Professional Documents

Culture Documents

7 Compression Tanks.28123914

Uploaded by

lutfi awnCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

7 Compression Tanks.28123914

Uploaded by

lutfi awnCopyright:

Available Formats

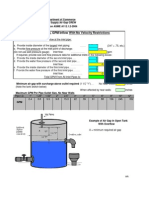

Energy Efficient Building Design College of Architecture Illinois Institute Of Technology (IIT), Chicago

Volume of Pipes in System

Color Codes Nom Inside Volume Length Volume

Project Name Size Diam per ft per size per size

Project No. (ins) (ins) (cu.ft.) (ft) (cu.ft.)

System Type 3/8 0.49 0.001 0.00

Date 1/2 0.62 0.002 0.00

Tank Identif. / Name 3/4 0.82 0.004 20 0.07

Tank Description Cylindrical / Horizontal 1 1.05 0.006 30 0.18

Location (building) 1 1/4 1.38 0.010 0.00

1 1/2 1.61 0.014 30 0.42

Volume System Equipt Properties of Water 2 2.07 0.023 20 0.47

Equipt Dscr Volume Temp Sp.Vol e Temp Sp.Vol e 2 1/2 2.47 0.033 30 1.00

(replace/edit) (cu.ft.) T deg F V ft3/lb % exp T deg F V ft3/lb % exp 3 3.07 0.051 20 1.03

Chillers - Evap 20 35 0.01600 0 160 0.01639 2.44 3 1/2 3.55 0.069 0.00

Chillers - Cond 40 0.01602 0.12 170 0.01645 2.81 4 4.03 0.088 30 2.65

Cooling Towers 50 0.01602 0.12 180 0.01651 3.19 5 5.05 0.139 0.00

CHW Pumps 10 60 0.01604 0.25 190 0.01657 3.56 6 6.07 0.201 50 10.03

CW Pumps 70 0.01605 0.31 200 0.01663 3.94 8 7.89 0.340 30 10.19

Boilers - WT 80 0.01607 0.44 210 0.01670 4.38 10 10.02 0.548 0.00

HW Pumps 90 0.01610 0.62 220 0.01677 4.81 12 11.94 0.777 20 15.55

Heat Exchangers 100 0.01613 0.81 230 0.01684 5.25 14 13.13 0.940 0.00

Cooling Coils 50 110 0.01617 1.06 240 0.01692 5.75 16 15.00 1.227 0.00

Heating Coils 120 0.01620 1.25 250 0.01700 6.25 18 16.88 1.553 70 108.73

Radtrs, Convtrs 130 0.01625 1.56 260 0.01708 6.75 20 18.81 1.931 0.00

Fan Coil Units 30 140 0.01629 1.81 270 0.01719 7.44 22 20.75 2.348 0.00

Terminal Equipt 150 0.01634 2.13 280 0.01726 7.88 24 22.64 2.796 0.00

Miscell Equipt 10 26 25.25 3.477 0.00

Equip Vol (ft3) 120 e = % Expansion of Water from 35 F to t 28 27.25 4.050 0.00

System Vol (ft3) = 270 e = 100*( Vt - 0.016 ) / 0.016 30 29.25 4.666 0.00

Contigency Factor ( %) = 10 t = Max temp of water (deg F) 32 31.25 5.326 0.00

Sys Vol + % age (ft3 ) = Vs 297 Vt = Sp. Vol at temp t (ft3/lb) 34 33.25 6.030 0.00

Equiv lbs of Water = Vp 18,555 a = Coeff of Exp of Steel (in / in) = 0.0000065 36 35.25 6.777 0.00

Equiv gals of Water = Vg 2,226 a = Coeff of Exp of Copper (in / in) = 0.0000095 Total Volume of Pipes (ft3) = 150.3

E = Net Pressurization Factor for diaphragm tanks E = Net Exp of water (gals) heated from T1 to T2

T E T E T E T E T 100 120 150 200 280

90 0.004 110 0.008 130 0.012 150 0.018 e = 0.006 0.010 0.018 0.034 0.070

100 0.006 120 0.010 140 0.015 160 0.021 E = exp 13.4 22.3 40.1 75.7 155.8

Sizing Data (Enter as required by tank type & sizing method)

Maxim Water Temp - Tmax (F) T2 200 Average Operating Temp (F) T 200 dt = T2-T1 = 160

% Exp of Water fr 35 F to T2 e 3.94 Minim Water Temp - Tmin (F) T1 40 (V2/V1 - 1) = 0.0438

Tank Material (Steel / Copper) Steel Maxim Water Temp - Tmax (F) T2 200 Pa / P1 = 0.588

Coeff of Exp of Tank Material a 7E-06 Specific Volume at Tmin (ft3/lb) V1 0.0160 Pa / P2 = 0.3675

Tank Type (Open / Closed) Open Specific Volume at Tmax (ft3/lb) V2 0.0167 P1 / P2 = 0.625

Closed Type (Normal / Diaphragm) Normal System Volume (ft3) Vs 297 Pa' / Po = 0.0969

Tank Size (% of System Volume) 5 Min Press at Highest Point (psia) P1 25.0 3*a*dt = 0.0031

Default Diameter (inches) D 24 Max Press to open Safety Valve (psia)P2 40.0 psi x 2.31 = ft

Locatn w.r.t Pump (Suctn/Dischge) Suction Atmospheric Pressure (psia)) Pa 14.7 " Hg x 1.33 = ft

System Height above Tank (ft) H 90 Atmospheric Pressure (ft.Wtr) A, Pa' 33.9 ft3 x 7.5 = gals

Pr. Loss fr Tank to Pump (ft.Wtr) F 20 Venting Pressure (ft.Wtr) V 12 gals x 8.334 = lbs

Pump Head (ft Wtr) PH 70 Maxim Operating Pressure (ft Wtr) Po 350 ft3 x 62.4 = lbs

User Input

Calculated

Reference Data Chilled Water

Penthouse Equipt Room

Pressurization Tank Sizing

Instructor: Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings Merrill LLP 246504602.xls.ms_office

Energy Efficient Building Design College of Architecture Illinois Institute Of Technology (IIT), Chicago

Open Tank Sizing Sizing assumes Open Tank is: (1) vented to atmosphere, (2) at least

Vt Weight Volume 3' above highest point of system, & (3) connected to pump suction

gallons lbs ft3 D (in) L (ft) Vt = Minimum Volume of Expansion Tank (gals)

(1) As a Percentage of System Volume 111 928 15 24.0 4.7 Vt = Vs * (% of System Volume / 100)

(2) Using Min, Max Temp, Exp Coeff 96 804 13 24.0 4.1 Vt = Vs * (e/100) * 1.1 Exp Vol + 10%

from ASHRAE Systems 2000 181 1508 24 24.0 7.7 Vt = 2 * Vs * [ (V2/V1 - 1) - (3*a*dt)]

Closed Tank Sizing V = +ve venting pressure (= 12 ft if unknown)

Fill Pressure (Pf): The tank location w.r.t. the piping system affects the initial fill or minim press at the tank. F = frictional loss from tank to pump in order to

The tank can be at three possible locations with respect to the system as shown below. maintain +ve venting pressure (ft)

Pf Pa/Pf A = atmospheric pressure (ft)

Location of Tank ft H2O - Pa/Po H = system static head (ft) = distance between

(1) Tank is above the piping system Pf = V + F + A 65.9 0.51 0.42 0.19 0.81 tank and highest point of system

(2) Tank is on suction side of pump Pf = V + H + A 135.9 0.25 0.15 0.39 0.61 PH = pump head (ft) reqd to maintain +ve press.

(3) Tank is on discharge side of pumpPf = V + PH + A 115.9 0.29 0.20 0.33 0.67 at the top of the system

(1) Closed Tank:: T <= 160 T2 = 150 dt = 110 Vs = 297

V2 at T2 = 0.0163 E = e*Vs = 40 Vt = Minim Volume of Pressurization Tank (gals)

Location of Tank Denom Vt gals Lbs ft3 D (ft) L (ft)

(1) Tank is above the piping system 0.42 96 798 13 24.0 4.1 Vt = E ASHRAE 1987

(2) Tank is on suction side of pump 0.15 262 2185 35 24.0 11.1 (Pa/Pf) - (Pa/Po) for T <= 160 F

(3) Tank is on discharge side of pump 0.20 204 1704 27 24.0 8.7 E = Net expansion of water (gals) heated from 40 F to T

Using ASHRAE HdBk Systems 2000 0.22 193 1608 26 24.0 8.2

(2) Closed Tank:: 160 <= T <= 280 T2 = 200 Vs = 297 [(V2/V1) - 1] - (3* a*dt) ASHRAE

(0.00041 x T - 0.0466) x Vs = 79 (Pa/P1) - (Pa/P2) 2000

Location of Tank Denom Gallons Lbs ft3 D (ft) L (ft)

(1) Tank is above the piping system 0.42 189 1573.0 25.2 24.0 8.0

(2) Tank is on suction side of pump 0.15 517 4304.6 69.0 24.0 22.0 (0.00041*T - 0.0466) * Vs ASHRAE 1987

(3) Tank is on discharge side of pump 0.20 403 3357.5 53.8 24.0 17.1 ( Pa/Pf) - (Pa/Po ) 160 <= T <= 280

Using ASHRAE HdBk Systems 2000 0.22 410 3419 55 24.0 17.4

(3) Closed Chilled Water Tank T = 90 Vs = 297 (1) Tank Size is half of a hot water tank operating at 200 F

(0.00041 x T - 0.0466) x Vs = 79 (0.00041*T - 0.0466) * Vs

Location of Tank Denom Gallons Lbs ft3 D (ft) L (ft) 2 * [(Pa/Pf) - (Pa/Po)]

(1) Tank is above the piping system 0.81 97 809 13 24.0 4.1 ASHRAE 1987

(2) Tank is on suction side of pump 0.61 129 1074 17 24.0 5.5 (2) Tank Size can be estimated from:

(3) Tank is on discharge side of pump 0.67 118 982 16 24.0 5.0 (0.00041*T - 0.0466) * Vs

Using ASHRAE HdBk Systems 2000 0.22 205 1709 27 24.0 8.7 1 - (Pf/Po)

(4) Closed Diaphragm Water Tank T = 120 Vs = 297

E = 0.01 Num = E*Vs = 22 E * Vs ASHRAE 1987

Location of Tank Denom Gallons Lbs ft3 D (ft) L (ft) [ 1 - (Pf/Po) ] for T <= 160 F

(1) Tank is above the piping system 0.19 118 985 16 24.0 5.0

(2) Tank is on suction side of pump 0.39 57 478 8 24.0 2.4 [(V2/V1) - 1] - (3*a*dt) ASHRAE

(3) Tank is on discharge side of pump 0.33 67 560 9 24.0 2.9 [ 1 - (P1/P2) ] 2000

Using ASHRAE HdBk Systems 2000 0.38 241 2010 32 24.0 10.3

References: (1) 1987 ASHRAE Handbook, pp. 13.11 - 13.15 (2) 2000 ASHRAE Handbook pp. 12.3 - 12.5

Pf/Po 1-Pf/Po

Basis of Sizing

Tank Size

Vs *

ASHRAE 2000

Vt =

Vt =

Vt =

Vs *

Vt =

Vt =

Pressurization Tank Sizing

Vt =

Pf = Initial or Min

Fill Pressure (ft)

Pa/Pf

Instructor: Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings Merrill LLP 246504602.xls.ms_office

Energy Efficient Building Design College of Architecture Illinois Institute of Technology (IIT), Chicago

PRESSURIZATION TANKS

Pressurization tanks include expansion tanks and compression tanks. The term expansion tank is used with low

pressure systems where the tank is located at the highest point of the piping system (open or closed) and the tanks

water surface is at atmospheric pressure. The height location of the expansion tank determines the static pressure

head available to the terminal equipment. The term compression tank applies to pressurized closed piping systems.

Make-up water is supplied through the pressurization tank.

Pressurization tank types include (1) Open and (2) Closed

Closed pressurization tank construction can be:

A regular tank where the pressurizing air or gas is in contact with the liquid.

A diaphragm tank where the air charge and liquid are permanently separated by a diaphragm to prevent

corrosion of the tank or contamination of the fluid.

System Volume

Pressurization tank size is based on the volume capacity of the system. System volume consists of:

the physical inside volume of all the pipe sections in the system. The pipe volume is converted into gallons of

liquid using the density of the liquid.

the liquid storage capacity of all the equipment in the system. The physical volume storage capacity of the

terminal equipment, primary equipment and miscellaneous equipment, etc., that is converted to liquid

volume using liquid density.

Open Tank Sizing

Open tank sizing assumes that the tank is:

vented to the atmosphere

at least three feet above the highest point in the piping system

connected to the suction side of the pump

Tank Volume

The tank volume size in gallons is estimated as a percentage of the total system volume The minimum recommended

volume is 6% in accordance with 1987ASHRAE Handbook. An alternative to sizing the tank based on percentage of

system volume, the system liquid expansion volume can be used to determinethe tank size. This expansion volume

is the difference in volumes at the maximum temperature of the piping system and at the minimum temperature.

Closed Tank Sizing

Fill Pressure: The tank location with respect to the piping system affects the initial fill or minimum pressure Pf

at the tank. The tank can be at three possible locations with respect to the system.

(1) Tank is above the piping system

V = positive venting pressure; (assumes 12 ft of liquid if not known)

F = frictional pipe losses from tank to pump that must be overcome in order to

obtain positive air venting pressure (ft of liquid as specified in input)

A = atmospheric pressure (ft of liquid)

(2) Tank is on suction side of the pump

H = system static head = distance between tank and highest point of piping system

(3) Tank is on discharge side of the pump

PH = pump head (ft of liquid) required to maintain positive pressure attop of system

In all three cases, the atmospheric pressure A is added to obtain absolute pressure

You must specify either the initial fill pressure Pf or the system static head H.

Pf = V + H + A

Pf = V + PH + A

Pf = V + F + A

Instructor: Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings Merrill LLP 246504602.xls.ms_office

Energy Efficient Building Design College of Architecture Illinois Institute of Technology (IIT), Chicago

Tank Sizing Equations (closed tanks)

(1) Tank with operating temperatures below 160 F

Vt = minimum volume of pressurization tank (gal)

E = net pressurization of water in the system when heated from min to max temp (gal)

Pa = pressure in tank when water first enters tank (ft of water absolute); At atmos.press.

Pf = initial fill or minimum pressure of tank (ft of water absolute)

Po = maximum operating pressure of tank (ft of water absolute)

(2) Tank with operating temperatures between 160 F and 280 F

T = maximum average operating temperature (oF)

Vs = system volume calculated from the piping system dimensions (gal)

Error: Denominator is Pa/Pf - Pa/Po

(3) Chilled Water Tank Error: Denominator is 1 - Pf/Po

Tank sizing for chilled water systems will result in tanks of very small size

because of the low pressurization coefficients (40 F to 90 F temperature range). For that

reason, closed compression tanks applied to chilled water systems are sized as follows:

(1) regular tank size is half the equivalent hot water size

(2) the piping system is considered to be operating from 70 F to 200 F

(4) Diaphragm Water Tank Specific Volume of Water

(ASHRAE Chapter-6, Table-4)

e = net pressurization factor for water Tmp Press Sp.Vol Expansion Sp.Vol Exp: ft3

F psia ft3 / lb ft3 / (F.lb) ft3 / gal / (F.gal)

* 1,000,000 * 1,000,000

0 0.0185 0.0174 0.1453

The lowest temperature of chilled water equals the minim 32 0.0886 0.0175 0.1456

design temperature. This can be assumed to be 35 oF. T 40 0.1217 0.0160 0.1335

The highest temperature is the highest anticipated ambient temp. 50 0.1781 0.0160 0.1335

The net pressurization factor e is obtained from table below 60 0.2564 0.0160 0.1337

Source: 1987 ASHRAE Handbook, Table 2, p. 13.15 70 0.3633 0.0161 1.6667 0.1338 8.6900

80 0.5074 0.0161 1.7500 0.1339 10.6845

Net Pressurization Factors Typical make-up water supply 90 0.6989 0.0161 2.0000 0.1342 13.5480

for Diaphragm Water Tank and expansion tank piping for 100 0.9503 0.0161 2.1667 0.1344 15.4570

plain steel tanks 110 1.2765 0.0162 2.4286 0.1348 18.0111

120 1.6947 0.0162 2.5000 0.1350 18.8850

130 2.2257 0.0163 2.7778 0.1354 21.4167

140 2.8926 0.0163 2.9000 0.1358 22.6086

150 3.7228 0.0163 3.0909 0.1362 24.3415

160 4.7469 0.0164 3.2500 0.1366 25.7855

170 5.9994 0.0165 3.4615 0.1371 27.6485

180 7.5194 0.0165 3.6429 0.1376 29.2453

190 9.3495 0.0166 3.8000 0.1381 30.6292

200 11.5375 0.0166 3.9375 0.1386 31.8401

210 14.1358 0.0167 4.1176 0.1392 33.3988

220 17.2010 0.0168 4.2778 0.1398 34.7843

230 20.7960 0.0168 4.4211 0.1403 36.0240

240 24.9873 0.0169 4.6000 0.1410 37.5564

250 29.8462 0.0170 4.7619 0.1417 38.9429

260 35.4502 0.0171 4.9091 0.1423 40.2033

280 49.2260 0.0173 5.2500 0.1438 43.1035

300 67.0350 0.0175 5.5769 0.1454 45.8781

0.015

0.018

0.021

Press.

Factor

e

0.004

0.006

0.008

0.010

0.012

Highest

Temp

F

90

100

110

120

130

140

150

160

P

P

-

P

P

E

=

V

o

a

f

a

t

( )

P

P

P

P

V

x 0.0466 - T x 0.041

=

V

o

a

f

a

s

t

( )

P

P

1

V

x 0.0466 - T x 0.041

=

V

o

f

s

t

P

P

- 1

V

e

=

V

o

f

s

t

Instructor: Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings Merrill LLP 246504602.xls.ms_office

Energy Efficient Building Design College of Architecture Illinois Institute of Technology (IIT), Chicago

PROPERTIES OF LIQUIDS

-30 0 30 60 100 150 210

Water 62.42 62.37 62.00 61.20 59.81

1.00 1.00 0.99 0.98 0.96

0.00 12.17 7.39 4.76 3.20

1.00 1.00 1.00 1.00 1.01

Glycol 67.98 67.55 67.11 66.55 65.74 64.68 63.12

1.09 1.08 1.08 1.07 1.05 1.04 1.01

595.00 190.00 85.40 48.60 22.60 12.50 6.40

0.70 0.73 0.76 0.78 0.81 0.85 0.88

Brine 78.59 78.21 77.71 77.21 76.09

1.26 1.25 1.25 1.24 1.22

171.70 77.50 34.70 21.80 8.90

0.66 0.67 0.68 0.69 0.71

Diesel 59.20 57.40 56.10 54.90 53.00 51.10

0.95 0.92 0.90 0.88 0.85 0.82

376.70 161.50 80.70 48.30 29.10 7.50

0.47 0.48 0.49 0.50 0.51 0.52

Petrol 46.10 45.50 44.90 44.70 44.30 42.40

0.74 0.73 0.72 0.72 0.71 0.68

11.00 9.80 8.80 7.00 5.50 3.00

0.47 0.48 0.49 0.50 0.51 0.52

PROPERTIES OF HIGH TEMPERATURE HOT WATER Increase in Frictional Pressure Loss

due to Pipe Age

Temp Satur. Density Specific Kinem Sp. Heat Hydraulic Handbook by Colt Industries

deg F Press lb/cu ft Gravity = Viscos Btu/lb oF Multipliers

psig Density/62.4 sq ft/sec

212 0 59.81 0.96 3.2 1.0055 Pipe Age Small Medium Large

220 2.5 59.63 0.96 3 1.0068 Years 1 - 3 4 to 12 14 - 48

240 10.3 59.1 0.95 2.7 1.0104 0 1 1 1

260 20.7 58.51 0.94 2.5 1.0148 5 1.4 1.35 1.3

280 34.5 57.94 0.93 2.3 1.02 10 2.2 1.9 1.6

300 52.3 57.31 0.92 2.1 1.26 15 3.6 2.7 1.8

350 119.9 55.59 0.89 1.9 1.044 20 5 3.5 2

400 232.6 53.65 0.86 1.7 1.067 25 6.3 4.2 2.1

450 407.9 51.55 0.83 1.5 1.095 30 7.25 4.73 2.2

35 8.1 5.2 2.3

40 8.75 5.58 2.4

45 9.25 5.93 2.6

50 9.6 6.23 2.86

60 10 7 3

Density (lb/cu ft)

Specific Gravity ( = Density / 62.4 )

Kinematic viscosity (sq ft/sec)

Specific heat (Btu/lb oF)

Density (lb/cu ft)

Specific Gravity ( = Density / 62.4 )

Kinematic viscosity (sq ft/sec)

Liquid Properties

Temperature

Density (lb/cu ft)

Specific Gravity ( = Density / 62.4 )

Kinematic viscosity (sq ft/sec)

Specific heat (Btu/lb oF)

Specific Gravity ( = Density / 62.4 )

Kinematic viscosity (sq ft/sec)

Specific heat (Btu/lb oF)

Specific heat (Btu/lb oF)

Density (lb/cu ft)

Specific Gravity ( = Density / 62.4 )

Kinematic viscosity (sq ft/sec)

Specific heat (Btu/lb oF)

Density (lb/cu ft)

Instructor: Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings Merrill LLP 246504602.xls.ms_office

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Heavy Oil Upgrading by The Separation and Gasification of AsphaltenesDocument11 pagesHeavy Oil Upgrading by The Separation and Gasification of Asphalteneslutfi awnNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Hydraulic Calculations MKIIDocument8 pagesHydraulic Calculations MKIIlutfi awnNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- E10 Blending Study Final ReportDocument107 pagesE10 Blending Study Final Reportlutfi awnNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Liquid Pressure DropDocument8 pagesLiquid Pressure Droplutfi awnNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Air Compressor Curve ToolDocument14 pagesAir Compressor Curve Toollutfi awnNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Astm D 86Document8 pagesAstm D 86lutfi awnNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Bitumen Upgrading Shell Canada LimitedDocument301 pagesBitumen Upgrading Shell Canada Limitedlutfi awnNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Liquid and Gas Velocity Gas Compressibility and Renolds Number.Document30 pagesLiquid and Gas Velocity Gas Compressibility and Renolds Number.lutfi awnNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Mixer Tank Jet Pumps Gea - tcm11 34889Document4 pagesMixer Tank Jet Pumps Gea - tcm11 34889Venodaren VelusamyNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Lubricating Oils: Test Methods Test MethodsDocument32 pagesLubricating Oils: Test Methods Test MethodsCorina StanculescuNo ratings yet

- Viscosity-Classifications Astm d2422Document8 pagesViscosity-Classifications Astm d2422Francisco TipanNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Air Compressor Tools APODocument7 pagesAir Compressor Tools APOlutfi awnNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- 2011 Chaudhuri U R Fundamentals of Petroleum and PetrochDocument33 pages2011 Chaudhuri U R Fundamentals of Petroleum and Petrochlutfi awnNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 04 Jet Mixing Design ApplicationsDocument6 pages04 Jet Mixing Design Applicationslutfi awnNo ratings yet

- Water Demand Calculation 1Document2 pagesWater Demand Calculation 1lutfi awnNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Molecular Sieve Dehydration OptimizationDocument24 pagesMolecular Sieve Dehydration Optimizationlutfi awn100% (1)

- H2S RiskDocument6 pagesH2S Risklutfi awnNo ratings yet

- Petroleum Average Conversion FactorsDocument2 pagesPetroleum Average Conversion Factorslutfi awnNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Conversion of Milligrams Per Cubic Meter To PPMDocument2 pagesConversion of Milligrams Per Cubic Meter To PPMlutfi awnNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Calculation ExampelDocument21 pagesCalculation Exampellutfi awnNo ratings yet

- PCVDocument2 pagesPCVlutfi awnNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Fonds Bombes - Surface MouilleeDocument3 pagesFonds Bombes - Surface MouilleesegunoyesNo ratings yet

- Valve Sizing Worksheet InstructionsDocument11 pagesValve Sizing Worksheet Instructionslutfi awnNo ratings yet

- Plumbing H 2 Osu Pair Gap CalculatorDocument9 pagesPlumbing H 2 Osu Pair Gap Calculatorlutfi awnNo ratings yet

- GOR Vs GVFDocument8 pagesGOR Vs GVFlutfi awnNo ratings yet

- PumpDocument31 pagesPumpkajale_shrikant2325No ratings yet

- Gas TurbDocument10 pagesGas Turblutfi awnNo ratings yet

- Gas ReservesDocument8 pagesGas Reserveslutfi awnNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Centrifugalcompressorpower Si UnitsDocument4 pagesCentrifugalcompressorpower Si UnitsJoshi DhvanitNo ratings yet

- ZM KV Idag eDocument6 pagesZM KV Idag elutfi awnNo ratings yet

- 06 Brakes PDFDocument6 pages06 Brakes PDFAKILI PSINo ratings yet

- Full Download Test Bank For Financial Reporting Financial Statement Analysis and Valuation 8th Edition PDF Full ChapterDocument36 pagesFull Download Test Bank For Financial Reporting Financial Statement Analysis and Valuation 8th Edition PDF Full Chaptervespersrealizeravzo100% (18)

- Grade 8 MAPEH ReviewerDocument4 pagesGrade 8 MAPEH ReviewerVictoria DelgadoNo ratings yet

- Vibration ControlDocument513 pagesVibration ControlchandankrdumkaNo ratings yet

- 1.8 CarderoDocument29 pages1.8 CarderoRodrigo Flores MdzNo ratings yet

- Subcontracting Process in Production - SAP BlogsDocument12 pagesSubcontracting Process in Production - SAP Blogsprasanna0788No ratings yet

- MantrasDocument45 pagesMantrasharibhakta100% (1)

- Process Pipeline Repair ClampsDocument4 pagesProcess Pipeline Repair ClampsHeru SuryoNo ratings yet

- Systems of Linear Equations With Two VariablesDocument34 pagesSystems of Linear Equations With Two VariablesFatima KausarNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Laura Gentile Letter On Hampden County CourthouseDocument6 pagesLaura Gentile Letter On Hampden County CourthouseMassLiveNo ratings yet

- PVC Duct DesignDocument10 pagesPVC Duct DesigncitramuaraNo ratings yet

- NarcolepsyDocument12 pagesNarcolepsyapi-489712369No ratings yet

- Coronary Stents: Current StatusDocument42 pagesCoronary Stents: Current StatusMANSI SALUNKENo ratings yet

- GOLDEN DAWN 1 10 The Banishing Ritual of HexagramDocument4 pagesGOLDEN DAWN 1 10 The Banishing Ritual of HexagramF_RC86% (7)

- Spining Mill in IndiaDocument74 pagesSpining Mill in IndiaMahendra Shah100% (4)

- Fish CheeksDocument4 pagesFish Cheekshafsah aminNo ratings yet

- The Symbols Found in TarotDocument17 pagesThe Symbols Found in TarotPEdro100% (1)

- Atomic Rex A Kaiju Thriller (Matthew Dennion) (Z-Library)Document163 pagesAtomic Rex A Kaiju Thriller (Matthew Dennion) (Z-Library)Strictly Aviator Amritansh VermaNo ratings yet

- Role of BisoprololDocument43 pagesRole of BisoprololFidel Martua Marpaung67% (3)

- Marlinespike - Rope Breaking StrengthDocument7 pagesMarlinespike - Rope Breaking StrengthAnonymous ycFeyuLAt100% (1)

- R K Konodia Civil Gate Previous Year - by EasyEngineering - Net 1 PDFDocument214 pagesR K Konodia Civil Gate Previous Year - by EasyEngineering - Net 1 PDFDaante VermaNo ratings yet

- The Guardian Weekly 9-02-2024-2Document64 pagesThe Guardian Weekly 9-02-2024-2krris.galNo ratings yet

- Hopf 6870 - 1101Document58 pagesHopf 6870 - 1101macakafkaNo ratings yet

- Supplier S Documentation of Equipment PDFDocument32 pagesSupplier S Documentation of Equipment PDFzhangjieNo ratings yet

- Malabar Cements Performance AppraisalDocument92 pagesMalabar Cements Performance AppraisalDoraiBalamohan0% (1)

- The Anaphylactic ShockDocument8 pagesThe Anaphylactic ShockRooby JeanpierreNo ratings yet

- QB Som He306 2015 2016Document23 pagesQB Som He306 2015 2016etayhailuNo ratings yet

- Pediatric Airway ManagementDocument2 pagesPediatric Airway ManagementSilvy AmaliaNo ratings yet

- Electrical Circuits 1 QPDocument7 pagesElectrical Circuits 1 QPKitty MinogueNo ratings yet

- T - Cell DifferentiationDocument24 pagesT - Cell DifferentiationAnand Prakash YadavNo ratings yet