samss 012 PDFnadeem shaikhNo ratings yet

- Curriculum Vitae: INDIA: +91-8344756618Document4 pagesCurriculum Vitae: INDIA: +91-8344756618Ujwal KhandokarNo ratings yet

- Pump Alignment.Document3 pagesPump Alignment.sen_subhasis_58100% (1)

- Hydrotest Exemption DetailsDocument4 pagesHydrotest Exemption Detailsjoseph.maquez24No ratings yet

- Inspection and Test Plan For Shell and Tube Heat ExchangerDocument2 pagesInspection and Test Plan For Shell and Tube Heat Exchangeralokbdas100% (1)

- Microsoft Word - WET GAS COMPRESSOR OVERHAULING REPORTDocument8 pagesMicrosoft Word - WET GAS COMPRESSOR OVERHAULING REPORTAbhi SharmaNo ratings yet

- Presentation On Torqueing Tension IngDocument13 pagesPresentation On Torqueing Tension IngudayalNo ratings yet

- Boiler Erection ManualDocument51 pagesBoiler Erection ManualPhong Do100% (1)

- Load Table Forces and EffectsDocument1 pageLoad Table Forces and EffectsariyakkannaaNo ratings yet

- How To Check Pre Alignment MotorDocument6 pagesHow To Check Pre Alignment MotorJessie PimentelNo ratings yet

- TDBFP - Gear Pump API 676 PDFDocument42 pagesTDBFP - Gear Pump API 676 PDFRamon A. Ruiz O.No ratings yet

- Temporary Slip Blind Thickness Calculation ChartDocument3 pagesTemporary Slip Blind Thickness Calculation ChartthmaraishriNo ratings yet

- Snubbing PDFDocument40 pagesSnubbing PDFhamdibouhajar100% (1)

- Steam and Water Analysis System (SWAS) An OverviewDocument16 pagesSteam and Water Analysis System (SWAS) An OverviewDonatas Bertasius100% (1)

- Spring Support Inspection & MaintenanceDocument4 pagesSpring Support Inspection & MaintenanceSonaliNo ratings yet

- RWPL TG LP Rotor Replacement Scope of JobDocument5 pagesRWPL TG LP Rotor Replacement Scope of JobSreekanthMylavarapuNo ratings yet

- Valves and Valves Inspection & TestingDocument36 pagesValves and Valves Inspection & TestingSathish P Sathish PalanichamyNo ratings yet

- BY K.Prabhu 12BEEE1039Document30 pagesBY K.Prabhu 12BEEE1039raspberry piNo ratings yet

- Online Leak Sealing TenderDocument10 pagesOnline Leak Sealing TenderchennaiNo ratings yet

- Mov ItpDocument1 pageMov ItpMussab Salih100% (1)

- Explanation API 610 Pump ConfigurationsDocument11 pagesExplanation API 610 Pump ConfigurationsWandri Bojan Hidayat100% (1)

- AIE-PR-PRJ-005 - in Service Pipework Inspection Procedure Rev 01Document20 pagesAIE-PR-PRJ-005 - in Service Pipework Inspection Procedure Rev 01faraz_muslimNo ratings yet

- Maintanance of Spring Hanger by PTDocument2 pagesMaintanance of Spring Hanger by PTRagu NathanNo ratings yet

- Technical Bid Evaluation of Vendor Spring Hanger Offers With PDFDocument3 pagesTechnical Bid Evaluation of Vendor Spring Hanger Offers With PDFAmjadali ChoudhariNo ratings yet

- Erection & Installation ProcedureDocument3 pagesErection & Installation ProcedureForos IscNo ratings yet

- 4-Way Diverter Valve PDFDocument6 pages4-Way Diverter Valve PDFnadeemNo ratings yet

- Bhel PresentationDocument31 pagesBhel PresentationSamuel Bhukya100% (1)

- Vertical PumpsDocument27 pagesVertical PumpsmersiumNo ratings yet

- Inspection Report For Pipeline Route Survey Sign Copy and Blank FormatDocument1 pageInspection Report For Pipeline Route Survey Sign Copy and Blank FormatVishvjeet Prakash TiwariNo ratings yet

- Training On Alignment of Rotating EquipmentDocument21 pagesTraining On Alignment of Rotating EquipmentJayant SagadeNo ratings yet

- Saep 311Document31 pagesSaep 311brecht1980No ratings yet

- Rotary UPS SpecificationDocument15 pagesRotary UPS SpecificationRamu NallathambiNo ratings yet

- Induction Heating System for Drying Hull WastesDocument29 pagesInduction Heating System for Drying Hull WastesAshok TomarNo ratings yet

- B15 e 1DDocument28 pagesB15 e 1DPaúl ÁlvarezNo ratings yet

- Refri Star - Re-Installatio of Used PlantDocument4 pagesRefri Star - Re-Installatio of Used PlantmanonpomNo ratings yet

- Cooling Methods For Motors: Classification of The Cooling Methods (IC Code) Acc. To DIN EN 60034-6 and NEMA MG1 Part 6Document1 pageCooling Methods For Motors: Classification of The Cooling Methods (IC Code) Acc. To DIN EN 60034-6 and NEMA MG1 Part 6electworldNo ratings yet

- 1&2-WD170-EE460-C0009 - Rev.F Control Valve List (Seiten 51-52)Document2 pages1&2-WD170-EE460-C0009 - Rev.F Control Valve List (Seiten 51-52)Anibal QuezadaNo ratings yet

- 0-WD910-EM610-00001 - RevB O&M Manual For WTS (Page 181)Document1 page0-WD910-EM610-00001 - RevB O&M Manual For WTS (Page 181)Anibal QuezadaNo ratings yet

- 107 sb3 12 5009 GN en 01 255455 v1Document4 pages107 sb3 12 5009 GN en 01 255455 v1Anibal QuezadaNo ratings yet

- Bearing Lift Oil Skid Assembly Manual (Pages 1,46-47,136-138, 141-143, 149)Document10 pagesBearing Lift Oil Skid Assembly Manual (Pages 1,46-47,136-138, 141-143, 149)Anibal QuezadaNo ratings yet

- 0-WD170-EP442-C0001 - Rev.f - Manual Valve Datasheet & Drawings (Page 37)Document1 page0-WD170-EP442-C0001 - Rev.f - Manual Valve Datasheet & Drawings (Page 37)Anibal QuezadaNo ratings yet

- 9.steam Seal (Page 14) PDFDocument1 page9.steam Seal (Page 14) PDFAnibal QuezadaNo ratings yet

- Compressor Wash Skid Manual (Pages 1-14)Document14 pagesCompressor Wash Skid Manual (Pages 1-14)Anibal QuezadaNo ratings yet

- Chalk Point Fact SheetDocument1 pageChalk Point Fact SheetAnibal QuezadaNo ratings yet

- Multistage Vertical Inline Pumps PM1, PM3, PM5 Series: Specifications Information and Repair Parts ManualDocument12 pagesMultistage Vertical Inline Pumps PM1, PM3, PM5 Series: Specifications Information and Repair Parts ManualAnibal QuezadaNo ratings yet

- 25 - 40 Spare Parts 2010 Pricing (Rev01)Document1 page25 - 40 Spare Parts 2010 Pricing (Rev01)Anibal QuezadaNo ratings yet

- Mankenberg Vacuum ValveDocument10 pagesMankenberg Vacuum ValveAnibal QuezadaNo ratings yet

- 2015-10-02 Voith Mom Enersur Uptooct-2015v1.0Document14 pages2015-10-02 Voith Mom Enersur Uptooct-2015v1.0Anibal QuezadaNo ratings yet

- A Comparative Study of IEC 76 and ANSI C57.12 On TransformersDocument9 pagesA Comparative Study of IEC 76 and ANSI C57.12 On TransformersprasannamohandasNo ratings yet

- Bilfinger Investigates Compliance Violations in BrazilDocument1 pageBilfinger Investigates Compliance Violations in BrazilAnibal QuezadaNo ratings yet

- 0-WD992-ZZ100-00001 - RevAB Name Plate Drawing (Page 4)Document1 page0-WD992-ZZ100-00001 - RevAB Name Plate Drawing (Page 4)Anibal QuezadaNo ratings yet

- Bilfinger Investigates Compliance Violations in BrazilDocument1 pageBilfinger Investigates Compliance Violations in BrazilAnibal QuezadaNo ratings yet

- Log 3Document5 pagesLog 3Anibal QuezadaNo ratings yet

- Welding PositionsDocument116 pagesWelding PositionsASAPASAPASAPNo ratings yet

- Technical Information Letters Rev03 (01OCT2014)Document6 pagesTechnical Information Letters Rev03 (01OCT2014)Anibal QuezadaNo ratings yet

- Purchase Order Specification For Balancing Machine (Rev07)Document7 pagesPurchase Order Specification For Balancing Machine (Rev07)Anibal QuezadaNo ratings yet

- Bilfinger Investigates Compliance Violations in BrazilDocument1 pageBilfinger Investigates Compliance Violations in BrazilAnibal QuezadaNo ratings yet

- LGE and KUs Executed Asset Purchase Agreement With Bluegrass Generation CompanyDocument313 pagesLGE and KUs Executed Asset Purchase Agreement With Bluegrass Generation CompanyAnibal Quezada0% (1)

- ASTM A 178 Specification For ERW Carbon Steel and Carbon Manganese Steel Boiler and Superheater TubesDocument4 pagesASTM A 178 Specification For ERW Carbon Steel and Carbon Manganese Steel Boiler and Superheater TubesAnibal QuezadaNo ratings yet

- (HST) The BrainDocument19 pages(HST) The BrainAnibal QuezadaNo ratings yet

- Log 1Document5 pagesLog 1Anibal QuezadaNo ratings yet

- WP DeltaV SPI Integr PDFDocument14 pagesWP DeltaV SPI Integr PDFJoão FranciscoNo ratings yet

- Proguard SFDocument1 pageProguard SFahmedyahea181No ratings yet

- Rayleigh vs Rician Fading Channels under Frequency Selective ConditionsDocument4 pagesRayleigh vs Rician Fading Channels under Frequency Selective Conditionssrikar01No ratings yet

- Technical Analysis (Last 7 Steps) : Nikhita Rustagi 6017 Mba 4 Semester Project Planning, Analysis and ManagmentDocument16 pagesTechnical Analysis (Last 7 Steps) : Nikhita Rustagi 6017 Mba 4 Semester Project Planning, Analysis and ManagmentNikhitaNo ratings yet

- (Power Electronics and Power Systems) Slobodan N. Vukosavic - Grid-Side Converters Control and Design (2018, Springer International Publishing)Document288 pages(Power Electronics and Power Systems) Slobodan N. Vukosavic - Grid-Side Converters Control and Design (2018, Springer International Publishing)Isabella Bianchin100% (2)

- Leica DISTO™ Transfer PC GuideDocument34 pagesLeica DISTO™ Transfer PC GuidefistralloNo ratings yet

- Catalog of RBS Honda ListDocument35 pagesCatalog of RBS Honda Listcbaautoparts197No ratings yet

- Checking the Lubrication SystemDocument2 pagesChecking the Lubrication Systemhiram avilaNo ratings yet

- Fusite: With Fusite, Mission Critical Becomes Mission AccomplishedDocument4 pagesFusite: With Fusite, Mission Critical Becomes Mission AccomplishedkEWQ 865kNo ratings yet

- Maemo - I - Introduction To MaemoDocument15 pagesMaemo - I - Introduction To MaemoCatalin ConstantinNo ratings yet

- CAT-4003 MRI-M500 Series Intelligent Modules PDFDocument2 pagesCAT-4003 MRI-M500 Series Intelligent Modules PDFEddi Pelaez SalinasNo ratings yet

- SW Ass1Document9 pagesSW Ass1Mintesinot MeleseNo ratings yet

- 64 QAM FeatureDocument9 pages64 QAM Featurenassr_ismailNo ratings yet

- EN Installation Guide Cermate HMI Panel PT043-WSP - WSK 20140904 v4Document1 pageEN Installation Guide Cermate HMI Panel PT043-WSP - WSK 20140904 v4АлексейNo ratings yet

- Online BankingDocument38 pagesOnline BankingROSHNI AZAMNo ratings yet

- Laser Scanning TechnologyDocument13 pagesLaser Scanning TechnologyVirgilio F. Abundo Jr.No ratings yet

- ALM On Power Platform - A POVDocument12 pagesALM On Power Platform - A POVMudassar HassanNo ratings yet

- Chapter II NewDocument10 pagesChapter II NewAbigail Senaon De MesaNo ratings yet

- Graylog Product Adoption GuideDocument5 pagesGraylog Product Adoption GuideMiguel Angel Revuelta ManteconNo ratings yet

- 300W X 2 Channel Class D Audio Power Amplifier-1Document34 pages300W X 2 Channel Class D Audio Power Amplifier-1Sahab RathoreNo ratings yet

- Digital Literacy Research ReportDocument54 pagesDigital Literacy Research ReportSaul SalekyNo ratings yet

- ABB Review - 01 - 2023 - Layout Complete - EN - 72-300dpi PDFDocument82 pagesABB Review - 01 - 2023 - Layout Complete - EN - 72-300dpi PDFUsiNo ratings yet

- Title Layout: SubtitleDocument12 pagesTitle Layout: Subtitleriska augustNo ratings yet

- Manual de Serviço Mini System LG LM U2350ADocument55 pagesManual de Serviço Mini System LG LM U2350AAlbertNo ratings yet

- CM20150930 35537 44540Document2 pagesCM20150930 35537 44540fangrui maiNo ratings yet

- P630iDocument316 pagesP630iJamal AldwakeNo ratings yet

- 1 Essay Tu Viet LaidocxDocument2 pages1 Essay Tu Viet LaidocxLy Ngoc Thanh B1906074No ratings yet

- E Beam ManualDocument7 pagesE Beam ManualMarco SalvatoriNo ratings yet

- ADVANCE STANDALONE Yamaha Z1 (EN) PDFDocument10 pagesADVANCE STANDALONE Yamaha Z1 (EN) PDFTechno TechNo ratings yet