Professional Documents

Culture Documents

CE474lab2 1

Uploaded by

inrhgoiwnowbOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CE474lab2 1

Uploaded by

inrhgoiwnowbCopyright:

Available Formats

CE474 Lab 2 Spring 2014

JAR TEST

Coagulation and Flocculation

Josue Amigon

Date Due: March 31, 2014

Department of Civil Engineering at the City College(CCNY) of the City University of New York.

Email: jamigon@ccny.cuny.edu

The City College of New York

140th Street & Convent Avenue

New York, New York 10031

Page 2

Contents

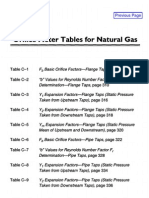

Table of Content Page No.

Abstract ... 3

1.0 Objective: .............. 3

2.0 Introduction .. 3

3.0 Procedure .. 4

3.1 Detailed Procedure............ 4

3.2 Equipment and Materials.. 5

3.2 Analysis Procedure .. 5

4.0 Results 6

5.0 Conclusion . 8

6.0 References .. 9

Appendix A 9

List of Tables

Table 1: Initial: pH, Alkalinity and Turbidity ... 6

Table 2: Final Data: pH, Alkalinity, and Turbidity .. .. 9

List of Figures

Figure 1: pH versus Alum dose .. .. 7

Figure 2: Alkalinity versus Alum dose ..... 7

Figure 3: Turbidity versus Alum dose .. 8

Abstract

Page 3

It is important to measure the turbidity of water because people a certain level of

acceptance on how cloudy is the water and because there is some standards for domestic water

supplies. The Jar Test simulates the coagulation, flocculation and settling in one experiment to

determine the optimum dose to reduce the turbidity to acceptable levels. The two most

commonly used coagulants are aluminum and ferric iron in this experiment the aluminum

coagulant will be used. The water sample being test is composed of tap water, clay and sodium

bicarbonate. The alkalinity and pH were of main concern but after the test the results showed

they were within the acceptable range. The residual turbidity curve was plotted to determine the

optimum dose, and it was determined that the dose is 60 mg/mL of alum coagulant to remove the

turbidity, color and bacteria. The type of source water will have a large impact on how often jar

tests are performed.

1.0 Objective

The purpose of this experiment is to gain practical experience in the laboratory,

strengthen the importance of testing parameters for waste and determining the turbidity.

2.0 Introduction

Coagulation/flocculation is the process of binding small particles in the water together

into larger, heavier clumps which settle out relatively quickly. The larger particles are known as

floc. Properly formed floc will settle out of water quickly in the sedimentation basin, removing

the majority of the water's turbidity. The assurance of water quality is a critical part of the

engineers role in solving the problems of concern to people. The interest in quality applies to

both the potable water supply, and wastewater management before release into the environment.

Several parameters both physical and chemical can be used to gauge water quality including

aesthetic properties (appearance, odor, taste), chemical profile (acidity, alkalinity, and

presence/absence of chemical compounds as pollutants), and concentrations of microorganisms.

Four of these metrics are of interest in this laboratory: the chemical properties of pH and

alkalinity, and the physical parameters of turbidity.

Through a series of steps including filtration and coagulation we can determine the

turbidity of the waste water sample. Turbidity is the cloudiness of water due to colloidal

particles, and is measured by gauging interference to the passage of light through the water. The

acidity of water is commonly expressed as the negative log of the molar concentration of

hydrogen ions (H+), or pH, which can be easily measured with a commercial meter. It is

measured in the laboratory through titration of the water in question with a strong acid, using a

visual pH indicator to identify when the solution reaches a certain acidity. The complete

processes for all tests conducted are discussed in the Procedures section of this report.

Page 4

Measurement of wastewater quality is important not only in finding the impact of release,

but in determining the efficiency of the treatment system. For example, data can be collected

from both primary influent (raw wastewater) and effluent (treated outflow) and compared to

determine the effect of the treatment process on a sample. Although equivalent parameters are

not compared directly in this laboratory for influent and effluent, a general comparison can be

made, particularly in aesthetic properties. The limits of sensitivity of the equipment available in

the lab make direct comparison difficult given the limited scope of this experiment.

The Procedure section of this report outlines the experimental process for each test, and details

the analysis methodology. The Results and Discussion of this report presents findings in tables

and figures.

3.0 Procedure

3.1 Detailed Procedure

The procedure of the experiment was given, and the experiment was conducted by me

and other students. The experiment was explained to us by Professor Vasil Diyamandoglu and

conducted at the Environmental Engineering Laboratory of the City College of New York. One

sample water is being experimented which is composed of a mixture of tap water, clay and

sodium bicarbonate. The Coagulant that is being used for this experiment is an aluminum sulfate

known as Alum. The beakers are then filled will the waste water sample of 1000 mL each. The

dose is assigned to each beaker to obtain an optimum dose for an acceptable turbidity level. The

initial pH of the waste water sample is measured using a pH meter. The initial alkalinity levels

are also measured by titration. A 100 mL sample is placed in a beaker and put a few drops of

color indicator that will turn dark blue at first but as the Titrant 0.02N H2SO4 is poured into the

beaker until the color changes into a light purple color then stop and measure the amount of

titrant poured the color change means that the pH is at 4.3. The Alum dose is poured into the

beakers which is mixed will the stirrers. The samples are mixed at approx. 100 rpm for 1minute,

then decrease the speed to approx. 30 rpm and Allow the sample to mix for a period of 10

minutes. Observe any changes in the suspended matte in the sample. At the end of the mixing

period, turn off the stirrer, let the flocs settle (at least 20 minutes) and carefully remove the

supernatant from each beaker and determine the turbidity in each of the samples with the

turbidimeter. This type of meter does not measure all of the deflected light, only that which is

deflected at a right angle (90 ) from the sample and light source. Determine the pH of each

treated water sample with the pH meter. Also measure the final alkalinity of the treated sample

the same as before.

Page 5

3.2 Materials and Equipment

1. Phipps & Bird Six-Place Stirrer

2. 1 or 2-liter beakers

3. Aluminum sulfate (alum) solution

4. Hach turbidimeter

5. pH meter

6. Pipettes/syringes

7. Burettes

8. Erlenmeyer Flasks

9. 0.02 N H2SO4 titrant

10. Water sample

11. Volumetric flasks

12. Methyl orange (MO) indicator

13. Beakers

3.3 Analysis Procedure

Equations

Volume of Alum solution added to beakers

()

()

Alkalinity(as CaCO

3

mg/L) , equivalent weight CaCO

3

= 50 mg/meq

(

)

( )(

)(

)

(2)

For the water sample being composed of tap water, clay and sodium bicarbonate, a turbidity,

alkalinity and pH analysis will be conducted using the procedure. Since many values are

required to find the parameters accurately a statistical analysis is required. The mean and the

standard deviation would have to be calculated to find the best solution. The volume of Alum to

be added to each beaker knowing the dose will be calculated using equation 1. The pH will be

determined using a pH meter and the alkalinity will be determined using equation 2. After the

final turbidity is found the residual turbidity will be plotted, the pH will also be plotted and the

Alkalinity will also be plotted. Then the optimum dose for turbidity will be determined from the

curve of the turbidity curve.

Page 6

4.0 Results

Table 1 shows the initial conditions of the raw water with its initial pH, alkalinity, and turbidity,

and taking their mean since many values were calculated. Table 2 shows the final results after

introducing the assigned Alum dose into each jar showing the residual pH, alkalinity and

turbidity that is in appendix A. To better understand the results they were plotted versus the

Alum dose. Figure 1 shows the pH of the sample water. The range of adequate coagulation pH

is from 5 to 8 which is the within range of the pH curve, it is also acceptable because as the alum

dose increases the pH of the sample should decrease(Davis,pg274). Figure 2 shows the residual

alkalinity of the sample water and as shown the results are acceptable because the alkalinity will

go down as the alum dose is increased. Figure 3 shows the turbidity, and as seen it is difficult to

determine the optimum dose because the stages 1, 2, and 3 that a turbidity curve has are

combined together, and you just see a small drop in turbidity and then it rises, and goes into the

final stage 4 where it decreases. The optimum dose could be 60 mg/mL of alum.

Table 1: Initial pH, Turbidity and Alkalinity

Test No Alum dose Initial pH Initial Turbidity Initial Alkalinity

Group1 0 7.76 45 150

Group2 0 7.99 40.4 150

Group3 0 8.22 40 140

Group4 0 7.96 41.5 138

Group5 0 7.6 24 122

Group6 0 8.02 23 145.12

Mean 0 7.925 35.65 140.85

Page 7

Figure 1: Residual pH of the sample water

Figure 2: Residual Alkalinity of sample water

0

1

2

3

4

5

6

7

8

9

0 20 40 60 80 100 120 140

R

e

s

i

d

u

a

l

p

H

Alum Dose(mg/mL)

pH

Acidity

0

20

40

60

80

100

120

140

160

0 20 40 60 80 100 120 140

R

e

s

i

d

u

a

l

A

l

k

a

l

i

n

i

t

y

(

m

g

/

m

L

)

Alum Dose(mg/mL)

Alkalinity

Alkalinity

Page 8

Figure 3: Residual turbidity of water sample

5.0 Conclusion

The Jar test is an important method in finding the optimum coagulant dose, we analyze

the residual turbidity, alkalinity, and pH of the water sample. The Alum dose caused an increase

in particle size to increase the collision which is a complex large precipitate known as flocs.

This removes the turbidity, color and bacteria which is important for drinking waters, during the

experiment small amounts of flocs formed, but it increased as the dose increased(Davis, pg 271).

As given before the Alkalinity and the pH decreased as the alum dose increased, which is a main

concern as an engineer. The consumption of alkalinity is the result of alum addition, and we

must make sure there is residual alkalinity in the water following the jar test. The optimum dose

was determined to be 5 mg/mL of alum and a good option is to cut out a section in between the

60 mg/mL and do the test again with smaller increments.

0

5

10

15

20

25

30

35

40

45

0 20 40 60 80 100 120

R

e

s

i

d

u

a

l

t

u

r

b

i

d

i

t

y

(

N

T

U

)

Alum dose(mg/mL)

Turbidity

Turbidity

Page 9

6.0 References

(Davis)-Introduction to Environmental Engineering by Mackenzie L. Davis and David A.

Cornwell

Appendix A: Raw data

Table 1: Initial pH, Turbidity and Alkalinity

Test No Alum dose Initial pH Initial Turbidity Initial Alkalinity

Group1 0 7.76 45 150

Group2 0 7.99 40.4 150

Group3 0 8.22 40 140

Group4 0 7.96 41.5 138

Group5 0 7.6 24 122

Group6 0 8.02 23 145.12

Mean 0 7.925 35.65 140.85

Table 2: Residual pH, Turbidity, and Alkalinity

Alum

Dose(mg/L)

Volume of

Alum

added(mL) Sample volume

Total Volume 0.2

H2SO4 Final pH

Final

Alkalinity

Final

Turbidity

0 0 100 14.5 8.06 145 40.7

2 0.2 100 13.9 7.53 139 32.9

5 0.5 100 13.7 7.2 137 28.3

6 0.6 100 13.4 7.64 134 32

8 0.8 100 12.6 7.3 126 37.2

10 1 100 12.2 7.35 122 41.5

10 1 100 13.7 7.84 137 36.7

12 1.2 100 13.1 7.65 131 32.6

15 1.5 100 13 7.61 130 31.3

20 2 100 12.8 7.57 128 24.4

25 2.5 100 12.3 7.46 123 24

30 3 100 12 7.18 120 17.1

10 1 100 13.4 8.3 134 33.1

15 1.5 100 13 7.9 130 25.5

20 2 100 12.4 7.7 124 22.5

25 2.5 100 12.6 7.6 126 17.2

40 4 100 12.4 7.44 124 7.96

Page

10

60 6 100 11.6 7.24 116 2.47

40 4 100 10.1 7.42 101 14

50 5 100 9.8 7.28 98 8.48

60 6 100 9.2 7.24 92 5.56

70 7 100 8.8 7.22 88 5.12

80 8 100 8.4 7.05 84 5.09

90 9 100 7.8 7.04 78 4.66

5 0.5 100 11.2 7.56 112 23.5

15 1.5 100 10.6 7.37 106 19.1

30 3 100 10.25 7.34 102.5 11.6

60 6 100 8.7 6.98 87 3.29

90 9 100 7.9 6.95 79 2.2

120 12 100 6.8 6.62 68 1.95

5 0.5 80 9.7 7.61 121.25 10.9

8 0.8 80 9.4 7.53 117.5 9.88

12 1.2 80 9.3 7.47 116.25 6.96

15 1.5 80 8.9 7.41 111.25 6.43

20 2 80 8.5 7.38 106.25 6.04

25 2.5 80 8.4 7.2 105 3.22

You might also like

- Function: 'There Is No Specific Solution'Document2 pagesFunction: 'There Is No Specific Solution'inrhgoiwnowbNo ratings yet

- Midterm 2Document6 pagesMidterm 2inrhgoiwnowbNo ratings yet

- Fundamentals of Engineering Exam Sample Math Questions: X z+6 zx+6 ZDocument9 pagesFundamentals of Engineering Exam Sample Math Questions: X z+6 zx+6 ZinspectorsufiNo ratings yet

- CE3500 Syllabus Fall 2010Document2 pagesCE3500 Syllabus Fall 2010inrhgoiwnowbNo ratings yet

- % Assigned Frame Spacing: FunctionDocument5 pages% Assigned Frame Spacing: FunctioninrhgoiwnowbNo ratings yet

- Name: - Student IDDocument7 pagesName: - Student IDinrhgoiwnowbNo ratings yet

- RefDocument1 pageRefinrhgoiwnowbNo ratings yet

- Ch9 SolutionsDocument41 pagesCh9 SolutionsinrhgoiwnowbNo ratings yet

- Dynamics: Vector Mechanics For EngineersDocument68 pagesDynamics: Vector Mechanics For EngineersinrhgoiwnowbNo ratings yet

- List of The Elements With Their Symbols and Atomic MassesDocument1 pageList of The Elements With Their Symbols and Atomic MassesinrhgoiwnowbNo ratings yet

- A Comprehensive Laboratory Manual For Environmental Science and Engineering 2010Document153 pagesA Comprehensive Laboratory Manual For Environmental Science and Engineering 2010kenlesurvivant100% (4)

- 2011 Fall Test 2Document5 pages2011 Fall Test 2inrhgoiwnowbNo ratings yet

- CE474lab2 1Document10 pagesCE474lab2 1inrhgoiwnowbNo ratings yet

- 474 Graphs CoagulationDocument2 pages474 Graphs CoagulationinrhgoiwnowbNo ratings yet

- MATH 392 HELP WITH HW 11 (Problems in Section 13.7)Document3 pagesMATH 392 HELP WITH HW 11 (Problems in Section 13.7)inrhgoiwnowbNo ratings yet

- Group 3 - Lab 2 DataDocument3 pagesGroup 3 - Lab 2 DatainrhgoiwnowbNo ratings yet

- Scale FactorsDocument1 pageScale FactorsinrhgoiwnowbNo ratings yet

- Parametrize The Following Surfaces (Sketch and Be Sure To State The Domain)Document1 pageParametrize The Following Surfaces (Sketch and Be Sure To State The Domain)inrhgoiwnowbNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- VCPBR 05043 en PRV OverviewDocument24 pagesVCPBR 05043 en PRV OverviewmagveyNo ratings yet

- Science Form 4 Chapter 5 5.6Document17 pagesScience Form 4 Chapter 5 5.6KSSM TSE100% (1)

- Viva QnsDocument2 pagesViva QnsExporting WarriorNo ratings yet

- Worksheet14 HybridDocument5 pagesWorksheet14 HybridRAGINI AGARWALNo ratings yet

- PN JunctionDocument5 pagesPN JunctionAshu BaghelNo ratings yet

- Aga TableDocument35 pagesAga TableilublessingNo ratings yet

- Mat Foundation PhilippinesDocument7 pagesMat Foundation PhilippinesAly Arquillano JrNo ratings yet

- Osmometry ElectrochemistryDocument25 pagesOsmometry ElectrochemistryMohamed MidoNo ratings yet

- Physics ProjectDocument13 pagesPhysics ProjectsherineNo ratings yet

- Engine Bearing Failure Analysis GuideDocument32 pagesEngine Bearing Failure Analysis Guidetiredforever100% (1)

- DARPA GaN AdvancesDocument4 pagesDARPA GaN Advancesbring it onNo ratings yet

- Final Exam Review 1528317655806 SCDocument18 pagesFinal Exam Review 1528317655806 SCAdil KhurshaidNo ratings yet

- Anti TpoDocument28 pagesAnti TpoFlorea RodicaNo ratings yet

- Tencate Mirafi HP 370Document1 pageTencate Mirafi HP 370Tony_candyNo ratings yet

- Lesson 3. The Relationship of Percent Composition and Chemical FormulaDocument4 pagesLesson 3. The Relationship of Percent Composition and Chemical FormulaRandel MontielNo ratings yet

- Overpressure Protection-Low Temp EffectsDocument4 pagesOverpressure Protection-Low Temp EffectsChem.EnggNo ratings yet

- Basic Nuclear Physics: Day 1-Lecture 1Document35 pagesBasic Nuclear Physics: Day 1-Lecture 1jody9090No ratings yet

- Astm B575Document5 pagesAstm B575Jota JacquesNo ratings yet

- Bachelor of Computer Application (B.C.A.) Semester-I Examination Supplementary English Paper-II (Other Compulsory Language)Document3 pagesBachelor of Computer Application (B.C.A.) Semester-I Examination Supplementary English Paper-II (Other Compulsory Language)Manaswini BhanseNo ratings yet

- Chemistry 11 Chap-1Document38 pagesChemistry 11 Chap-1piyush_2189No ratings yet

- Ce6411 Strength of Materials Laboratory (Civil)Document32 pagesCe6411 Strength of Materials Laboratory (Civil)KishanKanhaiyaNo ratings yet

- L-Shaped Plate Heat TransferDocument12 pagesL-Shaped Plate Heat Transfer700spymaster007No ratings yet

- Obj 2Document12 pagesObj 2Himanshu PareekNo ratings yet

- Seaflo Neo SL Z (1606) PDFDocument2 pagesSeaflo Neo SL Z (1606) PDFTrịnh Minh KhoaNo ratings yet

- Good Chromatographic PracticesDocument59 pagesGood Chromatographic PracticesSathish VemulaNo ratings yet

- Boron DeficiencyDocument2 pagesBoron DeficiencyManu MandaNo ratings yet

- Thermal EnergyDocument6 pagesThermal EnergyHannah Joy FranciscoNo ratings yet

- TA2103 Mid Term Exam 2018Document2 pagesTA2103 Mid Term Exam 2018nuel napitupuluNo ratings yet

- Topic 2.3 FormativeDocument2 pagesTopic 2.3 Formativeishaan50% (2)

- Control Valve Sourcebook - Chemical Unit Operations: Distillation ColumnDocument6 pagesControl Valve Sourcebook - Chemical Unit Operations: Distillation Columnkumar_chemicalNo ratings yet