Professional Documents

Culture Documents

Turbo TroubleShooting PDF

Uploaded by

namduong3680 ratings0% found this document useful (0 votes)

641 views1 pageDirty oil damage could result from: Blocked, damaged or poor quality oil filter. Dirt introduced during servicing. Engine wear or manufacturing debris. Malfunctioning oil filter by-pass valve. Degraded lubrication oil. Never continue to operate a turbocharger with damaged blades as the rotor balance will be affected.

Original Description:

Original Title

Turbo TroubleShooting.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentDirty oil damage could result from: Blocked, damaged or poor quality oil filter. Dirt introduced during servicing. Engine wear or manufacturing debris. Malfunctioning oil filter by-pass valve. Degraded lubrication oil. Never continue to operate a turbocharger with damaged blades as the rotor balance will be affected.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

641 views1 pageTurbo TroubleShooting PDF

Uploaded by

namduong368Dirty oil damage could result from: Blocked, damaged or poor quality oil filter. Dirt introduced during servicing. Engine wear or manufacturing debris. Malfunctioning oil filter by-pass valve. Degraded lubrication oil. Never continue to operate a turbocharger with damaged blades as the rotor balance will be affected.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

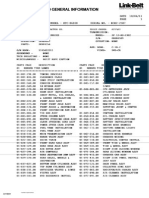

Dirty oil damages the turbocharger by causing heavy scoring of critical

bearing surfaces. To avoid damage, oil and lters should be of a quality

recomended by an OEM. These should be changed when a new

turbocharger is tted and at regular intervals according to the vehicle/

engine manufacturers specication.

Dirty oil damage could result from:

Blocked, damaged or poor quality oil lter.

Dirt introduced during servicing.

Engine wear or manufacturing debris.

Malfunctioning oil lter by-pass valve.

Degraded lubrication oil.

Impact

Damage

Dirt in Oil

Impact damage caused by foreign material entering the turbine

housing or compressor housing is clearly visible on the turbine wheel

or impeller.

Never continue to operate a turbocharger with damaged blades as the

rotor balance will be affected and this could impact its service life.

Caused by:

Dirty air cleaner.

Air intake system restriction.

Cracked mounting fange/gasket

missing.

Fuel pump/injectors/valve timing

incorrectly set.

Wastegate mechanism set

incorrectly.

Turbocharger damaged.

Excess Smoke

Remember, if the root cause of the problem is not identied and corrected your problem will remain!

Insufcient

Oil Supply

Carbon

build-up

Caused by:

Dirty air cleaner.

Air intake system restriction.

Cracked mounting fange/gasket

missing.

Exhaust for foreign object restriction.

Fuel pump/injectors/valve timing

incorrectly set.

Burnt valves and/or pistons.

Turbocharger damaged.

Engine Lacks Power

Often the noise comes from air/gas

leakage due to pre-turbine exhaust

gas or an air/boost leaks.

Check all joints - if noise continues

check turbocharger clearances and

wheels for housing contact.

Noisy/Whistling

If the turbocharger rotor assembly has

seized or is tight to rotate, this is often

due to lubricating oil degregation,

which can cause a high build up of

carbon in the bearing housing interior

restricting rotation. Insufcient or

an intermittent drop in oil pressure

can cause the rotor to seize, as can

introducing dirt into the lubricating oil.

Seized/Sluggish

A turbocharger has specifc axial

and radial rotor clearances. These

are sometimes mis-diagnosed

as worn bearings (See engine

manual or nearest authorised Holset

distributor). If the clearances are out

of specication the cause could be

attributed to a lubricating oil problem,

i.e. insufcient oil, dirt ingress, oil

contamination with coolant.

Worn/Excessive Clearance

Foreign object damage to impeller Foreign object damage to turbine wheel

Effects of using silicone sealants Insufficient lubrication oil

Dirt scored shaft Dirt scored bearing

Bearing damage due to hot shutdown Carbon build-up on shaft

Failure from excessive exhaust temperatures or hot shutdown of

engine results in carbon build-up. It is recommended that you idle the

engine for 2 to 3 minutes to cool the bearing system before shutting

down. Turbine end heat soak into the bearing housing results in oil

carbonisation and corrosion of the bearing system. The main damage

occurs to the shaft seal ring and grooves, turbine end bearing and

bearing housing oil drain cavity blockage.

Carbon build-up can be caused by:

Hot shutdown of engine.

Degraded oil quality carbonising in service.

Infrequent oil change intervals causing oil breakdown in service.

Air and gas leaks.

Faulty fuel injector pump/injectors.

Before changing your turbocharger, please make sure that you have correctly identied the cause of the fault.

Insufcient oil supply can be attributed to the following:

Re-tting a turbocharger without adequate priming.

Long periods of non-use.

Broken or restricted oil feed pipe.

Low engine oil pressure due to malfunctioning lubrication system.

Low or no oil in sump.

The use of sealants, which can restrict the oil fow.

Not priming a replacement oil lter with new oil. If this cannot be

done then crank the engine with no fuel to establish oil pressure.

Do not exceed idle conditions until oil pressure is established.

www.holsetaftermarket.com

Copyright 2008, Cummins Turbo Technologies Ltd. All rights reserved.

VGT, Command Valve and Super MWE are trade marks of Cummins Turbo Technologies Ltd.

Holset and the Holset Logo are registered trade marks of Cummins Turbo Technologies Ltd.

Cummins and the Cummins logo are registered trade marks of Cummins Inc.

Part No. 3766042 Rev.04 Ref. MS/AK Effect Date: 05:08

Turbocharger

troubleshooting guidelines

Never continue to operate an engine with a

suspect or noisy turbocharger as this could

result in total engine failure

You might also like

- Manitowoc 11000-1 Parts Manual PDFDocument1,040 pagesManitowoc 11000-1 Parts Manual PDFnamduong368100% (2)

- AutoCAD 2014 Tutorial 3DDocument26 pagesAutoCAD 2014 Tutorial 3DseleneletoNo ratings yet

- Delco: Carburetor Models 4MV-4MC-M4ME-M4MC Service ManualDocument46 pagesDelco: Carburetor Models 4MV-4MC-M4ME-M4MC Service ManualTassNo ratings yet

- 2019 ERIKC Diesel Injector Spare Parts & Tool Catalog PDFDocument33 pages2019 ERIKC Diesel Injector Spare Parts & Tool Catalog PDFHerbert SanchezNo ratings yet

- Operation Maintenance Course C40 PDFDocument87 pagesOperation Maintenance Course C40 PDFpoetraditya100% (1)

- CAT - C7 (Prefix C7S) .C7S300-UpDocument12 pagesCAT - C7 (Prefix C7S) .C7S300-UpPhil B.No ratings yet

- AutoCAD 2013Document264 pagesAutoCAD 2013panosscribd100% (1)

- 2015-03 Cummins Parts and Repair ServicesDocument55 pages2015-03 Cummins Parts and Repair ServicesjosephvanbacNo ratings yet

- Lampiran 2 Lampiran Penawaran Harga: Pengadaan Filter Untuk Kebutuhan Motor Induk Dan Motor Bantu Kapal Perintis 2021Document10 pagesLampiran 2 Lampiran Penawaran Harga: Pengadaan Filter Untuk Kebutuhan Motor Induk Dan Motor Bantu Kapal Perintis 2021Deni prastiyoNo ratings yet

- Air System: Cummins Training CentreDocument82 pagesAir System: Cummins Training CentreHydromech PartsNo ratings yet

- AutoCAD 3D Course ManualDocument166 pagesAutoCAD 3D Course ManualJed Tedor98% (47)

- LTM 1130-5.1 - PN - Technical Specification PDFDocument18 pagesLTM 1130-5.1 - PN - Technical Specification PDFnamduong368No ratings yet

- LTM 1130-5.1 - PN - Technical Specification PDFDocument18 pagesLTM 1130-5.1 - PN - Technical Specification PDFnamduong368No ratings yet

- LTM 1130-5.1 - PN - Technical Specification PDFDocument18 pagesLTM 1130-5.1 - PN - Technical Specification PDFnamduong368No ratings yet

- LTM 1130-5.1 - PN - Technical Specification PDFDocument18 pagesLTM 1130-5.1 - PN - Technical Specification PDFnamduong368No ratings yet

- Workshop Manual Technical Data TAD530 531 532GE TAD730 731 732 733GE Group 20 26Document140 pagesWorkshop Manual Technical Data TAD530 531 532GE TAD730 731 732 733GE Group 20 26Courtney French91% (23)

- Sebp5557 00 00 All PDFDocument839 pagesSebp5557 00 00 All PDFmhmoud tweel100% (1)

- Cat® Engine Specifications: C18 Acert Industrial EngineDocument5 pagesCat® Engine Specifications: C18 Acert Industrial EngineAsif MehmoodNo ratings yet

- Caterpillar PDFDocument218 pagesCaterpillar PDFStar Seal100% (1)

- CBE 25, MN PDFDocument95 pagesCBE 25, MN PDFnamduong368No ratings yet

- CBE 25, MN PDFDocument95 pagesCBE 25, MN PDFnamduong368No ratings yet

- CBE 25, MN PDFDocument95 pagesCBE 25, MN PDFnamduong368No ratings yet

- CBE 25, MN PDFDocument95 pagesCBE 25, MN PDFnamduong368No ratings yet

- CBE 25, MN PDFDocument95 pagesCBE 25, MN PDFnamduong368No ratings yet

- CBE 25, MN PDFDocument95 pagesCBE 25, MN PDFnamduong368No ratings yet

- Turbo Oil Leak TrainingDocument20 pagesTurbo Oil Leak TrainingTrường Bửu Trần100% (1)

- Engine Overhaul - Bs-Iii Cummins EngineDocument28 pagesEngine Overhaul - Bs-Iii Cummins EngineAshesh BhattaraiNo ratings yet

- Manitowoc 4600 S4 Lubrication Guide PDFDocument40 pagesManitowoc 4600 S4 Lubrication Guide PDFnamduong368100% (1)

- Hypac C766C, C778B - Om PDFDocument122 pagesHypac C766C, C778B - Om PDFnamduong368100% (2)

- 3 - Electrical System PDFDocument39 pages3 - Electrical System PDFnamduong3680% (1)

- Section 8 - Level 3 Group 6: Lubricating System Component Rebuild Tools GroupDocument7 pagesSection 8 - Level 3 Group 6: Lubricating System Component Rebuild Tools GroupSpectrumRaijinNo ratings yet

- Specification Manual 2206-E13 KENR6905 May 08Document36 pagesSpecification Manual 2206-E13 KENR6905 May 08Kornelius David PattiselannoNo ratings yet

- Xpi Fuel Circuit - 9 & 13 Litre Engine - 0314-06 Issue - 1Document3 pagesXpi Fuel Circuit - 9 & 13 Litre Engine - 0314-06 Issue - 1NoeRtjahya AhmadNo ratings yet

- KTA 19 Parts Catalogue PDFDocument58 pagesKTA 19 Parts Catalogue PDFArgee PadauanNo ratings yet

- Manitowoc 8500-1 Parts Manual PDFDocument1,046 pagesManitowoc 8500-1 Parts Manual PDFnamduong368100% (1)

- Clutch Troubleshooting and Warranty Analysis Guide - UnknownDocument84 pagesClutch Troubleshooting and Warranty Analysis Guide - Unknownbotan_mihaiNo ratings yet

- Mitsubishi L-Series Operator ManualDocument42 pagesMitsubishi L-Series Operator ManualDmitryGavrilin100% (1)

- Cummins QSK60 Engine Spare Parts CatalogDocument22 pagesCummins QSK60 Engine Spare Parts CatalogMamadou lyNo ratings yet

- 19hydraulic ClampingDocument72 pages19hydraulic ClampingMarian DunareanuNo ratings yet

- Basic Training - Diesel GeneratorDocument76 pagesBasic Training - Diesel Generatoroledtest userNo ratings yet

- Section 5 - Level 3 Group 3: Cam Followers/Tappets Component Rebuild Tools GroupDocument4 pagesSection 5 - Level 3 Group 3: Cam Followers/Tappets Component Rebuild Tools GroupSpectrumRaijinNo ratings yet

- Keihin Pe Carb Exploded ViewDocument2 pagesKeihin Pe Carb Exploded ViewHishamuddin Hmr100% (1)

- G3600 PKG Tips - Air Intake & ExhaustDocument49 pagesG3600 PKG Tips - Air Intake & ExhaustshivNo ratings yet

- General Information: 018-001 SpecificationsDocument10 pagesGeneral Information: 018-001 SpecificationsLaiqNo ratings yet

- Overhaul EngineDocument4 pagesOverhaul EngineAngga RezzaNo ratings yet

- Captiva Control MotorDocument52 pagesCaptiva Control Motorsertex_jo71% (7)

- Manitowoc 4600 S4 Parts Manual PDFDocument108 pagesManitowoc 4600 S4 Parts Manual PDFnamduong36850% (2)

- Manitowoc 4600 S4 Parts Manual PDFDocument108 pagesManitowoc 4600 S4 Parts Manual PDFnamduong36850% (2)

- H Service Data Sheet PDFDocument8 pagesH Service Data Sheet PDFAbhijit MannaNo ratings yet

- Cramkshaft Main Bearimg InstallDocument5 pagesCramkshaft Main Bearimg InstallNimNo ratings yet

- Catalogue Yanmar 4TNV106T GGEDocument17 pagesCatalogue Yanmar 4TNV106T GGEMikh MIKH100% (1)

- CT - 100 - SPC - Rev01 Mar 2015Document67 pagesCT - 100 - SPC - Rev01 Mar 2015Ittoop and sons AutomobileNo ratings yet

- TB 80 EngineDocument51 pagesTB 80 EngineRonald100% (1)

- Manuel CJ750 M1 M1MDocument27 pagesManuel CJ750 M1 M1MFerrousstateNo ratings yet

- Unit Description SpecificationDocument20 pagesUnit Description SpecificationAbel Oviedo100% (1)

- Reuse & Salvage Guidelines (Valve & Valve Spring Spec)Document25 pagesReuse & Salvage Guidelines (Valve & Valve Spring Spec)carlos angelNo ratings yet

- Turbo Failure GuideDocument4 pagesTurbo Failure GuideRoman AdamNo ratings yet

- Cummins K38 Engine Standard Overhaul Spare PartsDocument1 pageCummins K38 Engine Standard Overhaul Spare PartsOkey Okoli100% (1)

- Overhead Set (OBC)Document19 pagesOverhead Set (OBC)MohamedNo ratings yet

- Yanmar MarineDocument29 pagesYanmar MarineMichell Quinteros Giler100% (1)

- Power2 340-H44: Operation ManualDocument166 pagesPower2 340-H44: Operation ManualDmitrii PustoshkinNo ratings yet

- Gallon To Overhaul PC4000-6Document35 pagesGallon To Overhaul PC4000-6Hingga Setiawan Bin SuhadiNo ratings yet

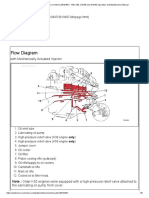

- Flow Diagram: With Mechanically Actuated InjectorDocument8 pagesFlow Diagram: With Mechanically Actuated InjectorAHMAD100% (1)

- 03 Mechanical AdjustmentDocument25 pages03 Mechanical AdjustmentHải Lưu MinhNo ratings yet

- Manual de Partes R1600GDocument0 pagesManual de Partes R1600GPercy CheroNo ratings yet

- CBD&CBG 25manual PDFDocument120 pagesCBD&CBG 25manual PDFnamduong368No ratings yet

- Engine Failure Cause PDFDocument5 pagesEngine Failure Cause PDFRohmanNo ratings yet

- Cylinder Head: SpecificationsDocument5 pagesCylinder Head: SpecificationsFares100% (1)

- Manual Reparatii Audi A2 1.6 FSIDocument104 pagesManual Reparatii Audi A2 1.6 FSIbmarian660% (1)

- TF-80ME: Yanmar Industrial EngineDocument1 pageTF-80ME: Yanmar Industrial Enginecabdirisaaq shaqaleNo ratings yet

- Fatigue Failure of A Connecting RodDocument16 pagesFatigue Failure of A Connecting RodCamilo Rojas GómezNo ratings yet

- Aeb04112 PDFDocument6 pagesAeb04112 PDFCesar G.0% (1)

- Cummins KTA19 Engine Spare Parts Catalog: Part Number DescriptionDocument22 pagesCummins KTA19 Engine Spare Parts Catalog: Part Number Descriptionsaeedt538100% (1)

- Adjustment of Pinion HeightDocument11 pagesAdjustment of Pinion HeightSobakinNo ratings yet

- 03 3500B Engine ComponentsDocument53 pages03 3500B Engine ComponentsHải Lưu MinhNo ratings yet

- 02 Torque and Socket OptimizeDocument26 pages02 Torque and Socket OptimizeANDI SETIAWANNo ratings yet

- Valvoline 6Document2 pagesValvoline 6munh100% (1)

- Spares To Suit 16V-92: 1.1 Cylinder Block 1.2 Cylinder Head 1.3 Crankshaft, Oil Seals and StabilizersDocument12 pagesSpares To Suit 16V-92: 1.1 Cylinder Block 1.2 Cylinder Head 1.3 Crankshaft, Oil Seals and StabilizersSonthi MooljindaNo ratings yet

- SAGAseries2013 PDFDocument6 pagesSAGAseries2013 PDFDeno Manuel LudzanNo ratings yet

- Tekiro Galaxy LTC CatalogDocument37 pagesTekiro Galaxy LTC CatalogReza Kartadiwiria100% (2)

- Catalogue of Oil Pressure Sensor From Okay MotorDocument4 pagesCatalogue of Oil Pressure Sensor From Okay MotortdnramonNo ratings yet

- Catalogue For Marine Transmission - 201005 - Final PDFDocument14 pagesCatalogue For Marine Transmission - 201005 - Final PDFdamith100% (1)

- Intake Manifold Boost Pressure SensorsDocument4 pagesIntake Manifold Boost Pressure SensorsSamuel Contreras FloresNo ratings yet

- Energy Drilling - CAT C13 Engine at 23888 HoursDocument20 pagesEnergy Drilling - CAT C13 Engine at 23888 HoursYourKard100% (1)

- QSKV 45/60: Heads: CYLINDER HEAD - Familiarization Scene AudioDocument3 pagesQSKV 45/60: Heads: CYLINDER HEAD - Familiarization Scene Audionugraha kurniawanNo ratings yet

- Caution: Counterclockwise, As Viewed From TheDocument19 pagesCaution: Counterclockwise, As Viewed From TheanilNo ratings yet

- Marine Generator Set: 30.0 Ekw (60 HZ) at 1800 RPM 24.5 Ekw (50 HZ) at 1500 RPMDocument2 pagesMarine Generator Set: 30.0 Ekw (60 HZ) at 1800 RPM 24.5 Ekw (50 HZ) at 1500 RPMByron CheleNo ratings yet

- S433 Genset Spare ListDocument42 pagesS433 Genset Spare Listvpsales2123No ratings yet

- Cummins Kits Reparacion Isx y N14 PDFDocument2 pagesCummins Kits Reparacion Isx y N14 PDFAlexis SanchezNo ratings yet

- Operation and MaintenanceDocument13 pagesOperation and MaintenanceLe DuNo ratings yet

- Engine Crankshaft Deflection MeasurementDocument9 pagesEngine Crankshaft Deflection MeasurementVannex MensidorNo ratings yet

- K 38Document1 pageK 38IKNo ratings yet

- ZF - 3HP12 For BMW Workshop ManualDocument36 pagesZF - 3HP12 For BMW Workshop Manualnamduong368100% (1)

- TEREX AC1000 - Load Chart PDFDocument116 pagesTEREX AC1000 - Load Chart PDFduongpnNo ratings yet

- Energies 10 00666 PDFDocument46 pagesEnergies 10 00666 PDFnamduong368No ratings yet

- SM-751 - 1 To 22 PDFDocument22 pagesSM-751 - 1 To 22 PDFnamduong368No ratings yet

- SM-751 - 67 To 88 PDFDocument22 pagesSM-751 - 67 To 88 PDFnamduong368100% (1)

- Manitowoc SC70 Lubrication Guide PDFDocument32 pagesManitowoc SC70 Lubrication Guide PDFnamduong368No ratings yet

- Link Belt RTC80130 Parts Manual PDFDocument453 pagesLink Belt RTC80130 Parts Manual PDFnamduong368100% (1)

- Link Belt HTC86100 Parts Manual PDFDocument423 pagesLink Belt HTC86100 Parts Manual PDFnamduong368No ratings yet

- M Di 0145 PDFDocument4 pagesM Di 0145 PDFJuanCarlosCastilloNo ratings yet

- Nitrous OxideDocument13 pagesNitrous OxideSambhav Golechha100% (1)

- Fuel Injection SystemsDocument33 pagesFuel Injection SystemsYashvir SinghNo ratings yet

- qsk45 Ja qsk60 EsiteDocument6 pagesqsk45 Ja qsk60 EsitemortezaNo ratings yet

- MTU 400 KW 8V1600G80S EPA Tier 3 Emissions Engine Spec SheetDocument2 pagesMTU 400 KW 8V1600G80S EPA Tier 3 Emissions Engine Spec SheetJoanne CordesNo ratings yet

- 1989 Engine Performance On-Vehicle AdjustmentsDocument14 pages1989 Engine Performance On-Vehicle AdjustmentsJose PichinteNo ratings yet

- M 89Document2 pagesM 89navneetkpatil8409No ratings yet

- Univeng, m-40bDocument2 pagesUniveng, m-40bJoe SeraphinNo ratings yet

- KLX 150 BFDocument84 pagesKLX 150 BFJohan CahyantoNo ratings yet

- Quincy QR25 Model350Document33 pagesQuincy QR25 Model350Ramiro correa100% (1)

- Volvo Plane Ice ReportDocument18 pagesVolvo Plane Ice ReportAreebNo ratings yet

- List Mtu 12 VDocument10 pagesList Mtu 12 VRaymond OwenNo ratings yet

- Electronic Parts Catalog - Option DetailDocument2 pagesElectronic Parts Catalog - Option DetailmunhNo ratings yet

- Compass 2008 2.0LDocument234 pagesCompass 2008 2.0LDavid Ulloa SalazarNo ratings yet

- The Training Resource Disk For The Level 1 Diploma in Principles of Light Vehicle Operations - Sample PagesDocument3 pagesThe Training Resource Disk For The Level 1 Diploma in Principles of Light Vehicle Operations - Sample PagesPearson SchoolsNo ratings yet

- MECH4429 Unit Outline Summary 2013Document2 pagesMECH4429 Unit Outline Summary 2013arvinkhoNo ratings yet

- Simulation VariablesDocument114 pagesSimulation VariablesHangarCeroUno DevelopmentNo ratings yet

- 11-MURAT AUTOMOTIVE MITSUBISHI - 2017 - 04 PRODUCT CATALOG - Compressed PDFDocument92 pages11-MURAT AUTOMOTIVE MITSUBISHI - 2017 - 04 PRODUCT CATALOG - Compressed PDFFredy HernanNo ratings yet

- Goran Kovacic MANDocument16 pagesGoran Kovacic MANpauloNo ratings yet