Professional Documents

Culture Documents

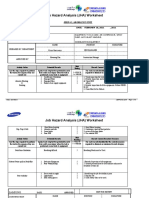

Risk Assessment - In-Situ Lamination in Manhole Systems

Uploaded by

loveson709Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Risk Assessment - In-Situ Lamination in Manhole Systems

Uploaded by

loveson709Copyright:

Available Formats

: :

Lack of knowledge on the

hazards of storing, handling and

application.

Engineer,

Supervisor,

workers

4 4 16 2 1 2

Construction Manager,

Site Engineer

Incompetent supervision Supervisor,

Involved workers

3 4 12 1 1 1 Construction Manager,

Site Engineer

Untrained workers / store

personnel

Involved workers,

Store personnel.

3 4 12 2 1 2 Site Engineer,

Gen.Foreman,.Store

keeper

Keeping / Handling at work

locations.

Store personnel,

Involved workers

3 4 12 2 1 2 Gen.Foreman,Foreman

*ALARP - As Low As Reasonably Practicable

:

Date: 1/2/2014 : Date: :

Signature : : :

Likelihood / Severity /

1 Remote / Minor /

2 Unlikely / Major /

3 Likely / Severe /

4 Frequent / Fatality /

Gen.Foreman.Foreman 12 4 3

Involved

personnel /

Others in the

vicinity

Spillage - Environmental /

hygeinic aspects

Bring only required quantity to work site and keep them protected

from sunlight .Ensure no source of ignition at locations of

application. Ensure No Smoking Rule.

Keep people away from and upwind of spill / leak.

Keep containers closed always. Use drip-trays. Avoid spillage /

entry into drains, sewers and water courses. Avoid subsoil

penetration.

1

Description of work : Installation of GRP Pipes (concrete surround )in microtunnelling 1200mm dia.

Roads and Infrastructure in Bani Hajer North. Phase 1 & 2

06/CGC/HSE/ RA/29 REV. 0

Project Name :

Ref No:

Signature:

Assessed by: Aaron Aaloosi

Refer the MSDS of Epoxy Venyl Ester Resin and Polyster Resin

(attached herewith). Explain hazards to Supervisor, involved

workers. Take all precautions mentioned in MSDS .

Assign competent supervisor having experience in handling and

application of Venyl Ester Resin and Polyster Resin

Select and train concerned workers including store personnel on

the storage, handling and application of Venyl Ester Resin and

Polyster Resin as per the MSDS.

Store below 30C in closed containers.

Store in dark away from oxidizing materials.

Ensure no source of ignition at storage place. Ensure No

Smoking Rule. Prevent unauthorised access to storage.

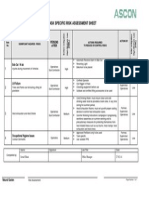

Storage - Flammable,

Decomposition can lead to

release of irritating gases and

vapours.

RISK ASSESSMENT FORM -

Assessment location :

Locations of storm water manholes on site.

:

SR #

Activity

Hazard / Conditions that could

develop hazard

Who Might be

Harmed

Initial Risk

Safety precautions needed to control the Risk to ALARP *

RESIDUAL

RISK

Responsible Person

:

C

o

n

s

e

q

u

e

n

c

e

s

L

i

k

e

l

i

h

o

o

d

/

In-situ Joint Lamination in manhole systems (Benching and cover slabs)

L

i

k

e

l

i

h

o

o

d

R

i

s

k

R

a

t

i

n

g

C

o

n

s

e

q

u

e

n

c

e

s

Date : 1-2-2014

R

i

s

k

R

a

t

i

n

g

Spillage shall be soaked up with inert absorbant such as sand,

Gather into labelled containers and dispose thru' approved waste

disposal contractor.

"

Reviewed by : Mr. Radi Shunnar ( Operations Manager)

1 1

16 2 1 2 Store keeper

Storing,handling and

application of Epoxy

Venyl Ester Resin

(Crystic VE

671) and Polyster

Resin (Crystic 272

E)

1

Store personnel,

Involved workers

4 4

4

3

2

1

16

6

Likelihood

4 3 2 1

12

8

4

12

9

3

8

6

4

2

4

3

2

1

HSEF 4.3.1-01-01 Issue: 1 Rev: 2 Issue Date: 20 Mar 2012 Page 1 of 6

: :

:

Description of work : Installation of GRP Pipes (concrete surround )in microtunnelling 1200mm dia.

Roads and Infrastructure in Bani Hajer North. Phase 1 & 2

06/CGC/HSE/ RA/29 REV. 0

Project Name :

Ref No:

RISK ASSESSMENT FORM -

Assessment location :

Locations of storm water manholes on site.

:

SR #

Activity

Hazard / Conditions that could

develop hazard

Who Might be

Harmed

Initial Risk

Safety precautions needed to control the Risk to ALARP *

RESIDUAL

RISK

Responsible Person

:

C

o

n

s

e

q

u

e

n

c

e

s

L

i

k

e

l

i

h

o

o

d

/

In-situ Joint Lamination in manhole systems (Benching and cover slabs)

L

i

k

e

l

i

h

o

o

d

R

i

s

k

R

a

t

i

n

g

C

o

n

s

e

q

u

e

n

c

e

s

Date : 1-2-2014

R

i

s

k

R

a

t

i

n

g

"

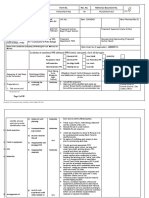

Health hazard - Inhalation -

harmful to internal organs /

functions.

involved workers 3 4 12 1 1 1 Supervisor,Involved

workers

Unknown of First aid measures involved workers 3 4 12 1 1 1 Gen,Foreman,

First sider /Site Nurse

Handling/ applying

strand mats

Dust hazard 3 4 12 1 1 1 Gen.Foreman,Foreman

*ALARP - As Low As Reasonably Practicable

:

Date: 1/2/2014 : Date: :

Signature : : :

Likelihood / Severity /

1 Remote / Minor /

2 Unlikely / Major /

3 Likely / Severe /

4 Frequent / Fatality /

involved workers, 3 4 1 1 Supervisor,

Involved workers

Health hazard - Irritating to skin

and eyes

Storing,handling and

application of Epoxy

Venyl Ester Resin

(Crystic VE 671)

and Polyster Resin

Crystic 272 E

(Contd)

Take of contaminated cloth immediately. Report to First aider and

get medical attention if irritation persists..

Avoid inhalation of vapour / dust. Use heavy duty dust masks to

cover nose and mouth. Avoid drinking, eating while handling VE

Resin and Polyster resin. Advise involved workers to wash hands

and mouth before eating /drinking.

Ensure workers use PVC hand gloves,safety googles, Face

shield, Plastic apron, coverall, safety shoes, helmet. Avoid

contact with skin and eyes.

Explain the First aid measures explained in the MSDS to involved

workers thru' Tool Box Talk. . Keep MSDS in site clinic, store and

work place for referring First aid measures

12

Signature:

Mr. Radi Shunnar ( Operations Manager)

Assessed by: Aaron Aaloosi

VE Resins and Polyster Resins are supposed to be used only in

well ventilated areas as per the MSDS.

Arrange local exhaust ventilation system like exhaust blowers of

suitable evacuation capacity with large dia exhaust hoses

wherever the venilation is not sufficient.

Keep the upstream and down stream manholes open and provide

fresh air supply through them into working manhole.

Lack of ventilation where

applying VE Resin and Polyster

Resin

Reviewed by:

2

1

3 4 12 2 1 Gen.Foreman,Foreman Involved workers

Ensure workers use thick dust masks to cover nose and mouth

,safety googles,cover all,safetyhelmet,safety shoes.

4

3

2

1

16

6

Likelihood

Severity

4 3 2 1

12

8

4

12

9

3

8

6

4

2

4

3

2

1

HSEF 4.3.1-01-01 Issue: 1 Rev: 2 Issue Date: 20 Mar 2012 Page 2 of 6

: :

:

Description of work : Installation of GRP Pipes (concrete surround )in microtunnelling 1200mm dia.

Roads and Infrastructure in Bani Hajer North. Phase 1 & 2

06/CGC/HSE/ RA/29 REV. 0

Project Name :

Ref No:

RISK ASSESSMENT FORM -

Assessment location :

Locations of storm water manholes on site.

:

SR #

Activity

Hazard / Conditions that could

develop hazard

Who Might be

Harmed

Initial Risk

Safety precautions needed to control the Risk to ALARP *

RESIDUAL

RISK

Responsible Person

:

C

o

n

s

e

q

u

e

n

c

e

s

L

i

k

e

l

i

h

o

o

d

/

In-situ Joint Lamination in manhole systems (Benching and cover slabs)

L

i

k

e

l

i

h

o

o

d

R

i

s

k

R

a

t

i

n

g

C

o

n

s

e

q

u

e

n

c

e

s

Date : 1-2-2014

R

i

s

k

R

a

t

i

n

g

"

Access and egress Involved workers 3 4 12 2 1 2 Site Engineer,Supervisor

*ALARP - As Low As Reasonably Practicable

:

Date: 1/2/2014 : Date: :

Signature : : :

Likelihood / Severity /

1 Remote / Minor /

2 Unlikely / Major /

3 Likely / Severe /

4 Frequent / Fatality /

Signature:

Establish a system for communication / signalling between the

Through the established signal, the safe condition of the worker

inside manhole should be checked and ensured at frequent

intervals by the hole watch and supervisor

The worker can convey his status to hole watch thru' lifeline.

Mr. Radi Shunnar ( Operations Manager)

Construction Manager,

Site Engineer,

Gen.Foreman, Foreman

Safety Officer

Lack of Emergency rescue

arrangements

Involved workers 4 4 16 3 1 3

Construction Manager,

Site Engineer,

Gen.Foreman,Foreman

Ensure full time presence of competent Supervision.

Worker inside

manhole

4 4 16 3 1 3

Monitor the work through PTW system for works inside confined

space, ensure precautionary measures as per PTW.

Take gas test,ensure oxygen presence of 21.8 %, no hazardous

gases. Ensure no wastes,contaminations inside.

Worker going inside should wear safety harness which shall be

attached with the lifeline /pulling rope of rescue pulling

equipment. The life line shall be hold by hole-watch and use for

signalling between him and the worker inside manhole.

Assessed by: Aaron Aaloosi

Reviewed by:

Works inside deep

manholes

2 Lack of monitoring Works inside

confined space.

Conduct pre-task talk on hazards and precautions required.

Keep ready emergency rescue equipments such as tripod stand

with pulling equipments. Ensure Self-contained breathing

apparatus available.

Hole watch person trained on emergency rescue should keep

watch outside. Maintain personnel Entry- Exit log. Self-contained

breathing apparatus to be kept ready in place.

Provide safe and seccured access ladder.Ladder should

extended 1 mtr above the groud level.

4

3

2

1

16

6

Likelihood

4 3 2 1

12

8

4

12

9

3

8

6

4

2

4

3

2

1

HSEF 4.3.1-01-01 Issue: 1 Rev: 2 Issue Date: 20 Mar 2012 Page 3 of 6

: :

:

Description of work : Installation of GRP Pipes (concrete surround )in microtunnelling 1200mm dia.

Roads and Infrastructure in Bani Hajer North. Phase 1 & 2

06/CGC/HSE/ RA/29 REV. 0

Project Name :

Ref No:

RISK ASSESSMENT FORM -

Assessment location :

Locations of storm water manholes on site.

:

SR #

Activity

Hazard / Conditions that could

develop hazard

Who Might be

Harmed

Initial Risk

Safety precautions needed to control the Risk to ALARP *

RESIDUAL

RISK

Responsible Person

:

C

o

n

s

e

q

u

e

n

c

e

s

L

i

k

e

l

i

h

o

o

d

/

In-situ Joint Lamination in manhole systems (Benching and cover slabs)

L

i

k

e

l

i

h

o

o

d

R

i

s

k

R

a

t

i

n

g

C

o

n

s

e

q

u

e

n

c

e

s

Date : 1-2-2014

R

i

s

k

R

a

t

i

n

g

"

Assigning untrained workers to

work inside confined

space.(inside manhole)

Worker going

inside manhole.

4 4 16 3 1 3

Site Engineer,

Gen.Foreman,Foreman

3 4 12 3 1 3

Lack of lighting inside manhole-

Poor visibilty to do work , Injuries worker inside

manhole

3 4 12 2 1 2

Site Engineer,

Gen.Foreman,Foreman

*ALARP - As Low As Reasonably Practicable

:

Date: 1/2/2014 : Date: :

Signature : : :

Likelihood / Severity /

1 Remote / Minor /

2 Unlikely / Major /

3 Likely / Severe /

4 Frequent / Fatality /

Air-blowers and air-compressor should be kept on level surfaces

and safe distance away from the edges of manhole.

Ensure safe operating condition of air compressor and

blower.Ensure whip arrestor at air hose end connection

Air hose line inserted into bottom of manhole should be secured

well.It should not obstruct the manhole entrance.

Substandard mounting / unsafe

condition of air blower, air

compressor and air-hose

Lack of air flow / ventilation

inside the manhole

Provide enough light inside the manhole using intrinsically safe /

spark proof lighting at 24 volt.The lighting should be well fixed

inside manhole against undesired hanging / movement and

interference with worker.

Assessed by: Aaron Aaloosi (HSE Manager) Reviewed by : Mr. Radi Shunnar ( Operations Manager)

Signature:

12 2

Provide Air supply through the upstream / down stream manholes

using air blowers. Provide air supply into the bottom of working

manhole at normal pressure, if sufficient air circulation is not

available.

Keep Open the the nearest manholes at upstream and down

stream of the manhole in which work is to be done.

Air supply into manhole is to be provided at a minor/normal

pressure only, monitored thru' control valve referring pressure

guage by an assigned person.

Lamination Works

inside deep

manholes. (contd..)

Only workers trained for working inside confined spaces and on

using of self contained / air-supplied breathing apparatus shall to

work inside the manhole. Explain him the hazards and to give

signal to hole watch on suffering any abnormality.

Worker inside

manhole

3 1 2 Site Engineer,

Gen.Foreman,Foreman.

Site Engineer,

Gen.Foreman.Foreman.

4

4

3

2

1

16

6

Likelihood

4 3 2 1

12

8

4

12

9

3

8

6

4

2

4

3

2

1

HSEF 4.3.1-01-01 Issue: 1 Rev: 2 Issue Date: 20 Mar 2012 Page 4 of 6

: :

:

Description of work : Installation of GRP Pipes (concrete surround )in microtunnelling 1200mm dia.

Roads and Infrastructure in Bani Hajer North. Phase 1 & 2

06/CGC/HSE/ RA/29 REV. 0

Project Name :

Ref No:

RISK ASSESSMENT FORM -

Assessment location :

Locations of storm water manholes on site.

:

SR #

Activity

Hazard / Conditions that could

develop hazard

Who Might be

Harmed

Initial Risk

Safety precautions needed to control the Risk to ALARP *

RESIDUAL

RISK

Responsible Person

:

C

o

n

s

e

q

u

e

n

c

e

s

L

i

k

e

l

i

h

o

o

d

/

In-situ Joint Lamination in manhole systems (Benching and cover slabs)

L

i

k

e

l

i

h

o

o

d

R

i

s

k

R

a

t

i

n

g

C

o

n

s

e

q

u

e

n

c

e

s

Date : 1-2-2014

R

i

s

k

R

a

t

i

n

g

"

*ALARP - As Low As Reasonably Practicable

:

Date: : 1/2/2014 : Date: :

Signature : : :

Likelihood / Severity /

1 Remote / Minor /

2 Unlikely / Major /

3 Likely / Severe /

4 Frequent / Fatality /

Possibility of accumulation of

vapours of Epoxy Venyl Ester

Resin and Polyster Resin while

applying them on manhole

internal surfaces.

Worker inside

manhole

Assessed by: Aaron Aaloosi (HSE Manager)

Use exhaust blowers to evacuate the vapour that may

accumulate inside manhole while applying mortar and paint.

Take gas test frequently to ensure safe conditions inside.

Ensure rotation of workers to minimise duration of exposure.

If accumulation of epoxy vapour observed during work , the

worker should be called out immediately. Resume work only after

ensuring full evacuation of vapour and ensuring safe conditions

by taking gas test.

4 3 12 3

Reviewed by : Mr. Radi Shunnar ( Operations Manager)

Signature:

Using breathing apparatus to

work inside manhole.

Involved workers 4 4 3

Safe condition of the worker should be ensured frequently by

hole- watch through the signalling system (thru' lifeline)

established between the hole watch and the worker inside.

Rescue equipments ( Tripod stand with pulley / lifting equipment)

should be kept ready with the life line attached to it to lift / rescue

the person in case of emergency. Competent supervisor and

persons trained on rescue operation should be present on site

during the work.

Duration of work using self contained breathing apparatus should

be limited to 20% less than than the time prescribed for using the

air cylinder by the supplier. Ensure the worker is well- trained on

using breathing apparatus.

1 3 Site Engineer,

Gen.Foreman,Foreman..

1 3 Site Engineer,

Gen.Foreman,Foreman..

Lamination Works

inside deep

manholes. (contd..)

16 Work using breathing apparatus should be done only if it is a

must to complete the initiated task due to technical reasons.

4

3

2

1

16

6

Likelihood

4 3 2 1

12

8

4

12

9

3

8

6

4

2

4

3

2

1

HSEF 4.3.1-01-01 Issue: 1 Rev: 2 Issue Date: 20 Mar 2012 Page 5 of 6

: :

:

Description of work : Installation of GRP Pipes (concrete surround )in microtunnelling 1200mm dia.

Roads and Infrastructure in Bani Hajer North. Phase 1 & 2

06/CGC/HSE/ RA/29 REV. 0

Project Name :

Ref No:

RISK ASSESSMENT FORM -

Assessment location :

Locations of storm water manholes on site.

:

SR #

Activity

Hazard / Conditions that could

develop hazard

Who Might be

Harmed

Initial Risk

Safety precautions needed to control the Risk to ALARP *

RESIDUAL

RISK

Responsible Person

:

C

o

n

s

e

q

u

e

n

c

e

s

L

i

k

e

l

i

h

o

o

d

/

In-situ Joint Lamination in manhole systems (Benching and cover slabs)

L

i

k

e

l

i

h

o

o

d

R

i

s

k

R

a

t

i

n

g

C

o

n

s

e

q

u

e

n

c

e

s

Date : 1-2-2014

R

i

s

k

R

a

t

i

n

g

"

Working inside

manhole (contd..)

Continuos work inside by a

single worker - Fatigue,Heat

stress etc.

Workers who

work inside

manhole

3 4 12 2 1 2 Site Engineer,

Gen.Foreman,Foreman.

Generation of spark / fore inside

manhole

Involved workers 4 4 16 3 1 3

Site Engineer,

Gen.Foreman,Foreman.

Unsafe grinder machine

Involved workers 3 4 12 1 1 1 Gen.Foreman, Foreman

*ALARP - As Low As Reasonably Practicable

:

Date: 1/2/2014 : Date: :

Signature : : :

Likelihood / Severity /

1 Remote / Minor /

2 Unlikely / Major /

3 Likely / Severe /

4 Frequent / Fatality /

Evacuate dust from manhole by exhaust blower.

Grinding work shall be done thru' hotwork permit only. Take gas

test and ensure no flammable gases present inside the manhole.

Check whether grinding shall be replaced with abrading using

rough emery paper.

Site Engineer,

Gen.Foreman,Foreman.

Provide rotation between trained workers to work inside the

manhole;so that they get intervals for rest,coming out to open air

to cool down their body and to breathe fresh air . Ensure

washing water and drinking water at work place

3 4 12

Assessed by: Aaron Aaloosi (HSE Manager) Reviewed by : Mr. Radi Shunnar ( Operations Manager)

Ensure generator is mounted on level ground at safe distance

from manhole entrance,safe and secured cables, spark proof

switches. Use industrial connectors.

Power supply for

lighting inside

manhole and water

pump.

Involved workers 2

Ensure presence of electrician at work location to ensure

interrupted lighting inside manhole and electrical safety.

Substandard mounting of

Generator on site / it's Unsafe

condition - Interruption of lighting

inside manhole / power supply,

overturning of generator,

damages, Injuries.

Signature:

Ensure the grinder have safety guard, proper grinding wheels.

Ensure the worker use dust mask, safety googles, face cover,

helmet,disposable cover all, helmet and safety shoes.

Rotate workers to prevent continuos exposure to dust / stress

Cable to manhole should be fixed with clamp so that it will not

interfere with workers manhole entrance and inside.

1 2

Site Engineer,

Gen.Foreman,Foreman

1 1 1

4

3

Grinding works to

abrade the surfaces

for lamination

Involved workers 3 4 12 Dust emission, Heat stress

4

3

2

1

16

6

Likelihood

4 3 2 1

12

8

4

12

9

3

8

6

4

2

4

3

2

1

HSEF 4.3.1-01-01 Issue: 1 Rev: 2 Issue Date: 20 Mar 2012 Page 6 of 6

8

HSEF 4.3.1-01-01 Issue: 1 Rev: 2 Issue Date: 20 Mar 2012 Page 7 of 6

8

HSEF 4.3.1-01-01 Issue: 1 Rev: 2 Issue Date: 20 Mar 2012 Page 8 of 6

8

HSEF 4.3.1-01-01 Issue: 1 Rev: 2 Issue Date: 20 Mar 2012 Page 9 of 6

8

HSEF 4.3.1-01-01 Issue: 1 Rev: 2 Issue Date: 20 Mar 2012 Page 10 of 6

8

HSEF 4.3.1-01-01 Issue: 1 Rev: 2 Issue Date: 20 Mar 2012 Page 11 of 6

8

HSEF 4.3.1-01-01 Issue: 1 Rev: 2 Issue Date: 20 Mar 2012 Page 12 of 6

You might also like

- Risk Assessment - Removing Existing Septic Tank and Connection of Live Foul Sewer To ManholeDocument14 pagesRisk Assessment - Removing Existing Septic Tank and Connection of Live Foul Sewer To Manholeloveson70971% (7)

- Risk Assessment - Erection of Temporary Shoring System at Valve Chamber No. 1 & No. 2rev1.1Document14 pagesRisk Assessment - Erection of Temporary Shoring System at Valve Chamber No. 1 & No. 2rev1.1Pang Lee ChingNo ratings yet

- Hazard Identification and Risk Assessment For Pipe LoweringDocument4 pagesHazard Identification and Risk Assessment For Pipe LoweringAchalere Shekhar Kashinath67% (3)

- Job Hazard Analysis (JHA) Worksheet: Sungchang & Al-Shaikh Contracting Co.,LtdDocument3 pagesJob Hazard Analysis (JHA) Worksheet: Sungchang & Al-Shaikh Contracting Co.,LtdTeodoro EsquilloNo ratings yet

- Job Hazard Analysis: IP-OPS-066Document9 pagesJob Hazard Analysis: IP-OPS-066ananthu.uNo ratings yet

- Safe Working Procedure: Thermoplastic Road MarkingsDocument1 pageSafe Working Procedure: Thermoplastic Road MarkingsABHINAV MISHAL100% (2)

- RA For Man Lift OperationDocument6 pagesRA For Man Lift Operationalla malikNo ratings yet

- Risk Assessment For Installation of BalustradeDocument6 pagesRisk Assessment For Installation of Balustradevictor100% (1)

- Risk Assessment For Repair of ManholeDocument5 pagesRisk Assessment For Repair of Manholeflmm09No ratings yet

- Wall Painting Risk AssesmentDocument3 pagesWall Painting Risk AssesmentJacob ChirayilNo ratings yet

- Hazard Identification Plan HIP HaradhDocument28 pagesHazard Identification Plan HIP HaradhBNCHNo ratings yet

- Risk Assessment For Hot WorksDocument4 pagesRisk Assessment For Hot Workseldho100% (1)

- JSA Demolish Existing Concrete Foundation EDGDocument1 pageJSA Demolish Existing Concrete Foundation EDGWidya PrasetyaNo ratings yet

- Task-Based Risk Assessment Painting WorksDocument6 pagesTask-Based Risk Assessment Painting Worksvinodhyper100% (2)

- Risk Assesment of Brick & Block WorkDocument40 pagesRisk Assesment of Brick & Block WorkGyanendra Srivastava0% (2)

- Risk Asses 65-Piping Fabricated and Assembly - H03Document11 pagesRisk Asses 65-Piping Fabricated and Assembly - H03Rochdi BahiriNo ratings yet

- Risk Assessment Form - Painting - BlastingDocument3 pagesRisk Assessment Form - Painting - BlastingIndermohan MehtaNo ratings yet

- Hse Plan SummaryDocument3 pagesHse Plan SummaryMohamed Hadjkacem75% (4)

- Soft Landscaping Risk Assessment SheetDocument1 pageSoft Landscaping Risk Assessment SheetMuhammad Ibrahim100% (3)

- Jsa Tank CleaningDocument5 pagesJsa Tank CleaningASLAM MULANINo ratings yet

- INSTALLATION OF Toilet Cubicle PartitionDocument4 pagesINSTALLATION OF Toilet Cubicle PartitionLeo Pascual100% (1)

- JSA For Diesel Filling at Del CampDocument6 pagesJSA For Diesel Filling at Del CampMohammed Ali QaziNo ratings yet

- Confined Space Entry For Painting Inside PontoonDocument4 pagesConfined Space Entry For Painting Inside PontoonAchalere Shekhar KashinathNo ratings yet

- RA Equipment MobilizationDocument1 pageRA Equipment MobilizationSn Ahsan100% (1)

- JHA Cutting of Asphalt Road For Replacement of Protection SlabsDocument5 pagesJHA Cutting of Asphalt Road For Replacement of Protection SlabsNasrullah JanNo ratings yet

- JSA - Foam RefillingDocument13 pagesJSA - Foam RefillingMuhammad Umar GondalNo ratings yet

- Cont HSE Alignment Kickoff Meeting F0228Document2 pagesCont HSE Alignment Kickoff Meeting F0228NAGARJUNA75% (4)

- Fabrication Work Risk AssessmentDocument11 pagesFabrication Work Risk Assessmentstansilous100% (1)

- 015 Risk Assessment - Painting WorksDocument5 pages015 Risk Assessment - Painting WorksVipul Shankar91% (11)

- Risk Assessment Leak SealingDocument5 pagesRisk Assessment Leak Sealingvictor100% (2)

- Method Statement For Interfacing With The Tarping & De-Tarping Station of 021-c13 Ver.00Document6 pagesMethod Statement For Interfacing With The Tarping & De-Tarping Station of 021-c13 Ver.00bryanNo ratings yet

- Sika Saudi Arabia: Safety Data SheetDocument4 pagesSika Saudi Arabia: Safety Data Sheetusman khalid100% (1)

- Risk Assessment For Tank BaseDocument5 pagesRisk Assessment For Tank Baseramod100% (2)

- Risk Assess Plastering 2006 Tcm17 26368Document2 pagesRisk Assess Plastering 2006 Tcm17 26368Anonymous QGHbz92uNo ratings yet

- Risk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)Document3 pagesRisk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)nsadnan0% (1)

- Risk Assessment For Manhole and ChamberDocument9 pagesRisk Assessment For Manhole and Chamberrahul60% (10)

- Risk Assessment Template For Combo Roof Waterproofing Work.Document14 pagesRisk Assessment Template For Combo Roof Waterproofing Work.Majaga MabhenaNo ratings yet

- SINOPEC JSA For HDPE PIPE & ACCESSORIES INSTALLATIONDocument12 pagesSINOPEC JSA For HDPE PIPE & ACCESSORIES INSTALLATIONtusharDJNo ratings yet

- Parking Area HIRADocument22 pagesParking Area HIRASafety DeptNo ratings yet

- Job Safety Analysis - Clinker StorageDocument4 pagesJob Safety Analysis - Clinker StorageMohammed MinhajNo ratings yet

- DM-PH&SD-P4-TG04 - (Guidelines For Entry Into Confined Spaces) PDFDocument3 pagesDM-PH&SD-P4-TG04 - (Guidelines For Entry Into Confined Spaces) PDFdemie figueroa100% (1)

- RMDJV Pj74 Hiradc Misc 01 (Housekeeping)Document2 pagesRMDJV Pj74 Hiradc Misc 01 (Housekeeping)myn maliQueNo ratings yet

- Job Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00Document6 pagesJob Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00poovazhaganNo ratings yet

- Risk Assessment For Confined Space Day and Night-1Document6 pagesRisk Assessment For Confined Space Day and Night-1balasubramaniam100% (1)

- DR - Rescue Plan Water Tank Cleaning (002) Rev-With LayoutDocument4 pagesDR - Rescue Plan Water Tank Cleaning (002) Rev-With LayoutSachin DharneNo ratings yet

- Anchor Bolt Setting - Rev 01Document26 pagesAnchor Bolt Setting - Rev 01Geherson AbustanNo ratings yet

- Risk Assessment For Aluminium Handrail InstallationDocument5 pagesRisk Assessment For Aluminium Handrail InstallationKalid Jmal100% (1)

- Material Safety Data Sheet: National Plastic EmulsionDocument2 pagesMaterial Safety Data Sheet: National Plastic EmulsionJHUPEL ABARIAL100% (4)

- JSA Manual Excavation and Cable LayingDocument3 pagesJSA Manual Excavation and Cable Layingimran100% (1)

- Risk Analisis Ramming WorksDocument2 pagesRisk Analisis Ramming Worksdefidmsp39No ratings yet

- JSA For Excavation of Fiber Optical Cable WR-501 To WR-617 Community To Petro Rabigh......Document15 pagesJSA For Excavation of Fiber Optical Cable WR-501 To WR-617 Community To Petro Rabigh......Habib ur rahmanNo ratings yet

- Procedure For Working at Walkable False CeilingDocument2 pagesProcedure For Working at Walkable False Ceilingsai krishna50% (2)

- RA Templates PipingDocument28 pagesRA Templates Pipingkla_alkNo ratings yet

- (EDIT) F-SAF-0046.11 Bolt Torquing Risk Assessment (Generic)Document10 pages(EDIT) F-SAF-0046.11 Bolt Torquing Risk Assessment (Generic)ainun mardiah75% (4)

- Material Safety Data Sheet: 1-IdentificationDocument3 pagesMaterial Safety Data Sheet: 1-IdentificationKhaled Anwar100% (1)

- Risk Assessment - Backfilling Around Foul Sewer and Storm Warter ManholesDocument6 pagesRisk Assessment - Backfilling Around Foul Sewer and Storm Warter Manholesloveson70950% (2)

- Safe WorkingDocument142 pagesSafe Workingrizonico0% (1)

- RA For High Pressure Cleaning Using HPCE 520-330Document3 pagesRA For High Pressure Cleaning Using HPCE 520-330George CristianNo ratings yet

- JHA For Radiography - Rev.01Document7 pagesJHA For Radiography - Rev.01Sreekumar100% (3)

- Method Statement For MpsDocument14 pagesMethod Statement For MpsAhmed NasserNo ratings yet

- App-16.2 - Risk Assessment For Vermeer Axis WorksDocument13 pagesApp-16.2 - Risk Assessment For Vermeer Axis Worksloveson709No ratings yet

- App-16.2 - RISK ASSESSMENT For Construction of in Situ Foundation & Installation of Package Substation.Document15 pagesApp-16.2 - RISK ASSESSMENT For Construction of in Situ Foundation & Installation of Package Substation.loveson709100% (2)

- Emergency Rescue Plan For Operatives Working at HeightDocument9 pagesEmergency Rescue Plan For Operatives Working at Heightloveson709100% (1)

- App-16.2 - RISK ASSESSMENT For In-Situ Manhole Construction in Al Wukair RoadDocument15 pagesApp-16.2 - RISK ASSESSMENT For In-Situ Manhole Construction in Al Wukair Roadloveson709No ratings yet

- App-16.2 - Risk Assessment For Traffic Signal SystemDocument13 pagesApp-16.2 - Risk Assessment For Traffic Signal Systemloveson709100% (2)

- Near Miss Report: Complete This Form and Email It ToDocument1 pageNear Miss Report: Complete This Form and Email It Toloveson709No ratings yet

- Emergency Rescue Plan For Operatives Working at HeightDocument9 pagesEmergency Rescue Plan For Operatives Working at Heightloveson709100% (1)

- INV Inv Ass Form TemplateDocument4 pagesINV Inv Ass Form Templateloveson70950% (2)

- Assmt 1 Incident PhotosDocument3 pagesAssmt 1 Incident Photosloveson709No ratings yet

- SCOPE:: Sacyr Medgulf Hse Management Systems Manual Crane Lift ProcedureDocument10 pagesSCOPE:: Sacyr Medgulf Hse Management Systems Manual Crane Lift Procedureloveson709100% (1)

- HSE Department Demobilization List: Trade May 2016Document1 pageHSE Department Demobilization List: Trade May 2016loveson709No ratings yet

- 3.1 SAMG-JV Emergency PreparednessResponse REV 00Document24 pages3.1 SAMG-JV Emergency PreparednessResponse REV 00loveson709100% (1)

- 3.1 SAMG-JV Emergency PreparednessResponse REV 00Document24 pages3.1 SAMG-JV Emergency PreparednessResponse REV 00loveson709100% (1)

- Incident Checklist: Other ActionsDocument1 pageIncident Checklist: Other Actionsloveson709No ratings yet

- Maintenance Log - TemplateDocument2 pagesMaintenance Log - Templateloveson709No ratings yet

- Yam Bahadur Budha CV PDFDocument2 pagesYam Bahadur Budha CV PDFloveson709No ratings yet

- RA082-C Grinding - ThornliebankDocument2 pagesRA082-C Grinding - Thornliebankloveson709No ratings yet

- INV Action Plan TemplateDocument2 pagesINV Action Plan Templateloveson709No ratings yet

- N.Selvam:, BE (Mechanical)Document2 pagesN.Selvam:, BE (Mechanical)loveson709No ratings yet

- Scaffold Erector Ram Sunar Yadav: PO Box 92986, Doha, Qatar Mob: 33428557Document2 pagesScaffold Erector Ram Sunar Yadav: PO Box 92986, Doha, Qatar Mob: 33428557loveson709No ratings yet

- Scaffold Erector Hiralal Mandal: PO Box 92986, Doha, Qatar Mob: 33428557Document2 pagesScaffold Erector Hiralal Mandal: PO Box 92986, Doha, Qatar Mob: 33428557loveson709No ratings yet

- 005 Ohs-Cop-Starrt & JhaDocument10 pages005 Ohs-Cop-Starrt & Jhaloveson709No ratings yet

- Board Reqd From AlkheesaDocument1 pageBoard Reqd From Alkheesaloveson709No ratings yet

- Loveson Glariyans: (Address, City, ST ZIP Code)Document2 pagesLoveson Glariyans: (Address, City, ST ZIP Code)loveson709No ratings yet

- Po Ak-00076 - MR 534Document1 pagePo Ak-00076 - MR 534loveson709No ratings yet

- PMC-FM-HSS-024 Near Miss ReportDocument1 pagePMC-FM-HSS-024 Near Miss Reportloveson709No ratings yet

- HSE Department Demobilization List: Trade May 2016Document1 pageHSE Department Demobilization List: Trade May 2016loveson709No ratings yet

- Epoxy COSHHDocument3 pagesEpoxy COSHHloveson709No ratings yet

- Loveson Resume HSE ManagerDocument7 pagesLoveson Resume HSE Managerloveson709No ratings yet

- QDC No ObjectionDocument1 pageQDC No Objectionloveson70950% (2)

- Cat ELC (Extended Life Coolant) ExtenderDocument8 pagesCat ELC (Extended Life Coolant) Extenderharikrishnanpd3327No ratings yet

- Aerrane Sojourn - MSDS PDFDocument7 pagesAerrane Sojourn - MSDS PDFSartika SapuletteNo ratings yet

- MSDS Zetag 8125 PDFDocument8 pagesMSDS Zetag 8125 PDFBhuvnesh SinghNo ratings yet

- MSDS - SteviaDocument5 pagesMSDS - SteviaAlyssa DuenasNo ratings yet

- Saudi Industrial Resins Limited: HETRON 922Document3 pagesSaudi Industrial Resins Limited: HETRON 922Amir QayyumNo ratings yet

- Uop 41Document2 pagesUop 41Julio Rivero100% (1)

- Msds Grease NesteDocument7 pagesMsds Grease NestejofNo ratings yet

- SDS US - UVEX Fog Eliminator ClothDocument6 pagesSDS US - UVEX Fog Eliminator ClothRaul RodriguezNo ratings yet

- Nalco 72310 SDSDocument9 pagesNalco 72310 SDSWaseem SyedNo ratings yet

- MSDS Duct SealantDocument6 pagesMSDS Duct SealantbuddhikasatNo ratings yet

- Kevlar MSDSDocument5 pagesKevlar MSDSsoumsarkar1No ratings yet

- SAFETY DATA SHEET - Butan 50 % LEL PDFDocument9 pagesSAFETY DATA SHEET - Butan 50 % LEL PDFRodrigues963No ratings yet

- Freon 12Document7 pagesFreon 12JodyNo ratings yet

- SolventsDocument22 pagesSolventsNadya HartasiwiNo ratings yet

- Ax SeriesDocument48 pagesAx Seriesradn23No ratings yet

- SD65075 - Swellseal 3V - (GB)Document6 pagesSD65075 - Swellseal 3V - (GB)nlmiNo ratings yet

- Lip BalmDocument3 pagesLip BalmĐạt Lại Phùng QuốcNo ratings yet

- Test HseDocument35 pagesTest Hseelmosawida100% (2)

- Haa149Document10 pagesHaa149dadi hartonoNo ratings yet

- 420-8 Toolbox Safety Meeting Form TemplateDocument2 pages420-8 Toolbox Safety Meeting Form Templatematt ridwanNo ratings yet

- Finish Powerball Quantum Ultimate Pro DishwashingDocument10 pagesFinish Powerball Quantum Ultimate Pro DishwashingCatalin DonceaNo ratings yet

- FP528 Instruction Manual V1.4x September 2018 200-626Document336 pagesFP528 Instruction Manual V1.4x September 2018 200-626Javier Eduardo Penagos VazquezNo ratings yet

- Smoke Flavour: Safety Data SheetDocument14 pagesSmoke Flavour: Safety Data SheetMalak BattahNo ratings yet

- EZ1001 Series - Aluminium: Method and Reagent Sheets 02/2019, Edition 3Document7 pagesEZ1001 Series - Aluminium: Method and Reagent Sheets 02/2019, Edition 3Anonymous owMJ21JRzCNo ratings yet

- Hydriodic Acid MSDSDocument5 pagesHydriodic Acid MSDSomkarchemicalsNo ratings yet

- Contractor Safety Evaluation Checklist: WHS Contractors Management ProcedureDocument1 pageContractor Safety Evaluation Checklist: WHS Contractors Management ProcedureMithileshNo ratings yet

- Safety Data Sheet Hydrogen Peroxide 50% Oxypure®: 1. Product and Company IdentificationDocument9 pagesSafety Data Sheet Hydrogen Peroxide 50% Oxypure®: 1. Product and Company Identificationwahyuni putriNo ratings yet

- Safety Data Sheet: 1. Product and Company IdentificationDocument7 pagesSafety Data Sheet: 1. Product and Company IdentificationshoyebNo ratings yet

- FINAL - FunctionalTrendsInArchCoatingsDocument60 pagesFINAL - FunctionalTrendsInArchCoatingsCHIRE SARAYASI MANUELNo ratings yet

- 3M Re Ective Graphic Film Scotchlite: Series 680 680-10Document8 pages3M Re Ective Graphic Film Scotchlite: Series 680 680-10Ngô Mạnh TiếnNo ratings yet