Professional Documents

Culture Documents

BLITZ Electric Gate Motor Manual PDF

Uploaded by

ps2cardOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BLITZ Electric Gate Motor Manual PDF

Uploaded by

ps2cardCopyright:

Available Formats

E

N

G

L

I

S

H

IMPORTANT REMARKS

For any installation problem please contact our Customer Service

at the number +39-0172.812411 operating Monday to Friday

from 8:30 to 12:30 and from 14:00 to 18:00.

V2 has the right to modify the product without previous

notice; it also declines any responsibility to damage or

injury to people or things caused by improper use or

wrong installation.

Please read this instruction manual very carefully

before installing and programming your control unit.

This instruction manual is only for qualified technicians, who

specialize in installations and automations.

The contents of this instruction manual do not concern the

end user.

Every programming and/or every maintenance service should

be done only by qualified technicians.

AUTOMATION MUST BE IMPLEMENTED IN COMPLIANCE

WITH THE EUROPEAN REGULATIONS IN FORCE:

EN 60204-1 (Machinery safety electrical equipment of

machines, part 1: general rules)

EN 12445 (Safe use of automated locking devices, test

methods)

EN 12453 (Safe use of automated locking devices,

requirements)

The installer must provide for a device (es. magnetotermical

switch) ensuring the omnipolar sectioning of the equipment

from the power supply.

The standards require a separation of the contacts of at

least 3 mm in each pole (EN 60335-1).

The plastic case has an IP55 insulation; to connect flexible

or rigid pipes, use pipefittings having the same insulation

level.

Installation requires mechanical and electrical skills,

therefore it shall be carried out by qualified personnel only,

who can issue the Compliance Certificate concerning the

whole installation (Machine Directive 98/37/EEC, Annex IIA).

The automated vehicular gates shall comply with the

following rules: EN 12453, EN 12445, EN 12978 as well as

any local rule in force.

Also the automation upstream electric system shall comply

with the laws and rules in force and be carried out

workmanlike.

The door thrust force adjustment shall be measured by

means of a proper tool and adjusted according to the max.

limits, which EN 12453 allows.

We recommend to make use of an emergency button, to be

installed by the automation (connected to the control unit

STOP input) so that the gate may be immediately stopped

in case of danger.

The appliance is not to be used by children or persons with

reduced physical, sensory or mental capabilities, or lack of

experience and knowledge, unless they have been given

supervision or instruction.

Children being supervised do not play with the appliance.

For correct installation of the system, we recommend

following the instructions issued by UNAC very carefully,

which can be consulted at the following web site:

www.v2home.com

DECLARATION OF CONFORMITY

The following statement is applicable only if the below listed

equipments are employed in accordance with the purpose indica-

ted in the instruction manual.

Company: Contact person:

V2 SPA Cosimo De Falco

Corso Principi di Piemonte 65 Chief Executive Officer

12035 RACCONIGI -ITALY

Tel. +39 01 72 82 10 11

Fax +39 01 72 82 10 50

V2 SPA declares that the series of BLITZ actuators are in

conformity with the provisions of the following EC directives:

73/23/EEC low voltage directive

89/366/CEE electromagnetic compatibility directive

98/37/EEC machine directive

Note: Declares that the above mentioned devices may not be

operated until the machine (automated gate) is identified, CE-

labeled, and declared to be compliant to the specifications of

Directive 89/392/EEC and following modifications.

The person in charge for the machine start-up must provide the

following records:

Technical specification paper

Declaration of conformity

CE-labeling

Testing record

Maintenance record

Operation manual and directions

Racconigi 20/10/2009

V2 SPA legal representative

Cosimo De Falco

7

E

N

G

L

I

S

H

8

TECHNICAL SPECIFICATIONS BLITZ-24V BLITZ-120V BLITZ-230V

Max. leaf lenght m

3 x 500 Kg

2,5 x 600 Kg

2 x 800 Kg

3 x 500 Kg

2,5 x 600 Kg

2 x 800 Kg

3 x 500 Kg

2,5 x 600 Kg

2 x 800 Kg

Power supply Vac / Hz 24 Vdc 120 / 60 230 / 50

Idling current A 1,5 3,8 1,8

Full load current A 7,5 4,5 2,5

Rated power W 45 400 400

Capacitor F - 30 8

Speed Rpm 1,4 0,5 1,9 1,6

Torque N m 320 340 340

Working temperature C -30 +60 -30 +60 -30 +60

Thermal protection C 140 140 140

Working cycle % 80 20 20

Motor weight Kg 14,6 14,6 14,6

INSTALLATION LAYOUT

1 BLITZ actuator

cable 4 x 1 mm

2

cable 1,5 x 2 mm

2

(Blitz-24V)

2 Control unit cable 3 x 1,5 mm

2

3 Blinker cable 2 x 1 mm

2

4 Aerial cable RG-58

5 Key or digital selector cable 3 x 0,5 mm

2

6 External photocells

cable 4 x 0,5 mm

2

(RX)

cable 2 x 0,5 mm

2

(TX)

7 Internal photocells +

GARDO50 pillars

cable 4 x 0,5 mm

2

(RX)

cable 2 x 0,5 mm

2

(TX)

8 Safety edge (EN 12978)

9 Proximity reader via radio or digital selector via radio +

pillar GARDO100

10Transmitter

E

N

G

L

I

S

H

9

PRELIMINARY OPERATIONS

The new series of actuadors BLITZ, has been devised to serve gates up to 800 Kg with leaf up to 3 meters wide (look at the table technical

data). Before proceeding with the installation, please make sure that your gate opens and closes freely, and that:

Pintles and pivots shall be in good order and properly lubricated

Nothing shall block the movement

No friction with earth and between the doors shall exist (mechanical expansion from 7 to 8 mm min.)

Your gate has to be equipped with central stop (1) and possibly side limits (2)

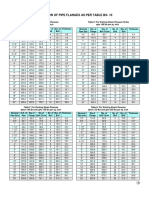

INSTALLATION MEASURES

To carry out a proper installation of the operator parts as well as to ensure the best automation performance, the measurement levels

shown in the following table shall be complied with. Change the gate structure to adapt it to one of the cases in the table, if necessary.

B [mm] A [mm] C [mm]

90

20 40 140 650

50 80 140 650

90 140 150 650

150 160 160 650

170 180 180 650

180 220 180 650

220 250 180 600

250 320 200 600

100

20 60 170 650

70 110 180 650

110 150 190 650

150 200 200 650

110

20 50 180 650

50 100 200 650

110 130 210 650

E

N

G

L

I

S

H

10

ACTUATOR FASTENING

As soon as the measures selected from the table, which is on the

previous page, have been marked on piers, proceed with the

following operations, considering figure 1 as a reference:

Fasten the anchor plate to the pier by making use of

proper screws and blocks.

Enter the ratiomotor into the anchor plate and fasten it by

means of screws , washers and nuts supplied (the

shaft must be turned downwards).

Assembly the articulated arm and the relevant bracket as

shown in the figure.

Fit the articulated arm into the shaft and fasten the screw .

Release the ratiomotor (see paragraph EMERGENCY LOCK

RELEASE).

Mark the front bracket fastening points on the door

according to the previous established levels.

Separate the front bracket F from the articulated arm.

Fasten the bracket on the door by means of screws or

directly weld it in case the material it is made of allows it.

Link the clamp to the pivoted arm.

Make several manual attempts in order to open and close

the doors by checking that no unwanted friction occurs.

Proceed with ELECTRICAL CONNECTIONS and ADJUSTMENT

OF STOP ENDS.

Insert the cap , the plug , the unclamping handle

and fix the two screws.

WARNING: For the left actuator install the motor as

shown in fig.2 and repeat the above operations.

Fig. 1

Fig. 2

E

N

G

L

I

S

H

11

ELECTRICAL CONNECTIONS

BLITZ-230V / BLITZ-120V

Rif. Left MOTOR (SX) Right MOTOR (DX)

GND GND

COMMON COMMON

OPENING CLOSING

CLOSING OPENING

Rif. Left MOTOR (SX) Right MOTOR (DX)

OPENING CLOSING

CLOSING OPENING

WARNING: always remember to connect the earth

according to current standards (EN 60335-1, EN 60204-1).

BLITZ-24V

ADJUSTMENT OF STOP ENDS

Opening stop end: release the actuator and put the door into

its opening position. Adjust the cam (LOWER for the RIGHT

motor and UPPER for the LEFT motor) until the microswitch is

entered (see figure). Then fasten the cam by closing the screw.

Closing stop end: release the actuator and put the door into its

closing position. Adjust the cam (UPPER for the RIGHT motor and

LOWER for the LEFT motor) until the microswitch is entered.

Then fasten the cam by closing the screw.

E

N

G

L

I

S

H

12

EMERGENCY RELEASE

In case of a blackout, the gate can be operated directly from the

motor. Insert the key supplied in the lock, perform 1/2 of a turn.

Open the door and turn the release lever to position 2. Turn

again the release lever to position 1, close the door, turn the key

and then close the plastic guard in order to restore the

automation.

You might also like

- BFT TIR 120 BrochureDocument9 pagesBFT TIR 120 BrochureRibeiroLuisNo ratings yet

- Libra MarDocument11 pagesLibra MarLiz FabiolaNo ratings yet

- Liwin V7-1 enDocument24 pagesLiwin V7-1 enClaudiu Radu100% (1)

- FRENICDocument136 pagesFRENICkaporaluNo ratings yet

- Inversor Abb 2 5kwDocument2 pagesInversor Abb 2 5kwapi-290643326No ratings yet

- GARD G6000: Installation Instructions For Swift Road BarriersDocument24 pagesGARD G6000: Installation Instructions For Swift Road BarriersShah JeeNo ratings yet

- Libra PDFDocument9 pagesLibra PDFGary HuskinsonNo ratings yet

- 3ADW000193R0601 DCS800 Firmware Manual e FDocument466 pages3ADW000193R0601 DCS800 Firmware Manual e Fdat_nguyen_2100% (1)

- BFT IcaroDocument9 pagesBFT IcaroptorojNo ratings yet

- Installation manual for LIBRA-C-MA control panelDocument10 pagesInstallation manual for LIBRA-C-MA control panelmcilNo ratings yet

- FRENIC 5000 G11S P11S Instruction Manual INR SI47 1206 E PDFDocument132 pagesFRENIC 5000 G11S P11S Instruction Manual INR SI47 1206 E PDFtrangiang9690No ratings yet

- Instruction Manual: Model 7SL High/Low LimitrolDocument48 pagesInstruction Manual: Model 7SL High/Low LimitrolkmpoulosNo ratings yet

- EC DECLARATION OF CONFORMITY FOR MACHINESDocument15 pagesEC DECLARATION OF CONFORMITY FOR MACHINESMisi SzaszNo ratings yet

- Manual Carel 1Document16 pagesManual Carel 1bircsa10No ratings yet

- BFT Mizar 6Document5 pagesBFT Mizar 6CésarSá100% (1)

- Digital Industrial Controller 1 General Safety InstructionsDocument6 pagesDigital Industrial Controller 1 General Safety InstructionsGerardo Basaldú MoralesNo ratings yet

- ECX 400 SeriesDocument16 pagesECX 400 SeriesGeneral Electronic Facility LandsideNo ratings yet

- DCS800ServiceManual RevADocument96 pagesDCS800ServiceManual RevAElinplastNo ratings yet

- 3ADW000194R0601 DCS800 Hardware Manual e FDocument128 pages3ADW000194R0601 DCS800 Hardware Manual e FDeepak JainNo ratings yet

- FRENIC-Eco Starting GuideDocument49 pagesFRENIC-Eco Starting GuideMikhail YudhiantaraNo ratings yet

- Mitsubishi FR A700 ManualDocument826 pagesMitsubishi FR A700 ManualTh NattapongNo ratings yet

- LexiumDocument32 pagesLexiumIbrahima DiawNo ratings yet

- Powtran PI8600Document150 pagesPowtran PI8600Panisa NarumitrekhagarnNo ratings yet

- C6097a 2310 SpecificationDocument5 pagesC6097a 2310 SpecificationR NandakumarNo ratings yet

- SMD ManualDocument8 pagesSMD ManualJose K ManadanNo ratings yet

- ZL180 Came PDFDocument20 pagesZL180 Came PDFRicardo López VelázquezNo ratings yet

- Color Monitor: Service ManualDocument43 pagesColor Monitor: Service ManualzeugenioNo ratings yet

- TX-28/25/21MD4 Service ManualDocument36 pagesTX-28/25/21MD4 Service ManualIpko SalimNo ratings yet

- LG Flatron t530s Chassis CA-138Document42 pagesLG Flatron t530s Chassis CA-138victorino2009No ratings yet

- REX-C100/C400/C410/C700/C900: 1. Product CheckDocument8 pagesREX-C100/C400/C410/C700/C900: 1. Product CheckHmilkNo ratings yet

- CB100/CB400/CB500/CB700/CB900: 1. Product CheckDocument12 pagesCB100/CB400/CB500/CB700/CB900: 1. Product CheckJorge BurbanoNo ratings yet

- Installation, Operation and Service Manual for T40000RT Pool/Spa Equipment Control PanelDocument4 pagesInstallation, Operation and Service Manual for T40000RT Pool/Spa Equipment Control PanelOlga Joy Labajo GerastaNo ratings yet

- BFT LIBRA Control PanelDocument10 pagesBFT LIBRA Control PanelAADAFFAFASASNo ratings yet

- Maintenance and User Manual: Borehole TV Camera Inspection System Setting Up InstructionsDocument21 pagesMaintenance and User Manual: Borehole TV Camera Inspection System Setting Up InstructionsFranklin L SilvaNo ratings yet

- Altivar 18Document35 pagesAltivar 18veroljubdjNo ratings yet

- Nilfisk Alto Attix 19 Owners ManualDocument23 pagesNilfisk Alto Attix 19 Owners ManualmzstNo ratings yet

- Hardware Manual ACS800-01 Drives (0.55 To 200 KW) ACS800-U1 Drives (0.75 To 200 HP)Document174 pagesHardware Manual ACS800-01 Drives (0.55 To 200 KW) ACS800-U1 Drives (0.75 To 200 HP)virgil guimanNo ratings yet

- Spectrum Analyzer: User ManualDocument40 pagesSpectrum Analyzer: User ManualBenjaminBaezNo ratings yet

- Barrera Came ZL38 - T46 Ver13 GBDocument14 pagesBarrera Came ZL38 - T46 Ver13 GBMario Corval LorenzanaNo ratings yet

- STI Positioner CatalogueDocument48 pagesSTI Positioner CatalogueArun Babu100% (2)

- XF195 ManualDocument72 pagesXF195 ManualSquinkleNo ratings yet

- v350 35 Ta24 Instal GuideDocument10 pagesv350 35 Ta24 Instal GuideDejan IlievNo ratings yet

- LG Color Monitor Service ManualDocument36 pagesLG Color Monitor Service ManualJose M. CastilloNo ratings yet

- ABB Control PanelDocument100 pagesABB Control Panelselvamnathan100% (1)

- FinkbeinerDocument38 pagesFinkbeinermordidomiNo ratings yet

- PWS6500 Hardware ManualDocument15 pagesPWS6500 Hardware ManualOmar Alberto Quisbert TapiaNo ratings yet

- Color Monitor: Service ManualDocument24 pagesColor Monitor: Service Manualmoshu_85No ratings yet

- 3ADW000194R0506 DCS800 Hardware Manual Es eDocument124 pages3ADW000194R0506 DCS800 Hardware Manual Es eIvan ParodiNo ratings yet

- Manual Mantenimiento Celdas 8BK20Document16 pagesManual Mantenimiento Celdas 8BK20Alejandro Garay Moreno100% (1)

- Pretty: Instructions and Recommendations For Installation and UseDocument28 pagesPretty: Instructions and Recommendations For Installation and UseAnonymous u5cZWQ8i1DNo ratings yet

- Agile: Operating Instructions Frequency Inverter 230V / 400V 0.25 KW ... 11 KWDocument20 pagesAgile: Operating Instructions Frequency Inverter 230V / 400V 0.25 KW ... 11 KWrollinga2013No ratings yet

- Operational Manual Air Cooled Screw Nov 2010Document20 pagesOperational Manual Air Cooled Screw Nov 2010Chinh Viet HoangNo ratings yet

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- Delco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationFrom EverandDelco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- 110 Waveform Generator Projects for the Home ConstructorFrom Everand110 Waveform Generator Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Wall-E Lego InstructionDocument128 pagesWall-E Lego InstructionFabien Brochard67% (3)

- Mercury HD Quad Core 2015 III Q ManualDocument182 pagesMercury HD Quad Core 2015 III Q Manualps2cardNo ratings yet

- Dhp-W307av A1 Manual v1.00 (Eu)Document82 pagesDhp-W307av A1 Manual v1.00 (Eu)pianissimoleggeroNo ratings yet

- RetroGamerIssue148 2015Document116 pagesRetroGamerIssue148 2015ps2card100% (1)

- SA300 UserGuideDocument243 pagesSA300 UserGuideps2cardNo ratings yet

- Mercury HD Quad Core 2015 III Q ManualDocument182 pagesMercury HD Quad Core 2015 III Q Manualps2cardNo ratings yet

- Mercury HD Quad Core 2015 III Q ManualDocument182 pagesMercury HD Quad Core 2015 III Q Manualps2cardNo ratings yet

- EOS 550D - HG - EN - FlatDocument260 pagesEOS 550D - HG - EN - FlatyannishariNo ratings yet

- ADocument13 pagesAps2cardNo ratings yet

- DK LEGO MinifigureChecklist PDFDocument1 pageDK LEGO MinifigureChecklist PDFps2card100% (3)

- WishboneDocument14 pagesWishboneSapana Kudake SK0% (1)

- Seminar ON Water Jet Cutting: Raj Kumar Goel Institute of TechnologyDocument17 pagesSeminar ON Water Jet Cutting: Raj Kumar Goel Institute of TechnologyRahul kumarNo ratings yet

- Calorifier ManualDocument6 pagesCalorifier ManualKanak MevadaNo ratings yet

- Centrifugal Pump Definition Components Working Priming Advantages Disadvantages and Applications PDFDocument7 pagesCentrifugal Pump Definition Components Working Priming Advantages Disadvantages and Applications PDFMuhammad Yasar JavaidNo ratings yet

- Town and Contry 4.0 2008Document4 pagesTown and Contry 4.0 2008Jessica BustillosNo ratings yet

- COMPRESOR Powerex Scroll Sed-Set-Seq (1) Sistema ExistenteDocument2 pagesCOMPRESOR Powerex Scroll Sed-Set-Seq (1) Sistema ExistenteCAROLINA MONGUINo ratings yet

- General Ventilation RequirementsDocument19 pagesGeneral Ventilation RequirementsNelson VargasNo ratings yet

- Process Engineering Manual 005 IIDocument29 pagesProcess Engineering Manual 005 IIzoeNo ratings yet

- Steady Heat Transfer AND Thermal Resistance Networks: Dr. Şaziye Balku 1Document24 pagesSteady Heat Transfer AND Thermal Resistance Networks: Dr. Şaziye Balku 1Pankaj KumarNo ratings yet

- Caja Transfer MTC - SpecDocument2 pagesCaja Transfer MTC - SpecDanny M Hurtado TaypeNo ratings yet

- Boilers, Evaporators, and CondensersDocument852 pagesBoilers, Evaporators, and CondensersJosé Carlos Chan Arias83% (6)

- Work Method Manual Mechanical Pump Test Run - Rev 0-28.04.10Document14 pagesWork Method Manual Mechanical Pump Test Run - Rev 0-28.04.10Iwan PrawitoNo ratings yet

- Ball Screw SKFDocument53 pagesBall Screw SKFRandima Gajanayaka0% (1)

- Válvula ContrabalanceDocument16 pagesVálvula ContrabalanceMauricio Ariel H. Orellana100% (1)

- Hydraulic FittingDocument124 pagesHydraulic FittingDhanraj PatilNo ratings yet

- PIPE FLANGE DIMENSIONSDocument5 pagesPIPE FLANGE DIMENSIONSViral ParmarNo ratings yet

- Classic500 - EFI - Owners - Manual - Domestic 2 PDFDocument97 pagesClassic500 - EFI - Owners - Manual - Domestic 2 PDFKannan Jayaprakash SreedeviNo ratings yet

- PHYS 211 6.STATIC 1ST CONDITION MergedDocument36 pagesPHYS 211 6.STATIC 1ST CONDITION MergedLEENo ratings yet

- Vibration Equations PDFDocument1 pageVibration Equations PDFgenas7265No ratings yet

- Sanwa Export 02 Gate ValveDocument1 pageSanwa Export 02 Gate ValveTou SvnkNo ratings yet

- Boston Export (Profile-Brochure) PDFDocument10 pagesBoston Export (Profile-Brochure) PDFGIRISH RAJ PUROHITNo ratings yet

- Question Bank Me2401Document13 pagesQuestion Bank Me2401Anonymous p8bHAAxNo ratings yet

- 4102 Series Diesel Engine: Operation and Maintenance ManualDocument16 pages4102 Series Diesel Engine: Operation and Maintenance ManualedI_restrepo_1No ratings yet

- Atemperador ShiniDocument47 pagesAtemperador ShiniJulio Cesar Diaz RamosNo ratings yet

- Bobcat 730SH Sideshift Backhoes Service Repair Manual PDFDocument17 pagesBobcat 730SH Sideshift Backhoes Service Repair Manual PDFfujsjejfksekmem100% (1)

- A General Review of The Causes and Acceptance of Shape ImperfectionsDocument7 pagesA General Review of The Causes and Acceptance of Shape ImperfectionsMuhammed SulfeekNo ratings yet

- GPG291 Designer's Guide To The Options For Ventilation and Cooling 2001Document40 pagesGPG291 Designer's Guide To The Options For Ventilation and Cooling 2001IppiNo ratings yet

- Laporan Harian WS 34 Dan 15 2021Document2 pagesLaporan Harian WS 34 Dan 15 2021tyok sajaNo ratings yet

- DSC4 BRDocument2 pagesDSC4 BREdilberto Alegato (EPPI)No ratings yet

- Give at Least 10 Advantages Aasdnd 10 Disadvantages of Steel As A Structural MaterialDocument4 pagesGive at Least 10 Advantages Aasdnd 10 Disadvantages of Steel As A Structural MaterialAdvincula Jericson79% (14)