Professional Documents

Culture Documents

Residential Pump Fundamentals

Uploaded by

peroooOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Residential Pump Fundamentals

Uploaded by

peroooCopyright:

Available Formats

2001 Goulds Pumps

Effective August, 2001 www.goulds.com

Residential

Pump Fundamentals

Goulds Pumps and the ITT Engineered Blocks symbol are

registered trademarks and tradenames of ITT Industries.

2

Sources of Water

A source of water or a well is often referred to as shallow or deep.

These terms are referring to the depth of the water source or well.

A shallow well is one where the water is within 2 feet of the ground

surface. A deep well is where the static water level is more than 2 feet

down.

The standing water level in a well is called the static level. This is the

water level when the pump is not operating. !hen the pump comes on

and is running there often is a change in the water level. This is referred

to as drawdown. The drawdown occurs and the water level reaches

what is referred to as the pumping level. This is the operating level of

the pump. The lowest level to which the water will drop is the level from

which it must "e pumped.

#riven !ell #rilled !ell #ug !ell $istern %pring, &a'e, or

%urface !ater

2 ft.

A Shallow Well

(s an) source of water where the water is within 2 feet of ground level. !hen water is pumped from a well the

water level will draw down. The lowest level to which it will drop is the level from which it must "e pumped.

#riven !ell #rilled !ell #ug !ell

2 ft.

Draw

Down

Static Level

Pumping

Level

A Deep Well

(s an) source of water where the low water level is more than 2 feet "elow the ground level.

Pump

Types

*

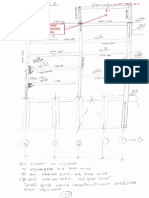

Typical Jet Pump Installations

SHALLOW

WLL S!ST"

TWI# PIP

DP WLL

S!ST"

PA$%&

DP WLL

S!ST"

+se chec'

valve here

or foot valve

at end of

suction pipe.

Shallow Well Jet Pump

(n a shallow well ,et s)stem,

the ,et assem"l) is fastened

to the outside of the centrifu-

gal pump as illustrated. .r

the ,et assem"l) can "e "uilt

into the centrifugal pump

casing.

(n either case there is onl)

one pipe e/tending into the

well or source of water 0

the suction pipe.

Deep Well Jet Pump

A deep well ,et s)stem is

"asicall) the same as a

shallow well s)stem with

one ma,or difference1

the ,et assem"l) is

separate from the

centrifugal pump,

located in the well,

usuall) "elow the

pumping level of the

water, and piped to the

centrifugal pump with

two pipes. A suction

pipe and a pressure or

drive water pipe.

AW '( ADAPT&

Typical )oul*s Jet Pump Installations

(+PIP

PITLSS

ADAPT&

O,& TH WLL

2

Pump Types

(continued)

Typical Su-mersi-le Pump Installation

Goulds Pumps

Goulds 23

su"mersi"le

pump with a

lightning

protected

motor. Two or

three wire

models

availa"le.

Pressure Tan.

.ffers water storage for

fewer pump c)cles.

Provides air cushion to

operate against. Tan'

should "e si4ed so that

draw down is e5ual to

capacit) of pump.

The / 0asic

1uestions

2 $apacity #ee*e*

6ow "ig must the pump "e7

( Well $on*itions

(s a shallow or deep well pump needed7

/ Discharge $on*itions

6ow much pressure is needed7

The illustration a"ove poses a t)pical water s)stem pro"lem. The source of water is in nearl)

all cases lower than the house or "uilding. This is wh) a pump is needed 0 to raise the water

up

to the faucets and fi/tures. These are the three 5uestions to "e considered1

2 $apacity #ee*e*

6ow much water in gallons per hour or gallons per minute are needed7 This determines what si4e pump to use.

( Well $on*itions

!hat is the total suction lift7 !hat is meant ") 8total suction97 !e learn from this what to e/pect from a

shallow well pump and when and wh) to use a deep well pump.

/ Discharge $on*itions

6ow much pressure is needed at the pump7 6ow much pressure will result at the faucet7

!henever and wherever a pump is to "e used, the correct answers to these three 5uestions will tell the actual

pumping conditions or specificall) 0 what is re5uired of the pump. !ith this information, )ou can alwa)s

select the right pump from the catalog.

6

2 $apacity #ee*e*

6ow much water is availa"le7

6ow much water is needed7

6ow large must the pump "e7

Limiting 3actors

6ow much water is

availa"le7 :efore we

select a pump "ased on

need we must determine

if the suppl) is ade5uate.

;an) areas have what we

refer to as low )ield wells,

!ell recover) rates ma) "e

as low as 1 GP; or less.

A t)pical low )ield <1 0 2

GP;= well, cannot suppl)

the 10-12 GP; re5uired

") an average home. (f we

pump at 12 GP; and the

water enters the well at

2 GP; we will soon run

the pump dr). This s)stem

would re5uire a pump

protection device to turn

the pump off when it runs

out of water.

>ortunatel) some low

)ield wells have a great

deal of water stored in the

well due to high static

water levels. There are

00? deep wells with static

water levels, when not

multiple loads of laundr)

are out of the 5uestion,

this application could

provide a cost effective,

relia"le water suppl)

without the use of large

e/pensive storage tan's

and "ooster pumps. The

customer should "e made

aware of the limitations

of the well and the

options availa"le.

(f using a deep well ,et

pump in a low )ield well

)ou should use a *2? tail

pipe on the "ottom of the

,et assem"l). This will

prevent over pumping a

deep well. %ee the section

on +sing Tail Pipes in the

Technical ;anual of )our

catalog.

Another wea' well

scenario is to select a

su"mersi"le pump si4ed

for a ma/imum pumping

depth somewhat less than

the actual depth at which

the pump will "e installed.

(t will then "e impossi"le

for the pump to over

pump the well and run

dr). Another option is to

install a low water level

cut off s)stem with

electrodes to turn the

pump off at a predeter-

mined level. (t can "e set

up to automaticall) reset

when the water level rises.

+nli'e totall) electronic

protection devices the

electrodes must "e

installed in the well.

(f the source of suppl) is

a deep cased well, the

casing diameter and

depth to water are

limiting factors in how

much water can "e

pumped. A 23 casing

supplied. %mall diameter,

deep wells e5ual low

capacit) pumps. The) also

dictate the pump st)le

that can "e used.

4ample5

$ustomer has a 23 well

casing with a 100?

pumping level. !hat is

the correct pump and

what will it produce7

The ma/imum pump

capacit) is a"out @

GP; using a 23 pac'er

assem- "l) with a 2 6P,

2 stage ,et pump.

(n cases where we have no

limiting factors, where we

have all the water re-

5uired and a well that will

accommodate a reason-

a"l) si4ed pump. !e can

proceed to determine the

correct capacit) needed to

satisf) the customers

re5uirements.

Physical &estrictions

23 $asing

"eing pumped, of 20?. A

23 well casing stores

cannot accommodate a

su"mersi"le pump. A

23 diameter limits )ou to a

appro/imatel) .A2

gallons per foot or 1.2

gallons per foot in a A3

well. (n this case, a 23 well

stores *12 gallons and a

A3 stores AB2 gallons. (t is

possi"le to use a B or 10

GP; pump and not over

pump the well due to the

large amount of water

stored in the casing. !hile

lawn watering and dail)

Tail Pipe

Cet Assem"l)

*2?

>oot Dalve

deep well ,et pump with a

pac'er or single pipe

s)stem. A 23 pac'er

s)stem can suppl)

appro/imatel) *.* GP;

from a 200? water level at

*0 P%(. 6owever, a

su"mersi"le pump in a

23 diameter, 200? deep

well can easil) suppl) over

A0 GP; at A0 P%(. There-

fore, we can see that small

diameter wells limit the

availa"le flow that can "e

23

%u"

23

$asing

!ell

Too %mall

200?

&ow !ater

&evel

7

2*?

Piping

'itchen sin' to shower

head e5uivalent length 20?

Piping

pump tan' to 'itchen

sin', e5uivalent

length *0?

%tatic

water level,

pump not

running

Pumping

water level,

pump

running

Deman*

10?

*0?

20?

availa"le is used and

man) users are dissatisfied

with the results. The)

either

canEt ta'e a shower or fill a

tu" while sprin'ling the

lawn, or if a toilet is

flushed when ta'ing a

shower, the shower

diminishes to a dri""le, or

some similar interruption

occurs. The trou"le of

course is that the

The rate of flow from a

faucet or fi/ture depends

on its t)pe and si4e, the

length and si4e of pipe

suppl)ing it and the

difference in elevation

"etween it and the pump

or tan'. >urthermore, it is

impossi"le to determine ")

sight the e/act rate of flow

"eing delivered from a

This of course is not

alwa)s practical. The

capacit) of pumps

changes with pumping

conditions such as

pumping level of the water

and the operating

pressure. Accordingl), it is

good practice to provide a

pump capacit) for the

average home of from 10

to 12 gpm when availa"le.

The capacit) re5uired of

the pump is determined ")

the num"er of continu-

ousl) flowing demands

<showers, sprin'ling, filling

a tu" or stoc' trough, etc.=

which are li'el) to "e in

use at the same time with

consideration given to a

minimum rate of flow from

each of these outlets which

can "e considered as

satisfactor)

Appro4imate Water

Supply &e6uirements

Home 3i4tures

>illing .rdinar) &avator) 0 2 gal.

>illing avg. :ath Tu" 0 *0 gal.

>lushing !ater $loset 0 A gal.

Each %hower :ath 0 +p to A0

gal. #ishwashing ;achine 0

1 gal.Fload

Automatic &aundr) ;achine 0

+p to 0 gal.Fload

:ac'washing #omestic !ater

too small pump canEt

deliver water fast enough

to suppl) the demand 0 its

capacit) is too little.

#etermining how much

capacit) is re5uired is

not an e/act science. The

o",ective is to provide a

water service similar to that

availa"le from a good cit)

water s)stem. This provides

practicall) an unlimited rate

of flow from an) or all the

faucets or other outlets

either one at a time or all

used at the same time. A

home water s)stem can

provide this t)pe service

"ut there are few domestic

well that will furnish such a

5uantit) and it isnEt at all

li'el) that all the faucets in

a home will "e opened

faucet.

(t has "een determined

") test and ")

o"servation that the

smallest or

minimum rate of flow from

a faucet should "e a"out

three gallons per minute

<* GP;=. An) less than

this approaches what

appears to "e a dri""leG

somewhat more is much

more satisfactor).

According to this, if a

pump or water s)stem in

a home is to suppl) two

faucets or outlets such as

a shower and a 'itchen

sin' at the same time, its

capacit) should "e two

times three or si/ gallons

per minute <*A0 gallons

per hour=.

The water from the pump

or tan' will not necessaril)

flow to fi/tures or faucets

at the rates ,ust discussed.

This is determined ") the

resistance to water flow in

the house plum"ing and

is e/plained in the third

step of the procedure 0

#is- charge $onditions. (t

should, however, "e

o"vious now that in order

to use water from more

than one outlet at a time,

the capacit) of the pump

should "e greater than the

rate of flow in GP;

availa"le from an) one

faucet.

%oftener 0 +p to 100 gal.

!ar* 3i4tures

1

H23 6ose with Io44le 0 * gpm

*

H23 6ose with Io44le 0 gpm

&awn %prin'ler 0 2 gpm

The capacit) of a water

s)stem or pump deter-

mines its si4e. The "igger

it is, the higher its price.

$onse5uentl), in man)

cases the smallest si4e wide at the same time.

(t can "e assumed that in the average home an) two

faucets or outlets ma) "e opened at once. The pump

must have sufficient capacit) to suppl) them. This will

prevent the difficult) of not "eing a"le to use the shower

when

the 'itchen sin' is in use, and vice versa.

8

%hower in use

same time as

'itchen sin'

faucet on.

2 continuous uses re5uire A G.P.;. minimum

The capacit) re5uired ofthe pump is determined ") the num"er of continuous use

outlets in use at the same time. Jou can?t use water at one or a num"er of outlets

an) faster than the pump supplies it.

9

( Well $on*itions

The level of the water to

"e pumped is practicall)

alwa)s "elow ground. (t

can "e onl) a few feet

as in a spring, shallow

well, pond, etc., or it can

"e man) feet as in a

deep well. (f we could

alwa)s locate the

pumping mechanism in

the water, as we do with

su"mers- i"le pumps, our

pro"lem

e5ual to a"out 12.B l"s.

per s5uare inch at sea

level. !hen the pressure

of atmosphere is removed

from inside of a pump the

resulting condition is a

vacuum or partial

vacuum. (t is also called

suction.

The vacuum or suction

cham"er of a pump is

piped <suction pipe= to a

determine how high

water can "e raised ")

suction.

>irst, letEs consider terms

of measurement and their

relation to each other.

Pressure is usuall) e/-

pressed in pounds per

s5uare inch <P%(=.

Pressure is used to

raise water to a height

e/-

07 1 pound pressure

e5uals 2.*1 feet head.

$7 Atmospheric pressure

of 12.B / 2.*1 K

**.@ft. head, which is

the ma/imum possi"le

lift at sea level.

2'78 l-s7

9 (7/2 ft7

//7: ft7

(7/2 ft7

would "e simpler "ecause

then the water would

flow into the pump.

source of water. The

surface of the water

should "e e/posed to the

pressed in feet. This

height is also e/pressed

as feet head.

2 l-7 2'78 l-s7

6owever, standard electric

motors and switches are

not designed for su"-

merged operation.

Therefore the) must "e

located a"ove ground.

This poses the 5uestion1

6ow does the water get

pressure of atmosphere.

!hen the pump operates

it develops an un"alanced

pressure condition due to

the suction or vacuum it

produces. This un"al-

anced pressure <12.B l"s.

per s5. in. atmospheric

Dacuum is measured with

a vacuum gauge. The

gauge can "e cali"rated

in feet suction lift or

inches vacuum.

A7 1 inch vacuum e5uals

1.1* feet suction.

07 $7

#OT5 Jou lose

appro/i- matel) one foot

of suction lift per 1000

ft.

of elevation.

E/ample1 #enver, $.

is appro/imatel) 000

ft.

into the pump7

!e call it suction, "ut

what is it7 !hat actuall)

ma'es the water flow

uphill into the pump7

6ow high can we raise

water ") suction7

pressure on the surface of

the water with vacuum or

a"sence of pressure in the

pump= causes water from

the source to flow up the

suction pipe into the

pump. >rom this we can

(;

A7

,&TI$AL LI3T

PL<S 3&I$TIO#

((7=>

,acuum

)auge

a"ove sea level. The total

suction lift would onl) "e

2L.@ ft. not **.@ ft. li'e at

sea level.

1. The atmosphere all

around us has weight and

therefore e/erts pressure

Atmospheric Pressure

Atmospheric

Pressure

2'78 L0S7

Water Level

Tr) to lift soda from a "ottle ")

closing )our mouth over the

mouth of the "ottle. (t canEt "e

done. !hen )ou use a straw, it

is eas) 0 )ou are creating a

partial vacuum in )our mouth,

e/posing the surface li5uid to

atmospheric pressure, the

difference in pressure raises the

li5uid.

A reading of 203 on a vacuum

gauge placed on a suction side

of the pump would tell )ou

that )ou had a vacuum or

suction lift of 22.A ft.

203 / 1.1*? K 22.A ft.

T.TA& &EIGT6 .> %+$T(.I P(PE (% 100E

$APA$T(J .> P+;P (%

B GA&&.I% PEM ;(I+TE

B ft.

%TAT($ &EDE& .> !ATEM

2* ft.

DEMT($A& &(>T <E&EDAT(.I= K 2*? . . . . . . . . . 2*?

2 ft.

P+;P(IG &EDE&

.> !ATEM

>M($T(.I .> B GP;

(I 100 >T. .> P(PE 13 K *.A? 1

1

/23 K .@*?

T.TA& %+$T(.I &(>T K 2A.A? . . . . . . . . . 22?

.:D(.+%&J 1

1

/23 P(PE ;+%T :E +%E#.

Summing this up5 !hen

the atmospheric pressure

is 12.B l"s. per s5. inch a

perfect vacuum

should "e *0 inches and

this would lift water ")

suction

to a height of **.@ ft.

;ost shallow well or suction

pumps are capa"le of

developing a near perfect

vacuum, and at sea level

the) can lift water a"out

thirt) feet. 6owever,

suction

lifts of more than 2 ft.

at sea level are not

recom-

mended. %hallow well ,et

pumps deliver inade5uate

capacit) on lifts over 2

ft.

%uction conditions, or total

suction lift must include all

resistances to the flow of the

water through the suction

pipe up to the pump. 6eight

or vertical lift is one resis-

tance. >riction "etween the

water and the pipe walls is

the other resistance.

waste the least possi"le

amount of wor'. Neep

in mind that all wor'

"eing done on the

suction side of the pump

is actuall)

performed ") the

pressure of atmosphere.

%ince in

common practice we

consider this pressure

is

sufficient to overcome onl)

2 ft., the 2 ft. must

alwa)s include an) losses

due to

friction.

!e donEt have to "e too

concerned with how or wh)

friction loss is incurred, "ut it

is essential that we accept it

as occurring alwa)s when

water flows through pipes. (t

is, also, most essential that

we understand how it is

measured.

(n our discussion of suction

lift, atmospheric pressure

and the height this

pressure will raise water,

we esta"- lished the fact

that 12.B l".

pressure will raise water to a

height of **.@ ft. Although

there is no relation "etween

atmospheric pressure and

friction loss, the relation

"etween pounds pressure

and feet elevation or head

as we call it, is the

same whether the

pressure is

coming from atmosphere or

an) other source. %o, as

stated "efore, 12.B l"s.

pressure from an) source

will raise water **.@ ft. and

this gives us the conversion

factor to change our terms

from pressure to feet or the

reverse of this. Therefore,

1 l". of pressure is alwa)s

e5ual to 2.*1 ft. <**.@

divided ") 12.B e5uals 2.*1=.

Iow getting "ac' to friction

loss, the amount of this loss

increases as the 5uantit) of

water flowing through a

given si4e pipe is increased.

There are formulas to

determine the amount of

flow and an) pipe si4e. :ut

we donEt have to "e con-

cerned with this, since it

has all "een carefull)

calculated and set up in the

friction loss ta"le as shown

"elow. 4ample5 The

e/ample at the top of the

page shows that using the

correct si4e pipe will reduce

friction loss. .n some ,o"s,

a smaller pump with larger

pipe will do the same wor'

<flow= as

a larger pump with

smaller pipe. &arger pipe is

not

much more e/pensive "ut

larger pumps are. &arger

pumps also use more

energ). +sing the correct

pipe si4e saves mone) in the

long run. $alculating friction

loss is especiall) important if

)ou are not sure of the well

drawdown. (t is a ver)

good rule of thum" to

alwa)s use

a suction pipe that is the

same si4e or larger than

the

3riction Loss

!hen water flows through

pipe, the inner wall of the

3riction of Water per ach 2;; 3eet of #ew Steel

Pipe

)P" )PH

pump suction.

pipe resists the flow of the

water. This resistance

is called pipe friction.

3riction Loss Increases

when $apacit) (ncreases

or

Pipe &ength (ncreases

Pipe friction means e/tra

wor' for the pump or

s)stem and presents a

total

loss. Therefore, it is desira"le to 'eep friction loss as low as

is practica"le in order to

/

?@A Pipe

2

?(A Pipe

/

?'A

Pipe 2A Pipe 2

2

?'A

Pipe 2

2

?(A Pipe (A

Pipe (

2

?(A Pipe /A

Pipe 'A Pipe

3t7 L-s7 3t7 L-s7 3t7

L-s7 3t7 L-s7 3t7 L-s7

3t7 L-s7 3t7 L-s7 3t7

L-s7 3t7 L-s7 3t7 L-s7

1 A0 2.*0 1.LA 1.LA .L1 0.2A

0.11

2 120 1.00 A.2@ 2.BL 2.0B 1.21

0.2 0.*L 0.1A

* 1L0 *1.L0 1*.BB 10.00 2.** 2.0

1.0L 0.BB 0.**

2 220 2.@0 2*.BB 1B.10 B.20 2.21

1.L2 1.*0 0.A 0.*2 0.1

*00 L*.0 *A.2 2.L0 11.1B A.*2

2.B2 1.@* 0.L2 0.1 0.22 0.22 0.10

A *A0 *A.0 1.L0 L.LB

*.L2 2.AL 1.1A 0.B0 0.*0 0.** 0.12

0.10 0.02

B 220 2L.B0 21.0L 11.L0

.11 *.A 1.2 0.@* 0.20 0.22 0.1@

0.1* 0.0A

L 2L0 A2.B0 2B.12 1.00 A.2@ 2.2 1.@B 1.1L 0.1 0.A 0.22 0.1B 0.0B

@ 20 1L.L0 L.12 .A 2.2 1.2A 0.A* 0.A@ 0.*0 0.21 0.0@

10 A00 2*.00 @.@A A.LA 2.@B 1.BB 0.BB 0.L* 0.*A 0.2 0.11 0.11 0.0 0.02 0.02

12 B20 *2.A0 12.11 @.A2 2.1A 2.2L 1.0B 1.1A 0.0 0.*2 0.1 0.1 0.0A 0.0 0.02

1 @00 2@.B0 21.2 12.B0 A.*A *.B2 1.A2 1.B 0.BA 0.2 0.2* 0.22 0.10 0.0L 0.0*

20 1200 LA.10 *B.2B 2.10 10.LB A.*2 2.B2 2.@2 1.2B 0.LB 0.*L 0.*A 0.1A 0.1* 0.0A

2 100 *L.A0 1A.B1 @.A 2.1L 2.2L 1.@2 1.*0 0.A 0.2 0.2* 0.1@ 0.0L

*0 1L00 2.A0 2*.A2 1*.A0 .L@ A.2A 2.B1 1.L2 0.B@ 0.B 0.*2 0.2A 0.11

* 2100 B*.20 *1.BB 1L.20 B.LL L.*B *.A2 2.22 1.0 1.00 0.2* 0.* 0.1

20 2200 @.00 21.1* 2*.0 10.1B 10.B@ 2.AB *.10 1.*2 1.2L 0. 0.22 0.1@

2 2B00 *0.B0 1*.2@ 1*.2 .L2 *.L 1.AB 1.A0 0.A@ 0. 0.22

0 *000 *A.00 1.L 1A.20 B.10 2.AB 2.02 1.@2 0.L2 0.AA 0.2@ .1L .0L

B0 2200 AL.L0 2@.BL *1.*0 1*. L.LA *.L2 *.A* 1.B 1.22 0.* .* .1

100 A000 A2.20 2A.@* 1B.20 B.* B.11 *.0L 2.*@ 1.0* .A* .2B

10 @000 *L.00 1A.2 1.20 A.AB .12 2.2* 1.*2 .B

200 12000 AA.*0 2L.B0 2A.B0 11.A L.@0 *.L 2.2B .@L

20 1000 @0.B0 *@.2A 22.L0 1L.* 12.10 A.10 *.A0 1.A

*00 1L000 L.0 2.*2 1@.20 L.*1 2.L@ 2.12

*0 21000 B@.20 *2.2@ 2A.@0 11.A A.B2 2.@1

@

12

/ Discharge

$on*itions

!hat are the conditions

under which the water

s)stem must discharge its

capacit)7

The capacit) of the

pump has alread) "een

esta"- lished so we are

now concerned onl) with

the

!ould )ou rather have

at a faucet one gallon

per minute at a hundred

pounds pressure or ten

gallons per minute at ten

pounds pressure7 !hich

will fill a tu" 5uic'er7

100 10

friction loss in feet

calculated and changed to

pounds pressure <again the

same relation, 1 l".

Pressure e5uals 2.* ft. or

this can "e read directl)

from the ta"le in l"s.=G the

service pressure or

pressure

ADEMAGE $.I#(T(.I%

I. PM.:&E;

+I+%+A& $.I#(T(.I

pressure re5uired of the

s)stem.

(t seems that the pressure

and its use in a domestic

water s)stem are generall)

misunderstood, so perhaps

P%(

PME%%+ME

1 GA&&.I

PEM ;(I+TE

P%(

10 GA&&.I%

PEM ;(I+TE

re5uired at the faucet must

"e decidedG the total

of these three will "e

the discharge

conditions or

operating pressure re5uired

of the pump.

>M($T(.I &.%%7

E&EDAT(.I7

some e/planation is in

order. Ouite often it is

stated that a particular

pump is delivering suffi-

cient capacit) "ut fails

to

develop ade5uate

pressure. (n most cases this

is a misstatement and the

opposite condition is true.

This complaint is generall)

made when a particular

s)stem fails to provide

sufficient flow through

several outlets at the

same

Iow as to the resistance to

flow which will "e encoun-

tered, there are three

causes. These are <1= the

resistance ") the outlet

itself such as a partiall)

rusted shower head, <2=

friction loss in pipe

lines,

and <*= that resistance

due to difference in

elevations.

Actuall) none of these will

have to "e computed in

most applications "ecause

usuall) the pump is

4ample

%ervice pressure desired 0

*0 l"s. min .................... *0 l"s.

Elevation 2* ft.

1 l". K 2.* ft.

2* ft. F 2.* ft. K 10 l"s. .. 10

l"s.

>riction1

Pump capacit) is B gpm

This flow through 200 ft.

of 13 pipe gives a friction

loss of *.0A l"s. .................. * l"s.

*0

P%(

2*?

time. This is caused in most

cases ") the demand in

rate of flow "eing greater

than the capacit) of the

s)stem. (f the s)stem has

sufficient capacit) to suppl)

the ma/imum num"er of

outlets which are li'el) to

"e used at the same

time,

our onl) concern with

pressure is that we

have sufficient pressure

to

overcome the resistance

to flow which will "e

encountered. (f )ou have

an) dou"ts a"out this,

consider )our answer

to this 5uestion1 installed at the house, and

the standard pressure

range of the s)stem is

sufficient to overcome

these resistances and

deliver its capacit) to the

various outlets. An e/ample

in which these computa-

tions must "e made is

when the pump or s)stem

is located at considera"le

distance from the point of

use and on a lower

elevation.

(n such a case the differ-

ence in elevation must "e

determined <1 l". Pressure

is necessar) to overcome

each 2.* ft. elevation=G the

2

* l"s.

Pressur

e

switch

setting

at the

pump

would

"e <2*-

A*

l"s.=

This

means

when

the

pressure switch

cuts the pump on

at a"out

2* l"s. Tan'

pressure, the

pressure at the

house will "e *0

l"s. !hen the

water is flowing

at a rate of

B gallons per

minute.

13

200? 13 P(PE E&ED AT(.I

14

Jet Systems

The first 5uestion with Cet Pumps is what is the suction

cham"er and how is the vacuum created.

The Cet Assem"l) itself forms the suction cham"er and

the vacuum is created ") the ver) high velocit) of a

stream of water passing through the ,et. :asicall), the ,et

assem"l) is composed of two parts. >irst, a no44le which

produces the high velocit) stream of water. This high

velocit) stream of water is in,ected through a small

compartment which is the suction cham"er, there")

causing the vacuum. ."viousl), the suction pipe is

connected to this compartment or suction cham"er. The

vacuum caused ") the ,et permits the greater pressure of

atmosphere on the surface of a "od) of water to force

water into the suction cham"er.

The second "asic part of the Cet Assem"l) is the venturi

tu"e. (t is installed in the discharge of the suction

cham"er. (ts function is to convert the velocit) of the

water into pressure. This is accomplished ") the shape

of its water passage. Perhaps )ou can "est visuali4e this

") thin'ing of a no44le in reverse. The no44le speeds up

the flow of the drive water converting pressure into

velocit) and when it has passed through the suction

cham"er,

the venturi slows it down again converting the velocit)

"ac' into pressure.

8#rive water9 is that water which is piped under pres-

sure to the ,et assem"l) or suction cham"er. The dis-

charge from the suction cham"er or ,et assem"l) is

composed of "oth the drive water and that water

pumped from the well. The total amount pumped from

the well can "e used as discharge from the s)stem and

is the output or capacit).

Shallow Well Jet Pump

>rom the foregoing discussion it is o"vious that the

operation of the Cet s)stem is dependent on the com-

"ined functions of "oth the Cet Assem"l) or suction

cham"er and the centrifugal pump. Also, that these two

main components of the s)stem are entirel) separate

and their locations with respect to each other is a

matter of design.

Types of Pumps

(n shallow well ,et pumps the ,et assem"l) is "uilt into

the pump casing as in the Goulds Pumps C%. .r, the

,et assem"l), shallow well adapters, can "e "olted to

the centrifugal pump. (n either case there is onl) one

pipe e/tending into the well . . . the suction pipe.

Deep Well Jet Pump

The onl) "asic or fundamental difference "etween

%hallow !ell and #eep !ell Cet Pumps is the location of

the Cet Assem"l). (t must alwa)s "e located in such a

position that the total suction lift "etween it and the

pumping level of the water to "e pumped does not

e/ceed that which can "e overcome ") the pressure of

atmosphere. This, of

course, means that when this pumping level is at a

distance lower than the ground level which cannot "e

overcome ") atmospheric pressure, the Cet Assem"l) must

"e located at least five feet "elow the low water in the

well.

!e must have a closed compartment in which to install

the no44le and the venturi and to form the suction

cham"er. This part is called the ,et "od). (ts shape is such

that it will fit into the casing of a drilled well and the pipe

connections

are located for accessi"ilit). There are two on the top side,

one for connection to the pressure pipe which supplies the

drive water, the other for connection to the suction pipe

which returns "oth the drive water and the water pumped

from the well. >or this reason, this connection is one pipe

si4e larger than that for the pressure pipe. !ater from the

well enters through a third opening which is on the

"ottom side of the ,et "od).

The last accessor) for the Cet %)stem is the pressure

control valve. (t is a valve installed in the discharge piping

from the centrifugal pump "etween the pump and the

tan'G in the pump when the pump is mounted on a tan'.

+sed onl) in deep well s)stems, its purpose it to assure a

minimum operating pressure for the ,et.

Pressure

$ontrol

Dalve <AD22=

(nstall

$hec'

Dalve

6ere .r

>oot

Dalve at

End of

%uction

Pipe

%uction

Pipe

Pressure Pipe

Dent

uri

15

I

o

4

4

l

e

Dent

uri

Twin Pipe

#eep !ell

Cet Assem"l)

>oot Dalve

16

Su-mersi-le Pump

%u"mersi"le pumps are so named "ecause the whole

unit, pump and motor is designed to "e operated under

water. This means the pump does not have to "e primed.

.nce installed and turned on, water flows up the pipe.

The pump end is a multistage <man) impellers= centrifugal

pump, close coupled to a su"mersi"le electric motor. All of

the impellers of the multistage su"mersi"le rotate in the

same direction ") a single shaft. Each impeller sits in a

"owl and the flow from the impeller is directed to the ne/t

impeller through a diffuser. These three parts <"owl,

impeller and diffuser= are 'nown as a stage.

#iffuser

#iameter of (mpeller

Affects Pressure

(mpeller

!idth of (mpeller Danes

Affects $apacit)

%u"mersi"le pumps are so much more efficient than ,et

pumps and the installation so much simpler that a

su"mers- i"le pump should "e considered first for all pump

applica- tions where the ph)sical dimensions of the source

of the water will accommodate the unit in a su"merged

position.

4ample5 A0 ft. pumping levelG

*0-0 l"s. Pressure.

1

H2 6P su"mersi"le ................................................ 11 gpm

1

H2 6P ,et s)stem ..................................................... A gpm

$entrifugal Pump

The centrifugal pump does two things. (t circulates the

drive water at the pressure re5uired to produce the

necessar) velocit) in the Cet. (t also "oosts the pressure

of that water "eing pumped from the well delivering it

through the discharge of the s)stem at a satisfactor)

service pressure. %ince the one return pipe from the ,et

assem"l) contains "oth these 5uantities of water, this

:owl

%haft

The capacit) of a multistage centrifugal pump

<su"mersi"le= is largel) determined ") the width of the

impeller and diffuser, regardless of the num"er of stages.

The pressure

is determined ") the diameter of the impeller,

the speed at which it rotates and the num"er of

impellers. The diameter is limited to the si4e of

wells drilled. ;ost su"mersi"les are designed to

fit in four or si/ inch wells <or larger=.

A

1

H2 6P pump with seven impellers <designed

for capacit)= would deliver more water at L0?

than a

1

H2 6P pump with 1 impellers <designed for

pressure= "ut the latter pump would "e a"le

to raise water from a greater depth.

!ell water enters the unit through screened

openings at the middle of the unit "etween the

pump and motor. There is onl) one pipe connec-

tion which is at the top of the pump. This is the

discharge pipe. A chec' valve is located at the

top of the unit to prevent water from the s)stem

draining "ac' when the pump isnEt running.

return pipe is connected direct to the suction opening of

the centrifugal pump. The action of the centrifugal

pump can "e thought of as that of a paddlewheel. The

impeller is a multi-vane <or "lade= wheel and its design

is such that its si4e, shape and speed impart sufficient

energ) to the water in the s)stem to circulate it at the

desired rate.

As the water is discharged from the centrifugal pump, it

is divided. The drive water, or that amount re5uired to

operate the Cet is piped directl) to the Cet through the

pressure pipe. (t is continuousl) recirculated so long as

the centrifugal pump is running. That amount pumped

from the well is discharged from the centrifugal pump

directl) into the tan' and is the capacit) of the s)stem.

$entrifugal Pump $haracteristics

P (mpeller attached to a ;otorF#river

P (mpeller draws the 6P off the ;otorF#river

P >le/i"le machineG capa"le of

a range of performances at

good efficiencies

P !ill overload motor

<pumps ma/. capacit)=

P &imited %uction &ift capa"ilit)

<1-2?=

P (mpeller ma'es own pressure

<P%(=

P Adds its pressure to an) incoming pressure

P Poor air-handling capa"ilit) <$avitation, loss of suctionF

prime, and air-"inding=

Accessories

!hen appl)ing a pump to an) specific pro"lem pertain-

ing to domestic water suppl), our o",ective in practicall)

ever) case should "e to provide automatic running

water under pressure 0 a water service compara"le to

that which might "e e/pected from connection to a cit)

water main. :ut, a pump alone can hardl) perform the

several necessar) functions. $ertain other accessories are

necessar), and the com"ination of them all forms what

we call a water s)stem.

alwa)s "e considered. The larger a motor is in horse-

power the more starting power re5uiredG therefore, the

less fre5uentl) it should "e started.

(t is good practice to si4e the tan' to re5uire the pump

to run at least one minute per c)cle when using frac-

tional horsepower motors and two to three minutes for

larger motors.

There are three "asic t)pes of tan's in use toda).

"otors

The first accessor) is the drive medium which on practi-

call) all water s)stems of toda) is an electric motor.

Jou should remem"er that some of our pumps, in

particular

A(M D.&+;E

$.ITM.&

A(M

!ATEM

$onventional or )alvaniBe* Type

Me5uires an air volume control device

to 'eep proper amount of air cushion

in the tan'.

the ,et pumps in large motor si4es and su"mersi"le

pumps, are furnished with motors of current characteris-

tics as specified. Therefore, when ordering these, we

must "e advised the electrical characteristics.

Pressure Switch

The ne/t accessor) re5uired is a pressure switch to start

and stop the motor automaticall) at a predetermined

pressure. A tu"e connects the switch to some point in

the s)stem on the discharge side of the pump. The

pressure in the s)stem then acts directl) on a diaphragm

in the switch which in turn actuates the contacts in the

>&.AT(IG

#(%$

#(AP6MAG;

A(M

!ATEM

A(M

!ATEM

A(M DA&DE

3loating Disc Type

#isc helps in preventing water from

a"sor"ing air "ut is not a"solute. (t

re5uires periodic replenishment of air

through air valve.

Seale* Diaphragm Type !ater

and air are permanentl) separated

") sealed diaphragmG therefore,

the amount of air never changes.

The amount of draw-off also never

changes.

switch.

Pressure Tan.s

The rate at which water can "e used in a home, school,

motel, or an) other place can "e as little as one gallon a

minute <A0 gallons per hour= <"rushing teeth or rinsing

hands=. .r the ma/imum can "e hundreds or thousands

of gallons per hour depending on the num"er of water

using fi/tures and, or appliances in use at the same

time.

A pump capa"le of delivering a capacit) e5ual to the

ma/imum demand cannot necessaril) "e throttled to

the minimum demand.

The main purposes of a pressure tan' are to pressuri4e

the s)stem to ma'e it operate automaticall) and to

properl) c)cle the pump to properl) cool the motor.

This prevents e/cessive short c)cling <too rapid starting

and stopping=. The pump capacit) and si4e motor

should

&elief ,alve

As a precaution or protection against the possi"ilit) of

the switch "ecoming stuc' at some time allowing the

pump to continue running after sufficient pressure has

"een o"tained, a relief valve is necessar) with all

s)stems capa"le of developing pressures in e/cess of the

wor'- ing limits of the tan'. A relief valve is a spring

controlled valve located somewhere close to or in the

pump on the discharge side, or on the tan'. The tension

of the spring is so ad,usted that it will permit the valve

to open and allow the water to escape if the pressure in

the s)stem e/ceeds ") more than a"out 10 l"s. That at

which the pressure switch is set to cut off the current to

the motor.

3oot ,alve

A foot valve is a com"ination chec' valve and strainer.

Summary

Iow letEs summari4e

"riefl) the points weEve

covered. !e have shown

that in a water s)stem

application, there are three

factors to consider1

1. !ater Ieeded or #eter-

mination of $apacit)

2. %uction $onditions, and

*. #ischarge $onditions.

!e have concluded that

capacit) re5uired is deter-

mined ") the ma/imum

num"er of outlets which

will "e in continuous use

at the same time with a

minimum flow of three

gallons per minute per

outlet.

!e have shown that all ,et

pumps, whether shallow

well or deep well, have a

water end in which there is

a suction cham"erG that the

suction cham"er is actuall)

a closed container in which

a partial vacuum is created.

This allows atmospheric

pressure to force in the

water. The suction cham"er

must "e located within

a"out 2 feet vertical

distance a"ove the pump-

ing level of the water.

The main difference

"etween shallow well and

deep well pumps is that in

the former the water end is

"uilt onto the power end.

The water end of deep well

,et pumps is a separate

part. (t is installed in the

water and is used to pump

water from levels "elow a

2 feet depth. !e have

shown that a su"mersi"le

should "e used when

source will allow. %ince the

su"mersi"le is su"merged

in water onl) discharge

conditions appl). !eEve

esta"lished three distinct

forms of resistance to flow

encountered as #ischarge

$onditions and shown that

the) must "e considered

"ut computed onl) in

special cases. Also, that the

pump is onl) part of the

s)stem necessar) to

provide an automatic

service. .ther accessories

are necessar) and weEve

esta"lished the need and

function of each of these

accessories.

!e have mentioned *

GP; as a minimum

accepta"le flow rate per

outlet. :ut a larger flow

rate is more desira"le and

the following ta"le should

"e used as an average

suppl) re5uired when the

source of suppl) will allow

it.

!e would li'e to leave )ou

with one thought. That is,

capacit) and pressure are

inversel) related. !hen one

goes up, the other goes

down. Alwa)s chec' the

rating chart or curve of a

pump to ma'e sure if )ou

raise the pressure )ou will

still receive the needed

suppl) of water at )our

outlets.

+sing the rating chart

"elow, we would "e

getting L GP; from the

pump at 20 l"s. pressure.

(f we were tr)ing to

suppl) two outlets at

once, this would give us

appro/imatel) 2 GP; at

each one. (f we increase

the pressure to *0 l"s.

pressure, we onl) get

A GP; which will give us

appro/imatel) * GP; at

each outlet. :) raising the

pressure we have reduced

the amount of water at

each outlet ") appro/i-

matel) 2Q.

Alwa)s chec' the pump

performance rating

"efore ma'ing a change.

Performance &ating in

)allons per "inute

Seven "inute Pea. Deman* Perio* <sage

Outlets

3low &ate

)P"

Total <sage

)allons

0athrooms In Home

2 2

2

?( (+(

2

?( /+'

%hower or :ath Tu" * * * * B0

&avator) 2 2 2 2 A L

Toilet 2 10 1 20

Nitchen %in' * * * * *

Automatic !asher * 0 1L 1L 1L

#ishwasher 2 12 0 0 * *

Iormal seven minuteRpea' demand <gallons= 2 B0 @L 122

;inimum si4ed pump re5uired to meet pea'

#emand without supplemental suppl)

B GP;

<220=

10 GP;

<A00=

12 GP;

<L20=

1B GP;

<1020=

#ote5 Dalues given are average and do not include higher or lower e/tremes. R Pea' demand can occur

several times during morning and evening hours.

A**itional &e6uirements5 >arm, irrigation and sprin'ling re5uirements are not shown. These values must

"e added to the pea' demand figures if usage will occur during normal demand periods.

Pump Discharge Pressure

Total

Suction

Lift

(; PSI /; PSI

"a47

Shut+Off

in L-s7

feet

L

GP;

A

GP;

1 l"s.

1uestions C

Answers

1. !hat well conditions might possi"l) limit the

capacit) of the pump7

2. 6ow does the diameter of a cased deep well and

pumping level of the water affect the capacit)7

*. (f there are no limiting factors, how is capacit)

determined7

2. !hat is suction7

. !hat is atmospheric pressure7

A. 6ow much is the pressure due to atmosphere7

B. !hat is ma/imum theoretical suction lift7

L. 6ow does friction loss affect suction conditions7

@. !hen and wh) do we use a deep well ,et pump7

Mate of flow from the source of suppl), the diameter of

a cased deep well and the pumping level of the water in

a cased deep well.

&imits the si4e pumping e5uipment which can

"e used.

;a/imum num"er of outlets or faucets li'el) to "e in

use at the same time.

A partial vacuum created in suction cham"er of pump

o"tained ") removing pressure due to atmosphere,

there") allowing greater pressure outside to force

something <air, gas, water= into the container.

The atmosphere surrounding the earth presses against

the earth and all o",ects on it, producing what we call

atmospheric pressure.

This pressure varies with elevation or altitude. (t is

greatest at sea level <12.B l"s. Per s5. in.= and

graduall) decreases as elevation a"ove sea level is

increased. At the rate of appro/imatel) 1 foot per 1000

feet of elevation.

%ince suction lift is actuall) that height to which

atmospheric pressure will force water into a vacuum,

theoreticall) we can use the ma/imum amount of this

pressure 12.B l"s. per s5. in. at sea level which will raise

water **.@ ft. >rom this, we o"tain the conversion factor

of 1 l". per s5. in. of pressure e5uals 2.*1 ft. head.

The resistance of the suction pipe walls to the flow of

water uses up part of the wor' which can "e done ")

atmospheric pressure. Therefore, the amount of loss due

to friction in the suction pipe must "e added to the

vertical elevation which must "e overcome and the total

of the two must not e/ceed 2 feet sea level. This 2

feet must "e reduced 1 foot for ever) 1,000 feet eleva-

tion a"ove sea level which corrects for a lessened

atmospheric pressure with increased elevation.

!hen the water level is more than 2 feet "elow the

pump "ecause this is the ma/imum practical suction

lift which can "e o"tained with a shallow well pump at

sea level.

10. !hat do we mean ") water s)stem7

11. !hat is the purpose of a foot valve7

12. Iame the two "asic parts of a Cet Assem"l).

1*. !hat is the function of the no44le7

12. !hat is the purpose of the venturi7

1. !hat do we mean ") 8drive water97

1A. !hat is the source of the 8drive water97

1B. !hat is the purpose of the centrifugal pump7

1L. !here is the Cet Assem"l) usuall) located in a

%hallow !ell Cet %)stem7

1@. !hat is the principal factor which determines if a

shallow well ,et s)stem can "e used7

20. !hen is a deep well ,et s)stem used7

21. $an a foot valve "e omitted from a #eep !ell Cet

%)stem7 !h)7

22. !hat is the function of a chec' valve in the top of

a su"mersi"le pump7

2*. A su"mersi"le pump is made up of two "asic parts.

!hat are the)7

22. !h) did the name su"mersi"le pump come into

"eing7

A pump with all necessar) accessories, fittings, etc.,

necessar) for its completel) automatic operation.

(t is used on the end of a suction pipe to prevent the

water in the s)stem from running "ac' into the source

of suppl) when the pump isnEt operating.

Io44le and Denturi.

The no44le converts the pressure of the drive water into

velocit). The velocit) thus created causes a vacuum in

the Cet Assem"l) or suction cham"er.

The venturi converts the velocit) from the no44le "ac'

into pressure.

That water which is supplied under pressure to drive the

,et.

The drive water is continuousl) recirculated in a closed

s)stem.

The centrifugal pump provides the energ) to circulate

the drive water. (t also "oosts the pressure of the

discharged capacit).

:olted to the casing of the centrifugal pump.

A ma/imum suction lift of 2? at sea level.

!hen the total suction lift e/ceeds 2 ?.

Io, "ecause there are no valves in the Cet Assem"l) and

the foot valve is necessar) to hold water in the s)stem

when it is primed. Also, when the centrifugal pump isnEt

running, the foot valve prevents the water from running

"ac' into the well.

To hold the pressure in the line when the pump

isnEt running.

Pump end and motor.

:ecause the whole unit, pump and motor, is designed to

"e operated under water.

2. A su"mersi"le pump can "e installed in a 23 well7

2A. A stage in a su"mersi"le pump is made up of

three parts. !hat are the)7

2B. A su"mersi"le pump has onl) one pipe connection7

2L. !hat are two reasons we should alwa)s consider

using a su"mersi"le first7

2@. The amount of pressure a pump is capa"le of

ma'ing is controlled ") what7

*0. The width of an impeller and guide vane control

what7

Io, the) re5uired a 23 well or larger for most domestic

use. &arger pumps with larger capacities re5uire A3

wells or larger.

(mpeller, diffuser and "owl.

True, for the discharge pipe.

(t will pump more water at higher pressure with less

horsepower. Easier installation.

The diameter of the impeller.

The amount of water or capacit) the pump is capa"le of

pumping.

Pro-lems

3riction of Water P& A$H 2;; 3T of #ew Steel Pipe

)P" )PH

/

?@A Pipe

2

?(A Pipe

/

?'A Pipe 2A Pipe 2

2

?'A Pipe 2

2

?(A Pipe (A Pipe (

2

?(A Pipe /A Pipe 'A Pipe

3t7 L-s7 3t7 L-s7 3t7 L-s7 3t7 L-s7 3t7 L-s7 3t7 L-s7 3t7 L-s7 3t7 L-s7 3t7 L-s7 3t7 L-s7

1 A0 2.*0 1.LA 1.LA .L1 0.2A 0.11

2 120 1.00 A.2@ 2.BL 2.0B 1.21 0.2 0.*L 0.1A

* 1L0 *1.L0 1*.BB 10.00 2.** 2.0 1.0L 0.BB 0.**

2 220 2.@0 2*.BB 1B.10 B.20 2.21 1.L2 1.*0 0.A 0.*2 0.1

*00 L*.0 *A.2 2.L0 11.1B A.*2 2.B2 1.@* 0.L2 0.1 0.22 0.22 0.10

A *A0 *A.0 1.L0 L.LB *.L2 2.AL 1.1A 0.B0 0.*0 0.** 0.12 0.10 0.02

B 220 2L.B0 21.0L 11.L0 .11 *.A 1.2 0.@* 0.20 0.22 0.1@ 0.1* 0.0A

L 2L0 A2.B0 2B.12 1.00 A.2@ 2.2 1.@B 1.1L 0.1 0.A 0.22 0.1B 0.0B

@ 20 1L.L0 L.12 .A 2.2 1.2A 0.A* 0.A@ 0.*0 0.21 0.0@

10 A00 2*.00 @.@A A.LA 2.@B 1.BB 0.BB 0.L* 0.*A 0.2 0.11 0.11 0.0 0.02 0.02

12 B20 *2.A0 12.11 @.A2 2.1A 2.2L 1.0B 1.1A 0.0 0.*2 0.1 0.1 0.0A 0.0 0.02

1 @00 2@.B0 21.2 12.B0 A.*A *.B2 1.A2 1.B 0.BA 0.2 0.2* 0.22 0.10 0.0L 0.0*

20 1200 LA.10 *B.2B 2.10 10.LB A.*2 2.B2 2.@2 1.2B 0.LB 0.*L 0.*A 0.1A 0.1* 0.0A

2 100 *L.A0 1A.B1 @.A 2.1L 2.2L 1.@2 1.*0 0.A 0.2 0.2* 0.1@ 0.0L

*0 1L00 2.A0 2*.A2 1*.A0 .L@ A.2A 2.B1 1.L2 0.B@ 0.B 0.*2 0.2A 0.11

* 2100 B*.20 *1.BB 1L.20 B.LL L.*B *.A2 2.22 1.0 1.00 0.2* 0.* 0.1

20 2200 @.00 21.1* 2*.0 10.1B 10.B@ 2.AB *.10 1.*2 1.2L 0. 0.22 0.1@

2 2B00 *0.B0 1*.2@ 1*.2 .L2 *.L 1.AB 1.A0 0.A@ 0. 0.22

0 *000 *A.00 1.L 1A.20 B.10 2.AB 2.02 1.@2 0.L2 0.AA 0.2@ .1L .0L

B0 2200 AL.L0 2@.BL *1.*0 1*. L.LA *.L2 *.A* 1.B 1.22 0.* .* .1

100 A000 A2.20 2A.@* 1B.20 B.* B.11 *.0L 2.*@ 1.0* .A* .2B

10 @000 *L.00 1A.2 1.20 A.AB .12 2.2* 1.*2 .B

200 12000 AA.*0 2L.B0 2A.B0 11.A L.@0 *.L 2.2B .@L

20 1000 @0.B0 *@.2A 22.L0 1L.* 12.10 A.10 *.A0 1.A

*00 1L000 L.0 2.*2 1@.20 L.*1 2.L@ 2.12

*0 21000 B@.20 *2.2@ 2A.@0 11.A A.B2 2.@1

>rom the ta"le, give the friction loss in ft. for the following

conditions1

*

H23 1

1

H23 23

100 >eet of Pipe

0 >eet of Pipe

10 >eet of Pipe

L0 >eet of Pipe

1. *A0 GP6 ................................. a " c

2. A00 GP6 ................................. a " c

*

H23 1

1

H23 23

*. 220 GP6 ................................. a " c

2. A00 GP6 ................................. a " c

1

H23 13 1

1

H23

. 220 GP6 ................................. a " c

A. 2L0 GP6 ................................. a " c

*

H23 13 1

1

H23

B. *A0 GP6 ................................. a " c

L. A00 GP6 ................................. a " c

Pro-lems (continued)

27 (7

Total E5uivalent &ength of %uction

Pipe from Pump #own into !ell.

*0 ft.

*

H23 Pipe

Total E5uivalent &ength of %uction

Pipe from Pump #own into !ell.

120 ft. Pipe

%tanding level of water

Pumping level of water

1 ft. Dertical &ift

%tanding level of water

Pumping level of water

1L ft. Dertical &ift

Pump $apacit) A GP;

a. !hat is friction loss7

". !hat is total lift7

Pump $apacit) 10 GP;

a. !hat si4e suction pipe is re5uired to 'eep total

lift within 2 feet7

". !hat is friction loss7

c. !hat is total lift7

/7

Pump $apacit) A

GP; Elevation1 2* ft.

>riction &oss1 2 l"s.

.perating Pressure1 20-20 l"s.

a. !hat is the %ervice Pressure7

>riction

%ervice Pressure

Elevation

!ell 6ouse

Pump and Tan'

Pro-lems (continued)

'7 D7

%ervice

Pressure

%ervice

Pressure

>riction Elevation

>riction

Elevation

!ell

6ouse

Pump and Tan'

Pump $apacit) A GP;

!ell

6ouse

Pump and Tan'

Pump $apacit) 10 GP;

Elevation1 2* ft.

.perating Pressure1 20-20 l"s.

200 ft. of

*

H23 #ischarge Pipe

a. 6ow much is friction loss7

". !hat is the %ervice Pressure7

c. !hat change would )ou ma'e in this s)stem

and what would the result "e7

Elevation1 L0 ft.

%ervice Pressure Me5uired1 20-20 l"s.

&ength of #ischarge Pipe1 *00 ft.

a. !hat si4e pipe to use7

". 6ow much is friction loss7

c. !hat will the operating pressure of the pump

"e7

d. 6ow man) continuous use outlets operating at

the same time will this capacit) suppl)7

Pump $apacit) is L GP;.

%ervice Pressure Me5uired at Tan' in

:asement is *0 l"s.

a. !hat is the total length of pipe to "e considered

for friction loss7 >t.

". !hat is the friction loss in feet7 >t.

c. !hat is the total feet the pump will have to

overcome to get water to the tan'7 >t.

PME%%+ME

%!(T$6

0? E&EDAT(.I

120?

20?

P+;P(IG &EDE&

P+;P %ETT(IG

2001 Goulds Pumps

PM(ITE# (I +.%.A. SP$I3I$ATIO#S A& S<0J$T TO $HA#) WITHO<T #OTI$7

Pro-lems (continued)

>orm L2B2A-!% :P+;P

You might also like

- Bpump PDFDocument20 pagesBpump PDFgpskumar22No ratings yet

- Horse Power (H.P.) Selection: Calculation of Discharge Rate of Bore Well, Water Level, Friction Loss in Pipes, Valves & Fittings, H.P. Selection For Submersible Pump Sets, Unit ConversionDocument12 pagesHorse Power (H.P.) Selection: Calculation of Discharge Rate of Bore Well, Water Level, Friction Loss in Pipes, Valves & Fittings, H.P. Selection For Submersible Pump Sets, Unit ConversionSantosh Kumar93% (14)

- Ram Pump PDFDocument9 pagesRam Pump PDFoliververonamanuelNo ratings yet

- Pump Station Design For Storm Water Retention Ponds PDFDocument3 pagesPump Station Design For Storm Water Retention Ponds PDFAnonymous CX51waI100% (1)

- Sump Submersible Pumps DesignDocument4 pagesSump Submersible Pumps DesignAnonymous wIPMQ5rhNo ratings yet

- Plumbing Design MethodDocument23 pagesPlumbing Design MethodMechanicalLatestNo ratings yet

- Engineering Tips-Cooling TowerDocument6 pagesEngineering Tips-Cooling TowerSharon LambertNo ratings yet

- Livestock Watering: Using Stream Energy To Pump Livestock WaterDocument4 pagesLivestock Watering: Using Stream Energy To Pump Livestock WaterraffaNo ratings yet

- 06 Hydraulic PumpingDocument71 pages06 Hydraulic PumpingAZDOLMANNo ratings yet

- Cavitations 1-3: The Mcnally InstituteDocument5 pagesCavitations 1-3: The Mcnally InstituteBaqirMuhammadNo ratings yet

- Chapter 3 Mine PumpsDocument29 pagesChapter 3 Mine PumpsOolasyar KhattakNo ratings yet

- Well PumpsDocument18 pagesWell PumpsGodwin MasulaNo ratings yet

- 100 Water PumpDocument11 pages100 Water Pumpyudhi' gaulNo ratings yet

- Ducting and Piping Network Hydronic System TypesDocument36 pagesDucting and Piping Network Hydronic System TypesSharon LambertNo ratings yet

- Annexure-I (Sprinkler System)Document5 pagesAnnexure-I (Sprinkler System)ashilvantNo ratings yet

- Bilge Pump InstallationDocument5 pagesBilge Pump InstallationJim MarshNo ratings yet

- Guide To Submersible Well Pump Selection: 1. Well Capacity 6. 2-WIRE VS. 3-WIREDocument1 pageGuide To Submersible Well Pump Selection: 1. Well Capacity 6. 2-WIRE VS. 3-WIREBassel El Sayed AliNo ratings yet

- Hydraulic Ram PumpsDocument4 pagesHydraulic Ram PumpsSersio BordiosNo ratings yet

- Pipin StudyDocument81 pagesPipin StudyRaju NaiduNo ratings yet

- Chapter Three Liquid Piping SystemDocument51 pagesChapter Three Liquid Piping SystemMelaku TamiratNo ratings yet

- Guidelines For Submersible Pump Set For Bore Well, Tube Well & Dug Well (Open Well)Document16 pagesGuidelines For Submersible Pump Set For Bore Well, Tube Well & Dug Well (Open Well)Santosh Kumar88% (8)

- Manual of Information: RIFE Hydraulic RamDocument19 pagesManual of Information: RIFE Hydraulic RamSean100% (1)

- Chapter Five Jet Pumping System (JP)Document33 pagesChapter Five Jet Pumping System (JP)mghareebNo ratings yet

- Pump Filter SizingDocument3 pagesPump Filter SizingkavjoNo ratings yet

- 2011-03 Selection of Pumps PDFDocument47 pages2011-03 Selection of Pumps PDFKwabena OtchereNo ratings yet

- Septic Tank Size TableDocument5 pagesSeptic Tank Size TablenghiasipraNo ratings yet

- 4 PumpsDocument26 pages4 PumpsdhasdjNo ratings yet

- Guide To Fire Protection in Malaysia (2006) - 7. Hose Reel System PDFDocument6 pagesGuide To Fire Protection in Malaysia (2006) - 7. Hose Reel System PDFMFaiz RHamiraNo ratings yet

- Hydraulic Ram Pump ReportDocument7 pagesHydraulic Ram Pump ReportPali ParleyNo ratings yet

- Engineering Technical Bulletins: Selecting Valves and Piping CoilsDocument4 pagesEngineering Technical Bulletins: Selecting Valves and Piping Coilsforevertay2000No ratings yet

- The Hydraulic Ram PumpDocument49 pagesThe Hydraulic Ram PumpSiraye AbirhamNo ratings yet

- Sizing A Well Pump: Wellcare®Document3 pagesSizing A Well Pump: Wellcare®toots guiaoNo ratings yet

- Como Instalar Una Bomba SumergibleDocument23 pagesComo Instalar Una Bomba Sumergibleoscar_m_avilaNo ratings yet

- CCI Power ApplicationsDocument57 pagesCCI Power Applicationssukanya_ravichandran100% (1)

- Coil Pump Performance Under Variable Operating ConditionsDocument18 pagesCoil Pump Performance Under Variable Operating ConditionsIime Pertuz MontoyiitaNo ratings yet

- Hosereel SystemDocument5 pagesHosereel Systemrmaffireschool100% (3)

- Sucker Rod Pumps Bombeo MecanicoDocument10 pagesSucker Rod Pumps Bombeo MecanicoGabriel José Gonzalez Granela100% (1)

- I150 I350 Installation Operation Manual enDocument9 pagesI150 I350 Installation Operation Manual enIvan ZuritaNo ratings yet

- Centrifugal Pump InstallationDocument4 pagesCentrifugal Pump Installationjfisher2534No ratings yet

- Treadle NoteDocument8 pagesTreadle NoteredaeNo ratings yet

- Plumbing Lecture 11Document39 pagesPlumbing Lecture 11ahmedemadd19No ratings yet

- Catalog HydroDocument4 pagesCatalog HydroZy RoldaNo ratings yet

- Instalaciones Fuentes y PiscinasDocument8 pagesInstalaciones Fuentes y PiscinasmetalsystemtorresNo ratings yet

- Stinger or Tailpipe Placement of Cement Plugs: Table 1-Well ParametersDocument3 pagesStinger or Tailpipe Placement of Cement Plugs: Table 1-Well ParametersDouadi AbderraoufNo ratings yet

- Sump Pump SizingDocument4 pagesSump Pump Sizingyavorn3348100% (1)

- Centrifugal Pumps TipsDocument34 pagesCentrifugal Pumps TipsFaizan AbbasiNo ratings yet

- Applications For Water PumpingDocument18 pagesApplications For Water PumpingjeniNo ratings yet

- Plumbing Short Handbook 1614599668Document79 pagesPlumbing Short Handbook 1614599668Mohamed BahkirNo ratings yet

- Ram Pump Final Report SP2013Document18 pagesRam Pump Final Report SP2013thomas.edwardsNo ratings yet

- Free Energy Ram Pump or Hydram TechnologyDocument21 pagesFree Energy Ram Pump or Hydram TechnologyLakshita SharmaNo ratings yet

- KSB Pumps As TurbinesDocument8 pagesKSB Pumps As TurbinesjohndaglishNo ratings yet

- Oil and Gas Artificial Fluid Lifting TechniquesFrom EverandOil and Gas Artificial Fluid Lifting TechniquesRating: 5 out of 5 stars5/5 (1)

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesFrom EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesRating: 5 out of 5 stars5/5 (1)

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshFrom EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshNo ratings yet

- Groundwater Technology Handbook: A Field Guide to Extraction and Usage of GroundwaterFrom EverandGroundwater Technology Handbook: A Field Guide to Extraction and Usage of GroundwaterRating: 5 out of 5 stars5/5 (1)

- Reboot Android Kodi Addon DownloadDocument2 pagesReboot Android Kodi Addon DownloadperoooNo ratings yet

- Bonney Forge Branch ConnectionsDocument45 pagesBonney Forge Branch ConnectionsperoooNo ratings yet

- B16 Inch mm.5Document29 pagesB16 Inch mm.5peroooNo ratings yet

- AutoCAD PLANT 3D 2015 System Tools Variables CadgroupDocument24 pagesAutoCAD PLANT 3D 2015 System Tools Variables CadgroupperoooNo ratings yet

- Design Manual - IsoplusDocument1 pageDesign Manual - IsoplusperoooNo ratings yet

- Nozzles - Process Design, From The OutsideDocument12 pagesNozzles - Process Design, From The OutsideperoooNo ratings yet

- XOMOXLinedPlugValvesEMEA TechnicalDataDocument20 pagesXOMOXLinedPlugValvesEMEA TechnicalDataperoooNo ratings yet

- Pages From 13R1 15R1 16R1 23 Do 27Document1 pagePages From 13R1 15R1 16R1 23 Do 27peroooNo ratings yet

- Katalog VeflonDocument82 pagesKatalog VeflonperoooNo ratings yet

- Technische Dokumentation Technical Documentation: Fully Lined Flanged Filters & Strainers (DIN Version), Type Y101, PN 16Document5 pagesTechnische Dokumentation Technical Documentation: Fully Lined Flanged Filters & Strainers (DIN Version), Type Y101, PN 16peroooNo ratings yet

- Asimina Triloba PDFDocument0 pagesAsimina Triloba PDFperoooNo ratings yet

- DSTV eDocument55 pagesDSTV eperoooNo ratings yet

- Bullet To The Head 2013Document56 pagesBullet To The Head 2013peroooNo ratings yet

- Electric Power Applications, Engine & Generator SizingDocument120 pagesElectric Power Applications, Engine & Generator SizingDIPPOSNo ratings yet

- Temporal BroadeningDocument10 pagesTemporal BroadeningMohamed BouhaddaNo ratings yet

- WDM Bi553Document138 pagesWDM Bi553florea_madfoxNo ratings yet

- 1 - Classful Ip AddressingDocument6 pages1 - Classful Ip AddressingBiruk Tesfaye Legesse100% (1)

- Some Observations On The Diophantine Equation Y2xa and Related ResultsDocument12 pagesSome Observations On The Diophantine Equation Y2xa and Related ResultsJose Roberto DuarteNo ratings yet

- Math 9 Textbook AnswersDocument43 pagesMath 9 Textbook AnswersMehak GillNo ratings yet

- 50 Input Output Practice Questions 1606810110009 OBDocument17 pages50 Input Output Practice Questions 1606810110009 OBJavid QuadirNo ratings yet

- B28 VivaDocument27 pagesB28 VivashubhamNo ratings yet

- Caliper Xy MemoryDocument6 pagesCaliper Xy MemoryA MuNo ratings yet

- Haaland EquationDocument1 pageHaaland EquationAmir AzmiNo ratings yet

- Diagnosis and Testing: Four Wheel Drive (4WD) Systems - Electronic ShiftDocument38 pagesDiagnosis and Testing: Four Wheel Drive (4WD) Systems - Electronic ShiftLojan Coronel José Humberto100% (1)

- The Effect of Axial Flow Velocity On Annular Gap Windage Power LossDocument12 pagesThe Effect of Axial Flow Velocity On Annular Gap Windage Power Losskien nguyenNo ratings yet

- Hemoglobin A1c: A) MES 2-Morpholinoethane Sulfonic Acid B) TRIS Tris (Hydroxymethyl) - AminomethaneDocument6 pagesHemoglobin A1c: A) MES 2-Morpholinoethane Sulfonic Acid B) TRIS Tris (Hydroxymethyl) - Aminomethanejoudi.jou95No ratings yet

- Introduction To Chaos: The Damped, Driven, Nonlinear PendulumDocument14 pagesIntroduction To Chaos: The Damped, Driven, Nonlinear PendulumKikkuNo ratings yet

- Midterm BUS510Document8 pagesMidterm BUS510Ramesh KomarapuriNo ratings yet

- Computer Networks: Introduction (Chapter 1)Document92 pagesComputer Networks: Introduction (Chapter 1)Speed PianoNo ratings yet

- Carbanions Carbocations and CarboradicalsDocument21 pagesCarbanions Carbocations and CarboradicalsAnaAmaruNo ratings yet

- 2015-NBLUCK LK260 Engine Part ListDocument16 pages2015-NBLUCK LK260 Engine Part ListPedroNo ratings yet

- 4.uses of Metals - 1-32 For StudentsDocument13 pages4.uses of Metals - 1-32 For StudentsnergisalihpasaogluNo ratings yet

- Metron 05 CR DataDocument10 pagesMetron 05 CR DatamkgohNo ratings yet

- Inorganic Chemistry - Lab Report 5Document7 pagesInorganic Chemistry - Lab Report 5AlpNo ratings yet

- 1 Egg & Egg Cookery LectureDocument15 pages1 Egg & Egg Cookery LectureErin DelavinNo ratings yet

- Spice-Simulation Using LTspice Part 1Document76 pagesSpice-Simulation Using LTspice Part 1suzsoltNo ratings yet

- Hope Therapy PDFDocument18 pagesHope Therapy PDFalexNo ratings yet

- WJMDocument6 pagesWJMAldianivo Nur FaizNo ratings yet

- (John F. Moulder) PHI Handbook of XRay Photoelectron SpectrosDocument192 pages(John F. Moulder) PHI Handbook of XRay Photoelectron SpectrosCamilo CorredorNo ratings yet

- Pov Nori Apr2007Document31 pagesPov Nori Apr2007DMRNo ratings yet

- Energy Audit Report by CPRIDocument247 pagesEnergy Audit Report by CPRImag_ktps20021520100% (2)

- Post Hoc Test in ANOVADocument17 pagesPost Hoc Test in ANOVAJelly Jean PayeNo ratings yet

- What Is A Stress Intensification FactorDocument7 pagesWhat Is A Stress Intensification FactorMahendra RathoreNo ratings yet