Professional Documents

Culture Documents

Directdrive PDF

Uploaded by

Hector Rivera0 ratings0% found this document useful (0 votes)

110 views16 pagesIDAM's product portfolio includes linear, rotary and two-coordinate direct drives. IDAM engineers started about 15 years ago designing motors and systems for the highly innovative and demanding productronics industry. A direct drive solution reduces the number of components, simplifies assembly and thus reduces the overall cost of the system.

Original Description:

Original Title

directdrive.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentIDAM's product portfolio includes linear, rotary and two-coordinate direct drives. IDAM engineers started about 15 years ago designing motors and systems for the highly innovative and demanding productronics industry. A direct drive solution reduces the number of components, simplifies assembly and thus reduces the overall cost of the system.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

110 views16 pagesDirectdrive PDF

Uploaded by

Hector RiveraIDAM's product portfolio includes linear, rotary and two-coordinate direct drives. IDAM engineers started about 15 years ago designing motors and systems for the highly innovative and demanding productronics industry. A direct drive solution reduces the number of components, simplifies assembly and thus reduces the overall cost of the system.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 16

Direct Drive Technology

INA - Drives & Mechatronics GmbH & Co.

oHG (IDAM), a member of the Schaeffler

Group Industrial, specializes in direct

drive solutions. Direct drive technology

is fascinating not only because of its

precision and dynamic performance but

also because of the many application

options.

IDAM, INA - Drives & Mechatronics

Your partner for direct drive technologies.

+

IDAM's product portfolio includes linear, rotary and two-coordinate direct drives

covering a wide range of dimensions and performance. In addition, IDAM can supply

all the required control technology for the system. Special attention should be given

to the IDAM precision cross tables (X-Y) and the customer specific, high performance

multi-axis (X-Y-Phi) systems.

Through the cooperation of INA, FAG and IDAM, a synergy has developed that ensures

IDAM direct drive positioning systems are optimized and incorporate the latest techni-

cal advancements. INA - Drives & Mechatronics has comprehensive experience in the

machine tools, automation, productronics, metrology and medical industries.

2

All IDAM direct drives are characterized

by five principles, which together stand

for improved quality and cost-effective-

ness.

IDAM engineers started about 15 years

ago designing motors and systems for

the highly innovative and demanding

productronics industry. Today IDAM

employees have expert knowledge in

many different industries.

Where product development demands

push technological limits, IDAM is ex-

perienced and ready to assist.

Dynamics.

Flexibility.

Safety.

Compactness.

2

3

4

5

Precision.

1

The principle of direct drive technology is

this: power needed for motion is applied

directly to the object that needs to be

moved. Mechanical interfaces such as

ball screws, belts, gear boxes and trans-

missions can be eliminated.

A direct drive solution reduces the num-

ber of components, simplifies assembly

and thus reduces the overall cost of the

system. All this while increasing the

dynamic performance and precision of

the system.

In short, productivity increases that can-

not be realized with traditional drive

systems can be realized with a direct

drive solution.

Know-how & competence.

Advantages of direct drives

Precision:

positioning accuracy in the submicron

range | optimal synchronization values |

extremely low path following error |

precise positioning without backlash |

high static and dynamic stiffness

Dynamics:

high acceleration and velocity capabili-

ties

Flexibility:

more controller options | more adaptable

to multi coordinate systems | more easily

combined with bearing support systems |

fewer components for a more simple

design | easier assembly with fewer

adjustments

Safety:

wear-free motion and consistent preci-

sion over product life | overload protec-

tion of the motor and thus the machine |

less complicated design

Compactness:

smaller design options | easier retrofit

into existing applications

1 3 4

5

2

IDAM direct drives are at the forefront of modern technology and are an optimal

solution for many applications. Let IDAM custom-made, high performance direct drive

systems enable your company to gain a competitive edge. Partner with IDAM on your

next project and receive the most advanced direct drive solutions available today.

An overview of our core competences is shown on the next few pages.

4

Linear Motors

High dynamics & power.

Thanks to our own AC synchronous and

reluctance motor designs and expertise,

IDAM is positioned to meet the growing

demand for highly dynamic and precise

motion control applications.

+

From extremely fast wire bonding machi-

nes, to highly precise measuring and

processing machines, to fast material

handling systems, IDAM has the exper-

tise and infrastructure to assist with a

wide variety of linear motor applications.

IDAM can further optimize a linear motor

system by combining it with either a

mechanical bearing or air bearing sup-

port system.

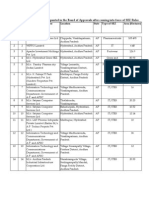

Motor type

Ironless motors

ULIM3-2P ULIM4-2P ULIM5-2P

ULIM4-3P ULIM5-3P ULIM7-3P

Slotless motors

FSM-2P series

Slotted Motors

L1-3P series

L2-3P series

L2D-3P series

Reluctance motors

LRAM series

Features

high dynamics | no cogging | F

p

up to 1,000 N | 2-phase

high dynamics | no cogging | F

p

up to 2,500 N | 3-phase

low profile | dynamic | no cogging | F

p

up to 300 N

compact | smaller sizes for lower masses | F

p

up to 1,000 N

optional cooling | low cogging forces | F

p

up to 10,000 N

balanced motor design | efficient | dynamic | F

p

up to 10,000 N

holding force: 10 N up to 400 N | resolution: 1 - 3 m

Design

5

Applications

handling systems, pick and place

applications, circuit manufacturing

machines, measuring machines,

machines for optical inspections, laser

cutting, milling and grinding machines,

packaging machines, plotter with laser

direct imaging, machine tools

Advantages

very good force mass ratio allows for

highly dynamic motors

precise positioning and uniform

motion because of no cogging and

very low active force pulsation

better performance and force density

is possible with optional cooling

system

precise control of the motor tempera-

ture

high level of reliability from the use of

modern manufacturing and testing

technologies

high quality, rare earth magnets are

used for long life even in very deman-

ding application enviroments

Single-phase linear motors (Moving Coil and Moving Magnet) work according

to electro-dynamic principles. They are designed for precise positioning and high

frequency oscillation applications with stroke lengths of a few millimeters.

Rotary (Torque) Motors

High torque, precision & dynamics.

+

6

Due to increased demands on the rota-

tional axis, direct drive rotary motors are

now more than ever replacing conventio-

nal motor and gearbox rotary systems.

Elasticity and friction is eliminated with

rotary motors because there are no

components for it to accumulate. Back-

lash is also completely eliminated. The

designers ability to create a more pre-

cise, dynamic, controllable rotary motion

system is greatly simplified with the use

of a rotary motor.

Motor type

Ironless motors

URM series

Slotless motors

RMK / RMF series

Slotted motors

RI / RE series

HSR / HSRE series

HSRV / HSRVE series

Features

customer specific | high dynamics | excellent synchronization |

no cogging | for precision machines, measuring tools

customer specific or integrated motors | no cogging | any

diameters up to 2.5 m | for peripheral speed up to 15 m/s

internal / external rotor | high torque up to 1,000 mm diameter |

M

p

up to 15,000 Nm

internal / external rotor | high speed, up to 50 m/s peripheral

speed | 50 kW

internal / external rotor | high speed, up to 50 m/s peripheral

speed | 50 kW| for spindle applications | customer specific

Design

Type: URM

Type: RMK

Type: RMF

Type: Internal rotor

Type: External rotor

7

Optimized motion

IDAM torque motors are ideal for machi-

ne tool applications where a high torque

and very accurate motion control are

required. A cooling system can also be

incorporated into the motor to further

enhance performance and maximize the

force density.

IDAM offers standard product solutions

that demonstrate outstanding perfor-

mance. These include the optimal com-

bination of the bearing and measuring

system.

Based on an application analysis, IDAM

will recommend a standard motor system

that will deliver the required torque,

velocity control and load carrying capa-

bilities.

Enhanced optimization with custom-

made drives

Since standard product solutions do

not cover the entire range of possible

applications, IDAM can also produce

customized motor systems. Based on

a detailed application analysis, IDAM

will customize a motor design to better

fit your specified requirements. This

includes the option of integrating the

motor directly into the machine structure.

This motor integration can reduce the

machine size and weight as well as

reduce the overall cost. Ask your IDAM

representative for an application analysis

form. Let us help you optimize your

design.

8

With planar motor systems, force is

produced via the reluctance principle.

Because of the strong magnetic attrac-

tion of the forcer on the stator, a planar

system can be used vertically as well as

overhanging. This despite a 10 - 15 m air

gap between the stator and forcer that

results in zero wear.

A planar system can also make more

efficient use of workspace by utilizing

more than one forcer per stator. Two or

more forcers acting independently on

the same stator can more effectively

utilize constrained production process

space.

Applications

assembly and repair of PCBs, bulb

assembly with integrated testing, laser

marking and trimming of resistors,

component sorting, mini-production

transport systems, pick and place,

connector pin mounting with integrated

testing, measuring and testing machines

Technical features

maximum stator size up to 1,000 x 1,500 mm

maximum holding force up to 330 N

speed 5 m/s - 1.0 m/s

repeatability 1 m - 3 m

settling time 20 - 200 ms

guidance accuracy up to 5 m over 300 mm

Planar Drives

High precision & flexibility.

Air bearing, planar drives are best

suited for point-to-point positioning

where the precision requirement is

in the m range.

+

Advantages

single-plane design X and Y axis are not stacked thus reduced height

air bearings support no wear | no slip stick | consistent motion over 100 million strokes

multiple forcers on one stator process optimization and space conservation

operating in all positions in space design flexibility: horizontal, vertical and overhanging

low moving mass high dynamic response

closed loop in 3 coordinates (X, Y, Phi) position controlled step motor | integrated, magnetic 3-coordinates measuring

system

integrated braking loss of power will stop air and allow magnetic attraction

design variation open frame | gantry | additional angular motion

light-weight stator design application specific stator design optimization

clean room compatible ideal for clean room applications

9

Electronic Devices

Compact, high-performance and optimized.

+

10

When new and better components enter

the market, IDAM is quick to improve

motor designs by implementing their

use. This constant product improvement

also applies to electronic controls. Direct

drive electronics must be constantly

updated to ensure compatibility with

future trends and customer demands.

From this, IDAM develops compact and

powerful high performance servo drives.

By constantly upgrading designs with

the latest electronic technology, IDAM

guarantees a high level of system accu-

racy, connection options, modern control

structures and interfaces.

Digital Servo Module for three-phase synchronous motors without hall sensors / profile generator,

digital position, velocity and current control, oversampling etc.

DSMRW253x 3 (1) x 230 V

AC

| I

N

= 12 A

rms

| I

max

= 30.5 A

Peak

for 3 s | 18 kHz PWM

DSMRW256x 3 x 400 V

AC

| I

N

= 8 A

rms

| I

max

= 20.4 A

Peak

for 3 s | 18 kHz PWM

Amplifier PWM for two-phase synchronous motors with / without hall sensors

SM2502 60 - 160 V

DC

| 8 or 12.5 (max. 25) A | 14 or 16 TE, 3 HE

SM0502 <45 V

DC

| 2.5 (max. 3.5) A | 8 TE, 3 HE

Amplifier linear for two-phase synchronous motors

AM1002 35 V

DC

| 5 (max. 10) A | 28 TE, 3 HE

Features Components

11

Interpolators for 1 V

pp

sin / cos signals

IP0550 5 - 50 fold analog | 400 kHz 1 V

pp

IP-HBK01 5 - 50 fold analog | 400 kHz 1 V

pp

IP-HBK10 25 - 250 fold analog | 100 kHz 1 V

pp

Motor filter du/dt filter for U

DCLV

= 600 V, with overvoltage protection, for top hat rail

MOFI I

rms

= 5 / 10 / 20 A

Features Components

More IDAM services

customer specific multi-axis controllers with multiple mounting options like

19" cabinet (iPSD, PDCON,...)

control of motion sequences with very high dynamics

special cables (HBK) and connection units for linear and torque motor

solutions

i n

s

i d

e

12

Through modelling and simulation, IDAM

determines the necessary options and

the type of direct drive to be used. Only

after consulting with the simulation team

does IDAM implement performance

enhancing modifications to an existing

system.

IDAM offers custom engineered linear

and rotary drive systems in combination

with INA / FAG linear guide and bearing

assemblies. By leveraging the expertise

of INA with linear bearings and FAG with

rotary bearings, IDAM has the ability to

offer the most optimal direct drive solu-

tion in the market.

System Solutions

Highly innovative custom designs.

As a direct drive motor specialist, INA -

Drives & Mechatronics is always striving

to find new and better system solutions.

Through customer collaboration and

technical expertise, IDAM is always

looking to improve products and reduce

cost. This ensures that the most cost

effective and technically advanced

system is delivered to the customer.

+

High speed linear axis

for material handling and automation

Handling system

for fineblanking press

2-axis positioning system

for the productronics industry

Linear axis

for the packaging industry

Flexible receiver

for the accurate measuring of parts

Rotary positioning unit

for the productronics and automation

13

5-axis manipulator

for a x-ray measuring machine

Fully automated multilayer

measuring and drilling system

Precision linear stage

for milling and grinding machines

Open frame transmitted light table

for the industrial productronics

Air bearing, single-axis system

for the optical industry

Air bearing, precision cross table

for high accuracy CNC laser machining

(system solutions: selected examples)

14

Technically competent engineers and

prompt service are your advantages

with IDAM. An IDAM sales engineer

will be happy to assist you with the

selection of your next direct drive

solution.

Industry: Machine Tools

Phone: +49 3681 / 7574-55

Industry: Productronics

Phone: +49 3681 / 7574-797

Industry: Automation Technology

Phone: +49 3681 / 7574-56

Industry: Metrology and Medical Technology

Phone: +49 3681 / 7574-56

Technical Information and Application Analysis

Need-to-know & qualified.

+

Linear Motors:

Series L1

Linear Motors:

Series L2

Linear Motors:

Series L2D

Linear Motors:

Series FSM

Linear Motors:

Series ULIM

Rotary Motors:

Series RE

Rotary Motors:

Series RI

Rotary Motors:

Series RM

Rotary Motors:

Series HSR / HSRV

Planar Reluctance

Motors

You are interested in more detailed technical information?

We would be happy to send you our product brochures. Contact us.

15

China

Schaeffler Co. Ltd.

Mr Thomas Bttner

CoCo Taicang Office 229 Yanshan Road,

Huahai Industrial Park Taicang Jiangsu

Province P.R. China 215400

Phone: +86 512 53590958

E-mail: buetttom@schaeffler.com

Finland

Schaeffler Finland Oy

Mr Kimmo Koops

Lautamiehentie 3 FI-02770 Espoo

Phone: +358 207 366238

E-mail: koopskmm@schaeffler.com

Italy

Schaeffler Italia S.r.l.

Mr Alessandro Massola

S.R. 229 Km 17 I-28015 Momo (Novara)

Phone: +39 0321 929267

E-mail: alessandro.massola@schaeffler.com

Israel

Frank Agencies

Mr Moshe Frank

4 Pinkas St. 62661 Tel Aviv

Phone: +972 3 5441941

E-mail: frank_ag@frank.co.il

Japan

Schaeffler Japan Co., Ltd.

Mr Junpei Suzuki

Square Building 15F 2-3-12, Shin-Yokohama,

Kohoku-ku Yokohama 222-0033

Phone: +81 45 4765913

E-mail: suzukjnp@schaeffler.com

Netherlands

Schaeffler Nederland B.V.

Mr Tim Vogel

Gildeweg 31 NL-3771 NB Barneveld

Phone: +31 342 403208

E-mail: t.vogel@schaeffler.com

Switzerland

Hydrel GmbH

Mr Ivo Bernhardsgruetter

Badstrasse 14 CH-8590 Romanshorn

Phone: +41 71 4666312

E-mail: ivo.bernhardsgruetter@hydrel.ch

Singapore

Schaeffler Singapore PTE. LTD.

Mr Michel Gnaba

151 Lorong Chuan, #06-01 New Tech Park

Singapore 556741

Phone: +65 6540 8686

E-mail: gnabamch@schaeffler.com

Spain

Schaeffler Iberia, s.l.

Mr Jos Miguel Martinez

Poligono Pont Reixat ES-08960 Sant Just

Desvern, Barcelona

Phone: +34 93 4803679

E-mail: jose.martinez@schaeffler.com

United Kingdom

Schaeffler (UK) Ltd

Mr George Partington

Forge Lane, Minworth Sutton Coldfield,

West Midlands, B76 1AP - UK

Phone: +44 121 3135839

E-mail: george.partington@schaeffler.com

USA

Schaeffler Group USA Corporation

Mr Jeff Gabriel

1585 Beach St Suite 102 San Francisco,

CA 94123

Phone: +1 704 5167517

E-mail: jeff.gabriel@schaeffler.com

IDAM worldwide.

INA - Drives & Mechatronics

GmbH & Co. oHG

Mittelbergstrasse 2

98527 Suhl I Germany

Phone +49 3681 I 7574-0

Fax +49 3681 I 7574-30

E-mail info@ina-dam.de

Web www.ina-dam.de

Status: October 2006 I Subject to modification without previous notice I Photos: IDAM GmbH & Co. oHG

You might also like

- Servomotors: Totally Drives - The Widest Range of ServomotorsDocument12 pagesServomotors: Totally Drives - The Widest Range of ServomotorsRaj ChavanNo ratings yet

- Stepper Catalog en-US RevC enDocument148 pagesStepper Catalog en-US RevC enJorge JuarezNo ratings yet

- Direct Drives: Siemens Direct Drives For Higher Dynamic Performance and PrecisionDocument8 pagesDirect Drives: Siemens Direct Drives For Higher Dynamic Performance and PrecisionCarli BraunNo ratings yet

- Laser Cutting Machine: Lc-F1 NTDocument12 pagesLaser Cutting Machine: Lc-F1 NTNatalie WyattNo ratings yet

- Stepper Motors Catalog en-US RevADocument146 pagesStepper Motors Catalog en-US RevAYazeed MomaniNo ratings yet

- Siemens Gearless DriveDocument10 pagesSiemens Gearless Drivemarn-in2501No ratings yet

- Rugged, Reliable, Versatile... ... Built To Last!: Features & Specifications Guide For Multicam 5000 Series RouterDocument11 pagesRugged, Reliable, Versatile... ... Built To Last!: Features & Specifications Guide For Multicam 5000 Series RouterMiscevic MilanNo ratings yet

- Sauer Danfoss Orbital Motors PDFDocument5 pagesSauer Danfoss Orbital Motors PDFSoledad Navarro LazoNo ratings yet

- Cat ManualDocument9 pagesCat ManualAlberto Sousa Lopes0% (1)

- Ametek PMC Capability BrochureDocument6 pagesAmetek PMC Capability BrochureElectromateNo ratings yet

- T100A en v2 0911Document8 pagesT100A en v2 0911Παναγιώτης ΤσάπαςNo ratings yet

- MultiCam 6000-Series CNC PlasmaDocument10 pagesMultiCam 6000-Series CNC PlasmaDaniel AustinNo ratings yet

- RM 1016 US-e HM Series Modular Balancing MachinesDocument26 pagesRM 1016 US-e HM Series Modular Balancing MachinesHuilber MartínezNo ratings yet

- IND Textile Finishing Toolbox BrochureDocument8 pagesIND Textile Finishing Toolbox Brochurekathirvelus9408No ratings yet

- Camco Catalog Web PDFDocument212 pagesCamco Catalog Web PDFCreuza Barbosa100% (1)

- MultiCam 3000-Series CNC PlasmaDocument9 pagesMultiCam 3000-Series CNC PlasmaDaniel AustinNo ratings yet

- LDDM Linear Direct Drive Motors. ULIM SeriesDocument24 pagesLDDM Linear Direct Drive Motors. ULIM SeriesajibNo ratings yet

- AKM Selection - Guide en US - RevB PDFDocument76 pagesAKM Selection - Guide en US - RevB PDFAgou Rango100% (1)

- Motoniveladora Cat 140M Motor C9 PDFDocument28 pagesMotoniveladora Cat 140M Motor C9 PDFdanilo100% (3)

- 5hp19eDocument2 pages5hp19eDevine LightNo ratings yet

- Sonceboz Hybrid StepperDocument2 pagesSonceboz Hybrid StepperLuciano DiasNo ratings yet

- Kollmorgen KBM Series 2011 CatalogDocument80 pagesKollmorgen KBM Series 2011 CatalogElectromateNo ratings yet

- Servo MotorsDocument32 pagesServo MotorsThamizhselvan KNo ratings yet

- PC80MR-5 Wenss08501 1905Document12 pagesPC80MR-5 Wenss08501 1905vitaliyNo ratings yet

- F Br-Ring Spinning Frame LowresDocument20 pagesF Br-Ring Spinning Frame LowresAshique100% (2)

- D 5 GDocument24 pagesD 5 GName NameNo ratings yet

- Brochure Drive Systems Crane and Special VehiclesDocument16 pagesBrochure Drive Systems Crane and Special Vehiclesmuha6825No ratings yet

- Version Von DFMC b10034 00 Simotics Motoren72dpiDocument26 pagesVersion Von DFMC b10034 00 Simotics Motoren72dpiRakshit SharmaNo ratings yet

- MultiCam 7000-Series CNC RouterDocument10 pagesMultiCam 7000-Series CNC RouterDaniel AustinNo ratings yet

- MH3037Document28 pagesMH3037Fulkan HadiyanNo ratings yet

- Frameless High Torque Motors: Product BrochureDocument20 pagesFrameless High Torque Motors: Product Brochurevivekcs11No ratings yet

- DDL Selection Guide En-En RevADocument82 pagesDDL Selection Guide En-En RevAVikash YadavNo ratings yet

- Sinamics V90: The Performance-Optimized and Easy-To-Use Servo Drive SystemDocument24 pagesSinamics V90: The Performance-Optimized and Easy-To-Use Servo Drive SystemYogeshPatelNo ratings yet

- AC Servo Motors - BSM SeriesDocument96 pagesAC Servo Motors - BSM SeriesIrving Alexander Morales PérezNo ratings yet

- 3aua0000206507 RevaDocument30 pages3aua0000206507 Revadiep leNo ratings yet

- Komatsu D61Document20 pagesKomatsu D61AlvaroNo ratings yet

- V90 KatalogDocument24 pagesV90 KatalogErdincNo ratings yet

- IDS - Optimized For VibrationDocument4 pagesIDS - Optimized For VibrationjeyaselvanmNo ratings yet

- Global Brochure PDFDocument16 pagesGlobal Brochure PDFElsa VelazquezNo ratings yet

- MAE Automatic Straightening Machines - M-AHDocument24 pagesMAE Automatic Straightening Machines - M-AHsemarasik_651536604No ratings yet

- Overview Marketing e RecentDocument16 pagesOverview Marketing e RecentHamilton BejeguenNo ratings yet

- 07 Frameless Motors & Gear MotorsDocument46 pages07 Frameless Motors & Gear Motorsfunny_motor67% (3)

- Matrix International: Altra Industrial MotionDocument8 pagesMatrix International: Altra Industrial Motioncontrax8No ratings yet

- SEW Eurodrive Industrial Gear UnitsDocument15 pagesSEW Eurodrive Industrial Gear UnitsSteve IpNo ratings yet

- 4029 Wiper SystemsDocument4 pages4029 Wiper SystemsHamdani NurdinNo ratings yet

- Ead BLDCDocument16 pagesEad BLDCAhmadTalibNo ratings yet

- Rexroth EcoDrive The Complete Servo Drive SolutionDocument23 pagesRexroth EcoDrive The Complete Servo Drive Solutiontomem666No ratings yet

- SIMINE Haul Truck: How To Execute Material Transport at Lowest Cost Per TonDocument20 pagesSIMINE Haul Truck: How To Execute Material Transport at Lowest Cost Per TonRolly FabianNo ratings yet

- Wheel Block Brochure - 0 PDFDocument20 pagesWheel Block Brochure - 0 PDF8310195025080No ratings yet

- D6K2Document20 pagesD6K2ivanamanticNo ratings yet

- P17500 P33000 PDFDocument14 pagesP17500 P33000 PDFAdrian GonzalezNo ratings yet

- Cat 16m Grader BrochureDocument24 pagesCat 16m Grader BrochureSauro GordiniNo ratings yet

- De DriveDocument6 pagesDe DriveEdgar RdzNo ratings yet

- Sinamics Perfect Harmony gh180 Catalog d15 1 en PDFDocument104 pagesSinamics Perfect Harmony gh180 Catalog d15 1 en PDFblazer111No ratings yet

- Cartilla Especificaciones Camion 793 PDFDocument32 pagesCartilla Especificaciones Camion 793 PDFKianna Ospino AlmenarezNo ratings yet

- Electrocraft EAD BLDC CatalogDocument16 pagesElectrocraft EAD BLDC CatalogElectromateNo ratings yet

- Manual de DragalinaDocument28 pagesManual de DragalinaedwardNo ratings yet

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Gibson Dark Fire Owner's ManualDocument39 pagesGibson Dark Fire Owner's ManualSamuel David CastilloTorresNo ratings yet

- Microservice - 500k CCU PDFDocument52 pagesMicroservice - 500k CCU PDFHoang Hoang JimmyNo ratings yet

- Network Programming in The .Net Framework PDFDocument212 pagesNetwork Programming in The .Net Framework PDFKhris H.100% (1)

- XML File UploadDocument5 pagesXML File Uploadkanhaiya_priyadarshiNo ratings yet

- KSG 50-70 Vertical - User and Service ManualDocument38 pagesKSG 50-70 Vertical - User and Service ManualRomuald Eric TefongNo ratings yet

- Diesel Generator Set QSK60 Series Engine: 1760kVA - 2500kVA 50 HZ 1825kW - 2250kW 60 HZDocument4 pagesDiesel Generator Set QSK60 Series Engine: 1760kVA - 2500kVA 50 HZ 1825kW - 2250kW 60 HZ3efooNo ratings yet

- 1 NW8803GMGDocument2 pages1 NW8803GMGmajochepe25No ratings yet

- Service Manual: XB-2, XB-SNDocument46 pagesService Manual: XB-2, XB-SNChristophe HomandNo ratings yet

- A New Approach Distance Protection Using: FOR Artificial Neural NetworkDocument5 pagesA New Approach Distance Protection Using: FOR Artificial Neural NetworkMedo PriensNo ratings yet

- Understanding Routing What Is Routing?Document17 pagesUnderstanding Routing What Is Routing?Sanjay Kumar MahanaNo ratings yet

- 8051 Microcontroller External Interrupt ProgrammingDocument28 pages8051 Microcontroller External Interrupt ProgrammingsharadaNo ratings yet

- Hydropneumatic Suspension SystemDocument7 pagesHydropneumatic Suspension Systemaniket wadheNo ratings yet

- 6 Data StructuresDocument59 pages6 Data StructuresAbraNo ratings yet

- ADVANCE STANDALONE Yamaha Z1 (EN) PDFDocument10 pagesADVANCE STANDALONE Yamaha Z1 (EN) PDFTechno TechNo ratings yet

- Cutting Master5 Manual EngDocument85 pagesCutting Master5 Manual Engdiegodaer77No ratings yet

- Digital Signatures Ensure Message AuthenticityDocument9 pagesDigital Signatures Ensure Message AuthenticityAshenafi Abebe DawudNo ratings yet

- Lean Management: KAIZEN Training of TrainersDocument24 pagesLean Management: KAIZEN Training of TrainersOscar LiraNo ratings yet

- Industrial-OS Watchdog DOC enDocument14 pagesIndustrial-OS Watchdog DOC enAldo RahmadNo ratings yet

- Role of Information Technology in Education System 170605100Document7 pagesRole of Information Technology in Education System 170605100farahdilafNo ratings yet

- List of Formal Approval SEZDocument34 pagesList of Formal Approval SEZsampuran.das@gmail.comNo ratings yet

- SW Ass1Document9 pagesSW Ass1Mintesinot MeleseNo ratings yet

- Online BankingDocument38 pagesOnline BankingROSHNI AZAMNo ratings yet

- DRAGER X TrainingDocument7 pagesDRAGER X TrainingAndreas Bacacau LliosteNo ratings yet

- User Manual - English (Vodacom)Document2 pagesUser Manual - English (Vodacom)OratilweNo ratings yet

- Manual de Instalacion 300mb-SbDocument24 pagesManual de Instalacion 300mb-SbEduardo Farrera RedondoNo ratings yet

- SCM Process Assessment and Evaluation: Abcan Consulting IncDocument25 pagesSCM Process Assessment and Evaluation: Abcan Consulting IncFadzilah MohamadNo ratings yet

- Training Report BhelDocument48 pagesTraining Report BheldjdeveshNo ratings yet

- New Product Developmen1Document5 pagesNew Product Developmen1srvjeetNo ratings yet

- Cyber Crimes in IndiaDocument11 pagesCyber Crimes in Indiaanoos04100% (1)

- Technical Analysis (Last 7 Steps) : Nikhita Rustagi 6017 Mba 4 Semester Project Planning, Analysis and ManagmentDocument16 pagesTechnical Analysis (Last 7 Steps) : Nikhita Rustagi 6017 Mba 4 Semester Project Planning, Analysis and ManagmentNikhitaNo ratings yet