Professional Documents

Culture Documents

1 s2.0 S1006706X12601137 Main PDF

Uploaded by

Felipe ArceOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 s2.0 S1006706X12601137 Main PDF

Uploaded by

Felipe ArceCopyright:

Available Formats

Available online at www.sciencedirect.

com

ScienceDirect

JOURNAL OF IRON AND STEEL RESEARCH, INTERNATIONAL. 2012, 19(7): 55-59

Microstructure Evolution in 9Cr Martensitic Steel During

Long-Term Creep at 650 "c

HU Zheng-fei' , WANG Qi-jiang' , ZHANG Bin'

(1. School of Material Science and Engineering, Tongji University, Shanghai 200092, China;

2. Institute of Baosteel, Shanghai 201900, China)

Abstract: Standardarized creep and rupture strength tests were conducted for commercial T91 martensitic heat-resist-

ant steel at 650 'C and corresponding microstructure was characterized by BSED, TEM and EDS. The martensitic

microstructure degenerated seriously during creep exposure, including martensitic substructure recovering, carbides

coarsening, dissolving and precipitating. EDS analysis shows that the M23 C6 carbides in different morphologies have

dissimilar compositions. The rod/sheet like MZ3 Cs particles within the matrix contain more additions, which might

precipitate in situ while fine MX particles were re-solving. The high content of silicon in these rod/sheet like MZ3Cg

carbides is probably related to self diffusion coefficient increasing for the exposed condition at 650 C close to Curie

temperature T,. For those reasons, martensite substructure becomes unstable, and microstructure evolution is accel-

erated and leads to creep strength deteriorating severely.

Key words: T91 steel; creep strength; microstructure; carbide; coarsening; self-diffusion

Tempered martensitic steels with Cr of 9% are

most popular materials used as components in power

plant due t o their excellent mechanical properties at

high Their prominent creep strength

with suitable toughness is achieved by martensitic mi-

crostructure coupled with dispersive distribution of

fine precipitates. The microstructure consists of

lath, block and packet martensite containing a high

density of dislocations and fine carbonitride parti-

cles. For long-term steady performance in practical

service condition, it is suggested that t he stability of

martensitic microstructure at elevated temperature is

i mp ~ r t a n t ~ ~ - ~ ' . In advanced 9CrlMo steels, high

creep strength has attained by the addition of V, Nb

and N which form fine precipitatesC5]. Furthermore,

in order to achieve anti-oxidation at high tempera-

t ure, the minor additions of silicon and sulphur are

From the past studies, the silicon ad-

dition effects on the long-term stability of martensit-

ic microstructure and creep resistance at high tem-

perature are not well understood. The present paper

describes the creep behavior and microstructure evo-

lution in T91 martensitic steel at 650 "C. More atten-

tion is paid to the fine characteristics of microstructure

evolution as well as precipitation behavior during

creep at temperature close to Curie temperature.

1 Experimental Procedure

A typical commercial T91 martensitic steel was

employed. Its chemical compositions (in mass percent,

%) were analyzed to be Cr 8. 3 , Mo 0. 90, Mn 0. 4 , Si

0. 32, V 0.21, Nb 0. 09, Ni 0. 09, and C 0.11. Creep

tests were carried out at 650 "C ( 923 K) up to about

2 X l o4 h under constant load condition, using speci-

mens of 10 mm in gauge diameter and 25 mm gauge

in length. The microstructure evolution during creep

was observed by BSED (backscatting scanning elec-

tron microscope) and TEM (transmission electron

microscope). To examine the size and composition

of the precipitates, extraction replicas as well as thin

foils were prepared and analyzed using spectroscope

EDS method. The methods of preparing the samples

are described in many references[*'

2 Results and Discussion

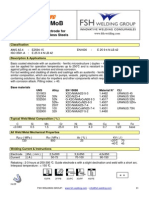

Fig. 1 shows t he results of accelerated test at

Foundation 1tem:Item Sponsored by National Natural Science Foundation of China (50871076)

Biography:HU Zheng-fei(l964-), Male, Doctor, Professor; E-mail: huzhengfatongji. edu. cn; Received Date: February 14, 2011

56 - Journal of I r on and Steel Research, International VOl. 19

.-

10 102 103 101 10

Timeih

Fig. 1 Plot of stress with rupture time exposed at 650 C

650 *C. Stress rupture data have been plotted in term of

log stress with rupture time. The curve shows that

stresses are linear with rupture times; t hus, t he

threshold st rengt h of t he examined T91 at 650 C

was determined by extrapolation method as follows :

Thi s result conforms t o t he requirement of

ASTM standard and is identical t o t he values given

by other reportsi3991.

Fig. 2 illustrates t he transmission electron mi-

crograph of t he examined T91 material in as-received

state. It clearly shows a typical lath martensitic micro-

structure, with carbides distributing along boundaries

and much finer particles in t he matrix.

It is known that t he steels with Cr of 9%-12%

&Q =57. 1 MPa (1)

Fig. 2 Transmission electron micrograph from

as-received microstructure

contain several precipitate types, such as M2,C6, MX

and Laves, which form either during t he final nor-

malizing and tempering heat treatment or during

subsequent creep exposure. These various precipi-

tates have special chemical compositions, which

mean that it is possible t o discriminate between them

by measurements of their chemical composition.

SEM can obtain backscattered electron (SEM-BSE)

images which present t he atomic number contrast t o

discriminate between particles. Fig. 3 gives the SEM-

( a) 140 MPa, 115 h;

Fig. 3

( b) 130 MPa, 386 h; ( c ) 120 MPa, 3685 h ; ( d) 110 MPa, 12353 h.

SEM-BSE images of accelerated test samples ruptured at 650 c under different stresses

Issue 7 Microstructure Evolution in 9Cr Martensitic Steel During Long-Term Creep at 650 C . 57

BSE images of the samples for accelerating rupture

tests under different stresses. It shows that the sizes

of the precipitates distributing along grain bounda-

ries increase obviously, especially the M,, c6 parti-

cles along prior austenitic boundaries have been

coarsened during creep deformation. The fine pre-

cipitates within the matrix do not exhibit obvious

coarsening. However the density of these fine parti-

cles within the matrix decreases with the rupture

time prolonging. It means that the precipitates

coarsen obviously during long-term rupture life. In

Fig. 3 ( d ) , the contour of prior austenite grain

boundaries outlined by M,, C6 become much more

clear but lath boundaries are indistinct or even disap-

peared. These indicate the martensitic lathes have

undergone a degeneration during long-term accelera-

ting at 650 C. The coarsening of laths is processing

by two ways, the recovery of dislocations within

lath boundaries and the recombination of two sub-

grain boundaries which mainly takes place near the

triple point of lath boundaries by moving and causes

0 2 4 6 8 10

the disappearance of lath boundaries. Furthermore,

during moving of lath boundaries to cause progres-

sive local-coalescence, dissolution and re-precipitati-

on of M2,C6 carbides distributing along lath bounda-

ries take place repeatedly.

What observed above is totally coincident with

the results mentioned by others[4391 that the rupture

strength of T/P91 deteriorates obviously over 600 C

and this characteristic is relative to the unstable mi-

crostructure for the much faster coarsening process

of carbides and lath structure.

The composition of the carbides is determined

in TEM via energy dispersive microanalysis (EDS) ,

as shown in Fig. 4. The unlabeled peaks in Fig. 4 are

from copper grids. It is shown that the carbides along

boundaries are Cr rich [Fig. 4 ( a) ] and correspond-

ing electron diffraction pattern inserted in Fig. 4 ( a)

is identified as M,,C, in the [lll] orientation. Other

fine precipitates dispersive within the matrix are

confirmed to be rich in V-rich or Nb-rich [Fig. 4

( a ) , marked as A in Fig. 5 (a)]. The inset electron

2 4 6 8 10 12 14 16 18 20

EncrgykeV

Fig. 4 EDS X-ray spectra of extraction replica from sample ruptured at 650 c under 140 MPa for 115 h

0 2 4 6 8 1 0 0 2 4 6 8 1 0 0 2 4 6 8 1 0

EnergykeV

(a) 140 MPa, 115 h; ( b) 120 MPa, 3386 h ; ( c ) 120 MPa, 12353 h.

Fig. 5 Typical TEM micrographs of extraction replica of accelerated test samples at 650 c under different

stresses and EDS X-ray spectra from particles B (d) , C (e) and D ( f )

58 . Journal of Iron and Steel Research, International VOl. 19

diffraction pattern in Fig. 4 ( b ) is identified as MX

carbonitrides and the zone axis is [112]. Even though

the MX carbonitrides seem highly stable against coarse-

ning for their sizes without obvious variety, their

number density tends to reduce. This implies that

partial MX particles have redissolved during long

term exposure at 650 "C.

Fig. 5 displays some rod or sheet like particles

marked as B, C and D, which are presented within

the matrix and some along grain boundaries. They

are much larger than those MX particles and also

recognized as Mz3 Cg by selected area diffraction

(SAD). From their sizes and morphologies, it im-

plies that these carbides within the matrix did not

undergo coarsening, so they are considered to be

precipitated during the accelerating test period.

Fig. 5 also indicates that the much complex composi-

tions of these Mz3Cg carbides and dominant elements

are chromium, iron, molybdenum, vanadium and

silicon. With the density of MX particles decreasing,

it implies that the precipitation of these M'sCg parti-

cles formed subsequently to the dissolving behavior

of MX. In other words, the MX particles in T91 are

not stable while exposing at 650 "C and apt to trans-

form into more stable M'3C6 carbides. These M23C6

particles form in-situ while MX dissolving. The EDS

spectra in Fig. 5 show a special phenomenon in the

rod/sheet like carbides. There is obvious silicon in

their alloying compositions and the Si content (atom

percent) is quite high ( as much as 1 7 %) and vary

strikingly between particles. However no silicon is

found in fine MX particles within the matrix and no

obvious silicon is detected in the Mz3C6 carbides in

different appearances along grain boundaries (Fig. 4).

In ferritic steels with Cr of 9%-12%, the ac-

tions of Si and Mn are contradictory to each other;

Si is a ferrite former, whereas Mn is an austenite

former. It has been claimed that ferritic steel has

better creep rupture when it has low concentration

of Si and Mn["-''' . Reduction of the contents of

both of these elements can lead to a low self-diffu-

sion coefficient in the ferrite matrix and improve

creep strength. Si works to decrease toughness by

promoting the Laves phase, whereas Mn, though

useful for toughness improvement, can impair the

high temperature stability of the ferrite structure by

decreasing the A, transformation temperature in the

same manner as Ni. From another point of view, the

addition of 9-12Cr in combination with appropriate

minor elements, such as silicon and sulphur, is re-

quired from the viewpoint of suitable high-tempera-

ture oxidation resi ~t ance"~' .

The facts of MX dissolving and rod/sheet like

Mz3 c6 carbides precipitating with high silicon con-

tent might be related to the compositions of the ex-

amined steel and high temperature. From the points

of past studies, diffusion coefficient is the most im-

portant parameter in creep, and is required to be as

small as possible in order to retain fine particles for

long duration and to slow down the recovery of the

martensitic substructure. It is known that ferritic

steel transforms from a para- to a ferro-magnetic

state near Curie temperature T, , and its self-diffu-

sion coefficient is reduced by the magnetic transfor-

mation['". Generally, high Cr ferritic steel is used

in this temperature regime just below T,. The diffu-

sion coefficient increases with decreasing T, of the

material. The additions of Si, Mn and Ni increase

diffusion coefficient for their effects to decrease Cu-

rie temperature. In the present study, the examined

samples were exposed at 650 "C which is close t o

Curie temperature, so the self-diffusion coefficient

might increase obviously. All these might promote

MX dissolution and new Mz3c6 precipitation, mean-

while, silicon segregates markedly into these Mz3 c6

particles within the matrix. That means the micro-

structure of T91 steel becomes unstable when expo-

sing at 650 "C under certain stress. With self-diffu-

sion coefficient increasing, the microstructure evolu-

tion is accelerated obviously, including MX precipi-

tates dissolving, rod/sheet like MZ3 C, carbides precipi-

tating and martensitic substructure undergoing re-

covery. These microstructure evolutions lead t o

creep strength deteriorating severely. The silicon

segregating to carbides or boundaries might be a sign

for the deterioration at high temperature for 9Cr

martensitic steels.

3 Conclusions

1) Creep strength of T91 martensitic heat-re-

sistant steel deteriorates severely when it exposed at

650 "C under certain stress and corresponding micro-

structure becomes unstable.

2 ) Martensitic substructure undergoes recovery.

The phenomena of carbonitrides MX re-dissolving

and particles of Mz3Cg forming in-situ, lead to M2,C6

carbides with different morphologies and dissimilar

composition.

3 ) The microstructure evolution is accelerated

obviously which may be related to enhancing self-dif-

fusion coefficient at 650 "C near Curie temperature.

Issue 7 Microstructure Evolution in 9Cr Martensitic Steel During Long-Term Creep at 650 C * 59

References :

Masuyama F. History of Power Plant and Progress in Heat Re-

sistant Steels [J]. ISIJ International, 2001, 41 : 612.

Ennis P J , Czyrska F A. Recent Advances in Creep-Resistant

Steels for Power Plant Applications [J]. Sadhana, 2003, 28(3/

4) : 709.

Abe F, Horiuchi T, Taneike M, et al. Stabilization of Marten-

sitic Microstructure in Advanced 9Cr Steel During Creep at

High Temperature [J]. Mater Sci and Eng, 2004, 378A: 299.

Hald J. Microstructure and Long-Term Creep Properties of

9-13Cr Steels [ J]. International Journal of Pressure Vessels

and Piping, 2008, 85: 30.

Abe F. Analysis of Creep Rates of Tempered Martensitic 9%Cr

Steel Based on Microstructure Evolution [J]. Mater Sci and

Eng, 2009, 510A: 64.

Ennis P, Quadakkers W J. The Steam Oxidation Resistance

9-12%Cr Steels [C] //Schubert F. Proceedings of the Seventh

Liege Conference on Materials for Advanced Power Engineer-

ing. Liege: [s. n. ], 2002: 1131.

[7]

Kutsumi H, Itagaki T, Abe F. Improvement of Steam Oxida-

tion Resistance for Ferritic Heat-Resistant Steels [C] // Schu-

bert F. Proceedings of the Seventh Liege Conference on Materi-

als for Advanced Power Engineering. Liege: [ s. n. 3, 2002 :

1629.

HU Zheng-fei, WU Xing-fang, LI Xiu-qiu, et al. M2C Precipi-

tate in Isothermal Tempering of High Co-Ni Alloy Steel [J]. J

Iron and Steel Res Int, 2001, X( 2) : 56.

Hattestrand M, Andren H 0. Evaluation of Particle Size Dis-

tributions of Precipitates in a 9%Cr Steel Using Energy Filtered

Transmission Electron Microscopy [J]. Micron, 2001, 22: 789.

Abe F. Coarsening Behavior of Lath and Its Effect on Creep

Rates in Tempered Martensitic 9Cr-W Steels [J]. Mater Sci

and Eng, 2004, 3X7A: 565.

[ll] Cerjak H, Hofer P , Schaffernak B. Microstructural Aspects

on Creep Behaviour of Advanced Power Plant Steels [J]. Key

Eng Mater, 2000, 171-174: 453.

Maruyama K, Sawada K, Koike J. Strengthening Mechanisms

of Creep Resistant Tempered Martensitic Steel [J]. ISIJ I nt er

national, 2001, 41(6): 641.

[S]

[9]

[ l o]

[12]

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- FINITEELEMENTMODELLINGOFTUBULARBOLTEDCONNECTIONOFALATTICEWINDTOWERFORFATIGUEASSESSMENTDocument88 pagesFINITEELEMENTMODELLINGOFTUBULARBOLTEDCONNECTIONOFALATTICEWINDTOWERFORFATIGUEASSESSMENTFelipe ArceNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Paper InvestigaciónDocument15 pagesPaper InvestigaciónFelipe ArceNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Front Matter - 2017 - Orthodontic Applications of Biomaterials PDFDocument1 pageFront Matter - 2017 - Orthodontic Applications of Biomaterials PDFFelipe ArceNo ratings yet

- 10 Frequent Handling Mistakes During Bonding 2017 Orthodontic Applications of BiomaterialsDocument7 pages10 Frequent Handling Mistakes During Bonding 2017 Orthodontic Applications of BiomaterialsFelipe ArceNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- 3 Structure Property Relationships in Orthodontic Ceramics 2017 Orthodontic Applications of BiomaterialsDocument11 pages3 Structure Property Relationships in Orthodontic Ceramics 2017 Orthodontic Applications of BiomaterialsFelipe ArceNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Bicycle Frames: Standard Test Methods ForDocument6 pagesBicycle Frames: Standard Test Methods ForFelipe ArceNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Miniscrew Implant Applications in ContemporaryDocument5 pagesMiniscrew Implant Applications in ContemporaryFelipe ArceNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- 15 The Welding Simulation Solution GuidelinesDocument152 pages15 The Welding Simulation Solution GuidelinesFelipe ArceNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- 1natural Convectionpaul PDFDocument17 pages1natural Convectionpaul PDFFelipe ArceNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Microstructure of Ferrous AlloysDocument148 pagesMicrostructure of Ferrous AlloysFelipe Arce100% (2)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Downloaded/printed by Universidad de Chile Pursuant To License Agreement. No Further Reproductions AuthorizedDocument224 pagesDownloaded/printed by Universidad de Chile Pursuant To License Agreement. No Further Reproductions AuthorizedFelipe ArceNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Selectarc Selectarc Selectarc Selectarc: Inox 2509mobDocument1 pageSelectarc Selectarc Selectarc Selectarc: Inox 2509mobGogo PNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- De Thi Hoc Ki 1 Mon Tieng Anh Lop 5 Co File NgheDocument10 pagesDe Thi Hoc Ki 1 Mon Tieng Anh Lop 5 Co File Nghetuyen truongNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- DNA ReplicationDocument19 pagesDNA ReplicationLouis HilarioNo ratings yet

- 13 Adsorption of Congo Red A Basic Dye by ZnFe-CO3Document10 pages13 Adsorption of Congo Red A Basic Dye by ZnFe-CO3Jorellie PetalverNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 2009 2011 DS Manual - Club Car (001-061)Document61 pages2009 2011 DS Manual - Club Car (001-061)misaNo ratings yet

- The Person Environment Occupation (PEO) Model of Occupational TherapyDocument15 pagesThe Person Environment Occupation (PEO) Model of Occupational TherapyAlice GiffordNo ratings yet

- Assessment of Students' Oral Communication in English ClassDocument10 pagesAssessment of Students' Oral Communication in English ClassKeebeek S ArbasNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Monergism Vs SynsergismDocument11 pagesMonergism Vs SynsergismPam AgtotoNo ratings yet

- LTE Networks Engineering Track Syllabus Overview - 23 - 24Document4 pagesLTE Networks Engineering Track Syllabus Overview - 23 - 24Mohamed SamiNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Mark Garside Resume May 2014Document3 pagesMark Garside Resume May 2014api-199955558No ratings yet

- Ron Kangas - IoanDocument11 pagesRon Kangas - IoanBogdan SoptereanNo ratings yet

- Lecturenotes Data MiningDocument23 pagesLecturenotes Data Miningtanyah LloydNo ratings yet

- Manual s10 PDFDocument402 pagesManual s10 PDFLibros18No ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- HirePro Video Proctored Online-Instruction Sheet - Bain IndiaDocument1 pageHirePro Video Proctored Online-Instruction Sheet - Bain Indiaapoorv sharmaNo ratings yet

- Time-Sensitive Networking - An IntroductionDocument5 pagesTime-Sensitive Networking - An Introductionsmyethdrath24No ratings yet

- Ozone Therapy - A Clinical Review A. M. Elvis and J. S. EktaDocument5 pagesOzone Therapy - A Clinical Review A. M. Elvis and J. S. Ektatahuti696No ratings yet

- Movie Piracy in Ethiopian CinemaDocument22 pagesMovie Piracy in Ethiopian CinemaBehailu Shiferaw MihireteNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- 70 Valves SolenoidDocument105 pages70 Valves SolenoidrizalNo ratings yet

- Pavement Design1Document57 pagesPavement Design1Mobin AhmadNo ratings yet

- 18 June 2020 12:03: New Section 1 Page 1Document4 pages18 June 2020 12:03: New Section 1 Page 1KarthikNayakaNo ratings yet

- Arens - Auditing and Assurance Services 15e-2Document17 pagesArens - Auditing and Assurance Services 15e-2Magdaline ChuaNo ratings yet

- Aptitude Number System PDFDocument5 pagesAptitude Number System PDFharieswaranNo ratings yet

- Fusion Implementing Offerings Using Functional Setup Manager PDFDocument51 pagesFusion Implementing Offerings Using Functional Setup Manager PDFSrinivasa Rao Asuru0% (1)

- Cisco SDWAN Case Study Large Global WANDocument174 pagesCisco SDWAN Case Study Large Global WANroniegrokNo ratings yet

- Strucure Design and Multi - Objective Optimization of A Novel NPR Bumber SystemDocument19 pagesStrucure Design and Multi - Objective Optimization of A Novel NPR Bumber System施元No ratings yet

- DN Cross Cutting IssuesDocument22 pagesDN Cross Cutting Issuesfatmama7031No ratings yet

- Week 7 Sex Limited InfluencedDocument19 pagesWeek 7 Sex Limited InfluencedLorelyn VillamorNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Fss Presentation Slide GoDocument13 pagesFss Presentation Slide GoReinoso GreiskaNo ratings yet

- Floating Oil Skimmer Design Using Rotary Disc MethDocument9 pagesFloating Oil Skimmer Design Using Rotary Disc MethAhmad YaniNo ratings yet

- Assembler Pass 2Document5 pagesAssembler Pass 2AnuNo ratings yet

- Ob NotesDocument8 pagesOb NotesRahul RajputNo ratings yet