Professional Documents

Culture Documents

LVDT Lab Manual

Uploaded by

guruabhay100%(2)100% found this document useful (2 votes)

2K views3 pagesinstrumentation

Original Title

lvdt lab manual

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentinstrumentation

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

100%(2)100% found this document useful (2 votes)

2K views3 pagesLVDT Lab Manual

Uploaded by

guruabhayinstrumentation

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

EXPERIMENT-6

Aim: To study the working of a linear variable differential transformer (LVDT).

Apparatus: LVDT Trainer kit, Multimeter etc.

Theory: Linear Variable Differential Transformer (LVDT) as the name suggests is a type of

transducer which uses the difference of the output of two windings as a resultant output to

indicate the unit of parameter to be measured. A typical LVDT is shown in fig.

A soft iron core provides the magnetic coupling between a primary coil and two secondary coils,

connected in series opposition. When the core is central and both secondaries are identical, the

voltage across them is equal in magnitude. However, the output is zero as both the secondaries

are in series oppositions. As the core moves up or down, the induced voltage of one secondary

coil increases while that of the other decreases. The output voltage, which is modulated, is the

difference of the two, since secondaries are in opposition. The output is proportional to the

displacement of the iron core. The device is very sensitive and is linear over a wide range of

motion.

The input voltage applied to LVDT is limited by the current carrying ability of the primary coil.

In most applications, LVDT sensitivities are great enough so that very conservative ratings can

be applied. Many commonly used transformers are made to operate on 2KHz frequency at 5V

peak to peak.

Higher frequencies provide increased sensitivity. However in order to maintain linearity, design

differences, primary core length may be required for different frequencies: and in general, a

given LVDT is designed for a specific input frequency.

Exciting frequency sometimes referred as carrier frequency limits the dynamic response of a

transformer.

Transformer sensitivity is usually stated in terms of mV output per volt input per 0.001 in core

displacement. It is directly proportional to exciting voltage and output also increases with

frequency. Of course the output also depends on LVDT design, and in general, the sensitivity

will increases with increased number of turns on the coils. There is a limit, however, determined

by the solenoid effect on the core. In many applications this effect must be minimized; hence

design of the general purpose LVDT is the result of compromise.

Solenoid or axial force exerted by the core is zero when the core is centered and increases

linearly with displacement.

General LVDT assembly

Description of hardware:

The Block diagram of the Trainer is shown below for your reference.

In the present LVDT Trainer, a frequency of 5KHz is generated with maximum voltage of 2

volts as output and is fed to the LVDT. The output of the LVDT is fed to an amplifier and is

amplified by a gain of 100 to bring the output voltage level in the order of volts. The offset is

adjusted in such a way that the output of the amplifier is zero when the core is in the center.

A micrometer gage is fixed in such a way that the 15mm reading of the micrometer is indicated

by zero of the amplifier.

The LVDT used here is a spring loaded. When the micrometer is rotated clockwise, the core is

moved inside the transformer. The current flowing through the two windings changes and the

difference of the two is amplified, rectified and displayed on the digital meter.

As the micrometer is moved to a level of 0mm of reading of displacement, the output is

maximum.

Procedure:

1) Switch on the power of the system.

2) Ensure that the micrometer setting is at 15 mm of reading. If it is not, then rotate in clockwise

or anti clockwise to bring it back to that position.

3) Note that the display shows approximately zero reading.

4) Rotate the micrometer clockwise by about 2 mm and see the reading. Note it down.

5) Rotate the micrometer further to about 5 mm position, and again note the reading of the

display.

6) You will see that the change in the displacement of the core through micrometer is producing

a proportional change in the meter reading.

7) Rotate the micrometer to zero position and note that the output displayed is 15.

8) Use an oscilloscope to see the input to the LVDT, the output waveform of the LVDT and the

rectified DC output of the amplifier. See the output waveform of the LVDT during clockwise

and anti clockwise rotation.

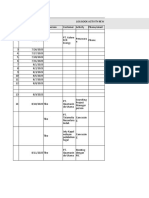

Observation Table

S. No. DISPLACEMENT (mm) OUTPUT VOLTAGE (volts)

Result:

Precautions:

1) Handle the lab equipments carefully.

2) Reading should be taken carefully.

3) Proper switch OFF the equipments after using.

You might also like

- Engineering Workshop Notes Viva Questions PDFDocument12 pagesEngineering Workshop Notes Viva Questions PDFMbogi TokaNo ratings yet

- Electrical Actuation SystemDocument8 pagesElectrical Actuation SystemShriyash KamatNo ratings yet

- Structural Steel Properties and TestingDocument11 pagesStructural Steel Properties and TestingRushikesh ChevaleNo ratings yet

- Self Generating SensorsDocument23 pagesSelf Generating SensorsVhan DarshNo ratings yet

- Developments in Electric Power Supply Configurations For Electrical-Discharge-Machining (EDM)Document6 pagesDevelopments in Electric Power Supply Configurations For Electrical-Discharge-Machining (EDM)فایلجو پروژه و مقالهNo ratings yet

- Excitation Phenomena in Transformers Excitation Phenomena With Out HysteresisDocument2 pagesExcitation Phenomena in Transformers Excitation Phenomena With Out Hysteresism_mustaqeem100% (1)

- ACD Lab Manual Spur Gear DesignDocument4 pagesACD Lab Manual Spur Gear Designbalaguru780% (1)

- KINEMATICS OF MACHINERY: UNIT 2: VELOCITY & ACCELARATION: Objective Questions From Gate With SolutionsDocument7 pagesKINEMATICS OF MACHINERY: UNIT 2: VELOCITY & ACCELARATION: Objective Questions From Gate With SolutionsVenkateswar Reddy MallepallyNo ratings yet

- Brushless DC MotorDocument3 pagesBrushless DC MotorSourav KumarNo ratings yet

- Welding Notes RTU KotaDocument65 pagesWelding Notes RTU KotaKushagra JainNo ratings yet

- Unit 5 Cad StandardsDocument57 pagesUnit 5 Cad StandardsArun K K100% (1)

- Assignment 2 Fluctuating LoadDocument3 pagesAssignment 2 Fluctuating Loadabhishek chaurasiyaNo ratings yet

- Cad Cam Lab Co PoDocument3 pagesCad Cam Lab Co PoRammohan ReddyNo ratings yet

- Electrical Engineering Lab Manual For II Mech Part IDocument54 pagesElectrical Engineering Lab Manual For II Mech Part IArivumani80% (5)

- Fuzzy Logic Control of Three Phase Induction Motor: A ReviewDocument3 pagesFuzzy Logic Control of Three Phase Induction Motor: A ReviewInternational Journal of Innovative Science and Research Technology100% (1)

- 3 Point StarterDocument6 pages3 Point StartersuryavigneNo ratings yet

- Summing AmplifierDocument6 pagesSumming AmplifierAhmed ShaabanNo ratings yet

- 8 MC StructureDocument26 pages8 MC StructureNitesh KumarNo ratings yet

- 1.0 Job/Experiment No.: Me594/05 2.0 NAME OF EXPERIMENT: Angle Measurement Using Sine Bar & SlipDocument6 pages1.0 Job/Experiment No.: Me594/05 2.0 NAME OF EXPERIMENT: Angle Measurement Using Sine Bar & SlipHimanshu Vasistha0% (1)

- 9032 Experiment 01Document13 pages9032 Experiment 01Satish KaradeNo ratings yet

- Moving Iron InsturmentsDocument3 pagesMoving Iron InsturmentsYash BansalNo ratings yet

- ME2405 Mechatronics Lab ManualDocument55 pagesME2405 Mechatronics Lab ManualThusith Wijayawardena50% (4)

- Ee2259 - Electrical Machines I LaboratoryDocument48 pagesEe2259 - Electrical Machines I LaboratoryswathianandaraoNo ratings yet

- 360 Topic 6 DC MachineDocument33 pages360 Topic 6 DC MachineAchsan ArfandiNo ratings yet

- 3 PH Induction Motor IntroductionDocument37 pages3 PH Induction Motor IntroductionNaga Raju AngajalaNo ratings yet

- Linear Variable Differential Transformer (LVDT)Document5 pagesLinear Variable Differential Transformer (LVDT)nikitaNo ratings yet

- Measurements and Instrumentation Question BankDocument4 pagesMeasurements and Instrumentation Question BankSurya SekaranNo ratings yet

- Basic Fuse Terminology: Fuse: Fuse Elements: Rated Current: Fusing Current: Fusing FactorDocument3 pagesBasic Fuse Terminology: Fuse: Fuse Elements: Rated Current: Fusing Current: Fusing FactorPralay RoyNo ratings yet

- Dual Variable Power SupplyDocument13 pagesDual Variable Power SupplyMayank SainiNo ratings yet

- Vibration Assisted EDMDocument13 pagesVibration Assisted EDMSanjay KumarNo ratings yet

- Magneto Optic CurrentDocument20 pagesMagneto Optic Currentjsrilakshmi4272No ratings yet

- Lecture 8 PDFDocument12 pagesLecture 8 PDFBelayneh Tadesse100% (1)

- 17ee82 - Ida - Mod 3 NotesDocument38 pages17ee82 - Ida - Mod 3 NotesManish Kumar SahaniNo ratings yet

- Practical 10 - Shear CentreDocument4 pagesPractical 10 - Shear CentreTbyTanNo ratings yet

- Design and Construction of A 2000W Inverter: Lawal Sodiq Olamilekan 03191100Document20 pagesDesign and Construction of A 2000W Inverter: Lawal Sodiq Olamilekan 03191100Da Saint100% (1)

- Form Measurement: Unit 3Document68 pagesForm Measurement: Unit 3Rama SamyNo ratings yet

- Torsion Testing MachineDocument5 pagesTorsion Testing Machinegosaye desalegnNo ratings yet

- Mechatronics - 302050: Lecture Notes / PPT Unit IDocument66 pagesMechatronics - 302050: Lecture Notes / PPT Unit ISwapvaibNo ratings yet

- Chapter 3 - Principles of Arc WeldingDocument32 pagesChapter 3 - Principles of Arc Weldingsipi maseleNo ratings yet

- Force and Torque MeasurementsDocument30 pagesForce and Torque MeasurementsArunabha Datta100% (3)

- ECDMDocument9 pagesECDMRobert NayakNo ratings yet

- ForgingDocument38 pagesForgingapi-26546070No ratings yet

- Solved Problems (1) Draw The Cam Profile For Following ConditionsDocument6 pagesSolved Problems (1) Draw The Cam Profile For Following Conditionsrakesh kumarNo ratings yet

- Straight Twist JointDocument3 pagesStraight Twist JointavanifbNo ratings yet

- Em 1 TestingDocument13 pagesEm 1 TestingAravindNo ratings yet

- Auto TransformerDocument9 pagesAuto TransformershathaNo ratings yet

- Presentation On Intstrumentation & Control Included Topics:-Deflection & Null Type InstrumentsDocument18 pagesPresentation On Intstrumentation & Control Included Topics:-Deflection & Null Type InstrumentsAakash ahujaNo ratings yet

- ME8491 Engineering Metallurgy COURSE PLANDocument4 pagesME8491 Engineering Metallurgy COURSE PLANKarthick NNo ratings yet

- SeminarDocument29 pagesSeminarMohan UrsNo ratings yet

- DCMTDocument37 pagesDCMTGloria HolcombNo ratings yet

- Inductive Transducers: Instructor: DR Alivelu M ParimiDocument26 pagesInductive Transducers: Instructor: DR Alivelu M ParimiSaketh DahagamNo ratings yet

- Variable Displacement Transformer, TransducerDocument3 pagesVariable Displacement Transformer, TransducerArunNo ratings yet

- Aim of The Experiment: Linear Variable Differential TransformerDocument20 pagesAim of The Experiment: Linear Variable Differential TransformerAryan BatraNo ratings yet

- LVDT ManualDocument7 pagesLVDT ManualShankar ArunmozhiNo ratings yet

- Linear Variable Differential Transformer LVDTDocument8 pagesLinear Variable Differential Transformer LVDTRakesh MahajanNo ratings yet

- Callibration of Transducers As Displacement SensorDocument13 pagesCallibration of Transducers As Displacement SensorPriyanshuNo ratings yet

- Seminar Project LVDT: - To Study The Basics, ConstructionDocument9 pagesSeminar Project LVDT: - To Study The Basics, ConstructionNaeem SaifNo ratings yet

- What Is An LVDT (Linear Variable Differential Transformer) ?Document3 pagesWhat Is An LVDT (Linear Variable Differential Transformer) ?muhammad aliNo ratings yet

- FSC20 BA en 21Document110 pagesFSC20 BA en 21Daniel G. AmlakNo ratings yet

- N 181 enDocument74 pagesN 181 enAbdoNo ratings yet

- Engineering Management Dissertation PDFDocument4 pagesEngineering Management Dissertation PDFPayPeopleToWritePapersColumbia100% (1)

- Vapor Sensor: Installation GuideDocument12 pagesVapor Sensor: Installation GuideShalvaTavdgiridzeNo ratings yet

- Selection of Diesel GeneratorDocument3 pagesSelection of Diesel GeneratordankorankoNo ratings yet

- Assess The Performanceof Positive-DisplacementPumps, CEP, Dec-2007 PDFDocument8 pagesAssess The Performanceof Positive-DisplacementPumps, CEP, Dec-2007 PDFSanjay Gupta100% (1)

- CapacitorDocument96 pagesCapacitorHipolito MBNo ratings yet

- Electra Saver II G2 75-100HP Rotary Screw Compressor Brochure PDFDocument2 pagesElectra Saver II G2 75-100HP Rotary Screw Compressor Brochure PDFgututoNo ratings yet

- IS 14697-1999 Edn 1.3Document35 pagesIS 14697-1999 Edn 1.3prajith555No ratings yet

- Informe2 - Ing - ElectricaDocument24 pagesInforme2 - Ing - ElectricaCarlos Coral TaipeNo ratings yet

- Exam Survival Guide (Voigt) PDFDocument388 pagesExam Survival Guide (Voigt) PDFJenYerroNo ratings yet

- Question Bank - Industrial DrivesDocument3 pagesQuestion Bank - Industrial DrivesManas ChakrabortyNo ratings yet

- LEFORT Antoine These Memoire VFDocument135 pagesLEFORT Antoine These Memoire VFLy Huynh PhanNo ratings yet

- Mock Board ReviewDocument153 pagesMock Board ReviewLovely Rose Dungan TiongsonNo ratings yet

- Berber SymbolsDocument2 pagesBerber SymbolsFernandoGarcíaLorca0% (1)

- Jimny PDFDocument237 pagesJimny PDFRustico Guerreiro100% (1)

- CURICULUM VITAE - Koko SantanaDocument2 pagesCURICULUM VITAE - Koko SantanaRiesky FirdyanNo ratings yet

- Kul-24.3200 Lecture PropII 01aDocument27 pagesKul-24.3200 Lecture PropII 01aLong NguyenNo ratings yet

- Forms of EnergyDocument10 pagesForms of EnergyTrollzzz dogeNo ratings yet

- Cuna Ge PandaDocument62 pagesCuna Ge PandaEmilio A Secas100% (1)

- DHL 2ndDocument7 pagesDHL 2ndSafi UllahNo ratings yet

- Crankcase BreathingDocument5 pagesCrankcase BreathingabjithNo ratings yet

- All About 2n2222 Transistor and Its Circuit DiagramsDocument5 pagesAll About 2n2222 Transistor and Its Circuit DiagramsSai KiranNo ratings yet

- 1.1.1 Company Profile: Figure 1:department List TreeDocument75 pages1.1.1 Company Profile: Figure 1:department List TreeHisham MostafaNo ratings yet

- GS Ep PVV 000 enDocument9 pagesGS Ep PVV 000 ensenthil muruganNo ratings yet

- Log Book ActivityDocument15 pagesLog Book ActivityGus BisantikoNo ratings yet

- Citrate Synthesis of Gold Nano ParticlesDocument4 pagesCitrate Synthesis of Gold Nano Particlestatiye560No ratings yet

- FRQ Post Nuclear PowerDocument2 pagesFRQ Post Nuclear Powerdenise solerNo ratings yet

- A Study On Implementation of CRM in Retail Fuel StationsDocument95 pagesA Study On Implementation of CRM in Retail Fuel StationsBhargav Alampuri100% (1)

- Spring Summer 2023 Technical Exams ListDocument10 pagesSpring Summer 2023 Technical Exams ListAshraf BadrNo ratings yet