Professional Documents

Culture Documents

Bridge Works

Uploaded by

ကိုနေဝင်းOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bridge Works

Uploaded by

ကိုနေဝင်းCopyright:

Available Formats

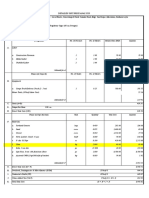

MINISTRY OF CONSTRUCTION

PUBLIC WORKS

ANALYSIS OF RATES

FOR

BRIDGE WORKS

GOVERNMENT OFTHE REPUBLIC OF THE UNION OF MYANMAR

SECOND EDITION

JUNE 2013

CONTENTS

SH-NO

1 . O

2.0

3.0

4.0

5.0

6.0

NAME OF SUB-HEAD

BRIDGES

SUB-HEADS

Foundation Work

P.C Girder

Steel Truss

Steel Plate Girder

Suspension and Cablestayed Bridge

Survey

Miscellaneous Notes

-

PAGE NO

1

Standard Data for Working Out Rates Per Unit Quantity ofltems of Work.

Foreman

Carpenter (1 st Grade)

Carpenter (2nd Grade)

Worker

Sr

No.

1

2.

3.

Particulars of Materials and Labour

X IX. BRIDGES

Foundation Works

Labour For Driving (250 mm) Diameter Timber

Piles inordinary Soil(With 500 kg drop hammer

from pulley winch and local trestle and manually

operated). Penetration average 6 m.

Labour

Plants

Pile driving frame (1)No

Sundries

Labour For Driving (250 mm)Diameter Timber

Piles inordinary Soil (With pile driving machine).

Penetration average 6 m.

Labour

Operator

Foreman

Carpenter (I st Grade)

Carpenter (2nd Grade)

Worker

For Operation

H.S.D

Grease

Plants

Pile driving frame (1)No

Sundries

Labour for Pile Driving reinforced cement con-

crete pile (350 mm x 350 mm x 12000 mm) in

ordinary soil (with 12m dieselhammer).

Penetration average 12 m.

Labour

Foreman

Pile driving machine operator

Pile driving machine Asst

Crane operator

Worker

Unit

Man-Day

Man-Day

Man-Day

Man-Day

Hour

L.S

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

litre

kg

Hour

L.S

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Quantity

0.3

0.5

0.5

3

4

-

0.3

0.3

0.5

0.5

3

3

0.1

2.7

-

0.3

0.3

0.3

0.3

6

Remarks

- Cost of Timber piles

according to varying dia;

with all necessary fittings

is to be included in the

main estimate.

- Cost of Timber piles

according to varying dia;

with all necessary fittings

is to be included in the

main estimate.

A

2

StandardData for Working Out Rates Per Unit Quantity of Items of Work-contd.

Particulars of Materials and Labour

'001s Required

12m)rail line trollies for transport of precast

bile.

One crane for loading unloading erecting

and pitching of precast pile.

Pile driving machine (1) No

;or Operation

H.S.D for Pile Driving Machine

H.S.D for Crane

Engine Oil

Sundries

.abour for Pile Driving reinforced cement con-

rete pile (350 mm x 350 mm x 12000 mm) in

~rdinary soil ( Using drop hammer with winch

~perated by machine).Penetration Average 12m.

.abour

Foreman

Operator

Worker

dachine

Pile driving machine (1)No

:or Operation

Diesel Oil

Grease Oil

Sundries

Making of Stand Pipe 8 rnrn thk; 12mm thk;

(800 mm 0 to 1 650 mm 0 ) (For 1 Sqm)

Steel fixer

Worker

Driving Stand Pipe

Driving of Stand Pipe1 350mm 0,1650mm 0

with Vibro Hammer for 1200mm 0 ,

1500mm 0 Bored Pile. ( For 1 m )

Stand pipe

Steel fixer

Head Worker

Worker

Unit

Hour

Hour

Hour

Man-Da:

Man-Da:

Man-Dti

Remarks

Cost for R.C Piles to be

calculated according to

the reqd.Size and inclu-

ded in the main estimate.

Cost for R.C Piles to be

calculated according to

the reqd.Size and inclu-

ded in the main estimate.

3

Standard Data for Working Out Rates Per Unit Quantity of Items of Work-contd.

Sr

No.

(b)

7.

(a)

(b)

Particulars of Materials and Labour

Electric Helper

Operator /Machine Driver

Sundries

H.S.D

Driving of Stand Pipel950rnrn 0,2650mm 0

with Vibro Hammer for1 800mm 0,2500mm0

Bored Pile. ( For 1 m )

Stand Pipe

Steel Fixer

Head Worker

Worker

Electric Helper

Operator /Machine Driver

Sundries

H.S.D

Removing Stand Pipe

Removing of Stand Pipe 1350mm 0,1650mm0

with Vibro Hammer for 1200 mm 0 ,

1500mm 0 Bored Pile. ( For 1 m )

Stand Pipe

Steel Fixer

Head Worker

Worker

Electric Helper

Operator Machine Driver

Sundries

Removing of Stand Pipe 1950mm 0,

2650 mm0 with Vibro Hammer for 1800mm 0,

2500mm 0 Bored Pile. ( For 1 m )

Stand Pipe

Steel Fixer

Head Worker

Worker

Electric Helper

Operator /Machine Driver

Sundries

H.S.D

Unit

Man-Day

Man-Day

L.S

litre

No

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

L.S

litre

No

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

L.S

No

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

L.S

litre

Quantity

0.5

0.7

-

-

1

1

3.2

0.5

0.7

-

-

-

0.7

0.5

2

0.5

0.5

-

-

0.7

0.7

2.5

0.5

0.5

-

-

Remarks

4

Standard Data for Working Out Rates Per Unit Quantity of Items of Work-contd

Head Worker

Worker

Operator Machine Driver

Sundries

H.S.D

Sr

No.

8.

9.

10.

1 1.

Remarks Particulars of Materials and Labour

Fitting of Drilling Equipment to dig Bored Pile.

1200rnm 0 , 1500rnm 0 ,1800mm 0,

2500rnm 0. ( For 1 time )

Head Worker

Worker

Operator /Machine Driver

Sundries

H.S.D

Dismantling of Drilling Equipment.

( For 1 time )

Drilling of 800mm 0 mini Bored Pile.

(Ground, Ordinary Soil) ( For 1 m )

Head Worker

Foreman

Worker

Operator Machine Driver

Water Pump Helper

Sundries

H.S.D

Machinary hair Charges

Drilling of 800 mm @mini Bored Pile.

(Ground , Weathered Soft Rock ) ( For 1 m )

Head Worker

Foreman

Worker

Operator Machine Driver

Water Pump Helper

Sundries

H.S.D

Machinary hair Charges

-

Unit

Man-Day

Man-Day

Man-Day

L.S

litre

Man-Day

Man-Day

Man-Day

L.S

litre

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

L.S

litre

L.S

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

L. S

litre

L.S

Quantity

2

7

0.8

-

-

2

7

0.8

-

-

0.7

0.5

2

0.3

0.3

-

-

-

1.3

1

4

0.7

0.7

-

-

-

5

Standard Data for Working Out Rates Per Unit Quantity of Items of Work-contd.

Sr

No.

12.

13.

14.

15.

Particulars of Materials and Labour

Drilling of 800 rnm 0 mini Bored Pile.

(Water, Ordinary Soil) ( For 1 m )

Head Worker

Foreman

Worker

Operator /Machine Driver

Water Pump Helper

Sundries

H.S.D

Drilling of 800mm 0 mini Bored Pile.

(Water , Weathered Soft Rock) ( For 1 m )

Head Worker

Foreman

Worker

Operator /Machine Driver

Water Pump Helper

Sundries

H.S.D

Drilling of 1200mm 0 Bored Pile

( Ordinary Soil ) ( For 1 m )

Head Worker

Foreman

Worker

Operator /Machine Driver

Water Pump Helper

Sundries

H.S.D

Drilling of 1500mm 0 Bored Pile

( Ordinary Soil ) ( For 1 m )

Head Worker

Foreman

Worker

Operator Machine Driver

Water Pump Helper

Sundries

H.S.D

Unit

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

L. S

litre

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

L.S

litre

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

L. S

litre

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

L. S

litre

Quantity

0.8

0.6

2.5

0.4

0.4

-

-

1.5

1.2

5

0.8

0.8

-

-

1

0.5

3

0.5

0.3

-

-

1.2

0.5

3.5

0.5

0.4

-

-

Remarks

Standard Data for Working Out Rates Per Unit Quantity of Items of Work-contd.

Quantity

1.4

0.8

4.3

0.7

0.5

-

-

1.5

0.8

4.5

0.8

0.5

-

-

1.5

0.8

4.8

0.8

0.5

-

-

1.3

0.5

3.5

0.5

0.4

-

-

Unit

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

L.S

litre

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

L.S

litre

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

L.S

litre

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

L.S

litre

Sr

No.

16.

17.

18.

19.

Remarks

Particulars of Materials and Labour

Drilling of 1500mm 0 R.C.D Bored Pile

( Ordinary Soil ) ( For 1 m )

Head Worker

Foreman

Worker

Operator Machine Driver

Water Pump Helper

Sundries

H.S.D

Drilling of 1800mm 0 , Bored Pile

( Ordinary Soil ) ( For 1 m )

Head Worker

Foreman

Worker

Operator /Machine Driver

Water Pump Helper

Sundries

H.S.D

Drilling of 2500rnm 0 , Bored Pile

( Ordinary Soil ) ( For 1 m )

Head Worker

Foreman

Worker

Operator /Machine Driver

Water Pump Helper

Sundries

H.S.D

Drilling of 1200mm 0 Bored Pile.

( Weathered Soft Rock Layer Only, Based on Soil

Test Result ) ( For 1 m )

Head Worker

Foreman

Worker

Operator /Machine Driver

Water Pump Helper

Sundries

H.S.D

I

Standard Data for Working Out Rates Per Unit Quantiry of Items of Work-contd.

Particulars of Materials and Labour

lrilling of 1500mm 0 Bored Pile

: Weathered Soft Rock Layer Only) Based on Soil

rest Result ) ( For 1 m )

Head Worker

Foreman

Worker

Operator Machine Driver

Water Pump Helper

Sundries

H.S.D

lrilling of 1500rnrn 0 R.C.D Bored Pile

Weathered soft rock Layer only Based on soil

Testresult) ( For 1 m )

Head Worker

Foreman

Worker

Operator Machine Driver

Water Pump Helper

Sundries

H.S.D

lrilling of 1800mm 0 Bored Pile

: Weathered Soft Rock Layer Only Based on

Soil Test Result ) ( For 1 m )

Head Worker

Foreman

Worker

Operator /Machine Driver

Water Pump Helper

Sundries

H.S.D

Drilling of 2500mm 0 Bored Pile

( Weathered Soft Rock Layer Only based on

Soil Test Result ) ( For 1 m )

Head Worker

Foreman

Worker

Operator Machine Driver

Unit

Man-Da:

Man-Da:

Man-Da:

Man-Da:

Man-Da:

L.S

litre

Man-D?

Man-D?

Man-D?

Man-Da:

Remarks

8

Standard Data for Working Out Rates Per Unit Quantity of hems of Work-contd.

Worker

Sundries

H.S.D

Sr

No.

24.

25.

26.

27.

28.

Particulars of Materials and Labour

Water Pump Helper

Sundries

H.S.D

Mixing of Betonite Solution. (For 1 cum)

Worker

Sundries

H.S.D

After drilling Bored Pile and fitting tremie pipe to

pour concrete , Proving of Slime Wash with

Compressor, for cleaning to Bored hole.

(For 1 hole)

Hanging of Steel Cage for 800mm0,1000rnrn 0 ,

1200 mm 0 to Bored Hole with Crane.

(For 12m length )

Welding Rod

Steel Fixer

Worker

Sundries

Hanging of Steel Cage for 1500 mrn 0 ,

1800 mm 0, 2500 mm 0 to Bored Hole with

Crane. (For 12m length )

Welding Rod

Steel Fixer

Worker

Sundries

H.S.D

Pouring (1 : 1 ?4 :3) Cement concrete by Tremie

Method. (1 cum)

Head Worker

Worker

Operator /Machine Driver

Sundries

H.S.D

Unit

Man-Day

L.S

litre

Man-Day

L.S

litre

Man-Day

L.S

litre

kg

Man-Day

Man-Day

L.S

kg

Man-Day

Man-Day

L.S

litre

Man-Day

Man-Day

Man-Day

L.S

litre

Quantity

0.7

-

-

0.8

-

-

3

-

-

-

2

6

-

-

3

8

-

-

0.5

0.8

0.1

-

-

Remarks

9

Standard Data for Working Out Rates Per Unit Quantity of Items of Work-contd.

Particulars of Materials and Labour

oining, Dismantling, Cleaning, Painting of

:arth oil & Grease of Tremie Pipe to be ready.

For 1 m )

Steel Fixer

Helper

Sundries

3reaking of Bored Pile Head. ( 1 cum )

Head Worker

Sundries

Well Foundation

Iigging and sinking of 1200mrn0 spun pipe

o get specified depth including removing soil

md water pumping. (Ground, Ordinary soil)

For 1 m)

Worker

Carpenter

Head Worker

Operator

Steel Fixer

Sundries

Iigging and sinking of 1200mm0 spun pipe

o get specified depth including removing soil

md water pumping. (Ground, Sand) (For 1 m)

Worker

Carpenter

Head Worker

Operator

Steel Fixer

Sundries

Digging and sinking of 1200mm0 spun pipe

to get specified depth including removing soil

md water pumping. (Ground, Weathered soft

rock) (For 1 m)

Worker

Carpenter

Head Worker

Unit

vim-Daj

vim-Daj

Man-Da:

Man-Dq

Man-Dq

L. S

Man-Dq

Man-Da,

Man-Da

Remarks

10

Standard Data for Working Out Rates Per Unit Quantity of Items of Work-contd.

Sr

No.

34.

35.

36.

37.

Particulars of Materials and Labour

Operator

Steel Fixer

Sundries

Digging and sinking of 1200mrn0 spun pipe

to get specified depth including removing soil

and water pumping. (Water, Ordinary soil)

(For 1 m)

Worker

Carpenter

Head Worker

Operator

Steel Fixer

Sundries

Digging and sinking of 1200mm0 spun pipe

to get specified depth including removing soil

and water pumping. (Water, Sand) (For 1 m)

Worker

Carpenter

Head Worker

Operator

Steel Fixer

Sundries

Digging and sinking of 1200mm0 spun pipe

to get specified depth including removing soil

and water pumping. (Water, Weathered soft

rock) (For 1 m)

Worker

Carpenter

Head Worker

Operator

Steel Fixer

Sundries

Digging and sinking of 2750mm0 cassion well

to get specified depth including removing soil

and water pumping. (Ground , Ordinary soil)

(For 1 m)

Quantity

1.6

1.2

-

15.6

1.2

1.2

1

0.7

-

19.6

1.6

1.2

1.2

1

-

31.2

2.4

2.2

1.9

1.4

-

Unit

Man-Day

Man-Day

L.S

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

L.S

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

L.S

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

L,S

Remarks

-1 -1

Standard Data for Working Out Rates Per Unit Quantity of Items of Work-contd.

Quantity

2

63

0.5

10

3

6

6.5

9

10.5

3

-

2.5

78.8

0.6

12.5

3.8

7.5

8.1

11.3

13.1

3.8

-

4

126

1

20

6

12

13

18

Unit

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

L.S

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

L.S

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Sr

No.

38.

39.

Remarks

Particulars of Materials and Labour

Head Worker

Worker

Welder

Operator

Steel Fixer

Foreman

Diver

Helper

Rigger

Carpenter

Sundries

Digging and sinking of 2750mm0 cassion well

to get specified depth including removing soil

and water pumping. (Ground , Sand)

(For 1 m)

Head Worker

Worker

Welder

Operator

Steel Fixer

Foreman

Diver

Helper

Rigger

Carpenter

Sundries

Digging and sinking of 2750rnm0 cassion well

to get specified depth including removing soil

and water pumping. (Ground, Weathered soft

rock) (For 1 m)

Head Worker

Worker

Welder

Operator

Steel Fixer

Foreman

Diver

Helper

12

Standard Data for Working Out Rates Per Unit Quantity of Items of Work-contd.

Remarks

Sr

No.

40.

41.

42.

Particulars of Materials and Labour

Rigger

Carpenter

Sundries

Digging and sinking of 2750rnm0 cassion well

to get specified depth including removing soil

and water pumping. (Water , Ordinary soil)

(For 1 m)

Head Worker

Worker

Welder

Operator

Steel Fixer

Foreman

Diver

Helper

Rigger

Carpenter

Sundries

Digging and sinking of 2750rnrn0 cassion well

to get specified depth including removing soil

and water pumping. (Water, Sand) (For 1 m)

Head Worker

Worker

Welder

Operator

Steel Fixer

Foreman

Diver

Helper

Rigger

Carpenter

Sundries

Digging and sinking of 2750mm0 cassion well

to get specified depth including removing soil

and water pumping. (Water, Weathered soft

rock) (For 1 m)

Head Worker

Unit

Man-Day

Man-Day

L.S

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

L.S

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

L.S

Man-Day

Quantity

21

6

-

2.4

75.6

0.6

12

3.6

7.2

7.8

10.8

12.6

3.6

-

3

94.6

0.7

15

4.6

9

9.7

13.6

15.7

4.6

-

4.8

13

Standard Data for Working Out Rates Per Unit Quantity of Items of Work-contd.

Mechanic

Worker

Standard Data for Working Out Rates Per Unit Quantity of Items of Work-contd.

15

Standard Data for Working Out Rates Per Unit Quantity of Items of Work-contd.

Sr

No.

-

54.

I

Particulars of Materials and Labour

Stressing for Post tension HT Wire to get

complete strength . (1 Tendon)

Erector

Steel Fixer

Operator Machine Driver

Machine Helper

Electric Helper

Worker

Sundries

55. Plugging (1 : 1: 1)Cement Concrete into the

Concrete cavity of the end-block. (Girder 1 No)

Mason

Worker

Sundries

56.

1 58. 1 ~ i x i n ~ lowering bar, jacking beam, hanger jack

Grouting high strength cement motor with Gro-

uting machine to sheating pipe. (Girder 1 No)

Mechanic

Electric Helper

Operator Machine Driver

Worker

Sundries

57.

Erector

Worker

Sundries

Fixing cycle trolley, launching arm and accesso-

ries on the bailey girder. (with crane and man)

Including fixing break wedge and sway braces.

(1 pair)

Erector

Worker

Sundries

Remarks Unit

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

L.S

Man-Day

Man-Day

L.S

Man-Day

Man-Day

Man-Day

Man-Day

L.S

Man-Day

Man-Day

L.S

Quantii

1

0.3

0.7

0.3

0.3

11

-

1

2

-

3

1

1

30

-

8

40

-

Man-Day 5

Man-Day 35

L.S -

16

Standard Data for Working Out Rates Per Unit Quantity ofItems of Work-contd.

Sr

No.

59.

60.

61.

62.

63.

64.

Particulars of Materials and Labour

Side shifting P.C Girder from casting position

to Launghing position distance l m . (1 time)

Erector

Worker

Sundries

Making Jack up P.C Girder, timber crib.

Tighting in hanging beam with steel cable,

removing crib, fixing to get right alignment

between two Launching Arm. (1 time)

Erector

Carpenter

Worker

Sundries

Pulling Steel cable from electric winch and

fixing them top of the launching Arm. (1 time)

Erector

Electric Helper

Worker

Launching P.C Girder by electric winch.

Launching (1 time)

Mechanic

Electric Helper

Erector

Worker

Making Jack Down Launched P.C Girder

bracing strut not to fall down. (1 time)

Erector

Carpenter

Worker

Sundries

After making jack down dismantling launching

equipment from P.C Girder,Pushing Launching

arm to the casting stagging. (1 time)

Erector

Machine operator driver

Worker

Unit

Man-Day

Man-Day

L.S

Man-Day

Man-Day

Man-Day

L.S

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

L.S

Man-Day

Man-Day

Man-Day

Quantity

5

20

-

4

2

15

-

2

1

3

4

1

2

20

4

4

4

-

2

1

6

Remarks

-

Sr

Jo.

-

55.

i6.

i7.

58.

69

17

Slandard Data for Working Out Rates Per Unit Quantity of Items of Work-contd.

Particulars of Materials and Labour

Levelling and carving on the Cross Beam for

fitting P.C Girder,carving 1200mm 0 x 254mm

grouting hole, fitting bearing plate. (1 sheet)

Mason

Erector

Worker

Sundries

Fixing pretension frame with anchor bolt on the

concrete pretension bench according to the

required design. (1 0 Nos)

Erector

Worker

Putting H.T wire coil (3MT)to the Dispencer

with crane using man,fixing bolt & nut.

(1 coil-3 ton)

Erector

Worker

Sundries

Pulling H.T wire to Dispencer for required

length,cutting then with griding machine.

(60 Nos)

Erector

Mechanic

Head Worker

Worker

Skill (Electric)

Sundries

Fixing repaired wires in pretension bench,

anchorage frame systematically.

(26m - 38 Nos)

Erector

Head Worker

Worker

Sundries

(18m - 38 Nos)

Erector

Unit

Aan-Daj

Aan-Daj

Am-Daj

L.S

Aan-Daj

Aan-Daj

Man-Da

Man-Da

Man-Da

L.S

Man-Da

Remarks

Standard Data for Working Out Rates Per Unit Quantig of Items of Work-contd.

Erector

Remarks Quantity

3

25

-

2

0.1

0.1

0.1

0.1

0.1

-

0.1

0.1

0.3

-

3

8

3

2

1

1

-

Unit

Man-Day

Man-Day

L.S

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

L. S

Man-Day

Man-Day

Man-Day

L.S

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

L.S

Sr

No.

70.

71.

72.

73.

74.

Particulars of Materials and Labour

Head Worker

Worker

Sandries

Fixing end plate each end of the P.C Girder

systematically whille arranging H.T wire.

(Girder 1 No)

Stressing for pretension H.t wire to get stressing

force3.45 MPa. ( wire 1 No)

Mechanic

Erector

Machine operator driver

Worker

Skill (electric)

Sundries

Stressing of 12mm 0 or 13 rnm 0 7 strand wire

(For 1 No)

Foreman

Steel Fixer

Worker

Sundries

After fixing and checking P.C wire and rein-

forcement due to design, stressing H.T wire to

get required design force and elongation.

(Wire 38 Nos)

Erector

Worker

Skill (electric)

Hard Worker

Operator (Jack operator)

Operator (Hydraulic pump)

Sundries

Fixing accessories on the P.C Girder as per

design.

(a)Making and fixing hook (2 points)

19

Standard Data for Working Out Rates Per Unit Quantity of Items of Work-contd

Remarks Quantity

2

-

7

3

-

0.4

-

0.1

-

0.8

-

0.2

-

3

Unit

Man-Day

L. S

Man-Day

Man-Day

L.S

Man-Day

L.S

Man-Day

L.S

Man-Day

L.S

Man-Day

L.S

Man-Day

Sr

No,

75.

76.

77.

78.

79.

Particulars of Materials and Labour

Erector

Sundries

@)Making and fixing shoe plate (1 0 Points)

Welder

(c)fixing througt bolt & nut (1 0 Nos)

Erector

Sundries

Fixing of R.S.T Beam, H Beam, Angle,

M.S Flat & Channel for casting bed only.

(For 10 kg)

Head Worker

Sundries

Dismantling of R.S.T Beam, H Beam, Angle,

M.S Plate, M.S Flat & Channel for casting bed

only. (For 10 kg)

Head Worker

Sundries

Fixing of L.S.T Part, Bailey Part & C.H Parts

system. ( (For 10 kg)

Head Worker

Sundries

Dismantling of L.S.T Part , Bailey Part & C.H

Parts system. ( (For 10 kg)

Head Worker

Sundries

Steel Truss

Labour for Launching of R.S.JS. over bridge

sup ports (Using two pulleys and winch from

the other side) (5No x 13000rnrn x 610mrn x

190mm) at (43.l)kg per RFT.

(Total Weight = 9.3 MTons)

Labour

Bridge Foreman

20

Standard Data for Working Out Rates Per Unit Quantity of Items of Work-contd.

Total Kit one

One hammer

Coir rope (25mm 0 61m)

25000 Kg Jacks (2)No

Bridge Foreman

Worker

Sundries

2 1

Standard Data for Working Out Rates Per Unit Quantity of Items of Work-contd

Quantity

-

-

-

-

-

-

-

-

-

-

-

-

20

150

1150

-

-

-

-

-

-

-

-

-

-

-

-

Unit

-

-

-

-

-

-

-

-

-

-

-

L.S

Man-Day

Man-Day

Man-Day

-

-

-

-

-

-

-

-

-

-

-

L.S

Sr

No.

83.

Remarks

Particulars of Materials and Labour

Tools Required

Total Kit one

One hammer

Coir rope (25mrn 0 61m)

4000 Kg Hand Winch (2)No

Bailey Roller (6)No

Jumper (1 0)No

Wire Rope (16mm 0 228m)

One local JIB

Double pulley (2)No

Single pulley (1)No

50000 kg Jacks (2)No

Sundries

(b) Labour for assembling and launching C.H.

bridge (6.5m Road way)bolts and nuts for all

steel works complete (48m) span double depth.

(Total Weight = 150 MTons) (By Crane)

Labour

Bridge Foreman

Skilled Worker

Unskilled Worker

Tools Required

Total Kit one

One hammer

Coir rope (25mm 0 61m)

4000 Kg Hand Winch (2)No

Bailey Roller (6)No

Jumper (1 0)No

Wire Rope (1 6mm 0 228m)

One local JIB

Double pulley (2)No

Single pulley (1)No

50000 kg Jacks (2)No

Sundries

Labour for assembling and German bridge

(3.35m Road way) on scaffolding and lowering

down on supports or launching (1 8m)span.

(Total Weight = 17.87 MTons)

22

Standard Data for Working Out Rates Per Unit Quantity of Items of Work-contd.

Bridge Foreman

Worker

Bridge Foreman

Skilled workers

Unskilled workers

Sr

No.

84.

85.

Particulars of Materials and Labour

Labour

Tools Required

Bailey Jacks = 2 No

Bailey rollers = 7 No

One spanner

One hammer

Sundries

Labour for assembling of R.P.T bridge on

scaffolding including rivetting and lowering

down on supports complete (30m).Span and

(5m) road way.

(Total Weight = 64.2 MTons)

Labour

Tools Required

4000 Kg hand winch

Wire rope (12rnm 0 457m)

Wire rope (1 6mm 0 457m)

Coir rope (25mm 0 152m)

Service bolts

Double pulley (2)No

Single pulley (1)No

One Bellow

Dollys (2)No

Rivetting guns (2)No

One compressor with (2)No. Hose pipe (1 52m)

Local JIB one No.

One hammer

75000 Kg Jacks (2)No

Sundries

Labour for assembling and launching of R.P.T

bridge after rivetting complete for all steel

works (3Om)span (5m) road way.

(Total Weight = 64.2 MTons)

Unit

Man-Day

Man-Day

-

-

-

-

L.S

Man-Day

Man-Day

Man-Day

-

-

-

-

-

-

-

-

-

-

-

-

-

-

L.S

Quantity

8

80

-

-

-

-

-

30

100

420

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Remarks

23

Standard Datafor Working Out Rates Per Unit Quantity of Items of Work-contd.

Sr

No.

86.

87.

Particulars of Materials and Labour

Labour

Bridge Foreman

Skilled workers

Unskilled workers

Tools Required

4000 Kg hand winch

Wire rope (1 2rnm 0 457m)

Wire rope (16rnm 0 457m)

Coir rope (25mm 0 152m)

Service bolts

Double pulley (2)No

Single pulley (1)No

One Bellow

Dollys (2)No

Rivetting guns (2)No

One compressor with (2)No. Hose pipe (500')

Local JIB one No.

Bailey rollers (6)No

Jumpers (1 0)No

75000 Kg Jacks (2)No

Sundries

Shifting Steel Truss and Bailey by Crane from

one place to another (Including hooking,

removing, handling with man) (10 MTons)

Foreman

Head Worker

Worker

Sundries

Sorting & arranging the steel truss systemati-

cally, Laying out them for preassambling works

systematically. (1 0 MTons)

Foreman

Head Worker

Worker

Sundries

Unit

Man-Day

Man-Day

Man-Day

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

L.S

Man-Day

Man-Day

Man-Day

L.S

Man-Day

Man-Day

Man-Day

L.S

Quantity

35

120

400

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

1

1

5

-

1

1

4

-

Remarks

Standard Data for Working Out Rates Per Unit Quantity ofltems of Work-contd.

Steel Fixer

Head Worker

Worker

Operator /Machine Driver

Electric Helper

Sundries

Remarks Quantity

2

1

2

0.5

0.5

-

4

2

4

1

1

-

1

4

1

0.5

4

0.5

0.8

0.5

3

0.5

Unit

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

L. S

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

L.S

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Sr

No.

88.

89.

90.

Particulars of Materials and Labour

Checking the steel truss according to the design

for preassembling works on the ground.

(1 000 kg)

(a) Erecting the preassembled steel truss from

pier to pier with erection crane according to

the design. (1000 kg)

Steel Fixer

Head Worker

Worker

Operator /Machine Driver

Electric Helper

Sundries

(b) Allowing 50% of the above expenditure

for dismentling.

(a) Installing Bolts & Nuts, Drift Pins & Tigh-

tenning according to the design while erecting

steel truss. (1000 Nos)

Steel Fixer

Worker

- Tightening them with & Electric Guns again

before transfering the target place. (1000 Nos)

Steel Fixer

Head Worker

Worker

Electric Helper

(b) Removing Bolt & Nuts (1 000 Nos)

Steel Fixer

Head Worker

Worker

Electric Helper

25

Standard Data for Working Out Rates Per Unit Quantity of Items of Work-contd.

Sr

No.

91.

92.

93.

94.

Particulars of Materials and Labour

Final Tightenning the ready installed Bolts &

Nuts according to theTightenning sequence

( including with checking them whether

standard or not ) (1 000 Nos)

Steel Fixer

Head Worker

Worker

Electric Helper

Sundries

Checking high tension Bolts & Nuts with check

Wrench whether standard or not. (1 000 Nos)

Steel fixer

Worker

Sundries

(a)Fixing the safety Net to the upper & lower

steel truss systematically. (1 00 m)

Carpenter

Head Worker

Worker

Sundries

(b) Removing Safety nets from Steel truss

Systemtically. (1 00 m)

Carpenter

Head Worker

Worker

Sundries

Fixing Sleeper on the top & bottom Chord of

the Steel truss. (200 mm x 200 rnm)

(a) Carving sleepers fixing on Top Chord.

(1 00 Nos)

Carpenter

Sundries

(b) Drilling holes on the sleepers for hooking.

(1 00 Nos)

Carpenter

Sundries

Unit

Man-Day

Man-Day

Man-Day

Man-Day

L. S

Man-Day

Man-Day

L.S

Man-Day

Man-Day

Man-Day

L.S

Man-Day

Man-Day

Man-Day

L.S

Man-Day

L.S

Man-Day

L.S

Quantity

2

1

6

1.5

-

1.5

5

-

4

6

50

-

2

3

25

-

4.5

-

2.4

-

Remarks

Standard Dafa for Working Out Rates Per Unit Quantity of Items of Work-contd.

r

Particulars of Materials and Labour Unit Quantity

Remarks

0.

(c) Shifting the sleepers within 30m with man

and arranging them Systemtically (not more

than one time. ) (100 Nos)

Carpenter Man-Day 4

Sundries L.S -

(d) Fixing the railway on the sleeper firmly on

the Top Chord of Installed steel truss.

- fixing with the required G.Bolt, U.Bolt along

the rail length for UIS & DIS. (10 m)

Steel Fixer Man-Day 2

Carpenter Man-Day 2

Head Worker Man-Day 1

Worker Man-Day 9

Operator /Machine Driver Man-Day 1

Electric Helper Man-Day 0.5

Sundries L.S -

(e) Fixing the railway on the the sleeper firmly

on the strainger of installed steel truss.

- fixing with the J.Bolt or Dog Spike for Up

Stream and Down Stream.

(10 m)

Steel Fixer Man-Day 1

Carpenter Man-Day 1

Head Worker Man-Day 1

Worker

Man-Day 4.5

Sundries L.S -

(f) Dismantling the railway (50 % of fixing)

95. Installing Erection Tower, Mast Crane & Multi-

purpose Crane on the Top Chord of the Steel

Truss. (1000 kg)

(a) With universal member

Steel Fixer Man-Day 5

Head Worker Man-Day 2

Worker Man-Day 13

Sundries L.S -

27

Standard Data for Working Out Rates Per Unit Quantity of Items of Work-contd.

Standard Data for Working Out Rates Per Unit Quantiv of Items of Work-contd.

Quantity

0.5

1

1

1

-

20

20

10

100

20

20

-

4

8

2

7

7

7

-

5

9

2

Unit

Man-Day

Man-Day

Man-Day

Man-Day

L.S

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

L.S

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

L.S

Man-Day

Man-Day

Man-Day

Sr

No.

99.

100.

Remarks

Particulars of Materials and Labour

Steel Fixer

Worker

Operator /Machine Driver

Electric Helper

Sundries

Shifting Erection Tower on the Top Chord fiom

one span to another with winch, Pretension the

Steel Cables Final tension with 500 MT Jack

and Checking Erection Tower. (1 Time)

Foreman

Steel Fixer

Head Worker

Worker

Operator /Machine Driver

Electric Helper

Sundries

While erecting steel truss fiom one Pier to

another for the required level, fixing with 100 M

Ton jack, 3001350 MTon jack,500 MTon jack,

on the bearing of the piers.

- After that, making jack up & Jackdown

- Shifting horizontally & longitudinally

- Other components Work

(a) 100 MTon Jack

(1 0 Nos per 1 Time)

Foreman

Steel Fixer

Head Worker

Worker

Operator /Machine Driver

Electric Helper

Sundries

(b) 3001350 MTon Jack

(1 0 Nos per 1 Time)

Foreman

Steel Fixer

Head Worker

29

Standard Data for Working Out Rates Per Unit Quantity of Items of Work-contd.

Sr

No.

101.

102.

(a)

(b)

(c)

103.

Particulars of Materials and Labour

Worker

Operator /Machine Driver

Electric Helper

Sundries

(c) 500 MTon Jack

(1 0 Nos per 1 Time)

Foreman

Steel Fixer

Head Worker

Worker

Operator /Machine Driver

Electric Helper

Sundries

Fixing of Bearing. (1 000 kg)

Steel Fixer

Head Worker

Worker

Sundries

Cutting steel plate to get required size (With gas)

12mm thk: (for 2500 mm)

Welder

Oxygen gas

Propane gas

16 mm to 20 rnm thk: (for 2500 rnrn)

Welder

Oxygen gas

Propane gas

25 mm to 30 rnrn thk: (for 2500mm)

Welder

Oxygen gas

Propane gas

Welding work. (one ply:)

(for 2500mm)

welding rod (5kglpkt)

Welder

Unit

Man-Day

Man-Day

Man-Day

L.S

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

L.S

Man-Day

Man-Day

Man-Day

L.S

Man-Day

kg

kg

Man-Day

kg

kg

Man-Day

kg

kg

Pkt

Man-Day

Quantity

8

8

8

-

6

11

3

8.5

10

10

-

2

2

9

-

1

4.5

1.5

1.5

5

1.5

2

6

1.5

0.2

1

Remarks

Standard Data for Working Out Rates Per Unit Quanlily of Items of Work-contd.

Remarks

Including Loading,

Unloadtig and shifting

Quantio

2.5

3.3

-

2

1.5

-

2

2

-

0.8

-

1

-

1

1

1

0.1

-

- Moving main cable coin

to cutting place by cran

- Cleaning main cable

- Levelling ground and

setting turn table for

cutting main cable with

wheel cutter & chain

block to get specified

length.

- Transferring cutted mai

cable

Unit

Man-Day

Man-Day

L.S

Man-Day

Man-Day

L. S

Man-Day

Man-Day

L.S

Man-Day

L. S

Man-Day

L.S

Man-Day

Man-Day

Man-Day

Man-Day

L.S

;r

Jo.

04.

05.

06.

07.

,08.

109.

Particulars of Materials and Labour

Steel Plate Girder

Preassembling of steel plate girder according

to design on the ground. (1000 kg)

Skilled Worker

Worker

Sundries

Fixing , Initial & final tightenning of bolt &

nuts and drip pins according to the design while

assembling steel plate girder .(I000 Nos)

Skilled Worker

Worker

Sundries

Installation of preassembled steel plate girder

by crane as per drawing from pier to pier.

(1 000 kg)

Skilled Worker

Worker

Sundries

Checking to final tightenned bolt nuts with

checking spanner whether standard or not.

(1 000 Nos)

Skilled Worker

Sundries

Placing bearing plate and fixing bolt & nut.

Skilled Worker

Sundries

Suspension and Cablestayed Bridge

Cutting and cleaning main cable (For 10 m)

Skilled Man

Head Worker

Worker

Machine Driver / Operator

Sundries

3 I

Standard Data for Working Out Rates Per Unit Quantity ofllems of Work-confd.

Sr

No.

11 0.

1 1 1.

112.

1 13.

114.

Particulars of Materials and Labour

Taking out and cleaning running cable from

Cable Drum and placing them on timber crib

(For 10 m)

Skilled Man

Head Worker

Worker

Sundries

Fixing running cable on Winch Drum at

Up stream and Down stream (For one winch)

Skilled Man

Head Worker

Sundries

Taking out and cleaning Pilot Cable from Cable

Drum and placing them on

timber Crib (For 10 m)

Skilled Man

Head Worker

Worker

Sundries

Fixing step by step steel wire rope Pilot Cable

on each side of Anchor on high Level.

(For lm)

Skilled Man

Head Worker

Worker

Sundries

Fixing Travelling Cage by safety belt on high

level of Tower with Pulley Travelly.

(For 1 Cage)

Skilled Man

Helper for Skilled Man

Head Worker

Electrician

Sundries

Unit

Man-Day

Man-Day

Man-Day

L.S

Man-Day

Man-Day

L.S

Man-Day

Man-Day

Man-Day

L.S

Man-Day

Man-Day

Man-Day

L. S

Man-Day

Man-Day

Man-Day

Man-Day

L.S

Quantity

0.1

0.1

0.1

-

3

4.5

-

0.3

0.2

0.4

-

0.3

0.2

0.1

-

13.5

7.5

1.5

0.8

-

Remarks

- Including installation of

lock, Bull Dog Grip

Standard Data for Working Out Rates Per Unit Quantity of Items of Work-confd.

Alignment (For one winch)

Skilled Man

Helper for Skilled Man

Sundries

3r

Particulars of Materials and Labour

qo.

15. Fixing 5 Mton winch According Tower Anchor

Fixing Supporting Frame Anchor Plate system-

tically according cable alignment behind

Anchorage. (For 1 Anchor Supporting Frame)

Skilled Man

Welder

Worker

Sundries

After installation main cable, dismantling

and cutting supporting Anchor Frame, extra

Anchor Plate ( For 1 Anchor Supporting

Unit

Frame.)

Quantit

Skilled Man

Welder

Worker

Sundries

Man-Day

Man-Day

L.S

3

4.5

-

Man-Day

Man-Day

Man-Day

L.S

3

1.5

6

-

Man-Day

Man-Day

Man-Day

Welder

Operator of welding M/C

Worker

Sundries

1

0.5

1.8

11 8. Fixing roller by welding on high level of Tower

with safety belt. (For 1 No)

Skilled Man

1 19. Making for Cable clamp systemmatically and

making hole for Bolt & Nut For Tower Tilting

work. (For Cable clamp 1 set)

Welder

Helper For Welder

Sundries

Man-Day

Man-Day

Man-Day

L.S

0.5

Man-Day

Man-Day

Man-Day

L.S

120. Fixing firmly Over lapping at least 5MTon Chain

0.3

1.3

1.8

-

I block, Steel Wire rope with Bull Dog Grip at

Remarks

- - ~

Including timber support

and wedging according

inline of Anchor slab

Including temporary

welding work

33

Standard Data for Working Out Rates Per Unit Quantity of Items of Work-contd.

Particulars of Materials and Labour

nall Anchor For Tower Tilting.(For small

achor (Dead men) 1 No)

Skilled Man

Sundries

king Over Lapping and chainging way of chain

)r 10 MTon Chain Block at 10 MTon pulley

tee1 Wire with Bull Dog Grip at Anchor Canopy

or Tower Tilting.

:or Anchor 1 Point)

Skilled Man

Worker

Sundries

urning back Tower According specific

besign For TowerTiting.

For One Tower (2)Nos)

Skilled Man

Worker

Sundries

'ransfering cable from stockyard to Anchorage

by men and placing one on another (8)shape

In timber crib. (For 10 m)

Skilled Man

Head Worker

Sundries

nstallation of Main Cable for Bridge (For1 Om)

Skilled Man

Head Worker

Electrician

Mechanic

Welder

Sundries

Unit

tan-Day

Ian-Day

L.S

tan-Day

Ian-Day

L.S

Remarks

Inserting Main Cable to

Anchor Plate

a Putting on place upon

temporary rope

. holding upon Main Cab1

at saddle at each Tower

with B.D Grip by safety

belt and layer with Filler

stand

. Transfering cable from

one Tower to another

Standard Data for Working Out Rates Per Unit Quantity of Items of Work-contd.

Head Worker

Electrician

Sundries

Head Worker

Worker

Sundries

Remarks

- Taking out cable from

Anchor Plate of Ancho-

rage

- Checking Cable of Back

stay between Tower and

Anchorage

- Numbering cable by

layer and layer

- Installation of Main

Cable on high level over

water by life jacket and

safety belt

- Joining heavy Cable

lamp to

Travelly by pulley and

chain block

- Specified cable marking

on main cable

- Doing difficulty on high

level of Main Cable

- Fixing Suspender Rod

on main cable with Hing

shaft and safety pin

- Transfering suspender

rod to working area

by Manpower

Quantity

14

3

4

-

0.3

0.1

-

0.4

-

7

2

0.5

-

Unit

Man-Day

Man-Day

Man-Day

L.S

Man-Day

Man-Day

L.S

Man-Day

L.S

Man-Day

Man-Day

Man-Day

L.S

Sr

No.

125.

(a)

(b)

(c)

126.

(a)

Particulars of Materials and Labour

Installation of Cable Top Clamp.

(For Cable Clamp 1 set)

Skilled Man

Tightening Bolt & Nut for one time

(For 10 Nos of Bolt)

Skilled Man

Electrician

Sundries

Painting Enamel paint for cable Top Clamp on

high level (For 1 no of Top Clamp)

Skilled Man

Sundries

Installation Suspender Rod

(For Suspender Rod 1 No)

Skilled Man

35

Standard Data for Working Out Rates Per Unit Quantity of Items of Work-contd.

Skilled Man

Mechanic for Grout pump

Electrician

Head Worker

Sundries

Remarks Quantity

0.1

0.1

-

0.1

0.1

-

0.2

0.1

-

1

0.1

-

3.5

0.5

0.5

5

-

0.5

-

Unit

Man-Day

Man-Day

L. S

Man-Day

Man-Day

L.S

Man-Day

Man-Day

L.S

Man-Day

Man-Day

L.S

Man-Day

Man-Day

Man-Day

Man-Day

L.S

Man-Day

L.S

Sr

No.

(b)

(c)

127.

128.

129.

130.

Particulars of Materials and Labour

Threading Suspender U bolt ,painting grease,

Checking Bolt & Nut washer and Specifing

U Bolt marking

Skilled Man

Head Worker

Sundries

Painting Enamel paint for Suspender rod by

safety belt on high level

Skilled Man

Head Worker

Sundries

Adjusting Back stayed (for 1 Om)

Skilled Man

Head Worker

Sundries

Stressing Main Cable and Specifing Elongation

within Anchor according specified tension.

(For 1 Om)

Skilled Man

Head Worker

Sundries

Grouting Cement motor for Cable Guide Tube

within Anchor after stressing Main cable.

(For 1 Om)

Releasing binding cable Working length position

of Main Cable For Enclosing Blockafter

stressing.

( For 1 No of cable )

Skilled Man

Sundries

36

Standard Data for Working Out Rates Per Unit Quantity of Items of Work-contd.

Skilled Man

Sundries

Sr

No.

13 1.

132.

133.

134.

135.

1 36.

137.

Particulars of Materials and Labour

Adjusting and cutting layer of cable to

install Anchor Plate For Stressing.

(For 1 No of cable)

Shifting bailey (or) Steel truss on ground for

PreAssembling work. (For 1000 Kg)

Skilled Man

Head Worker

Sundries

Preassembling work for bailey (or) steel truss.

(For 1000 Kg)

Skilled Man

Head Worker

Sundries

Shifting heavy bailey (or) Steel Truss from

Preassembled Yard to join cable car by Crane

(For 1000 Kg)

Skilled Man

Head Worker

Sundries

Fixing preassembled bailey (or)Steel Truss on

Suspender Rod of Main Cable.

(For 1000 Kg)

Skilled Man

Head Worker

Sundries

Fixing Safety Net (For 1 m)

Skilled Man

Sundries

Removing safety Net (For 1 m)

Skilled Man

Sundries

Unit

Man-Day

L.S

Man-Day

Man-Day

L.S

Man-Day

Man-Day

L. S

Man-Day

Man-Day

L.S

Man-Day

Man-Day

L.S

Man-Day

L.S

Man-Day

L.S

Quantity

0.1

-

1.5

1.5

-

5

0.5

-

0.8

1

-

7.5

10

-

0.5

-

0.2

-

Remarks

37

Standard Data for Working Out Rates Per Unit Quantity of Items of Work-contd.

Sr

No.

138.

139.

140.

14 1.

142.

143.

144.

Particulars of Materials and Labour

Laying systematically small Transon walk way

and Checking, Laying Decking Beam

(For 1 000 Kg)

Skilled Man

Sundries

Canying Decking Beam and small Transon

difficulty by man power on temporary walkway

at high level of main bridge. (For 1000 Kg)

Skilled Man

Sundries

Putting heavy Decking slab on main bridge

by crane (For 1000 Kg)

Skilled Man

Head Worker

Sundries

Adjusting bailey (or)Steel truss of main bridge

to get specified camber by wing temporary

cable and Cushion Block. (For Suspender

Hanger 1 Point)

Skilled Man

Sundries

Jacking Down bailey (or)Steel truss with right

alignment to get final R.L by using 30 MTon

Jack Cushion Block and M.S Plate.(For one Pier)

Skilled Man

Sundries

Fixing Bearing Bolt to Bearing Mat and Bailey

(or)Steel truss Pin to Bearing Mat & Bailey

(or)Steel truss. (For one Pier)

Skilled Man

Sundries

Pouring High Strength Concrete to get required

Bearing Level (For 1 Bearing)

Skilled Man

Unit

Man-Day

L.S

Man-Day

L.S

Man-Day

Man-Day

L.S

Man-Day

L. S

Man-Day

L.S

Man-Day

L. S

Man-Day

Quantity

9.5

-

2

-

0.8

1.3

-

3.5

-

13.5

-

12

-

5

Remarks

- Include adjusting bottom

surface of Bearing Mat

to get specified R.L.

- Including cushion.

Standard Data for Working Out Rates Per Unit Quantity of Items of Work-contd.

39

Standard Datafor Working Out Rates Per Unit Quantity of Items of Work-contd.

Quantity

0.5

0.5

0.5

0.5

0.5

0.5

0.3

1

1

1

1

1

0.5

0.5

Unit

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Sr

No.

152.

153.

154.

155.

156.

157.

158.

Remarks

Particulars of Materials and Labour

Reading and specifying the centre of the Bored

pile when driving stand pipe from control point

by using theodolite.(l Time)

Surveyor

Helper

Surveying and specifying concrete top level to

pour bored concrete.(l Time)

Surveyor

Helper

Checking Bored Pile position after pouring

concrete. (1 Time)

Surveyor

Helper

Surveying and Checking Bored Pile after pouring

concrete to know stable or unstable. (1 Time)

Surveyor

Helper

Surveying and specifying Cap position of

Abutment or Pier.(l Time)

Surveyor

Surveying and Checking settlement of pier cap in

water. (1 Time)

Surveyor

Surveying and specifying Shaft position of Abutment

159.

160.

or Pier.(l Time)

Surveyor

Surveying and specifling Bearing position of

Abutment or Pier. (1 Time)

Surveyor

Specifling and Checking Level to fix M.S Rod in

Pile Cap, Shaft , Cross-beam. (1 Time)

Surveyor

Helper

Man-Day

Man-Day

Man-Day

Man-Day

Standard Data for Working Out Rates Per Unit Quantity ofltems of Work-contd.

Particulars of Materials and Labour

Levelling Cap (or) Shaft (or) Cross Beam in their

form works before pouring concrete. (1 Time)

Surveyor

Helper

Helper

162. Rechecking position of Pile (or)Cap (or) Shaft (or)

Cross Beam after concreting. (1 Time)

Surveyor

before pouring concrete for one pier. (1 Time)

Surveyor

Helper

163.

Surveying , Checking and specifying centre of

Abutment (or) pier systematically. (1 Time)

Surveyor

Helper

Surveying bearing hole depth to get right depth

Surveying and Checking bottom ground of Pier in

water. (1 Time)

Surveyor

Helper

Transfering and rechecking level Mark for specifiec

place from one bench Mark to another.(100 m)

Surveyor

I

Helper

Unit Quantity

4

Man-Day

Man-Day

I

0.3

1

Man-Day

Surveying Echo Sounding Pier in water and water

level daily. (1 Time)

Surveyor

0.5

Man-Day 0.5

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

0.5

0.5

0.3

0.5

0.3

0.3

Man-Day

Remarks

0.5

Fixing bearing for one pier of main bridge (or)

1

Approach bridge (Position or Grouting to fix bearing

hole position Bearing.) (1 Time)

Surveying Position

Surveyor

Helper

Man-Daj

Man-Daj

41

Standard Data for Working Out Rates Per Unit Quantity of Items of Work-contd.

Quantity

3

3

0.5

0.5

0.5

0.5

0.3

1

0.3

1

0.3

1

0.5

0.5

0.5

0.5

Unit

Man-Day

Man-Day

Sr

No.

(b)

169.

Remarks

Particulars of Materials and Labour

Rechecking position.

Surveyor

Helper

Fixing bearing for one pier of main bridge (or)

(a)

(b)

170.

171.

(a)

(b)

172.

173.

Approach bridge(Position or Grouting to fix bearing

hole position Bearing.) (1 Time)

Levelling

Surveyor

Helper

Rechecking level

Surveyor

Helper

Surveying and Rechecking 18m(or)2 1 m(or)24m(or)

27m(or)30m Girder for pouring concrete. (1 No)

Surveyor

Helper

Surveying for erection of main truss to get specified

level. (1 Time)

Surveyor

Helper

Surveying , Leveling and checking for erection of

main truss to get specified level. (1 Time)

Surveyor

Helper

Surveying and Checking Level for Laying Precast

slab and finished level. (1 Time)

Surveyor

Helper

Surveying and specifjing Center line for installation

of Road Curb and Hand Rail. (1 Time)

Surveyor

Helper

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Standard Data for Working Out Rates Per Unit Quantity ofItems of Work-contd.

Road Curb and Hand Rail. (1 Time)

Surveyor

Sr

No.

174.

Helper

Particulars of Materials and Labour

Surveying and specifLing level for installation of

Man-Day

Man-Day

Remarks Unit

0.5

0.5

175.

176.

177.

178.

(a)

@)

179.

(a)

Quantitj

0.5

0.5

0.3

1

0.3

1

0.5

0.5

0.5

0.5

0.5

0.5

Surveying and specifling level for laying AC.(l Time)

Surveyor

Helper

Surveying Overlay, Road Curb, Hand Rail and AC

to get right alignment. (1 Time)

Surveyor

Helper

Surveying Precast Slab, Overlay, Road Curb,

Hand Rail level. (1 Time)

Surveyor

Helper

Surveying position of anywork before starting work

(Excavation or Fixing Reinforcement and forrnwork

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

or Pouring concrete or embedded plate or Hand Rail

or Road Curb or P.C Girder or Collosion Barrier or

Decking slab or Girder Overlay or AC or Anchor

Box or Bored Pile or Stand Pipe or Keyline or Cap

Skirting or Road or Drain or Box Culvert or Steel

Truss or Pier Cap or shaft Cross-beam or Abutment

or Retaining Wall or Rail Road or Vertical devia -

tion.) (1 Time)

Surveyor

Helper

Man-Day

Man-Day

Rechecking position of anywork after working.(l Time)

Surveyor

Helper

Man-Day

Man-Day

Surveying alignment (Center Line)of anywork before

working. (1 Time)

Surveyor

Helper

Man-Day

Man-Day

43

Srandard Data for Working Out Rates Per Unit Quantity ofltems of Work-contd

Quantity

0.5

0.5

0.5

0.5

0.5

0.5

0.5

0.5

0.5

0.3

0.5

0.3

0.5

0.5

0.5

1.5

2

4

Unit

Sr

No.

Remarks

Particulars of Materials and Labour

(b)

180.

(a)

(b)

18 1.

182

(a)

(b)

(c)

183.

184.

Rechecking alignment (Center Line)of anywork after

working. (1 Time)

Surveyor

Helper

Surveying and levelling anywork before working.

(1 Time)

Surveyor

Helper

Man-Day

Man-Day

Man-Day

Man-Day

Rechecking level of anywork before working.(l Time)

Surveyor

Helper

Surveying and checking settlement (Main Bridge or

Approach Bridge or Highway or Railway.)(l Time)

Surveyor

Helper

Man-Day

Man-Day

Man-Day

Man-Day

Checking for theodolite level and E.D.M instrument

which are used for surveying in bridge construction.

Theodolite Calibration. (1 Time)

Surveyor

Helper

Level Calibration. (1 Time)

Surveyor

Helper

E.D.M Calibration. (1 Time)

Surveyor

Helper

Determination of Pier Position by E.D.M including

finding distance between piers etc; other relevant

or equivalent works.(l Time)

Surveyor

Helper

Level Net Survey Calculation & Drawing.(l Time)

Surveyor

Helper

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

44

Standard Datafor Working Out Rates Per Unit Quantity of Items of Work-contd.

Sr

No.

185.

(a)

(b)

(c)

Particulars of Materials and Labour

Triangulation Net Survey

Basic Line Measurement (1 Time)

Surveyor

Helper

Calculation & Drawing.(l Time)

Surveyor

Helper

Check Base & Distance Measurement(1 Time)

Surveyor

Helper

Unit

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Man-Day

Quantity

3

4.5

2

4

0.5

0.5

Remarks

45

Standard Data for Working Oui Rates Per Unit Quantity of Items of Work-contd.

Sr

No.

1

2

Particulars of Materials and Labour

MISCELLANEOUS NOTES

For contractor's profit and overheads

(Taxes , safety charges , management & etc.)

For Bridge Machinery Work

(Use according to rate of analysis of Machanical

Department.)

Unit

L.S

L. S

Quantity

-

-

Remarks

You might also like

- Analysis of Rates ( BuildingWorks )Document132 pagesAnalysis of Rates ( BuildingWorks )ကိုနေဝင်း100% (12)

- Schedule BDocument43 pagesSchedule Bhardik sorathiyaNo ratings yet

- Rate Analysis - Highways-MDR - Part - IDocument389 pagesRate Analysis - Highways-MDR - Part - IAmitabha DebNo ratings yet

- Analysis of Rates (Nh-15 Barmer - Sanchor)Document118 pagesAnalysis of Rates (Nh-15 Barmer - Sanchor)rahulchauhan7869No ratings yet

- Spayed Wing Wall BBS 155+586 RHSDocument1 pageSpayed Wing Wall BBS 155+586 RHSHegdeVenugopal100% (1)

- Box 2 X 2Document15 pagesBox 2 X 2afifa kausarNo ratings yet

- 07 Cement ConsumptionDocument2 pages07 Cement Consumptiontechdocu100% (4)

- Minutes CBE Seminar 2012 FinalDocument29 pagesMinutes CBE Seminar 2012 FinalMUKESH VISPLNo ratings yet

- Final Road (Boq)Document100 pagesFinal Road (Boq)Prinkesh Barodiya100% (1)

- Estimate, Bridge Open FoundationDocument86 pagesEstimate, Bridge Open Foundationकुमुद पाठकNo ratings yet

- Design A RCC T Beam Girder Bridge To Suit The Following Data - Google SearchDocument1 pageDesign A RCC T Beam Girder Bridge To Suit The Following Data - Google SearchamitNo ratings yet

- Unit Cum: Taking Output 191 Cum (450 Tonnes)Document2 pagesUnit Cum: Taking Output 191 Cum (450 Tonnes)HPSIDC MehatpurNo ratings yet

- BOQ Box Culvert FinalDocument19 pagesBOQ Box Culvert FinalManoj AhirwarNo ratings yet

- Toe Wall-GantryDocument1 pageToe Wall-GantrySumant kumarNo ratings yet

- Book DetailsDocument1 pageBook DetailsHatender Tomar0% (1)

- Major Bridge Estimate (Well Found.)Document12 pagesMajor Bridge Estimate (Well Found.)Mohammed Faiz100% (1)

- Stagging CalculationDocument6 pagesStagging CalculationParvez KhanNo ratings yet

- Pipe - Culvert Design PDFDocument1 pagePipe - Culvert Design PDFDarshan M TNo ratings yet

- GSB WMM DBM BCDocument64 pagesGSB WMM DBM BCAnonymous skyQVAw5No ratings yet

- Lec 6 - Measurement by Approximate Area MethodsDocument19 pagesLec 6 - Measurement by Approximate Area MethodsBhushan RaisinghaniNo ratings yet

- Summary of Rate Analysis Chapter-1 Carriage of MaterialsDocument42 pagesSummary of Rate Analysis Chapter-1 Carriage of Materialsanon_789699787No ratings yet

- Indian Roads June 2009 ExtractDocument57 pagesIndian Roads June 2009 ExtractSaurav TalukdarNo ratings yet

- Standard Data Book (Roads & Bridges)Document353 pagesStandard Data Book (Roads & Bridges)shariqabideen81% (63)

- Price Variation Bid Project Cost in HAMDocument6 pagesPrice Variation Bid Project Cost in HAMUmesh Mishra100% (2)

- Cost Analysis For Bridge and CulvertsDocument14 pagesCost Analysis For Bridge and CulvertsjnshreyNo ratings yet

- Miscellaneous Bridge Components - ClassDocument86 pagesMiscellaneous Bridge Components - ClassAbhishekNo ratings yet

- Slipform Rate AnalysisDocument5 pagesSlipform Rate Analysischaithra_140% (1)

- Estimate Electrical Guwahati UniversityDocument19 pagesEstimate Electrical Guwahati UniversityTandon Abhilash BorthakurNo ratings yet

- Bridge Engineering by Ponnu SwamyDocument4 pagesBridge Engineering by Ponnu SwamySrinivas P20% (5)

- Crackwidth Calculation Spreadsheet (Restricted Version)Document11 pagesCrackwidth Calculation Spreadsheet (Restricted Version)Nicholas ThompsonNo ratings yet

- Analysis of Rate of Building DeportmentDocument242 pagesAnalysis of Rate of Building DeportmentManoj SinghNo ratings yet

- RateAnalysisVol 2Document1,341 pagesRateAnalysisVol 2babarNo ratings yet

- Wapda CSR 2013 Zone 3Document245 pagesWapda CSR 2013 Zone 3Naveed Shaheen91% (11)

- State DSR 2019-20 PDFDocument193 pagesState DSR 2019-20 PDFManoj MasutageNo ratings yet

- Final PPT Analysis and Design of T-Beam Girder and Box Girder SuperstructureDocument34 pagesFinal PPT Analysis and Design of T-Beam Girder and Box Girder Superstructureamit_saxena_1075% (4)

- ASTM Rebar MarkingDocument1 pageASTM Rebar Markingကိုနေဝင်းNo ratings yet

- 345-001071-1009 - R0 Beam & Slab Formworks First Aid Bldg.17Document1 page345-001071-1009 - R0 Beam & Slab Formworks First Aid Bldg.17Satya kaliprasad vangaraNo ratings yet

- Segmental Construction of BridgeDocument25 pagesSegmental Construction of BridgeShubh ChaudharyNo ratings yet

- PSC Girder Bridge Construction - Construction of A Bridge-Bridge Construction MethodDocument16 pagesPSC Girder Bridge Construction - Construction of A Bridge-Bridge Construction MethodVinay Raj100% (1)

- Model Minor Bridge EstimateDocument32 pagesModel Minor Bridge EstimateRavi KumarNo ratings yet

- Equipment Productivity DetailsDocument3 pagesEquipment Productivity DetailsRana Muhammad TalhaNo ratings yet

- Design of 15m Span Superstructure Re - 2Document1 pageDesign of 15m Span Superstructure Re - 2vivek100% (1)

- 60 M.bow String Girder-10411-7-RDocument1 page60 M.bow String Girder-10411-7-RkesharinareshNo ratings yet

- Rate Analysis For ShutteringDocument2 pagesRate Analysis For ShutteringSarin100% (2)

- PKG 3Document28 pagesPKG 3nk229330No ratings yet

- Toilet BlockDocument21 pagesToilet BlocklkovijayNo ratings yet

- Shimla Bypass Cable Stayed Bridge BOQDocument11 pagesShimla Bypass Cable Stayed Bridge BOQShaileshRastogi100% (1)

- Dynamic Prestress Technical Guidelines PDFDocument8 pagesDynamic Prestress Technical Guidelines PDFdhopat kalpesh100% (1)

- Data Rates Tunnel Works 4Document21 pagesData Rates Tunnel Works 4vpmohammedNo ratings yet

- 25m Span Superstructure of Bridge DesignDocument45 pages25m Span Superstructure of Bridge Designshekhar Nath chapagain75% (4)

- HPSR Building2009Document467 pagesHPSR Building2009Mandeep Singh100% (7)

- Road Design Standards 2021Document56 pagesRoad Design Standards 2021Engr.Towhidul IslamNo ratings yet

- Syphon Aqueduct DesignDocument7 pagesSyphon Aqueduct DesignSanjeev Mishra100% (2)

- Chapter-1 Carriage of Materials PreambleDocument8 pagesChapter-1 Carriage of Materials Preambleravindrarao_mNo ratings yet

- BridgeWorks PDFDocument47 pagesBridgeWorks PDFmaungNo ratings yet

- Analysis of Rates (AirfieldWorks)Document9 pagesAnalysis of Rates (AirfieldWorks)ကိုနေဝင်း88% (16)

- Fundamentals of MachiningDocument39 pagesFundamentals of Machiningpassion481100% (1)

- Basic Tool Plant Rate RajasthanDocument71 pagesBasic Tool Plant Rate RajasthanshreyesnegiNo ratings yet

- Data Rates-CD Works Part 1Document20 pagesData Rates-CD Works Part 1vpmohammedNo ratings yet

- Just 2012Document1,096 pagesJust 2012Ramachandra SahuNo ratings yet

- Design of Retaining WallsDocument28 pagesDesign of Retaining Wallsကိုနေဝင်းNo ratings yet

- Li - Asphalt Treated Base Course Material - Final11.02Document106 pagesLi - Asphalt Treated Base Course Material - Final11.02ကိုနေဝင်းNo ratings yet

- MOC Low Volume Rural RoadDocument356 pagesMOC Low Volume Rural Roadကိုနေဝင်းNo ratings yet

- MIP FactsDocument11 pagesMIP Factsကိုနေဝင်းNo ratings yet

- Asphalt Technology in MyanmarDocument53 pagesAsphalt Technology in Myanmarကိုနေဝင်း100% (1)

- 2013 Petroleum NotificationDocument4 pages2013 Petroleum Notificationကိုနေဝင်းNo ratings yet

- Soil StabilizationDocument75 pagesSoil Stabilizationကိုနေဝင်းNo ratings yet

- Knowledge FailuresDocument6 pagesKnowledge Failuresကိုနေဝင်းNo ratings yet

- HD Manual - COP For Structure Use of Concrete 2004 Rev - 2.3Document346 pagesHD Manual - COP For Structure Use of Concrete 2004 Rev - 2.3yin169No ratings yet

- Review On Petroleum ActDocument3 pagesReview On Petroleum Actကိုနေဝင်းNo ratings yet

- Myanmar - Fire and Disaster Old Document Till 2019Document30 pagesMyanmar - Fire and Disaster Old Document Till 2019ကိုနေဝင်း100% (1)

- Concrete NotesDocument37 pagesConcrete Notesကိုနေဝင်းNo ratings yet

- Structural ShapesDocument9 pagesStructural Shapesကိုနေဝင်းNo ratings yet

- LPG Regulation-MyanmarDocument12 pagesLPG Regulation-Myanmarကိုနေဝင်းNo ratings yet

- MNBC2020 Windspeed Design Data For YangonDocument1 pageMNBC2020 Windspeed Design Data For Yangonကိုနေဝင်း100% (1)

- Piping-Easy Guide To Home-OwnersDocument14 pagesPiping-Easy Guide To Home-Ownersကိုနေဝင်းNo ratings yet

- MNBC2020 Seismic Design Data For YangonDocument1 pageMNBC2020 Seismic Design Data For Yangonကိုနေဝင်းNo ratings yet

- Survey Datum ProjectionsDocument165 pagesSurvey Datum Projectionsကိုနေဝင်းNo ratings yet

- Myanmar (Burma) Petroleum Act 1934Document10 pagesMyanmar (Burma) Petroleum Act 1934ကိုနေဝင်းNo ratings yet

- Technical Paper (Al Sharq Tower)Document17 pagesTechnical Paper (Al Sharq Tower)ကိုနေဝင်းNo ratings yet

- BuildingFrame SystemDocument20 pagesBuildingFrame Systemကိုနေဝင်းNo ratings yet

- ခေတ်အလိုက်ဗုဒ္ဓဆင်းတုတော်များDocument19 pagesခေတ်အလိုက်ဗုဒ္ဓဆင်းတုတော်များကိုနေဝင်းNo ratings yet

- Eb 218 Design Manual Overtopping Cover 2Document115 pagesEb 218 Design Manual Overtopping Cover 2Rajiv SharmaNo ratings yet

- Construction LogbookDocument2 pagesConstruction LogbookGerard BorbonNo ratings yet

- MonolithicDocument1 pageMonolithicVishnu Teja Reddy100% (2)

- Jurnal Beton Busa PDFDocument8 pagesJurnal Beton Busa PDFIqbalArifkyNo ratings yet

- 7804 Idrocretekr1000 GBDocument4 pages7804 Idrocretekr1000 GByaw shuNo ratings yet

- Brochure Diaphragm WallsDocument16 pagesBrochure Diaphragm WallsmanandesNo ratings yet

- Worldwide Sprayed Concrete State-Of-The-Art Report 2005 - G.bracher Idiem PDFDocument11 pagesWorldwide Sprayed Concrete State-Of-The-Art Report 2005 - G.bracher Idiem PDFNicolásOCNo ratings yet

- ASTM C33 Standard Specification For Conc AggregatesDocument11 pagesASTM C33 Standard Specification For Conc AggregatesTariq Khan100% (3)

- IHS Energy CatalogueDocument8 pagesIHS Energy CatalogueMzee Boydd Mkaka MwabutwaNo ratings yet

- Revitalizing Abandoned Mills in India The Case of Tamil Nadu IJERTV10IS110184Document8 pagesRevitalizing Abandoned Mills in India The Case of Tamil Nadu IJERTV10IS110184SuyashNo ratings yet

- Brick&Bolt Quality Assessment System - QASCONDocument10 pagesBrick&Bolt Quality Assessment System - QASCONPulkit Chawla100% (2)

- Staircase DesignDocument28 pagesStaircase DesignIbnuyusoff77No ratings yet

- 84 Design of JointsDocument13 pages84 Design of JointsHasumati SolankiNo ratings yet

- Autovillage Area Rate Analysis 21 SepDocument116 pagesAutovillage Area Rate Analysis 21 Seprashmi bhailaNo ratings yet

- BP QuoteExampleDocument80 pagesBP QuoteExampleNur IrawanNo ratings yet

- Construction PerliteDocument23 pagesConstruction PerliteNomer Jaudines ArbanNo ratings yet

- CE 370 Tutorial Note 4Document5 pagesCE 370 Tutorial Note 4Ibrahim AlmohannaNo ratings yet

- History of Roads and HighwaysDocument6 pagesHistory of Roads and Highwaysjesica quijanoNo ratings yet

- Auroville ReportDocument35 pagesAuroville ReportIshani50% (2)

- ADC20023-DWG-PAV-404 - Hangar Pavement Typical DetailsDocument1 pageADC20023-DWG-PAV-404 - Hangar Pavement Typical DetailsAhmed SalahNo ratings yet

- 18il0059 Variation Order DupaDocument41 pages18il0059 Variation Order DupaMichelle GozonNo ratings yet

- Is - sp.57.1993 Hand Book Pipes and FittingsDocument103 pagesIs - sp.57.1993 Hand Book Pipes and FittingsMathiTwadCNo ratings yet

- Review of The Related Literature Raia FinalDocument4 pagesReview of The Related Literature Raia FinalShane Giacinth AmarilaNo ratings yet

- Sop 1Document19 pagesSop 1herybudiantoNo ratings yet

- MAPEIDocument51 pagesMAPEIJpolyPolyNo ratings yet

- Journal of Building EngineeringDocument17 pagesJournal of Building EngineeringCarlos JiménezNo ratings yet

- A Free Issue Items (To Be Issued by ATC Uganda)Document15 pagesA Free Issue Items (To Be Issued by ATC Uganda)Mushabe SamuelNo ratings yet

- 1986 Supplement To:: American Concrete InstituteDocument16 pages1986 Supplement To:: American Concrete InstituteAzmi BazazouNo ratings yet

- (Paper) Method To Calculate The Fire Resistance of Reinforced Concrete Columns With Rectangular Cross Section (NRCC 33114)Document12 pages(Paper) Method To Calculate The Fire Resistance of Reinforced Concrete Columns With Rectangular Cross Section (NRCC 33114)Gregory SimmonNo ratings yet