Professional Documents

Culture Documents

Leaflets - CRC - EN 50-60 HZ PDF

Uploaded by

vickers0 ratings0% found this document useful (0 votes)

27 views12 pagesClimaveneta has developed its own answer: efficient and reliable cooling units for the management of High Density racks. CRC stands for ideal integration to manage High Density severs (blade servers), better known as hot-spots. The new Dual Coil version has been developed to guarantee the 100% backup thanks to: double cooling coil and double regulation valve which are ccompletely independent.

Original Description:

Original Title

Leaflets_CRC_EN 50-60 HZ.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentClimaveneta has developed its own answer: efficient and reliable cooling units for the management of High Density racks. CRC stands for ideal integration to manage High Density severs (blade servers), better known as hot-spots. The new Dual Coil version has been developed to guarantee the 100% backup thanks to: double cooling coil and double regulation valve which are ccompletely independent.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

27 views12 pagesLeaflets - CRC - EN 50-60 HZ PDF

Uploaded by

vickersClimaveneta has developed its own answer: efficient and reliable cooling units for the management of High Density racks. CRC stands for ideal integration to manage High Density severs (blade servers), better known as hot-spots. The new Dual Coil version has been developed to guarantee the 100% backup thanks to: double cooling coil and double regulation valve which are ccompletely independent.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 12

Packaged cooling

system for High Density

racks management

New range

50/60Hz

2 l 3 CRC

Superior efficiency, high reliability,

low enegy consumption

Modern data center are

characterized by 24/7

operation all year long.

Climaveneta has

developed its own

answer: efficient and

reliable cooling units

for the management

of high density racks.

Hot Spot management

Scalability and Modularity

Free cooling

Redundancy and Reliability

CRC unit stands for ideal integration to manage high density severs (blade servers), better known as

hot-spots. The advantages are:

Extra cooling where it is needed

Direct Expansion systems with Inverter technology or chilled water version available

Modulating Air flow, thanks to EC high efficiency fans. The fans adapt to the thermal load

detected by sensors positioned in the hot and cold aisles

Perfectly compatible with most of racks and ready for expansion of the cooling system

The CRC units combine the efficiency of a hydronic system for heat dissipation together with the use

of new generation EC fans, allowing EER values over 100. High Density blade servers cooling systems

with single or dual circuit allow the use of warm water with a temperature > 15C. This contributes to

improve all those free-cooling systems performances even in places which are normally considered

too hot for such efficient systems. In the CRC Dual Circuit version, while the primary circuit (circuit 1)

could be water cooled via an external dry cooler in order to maximize the free cooling benefits, the

secondary backup circuit (circuit 2) can be easily combined with a Freecooling chiller to obtain best

values in terms of REDUNDANCY & EFFICIENCY.

Modern data centers have to guarantee an efficient 24/7 operation in order to eliminate the risks of

malfunctioning and failure. The total redundancy of the system is therefore of utmost importance for

the highest realiability of the data center.

The new Dual Coil version has been developed to guarantee the 100% backup thanks to: double

cooling coil and double regulation valve which are ccompletely independent.

The reliability of the system is also increased by the use of automatic switch for dual power

supply feed for a CONTINUOUS and REDUNDANT power supply.

The CRC units have been developed to be coupled with modern racks in data centers, allowing:

More versions available, suitable for 42U and 48U racks

GREAT SCALABILITY of the cooling system, as the units easily adapt to the real thermal

load of the server

MODULARITY of the cooling system and rapid Upgrade of the Data Center capacity

4 l 5 CRC

Versions

Four versions. Four specific technologies

specially designed to ensure superior

efficiency and reliability.

CRCX Direct Expansion Version

CONFIGURATIONS

CRCX-I - Direct Expansion Rack Cooler IN-ROW

CRCX-E - Direct Expansion Rack Cooler ENCLOSURE

The CRCX unit joins the efficiency of a new Direct Expansion system with the

use of the Inverter Technology and the latest brushless DC electric motor.

Good performance and high efficiency are the result of the adoption of

advanced technologies:

The Inverter DC technology on the Scroll compressor with the new

generation brushless motor

The electronic thermostatic valve: it allows to improve the inverter

compressor performance, and the frigorific cycle optimisation

New generation EC brushless fans ultralight

Completely sensible load (SHR=1)

'HOT SWAPPABLE' EC fans from the front

Easy handling due to integrated wheels

CONFIGURATIONS

CRCC-I - Chilled Water IN-ROW

CRCC-E - Chilled Water ENCLOSURE

In the hydronic version the cooling is provided by external chillers and dry

coolers, to better use the freecooling system. Good performance and high

efficiency are the result of the adoption of advanced technologies:

New generation EC brushless fans ultralight

3 way or 2 way (optional) modulating valves

Capacity from 20 to 35 Kw

Optimal integration with Climaveneta Freecooling chillers

'HOT SWAPPABLE' EC fans from the front

Easy handling due to integrated wheels

CRCC Chilled water version

Savings up to 30%

compared to traditional systems

bigger savings

thanks to the adaptive set

point according to the real thermal load

25%

CONFIGURATIONS

CRCD-I - Direct Expansion Dual Fluid Rack IN-ROW

CRCD-E - Direct Expansion Dual Fluid Rack ENCLOSURE

The Dual Fluid Rack Cooler features two separate circuits for the highest

redundancy in cooling capacity. Thanks to a system ensuring 100% back-up, the

high reliability of the system is always guaranteed, also in emergency situations.

Inverter DC Scroll compressor featuring last-generation electronic-switching

brushless motor

Electronic expansion valve to ensure superior performance of the inverter

compressor and frigorific cycle optimisation

New generation ultralight fans, with EC brushless motor

Complete sensible load (SHR=1)

Easy handling due to integrated wheels

Hot swappable EC fans from the front

CONFIGURATIONS

CRCF-I - Direct Expansion Rack with indirect free cooling IN-ROW

CRCF-E - Direct Expansion Rack with indirect free cooling ENCLOSURE

The CRCF Rack Cooler ensures high levels of energy efficiency thanks to the combination of

the direct expansion system with the indirect free cooling mode. The CRCF unit works in free

cooling mode when the outside temperature allows to use the outdoor air as a source of

indirect cooling. The simultaneous operation of the expansion system and the water system

contributes to increase the overall efficiency.

Inverter DC Scroll compressor featuring last-generation electronic-switching brushless motor

Electronic expansion valve to ensure superior performace of the inverter compressor and

frigorific cycle optimisation

New generation ultralight fans, with EC brushless motor

Complete sensible load (SHR=1)

Easy handling due to integrated wheels

Hot swappable EC fans from the front

CRCD Dual Fluid Version

CRCF Free Cooling Version

100% backup

Reliability all year long

of the year in free

cooling mode

60%

6 l 7 CRC

Configurations

Modern data centers are characterised by specific requirements: specific room

dimensions, redundancy, easy adaptation to preexisting structures. This is why

Climaveneta has developed two CRC configurations: In-row and Enclosure.

In-Row

CRCC-I: Chilled Water

CRCX-I: Direct Expansion

CRCD-I: Dual Fluid

CRCF-I: Free Cooling

In the InRow configuration the treated air is sucted in the

back of the unit from the hot aisle of the Data Center (35C),

with great advantages in terms of energy efficiency and

increased cooling capacity. The air is then cooled and

delivered to the cold aisle (18-20C) - i.e. the front side of

the rack.

Features and Benefits

Design

Back-Up system for power and cooling

Hot swappable EC fans from the front

Scalability and modularity

Data Center extension

Energy Savings

Cooling only where it is needed

Optimised management of the system

Extreme flexibility (applicability to

42U & 48U racks)

Highly efficient Operation

Reduced space occupancy (0,39 m

2

)

Plug & Play connections for a quick and

easy installation

User-friendly Cascade System for electrical

panel maintenance

Humidification System (optional)

Ideal for hot/cold

aisles

Enclosure

CRCC-E: Chilled Water

CRCX-E: Direct Expansion

CRCD-E: Dual Fluid

CRCF-E: Free Cooling

In the Enclosure configuration both the servers and the

conditioners are coupled on the same structure, avoiding the

mixing of indoor and outdoor air and the consequent

efficiency reduction. The air is directly treated inside the rack;

sucted at 46C, cooled down to 25- 30C and then delivered

back to the servers. This increases energy saving thanks to

the low amount of treated air.

Features and Benefits

Design

Back-Up system for Power and Cooling

Hot swappable EC fans from the front

Scalability and modularity

Data Center extension

Energy Savings

Increased energy savings thanks to the

low amount of treated air

Optimised blade management

Extreme flexibility (applicability to

42U & 48U racks)

Highly efficient Operation

Reduced space occupancy (1,8 m

2

)

Plug & Play connections for a quick and

easy installation

User-friendly Cascade System for electrical

panel maintenance

Humidification System (optional)

Ideal for removing

hot spots in stand

alone systems

-

1

5

%

-

1

5

%

-

4

5

%

-

4

5

%

-

1

0

%

-

1

0

%

P

l

u

g

-

i

n

(

A

C

)

E

C

(

D

C

)

E

C

P

U

L

g

e

n

e

r

a

t

i

o

n

(

D

C

)

POLYMERIC

ULTRALIGHT FAN

8 l 9 CRC

Technological choices

Inverter Compressor *for the CRCX, CRCF and CRCD versions

EC-PUL fans for all indoor units

EC-PUL FANS Also for outdoor units

The inverter driven compressor, through the variable frequency, modulates the power capacity

provided, hence enabling to optimize the performances at part load and increasing the overall

efficiency of the system in any condition.

Compared to the traditional On/Off compressors the Inverter compressor ensures:

Quick achievement of the desired temperature thanks to the BOOSTER function

Starting current & pick removal due to compressor speed and air flow modulation

Reduced vibrations and low noise levels

Efficient working performance at partial loads

The high efficiency EC brushless fan reduces both noise levels as well as energy

consumption, and assures a variable air flow at part loads, optimizing the operating

costs of the unit.

Main features:

Further noise level reduction 4-5 dB

Further absorbed power reduction by 15%

The use of EC brushless technology even on the remote motocondenser (optional) fan

assures a further average reduction of noise levels by 10%, together with a strong

reduction of energy consumption by 45% compared to traditional condensers with AC

technology.

TEGRATED DYNAMIC

MANAGEMENT OF THE TEMPERATURE

Electronic Thermostatic Valve

Ecologic Refrigerant

Evolution Control

The Direct Expansion CRC units with DC Inverter compressor make use of

electronic expansion valve as standard.

These valves have a much wider modulation capacity. It stands out for its quality

of control and its capacity to quickly reach and maintain the operating stability of

the unit. Joined with the INVERTER compressor technology, the valve ensures a

quick fluctuation-free regulation, and therefore a highly accurate adjustment to

the swings of load and ambient conditions.

The R-410A represents the most modern and look-ahead choice in refrigerant

technology: it clearly contributes to make the ICT GREEN since it complies with

environmental friendly policies and provide enhanced cooling efficiency.

The R-410A represents the most efficient long-term solution; it contributes to increase

the energy efficiency up to 5-6% compared to the R-407c refrigerant, avoiding air

pollution.

The units are provided with a new algorithm called IDM-INTEGRAL DYNAMIC

MANAGEMENT, which allows to avoid the stratification of the air temperature inside the

rack through the use of 4 integrated and independent sensors (2 for aspiring and 2 for

leaving). On the basis of the real load in each single blade, the sensors contribute to

improve the ventilation efficiency, working where it is requested. This helps to maximize

the energy efficiency. LIDM guarantees the optimal air temperature and humidity

management via a dynamic system able to avoid local condensation thus maintaining

SHR = 1-

Performances at the following conditions: 35/27% U.R. and 35C outdoor temperature

Performances at the following conditions: 46/16% U.R. and 35C outdoor air temperature

* Available versions: 460V/3/60Hz and 380V/3/60Hz

* Available versions: 460V/3/60Hz and 380V/3/60Hz

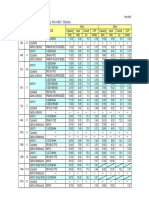

CRCX Direct Expansion Version CRCX-I + i-HCAT

Model

Power Supply

Total Cooling Capacity kW

Sensible Cooling Capacity kW

Power abs compressor kW

Power abs condensation fan

Power abs evaporator fan kW

Air flow m

3

/h

EER

No. circuits

Dimensions

Indoor unit HxPxL mm

Outdoor unit HxPxL mm

d

CRCX Direct Expansion Version CRCX-E + i-HCAT

Model

Power Supply

Total Cooling Capacity kW

Sensible Cooling Capacity kW

Power abs compressor kW

Power abs condensation fan

Power abs evaporator fan kW

Air flow m

3

/h

EER

No. circuits

Dimensions

Indoor unit HxPxL mm

Outdoor unit HxPxL mm

Performances at the following conditions: 35/27% U.R. and 10/15C water temperature

i temperatura aria esterna Performance alle seguenti condizioni: 46C/16% U.R. e 35 C d

CRCC Chilled Water Version CRCC-I

Model

Power Supply

Total Cooling Capacity kW

Sensible Cooling Capacity kW

Water pressure drops kPa

Water flow m

3

/h

Power abs evaporator fan kW

Air flow m

3

/h

No. circuits

Dimensions

Indoor unit HxPxL mm

Performances at the following conditions: 46/16% U.R. and 14/20C water temperature

CRCC Chilled Water Version CRCC-E

Model

Power Supply

Total Cooling Capacity kW

Sensible Cooling Capacity kW

Water pressure drops kPa

Water flow m

3

/h

Power abs evaporator fan kW

Air flow m

3

/h

No. circuits

Dimensions

Indoor unit HxPxL mm

0051 0071 0121

230V-1N-50/60Hz 400V/3N/50Hz* 400V/3N/50Hz*

max min. max min. max min.

10,63 4,72 16,59 6,78 28,62 11,76

9,61 4,72 15,67 6,78 27,37 11,76

2,63 0,77 4,56 1,17 7,19 1,81

0,31 0,31 0,45 0,45 0,90 0,90

0,16 0,04 0,304 0,064 0,860 0,090

1500 900 2700 1200 4200 1800

3,43 4,21 3,1 4,0 3,2 4,2

1 1 1

2100x1000x300 2100x1000x300 2100x1000x300

1240x420x900 1200x550x1450 1700x550x1450

0051 0071 0121

230V-1N-50/60Hz 400V/3N/50Hz* 400V/3N/50Hz*

max min. max min. max min.

11,84 5,64 18,71 8,19 33,02 14,09

11,84 5,64 18,71 8,19 33,02 14,09

2,68 0,73 4,65 1,15 7,40 1,81

0,31 0,31 0,45 0,45 0,90 0,90

0,160 0,04 0,304 0,064 0,860 0,090

1500 900 2700 1200 4200 1800

3,8 5,2 3,5 4,9 3,9 5,0

1 1 1

0020 0025 0035 0036

230V-1N-50/60Hz 230V-1N-50/60Hz 230V-1N-50/60Hz 230V-1N-50/60Hz

16,14 20,52 24,60 20,95

16,14 20,52 24,60 20,95

30,00 35,00 40,00 70,00

2,77 3,53 4,23 3,60

0,516 0,688 0,860 0,860

2520 3360 4200 4200

1 1 1 2

2100x1000x300 2100x1000x300 2100x1000x300 2100x1000x300

0020 0025 0035 0036

230V/1N/50Hz* 230V/1N/50Hz* 230V/1N/50Hz* 230V/1N/50Hz*

20,44 26,06 31,25 26,79

20,44 26,06 31,25 26,79

30,00 40,00 45,00 80,00

2.93 3,74 4,49 3,85

0,516 0,688 0,860 0,860

2520 3360 4200 4200

1 1 1 2

2100x1200x300 2100x1200x300 2100x1200x300 2100x1200x300

10 l 11 CRC

Technical data

CRCD-I + i-HCAT air cooled

(1) Performances at the following conditions: 35C/27% U.R., 35C outdoor air temperature

(2) Performances at the following conditions: 46C/16% U.R., 35C outdoor air temperature

(3) Performances at the following conditions: 35C/27% U.R., 10/15C water temperature

(4) Performances at the following conditions: 46C/16% U.R., 14/20C water temperature

* Available versions: 460V/3/60Hz and 380V/3/60Hz

(1) Performances at the following conditions: 35C/27% U.R., 30/35C condensing water temperature

(2) Performances at the following conditions: 46C/16% U.R., 30/35C condensing water temperature

(3) Performances at the following conditions: 35C/27% U.R., input water FC 10C

(4) Performances at the following conditions :46C/16% U.R., input water FC 14C

* Available versions: 460V/3/60Hz and 380V/3/60Hz

CRCD-E + i-HCAT air cooled

Model

Power suply

Performance (DX)

Total Cooling Capacity kW

Sensible Cooling Capacity kW

Compressor power abs Kw

Condensing units fan power abs kW

EER

Performance (CW)

Total Cooling Capacity kW

Sensible Cooling Capacity kW

Water flow l/h

CRCD pressure drop kPa

Fans

Air flow m

3

/h

Indoor units fan power abs kW

Dimensions

Indoor unit HxPxL mm

Outdoor unit HxPxL mm

CRCD Dual Fluid Version

CRCF Free Cooling Version CRCF-I + i-HCFT water cooled CRCF-E + i-HCFT water cooled

Model

Power suply

Performance (DX)

Total Cooling Capacity kW

Sensible Cooling Capacity kW

Compressor power abs compressor Kw

Condensing units fan power abs kW

EER

Performance (FC)

Total Cooling Capacity kW

Sensible Cooling Capacity kW

Water flow l/h

CRCF pressure drop kPa

Pump power abs kW

i-HCFT available pressure kPa

Fans

Air flow m

3

/h

Indoor units fan power abs kW

Dimensions

Indoor unit HxPxL mm

Outdoor unit HxPxL mm

0051 0071

230V-1N-50/60Hz 400V/3N/50Hz*

max (1) min (1) max (1) min (1)

10,95 4,55 13,99 6,93

10,24 4,55 13,99 6,93

2,64 0,77 3,58 1,17

0,31 0,31 0,6 0,6

3,35 4,06 2,87 3,76

Performance (3) Performance (3)

9,53 17,7

9,53 17,7

1640 3040

14,9 45,7

max min max min

1500 700 3360 1500

0,32 0,04 0,69 0,072

2100x1000x300 2100x1000x300

1240x420x900 1200x550x1450

0051 0071

230V-1N-50/60Hz 400V/3N/50Hz*

max (2) min (2) max (2) min (2)

12,7 5,4 16,71 8,41

12,7 5,4 16,71 8,41

2,71 0,74 3,65 1,15

0,31 0,31 0,6 0,6

3,80 4,95 3,38 4,62

Performance (4) Performance (4)

12,10 22,6

12,10 22,6

1740 3240

16,3 50,1

max min max min

1500 700 3360 1500

0,32 0,04 0,69 0,072

2100x1200x300 2100x1200x300

1240x420x900 1200x550x1450

0051 0071

230V-1N-50/60Hz 400V/3N/50Hz*

max (1) min (1) max (1) min (1)

11,29 4,66 14,67 7,16

10,38 4,66 14,67 7,16

2,41 0,69 3,08 1,06

0,6 0,6 1,2 1,2

3,02 2,68 2,73 2,61

Performance (3) Performance (3)

9,89 17,7

9,89 17,7

2370 3070

28,7 46,6

0,41 0,41

86 92

max min max min

1500 700 3360 1500

0,32 0,04 0,69 0,072

2100x1000x300 2100x1000x300

1200x550x1450 1700x550x1450

0051 0071

230V-1N-50/60Hz 400V/3N/50Hz*

max (2) min (2) max (2) min (2)

12,93 5,51 17,52 8,7

12,93 5,51 17,52 8,7

2,5 0,64 3,11 1,03

0,6 0,6 1,2 1,2

3,38 3,26 3,24 3,21

Performance (4) Performance (4)

12,48 22,8

12,48 22,8

2670 3570

35,9 59,6

0,41 0,41

77 81

max min max min

1500 700 3360 1500

0,32 0,04 0,69 0,072

2100x1200x300 2100x1200x300

1200x550x1450 1700x550x1450

C

R

C

_

0

4

-

2

0

1

2

_

E

N

G

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Thermal Applications CategoryDocument19 pagesThermal Applications CategoryvickersNo ratings yet

- Danfoss Banana Ripening Application BrochureDocument6 pagesDanfoss Banana Ripening Application BrochurevickersNo ratings yet

- Danfoss Facts Worth Knowing About ACDrivesDocument208 pagesDanfoss Facts Worth Knowing About ACDrivesvickersNo ratings yet

- Building Sustainability AnalysisDocument25 pagesBuilding Sustainability AnalysisvickersNo ratings yet

- Sanyo ScrollDocument24 pagesSanyo Scrollworker359567No ratings yet

- McQuay MCW-C-H Technical Manual EngDocument20 pagesMcQuay MCW-C-H Technical Manual EngCarlos Can PootNo ratings yet

- ASHRAE Testing-Adjusting-Balancing-HVAC-Systems PDFDocument74 pagesASHRAE Testing-Adjusting-Balancing-HVAC-Systems PDFvickers100% (1)

- 6 Adjustable Tripping Settings of A Circuit Breaker You MUST UnderstandDocument10 pages6 Adjustable Tripping Settings of A Circuit Breaker You MUST UnderstandvickersNo ratings yet

- Direct Expansion (DX) and Secondary Loop (SN) SystemsDocument2 pagesDirect Expansion (DX) and Secondary Loop (SN) SystemsvickersNo ratings yet

- Temperature To Resistance Chart NTC Thermistor: Temp C Temp F Resistance OhmsDocument1 pageTemperature To Resistance Chart NTC Thermistor: Temp C Temp F Resistance OhmsvickersNo ratings yet

- Cypetherm SuiteDocument72 pagesCypetherm SuitevickersNo ratings yet

- Cooling Load Temperature Difference Calculation MethodDocument3 pagesCooling Load Temperature Difference Calculation Methodvickers50% (2)

- Replacement Guideline For (ZR90K3, ZR11M3, ZR12M3, ZR16M3 and ZR19M3)Document10 pagesReplacement Guideline For (ZR90K3, ZR11M3, ZR12M3, ZR16M3 and ZR19M3)vickersNo ratings yet

- Comparative Table of ScrollsDocument11 pagesComparative Table of ScrollsvickersNo ratings yet

- Multi V Water PDB (08.04.10 - ) Final PDFDocument123 pagesMulti V Water PDB (08.04.10 - ) Final PDFMaxiaires RefrigeracionNo ratings yet

- Chiller CGA MInstallation, Operation, Air-Cooled Scroll Chillers 20-130 TonDocument152 pagesChiller CGA MInstallation, Operation, Air-Cooled Scroll Chillers 20-130 TonvickersNo ratings yet

- ThermostatCatalog 570-280Document12 pagesThermostatCatalog 570-280vickers0% (1)

- Chiller Types and ApplicationsDocument73 pagesChiller Types and Applicationsvickers100% (3)

- HVACR Service Trobleshooting With The Professor John TomczykDocument48 pagesHVACR Service Trobleshooting With The Professor John TomczykvickersNo ratings yet

- INT69 KRIWAN Diagnosis SystemDocument6 pagesINT69 KRIWAN Diagnosis Systemvickers100% (1)

- Bul-30RB Brine OptionDocument1 pageBul-30RB Brine OptionvickersNo ratings yet

- Fast, Easy Furnace TuningDocument2 pagesFast, Easy Furnace TuningvickersNo ratings yet

- R-22 en ChillersDocument4 pagesR-22 en ChillersvickersNo ratings yet

- Fasco Full Catalog PDFDocument184 pagesFasco Full Catalog PDFvickersNo ratings yet

- Supco TimersDocument7 pagesSupco Timersvickers100% (1)

- 30RB Opt28B Low Ambient OperationDocument1 page30RB Opt28B Low Ambient OperationvickersNo ratings yet

- Unilever Solar Assisted Ice Cream Cabinet With Danfoss Direct Current Operated Propane CompressorDocument2 pagesUnilever Solar Assisted Ice Cream Cabinet With Danfoss Direct Current Operated Propane CompressorvickersNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Panasonic SCPM25 UputstvoDocument29 pagesPanasonic SCPM25 UputstvoВладимир СтајићNo ratings yet

- Evolis letEN00Document2 pagesEvolis letEN00Arun KumarNo ratings yet

- Chennai Forge Products PVT LTD ProfileDocument33 pagesChennai Forge Products PVT LTD ProfilepmlmkpNo ratings yet

- Jade Thermal Massage Bed: Camilla Térmica JadeDocument8 pagesJade Thermal Massage Bed: Camilla Térmica JadeEugeniaLeca-BurceaNo ratings yet

- XRXS 566 CD XRVS 606 CD: Parts List For Portable CompressorsDocument162 pagesXRXS 566 CD XRVS 606 CD: Parts List For Portable CompressorsSales AydinkayaNo ratings yet

- Buck ConverterDocument31 pagesBuck Converterbalak144No ratings yet

- Get Uk 2019Document32 pagesGet Uk 2019Gabriel Paredes E.100% (1)

- Cable To Cable - XACY7Y7 (221166)Document2 pagesCable To Cable - XACY7Y7 (221166)imranNo ratings yet

- MF-10 Recommendable Lub. Oil ListDocument22 pagesMF-10 Recommendable Lub. Oil ListpcatruongNo ratings yet

- Electromagnetic Clutch System Full Seminar Report 4537Document30 pagesElectromagnetic Clutch System Full Seminar Report 4537Lalit Tanan100% (1)

- CG Power and Industrial Solutions Limited: LT Motors Division AhmednagarDocument1 pageCG Power and Industrial Solutions Limited: LT Motors Division Ahmednagaranurag dhyaniNo ratings yet

- Monitoring Systems For Data Centers - Developed by GamatronicDocument6 pagesMonitoring Systems For Data Centers - Developed by GamatronicGamatronicNo ratings yet

- Status Report Rinnen Foreuse C9 MBD08641 La Totale - PSRPT - 2021-07-20 - 14.03.53Document4 pagesStatus Report Rinnen Foreuse C9 MBD08641 La Totale - PSRPT - 2021-07-20 - 14.03.53Jean DiscretNo ratings yet

- Electricity CostDocument2 pagesElectricity Costinfinite onlineNo ratings yet

- Ph27000Pri Engine (157F) : Valve Cover AssyDocument3 pagesPh27000Pri Engine (157F) : Valve Cover AssyAriel Rodrigo MuñozNo ratings yet

- Class 11 Chapter 1 Computer SystemDocument34 pagesClass 11 Chapter 1 Computer Systemprasadnehra77No ratings yet

- Certificates FormatDocument10 pagesCertificates FormatJohn Christopher JusayanNo ratings yet

- 1 Table of Contents 3 Before Starting: HM 460 HM 660Document22 pages1 Table of Contents 3 Before Starting: HM 460 HM 660Muzaffar shahidNo ratings yet

- Gpro SettingDocument64 pagesGpro SettingHughJars0% (1)

- Report 10128783605703828058Document4 pagesReport 10128783605703828058JESUSNo ratings yet

- User Manual: SDS1000 Series Digital Storage Oscilloscope Version No.: V 1.2Document148 pagesUser Manual: SDS1000 Series Digital Storage Oscilloscope Version No.: V 1.2juampicNo ratings yet

- JBC Tools Touch PDFDocument4 pagesJBC Tools Touch PDFJanel, Inc.No ratings yet

- FVG 36-125 enDocument2 pagesFVG 36-125 enVoiculescu SeverNo ratings yet

- Rhino EngDocument2 pagesRhino EngDiego BernalNo ratings yet

- 12352201-107 en Es FRDocument121 pages12352201-107 en Es FRAnibal Jose Cruz LarezNo ratings yet

- Gunn Oscillator DesignDocument11 pagesGunn Oscillator DesignSwagato MukherjeeNo ratings yet

- Anti Sleep Alarm RDocument31 pagesAnti Sleep Alarm RPrints Bindings100% (1)

- K2042 ManualDocument20 pagesK2042 ManualAthanasios S. ArampatzisNo ratings yet

- M101Document1 pageM101Eong Huat Corporation Sdn BhdNo ratings yet

- Cannondale Super V and Super V Raven Owner'S ManualDocument6 pagesCannondale Super V and Super V Raven Owner'S ManualJVH1978No ratings yet