Professional Documents

Culture Documents

Practise Set

Uploaded by

durgaraokamireddy0 ratings0% found this document useful (0 votes)

252 views1 pageDynamics of machines practice questions on some of the important concepts

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentDynamics of machines practice questions on some of the important concepts

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

252 views1 pagePractise Set

Uploaded by

durgaraokamireddyDynamics of machines practice questions on some of the important concepts

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

1. A double riveted lap joint is made between 15 mm thick plates.

The rivet diameter and

pitch are 25 mm and 75 mm respectively. If the ultimate stresses are 400 MPa in

tension, 320 MPa in shear and 640 MPa in crushing, find the minimum force per

pitch which will rupture the joint. If the above joint is subjected to a load such that

the factor of safety is 4, find out the actual stresses developed in the plates and the

rivets.

2. Find the efficiency of the following riveted joints : (1). Single riveted lap joint of 6

mm plates with 20 mm diameter rivets having a pitch of 50 mm., (2). Double riveted

lap joint of 6 mm plates with 20 mm diameter rivets having a pitch of 65 mm.

Assume Permissible tensile stress in plate = 120 MPa, Permissible shearing stress in

rivets = 90 MPa, Permissible crushing stress in rivets = 180 MPa.

3. Two plates of 10 mm thickness each are to be joined by means of a single riveted

double strap butt joint. Determine the rivet diameter, rivet pitch, strap thickness and

efficiency of the joint. Take the working stresses in tension and shearing as 80 MPa

and 60 MPa respectively.

4. A double riveted double cover butt joint in plates 20 mm thick is made with 25 mm

diameter rivets at 100 mm pitch. The permissible stresses are

t

= 120 MPa, = 100

MPa and

c

= 150 MPa. Find the efficiency of joint, taking the strength of the rivet in

double shear as twice than that of single shear.

5. Find the following for a double riveted lap joint with chain riveting for plates of

20mm thick taking allowable values of stress in shear, tension and compression equal

to 60 MPa, 90MPa &120 MPa respectively. i) Rivet diameter ii) longitudinal pitch

iii) Transverse pitch.

6. Design a double riveted lap joint with zig zag riveting for 13mm thick plate. Take

strength in tension, shear and compressive respectively as 80, 60 and 120 MPa. Find

the efficiency of the joint.

7. Design a double riveted butt joint with two cover plates for the longitudinal seam of a

boiler shell 1.5 m in diameter subjected to a steam pressure of 0.95 N/mm

2

. Assume

joint efficiency as 75%, allowable tensile stress in the plate 90 MPa; compressive

stress 140 MPa; and shear stress in the rivet 56 MPa.

8. It is required to design the longitudinal rivet joint for a boiler of inner diameter 1.5m.

the steam pressure in the boiler is 2 MPa. The longitudinal joint is triple riveted

double cover plate butt joint of unequal width. The pitch in the outer row is twice the

pitch of rivets in inner rows. The efficiency of the joint is 82%. Assume the rivets in

double shear are 1.875 times stronger than in single shear. The allowable stresses in

shear and crushing of rivets are 60 MPa and 120 MPa respectively. Tensile stress for

material of plate = 80 MPa.

You might also like

- 1 Riveted Joints PDFDocument1 page1 Riveted Joints PDFHemanth ParisaNo ratings yet

- 1 Riveted JointsDocument1 page1 Riveted JointsHemanth ParisaNo ratings yet

- DME - 1 Assignment - II Problem Sheet (2019-20)Document2 pagesDME - 1 Assignment - II Problem Sheet (2019-20)VenkateshNo ratings yet

- Assignment No. 3 &4 B.Tech Mechanical Engineering Third YearDocument4 pagesAssignment No. 3 &4 B.Tech Mechanical Engineering Third Yearharish_kumar201301No ratings yet

- Dme Question Bank 2Document4 pagesDme Question Bank 2Ronak HadiyaNo ratings yet

- Sheet-Machine Design1Document1 pageSheet-Machine Design1zzcvx99No ratings yet

- MDDocument4 pagesMDਲਖਵੀਰ ਸਿੰਘ ਖਾਨਾNo ratings yet

- Sheet4 MachineDesign1Document2 pagesSheet4 MachineDesign1محمد معوضNo ratings yet

- Question Bank Machine Design A: Numerical Problems: Problems On Pin, Cotter and Knuckle JointsDocument25 pagesQuestion Bank Machine Design A: Numerical Problems: Problems On Pin, Cotter and Knuckle Jointsamol pogakeNo ratings yet

- Sheet: 4: 1) Two Plates of 7 MM Thick Are Connected by A Triple Riveted Lap Joint of ZigDocument1 pageSheet: 4: 1) Two Plates of 7 MM Thick Are Connected by A Triple Riveted Lap Joint of ZigBen AhmedNo ratings yet

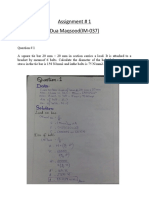

- Assignment # 1 (IM-037)Document8 pagesAssignment # 1 (IM-037)dua maqsoodNo ratings yet

- Assignment No. 6Document4 pagesAssignment No. 6NARENDRA SINGHNo ratings yet

- SM Mid3 Model QuestionsDocument3 pagesSM Mid3 Model QuestionsSaitama BackupNo ratings yet

- DME Q Bank-1 - 1 PDFDocument2 pagesDME Q Bank-1 - 1 PDFMobin ThomasNo ratings yet

- Diploma 6 Sem (Mechanical Engineering) Course Code: 601 Subject Name: Design of Machine Elements Important Questions Chapter-1Document4 pagesDiploma 6 Sem (Mechanical Engineering) Course Code: 601 Subject Name: Design of Machine Elements Important Questions Chapter-1suneel kumar rathoreNo ratings yet

- 7-Design of Riveted Joints - Introduction-03-Sep-2018 - Reference Material I - Module 4A - Rivetted JointsDocument62 pages7-Design of Riveted Joints - Introduction-03-Sep-2018 - Reference Material I - Module 4A - Rivetted Jointsakhil govindNo ratings yet

- PED AssignmentProblems 2017 PDFDocument10 pagesPED AssignmentProblems 2017 PDFSwapnil GudmalwarNo ratings yet

- DME Chapter 2Document5 pagesDME Chapter 2dhananjayvermaNo ratings yet

- QP Pe Series 2Document2 pagesQP Pe Series 2AADARS M SNo ratings yet

- Answers To 1 Problem SetDocument7 pagesAnswers To 1 Problem SetJherod LoversonNo ratings yet

- MD Tut PDFDocument6 pagesMD Tut PDFNelsan PatelNo ratings yet

- Final Exam QPDocument2 pagesFinal Exam QPsutha_me20098282No ratings yet

- ME-323 Threaded-Members 42423Document48 pagesME-323 Threaded-Members 42423Jam Maica TuboNo ratings yet

- Me8593 Iq R17Document4 pagesMe8593 Iq R17Vaideesh LJNo ratings yet

- DME Assignment 1Document2 pagesDME Assignment 1sumikannuNo ratings yet

- DME 1 Question BankDocument5 pagesDME 1 Question BankRahul YedduNo ratings yet

- Department of Mechanical Engineering ME-311, Fundamentals of Machine Design Assignment Sheet No.1 1Document6 pagesDepartment of Mechanical Engineering ME-311, Fundamentals of Machine Design Assignment Sheet No.1 1VishnuNo ratings yet

- Thick Cy FinalDocument5 pagesThick Cy FinalAshok PradhanNo ratings yet

- Quiz 2 Problem Statement (A, B, C)Document1 pageQuiz 2 Problem Statement (A, B, C)AbdullahJavedNo ratings yet

- Meng Ass 2Document2 pagesMeng Ass 2sutha_me200982820% (1)

- 3.1 Keys and Couplings 1Document2 pages3.1 Keys and Couplings 1Edrian PentadoNo ratings yet

- PresentationDocument12 pagesPresentationK ULAGANATHANNo ratings yet

- CHAPTER - 44 Design of Riveted Joints Design of Riveted Joints Design of Riveted Joints Design of Riveted JointsDocument41 pagesCHAPTER - 44 Design of Riveted Joints Design of Riveted Joints Design of Riveted Joints Design of Riveted JointsVarshaNo ratings yet

- Amd Tutorial Me Cadcam 2017Document5 pagesAmd Tutorial Me Cadcam 2017rip111176No ratings yet

- Torsion TutorialDocument2 pagesTorsion Tutorialankurshah1986No ratings yet

- Unit 2 Design of Riveted JointDocument18 pagesUnit 2 Design of Riveted Jointaditya.1540011No ratings yet

- R7310305 Design of Machine Members - IDocument1 pageR7310305 Design of Machine Members - IsivabharathamurthyNo ratings yet

- Homework 3-Due Feb 13 2020Document1 pageHomework 3-Due Feb 13 2020sai ayyankiNo ratings yet

- G For The Material Is 82 GN/m2. If The I-Section Is Replaced by A T-Section Made of TheDocument6 pagesG For The Material Is 82 GN/m2. If The I-Section Is Replaced by A T-Section Made of Theክበር ተመስጌንNo ratings yet

- AMD Tutorial ME CADCAM 2022-23Document6 pagesAMD Tutorial ME CADCAM 2022-23rip111176No ratings yet

- Problems On Stresses in BeamsDocument1 pageProblems On Stresses in BeamsUtkarshNo ratings yet

- Design of Riveted JointsDocument12 pagesDesign of Riveted JointsK ULAGANATHAN100% (1)

- Rivet ProblemDocument4 pagesRivet ProblemK ULAGANATHANNo ratings yet

- BotlsDocument32 pagesBotlsJohn Lancer FabonNo ratings yet

- 07 Group Work Tension MemberDocument12 pages07 Group Work Tension MemberRi MarkuNo ratings yet

- TORSIONDocument5 pagesTORSIONJobert CajayonNo ratings yet

- 3-1 DMM1 (Nov 2009 Regular)Document9 pages3-1 DMM1 (Nov 2009 Regular)micmechNo ratings yet

- DME AssignmentDocument2 pagesDME Assignmentchirag sanghaniNo ratings yet

- Question Bank For Prelim ExamDocument3 pagesQuestion Bank For Prelim ExamsonawanepmsNo ratings yet

- Torsion ProblemsDocument2 pagesTorsion ProblemsSudeep magarNo ratings yet

- Dme Quest Ut-2Document9 pagesDme Quest Ut-2aadhithyarajasekaranNo ratings yet

- Machine Design & Industrial Drafting SUBJECT CODE:-2141907 Tutorial - 01Document10 pagesMachine Design & Industrial Drafting SUBJECT CODE:-2141907 Tutorial - 01The AIRS CreationsNo ratings yet

- Draw The Stress - Strain Diagram For Mild Steel. Explain.: Unit - IDocument9 pagesDraw The Stress - Strain Diagram For Mild Steel. Explain.: Unit - IKomma Hema100% (1)

- MF & SMO 14th SEP 2022 WTMDocument60 pagesMF & SMO 14th SEP 2022 WTMDeepak KumarNo ratings yet

- Dme - Ii (17me64) : Assignement 01Document3 pagesDme - Ii (17me64) : Assignement 01NAVEEN H ENo ratings yet

- Week 3 Lecture Material - WatermarkDocument53 pagesWeek 3 Lecture Material - WatermarkVaibhav SharmaNo ratings yet

- Title of The Paper: First Author, Second Author, Third AuthorDocument1 pageTitle of The Paper: First Author, Second Author, Third AuthordurgaraokamireddyNo ratings yet

- Vectors Tensors 14 Tensor CalculusDocument9 pagesVectors Tensors 14 Tensor Calculusanand singhNo ratings yet

- Article - Predicting The Effect of Field ShaperDocument8 pagesArticle - Predicting The Effect of Field ShaperdurgaraokamireddyNo ratings yet

- Influence of The Free Compression Stage On Magnetic Pulse Welding of TubesDocument27 pagesInfluence of The Free Compression Stage On Magnetic Pulse Welding of TubesdurgaraokamireddyNo ratings yet

- AmazonDocument1 pageAmazondurgaraokamireddyNo ratings yet

- Episodes From Srimad BhagavatamDocument309 pagesEpisodes From Srimad BhagavatamEstudante da Vedanta100% (5)

- Manu 143 4 041004Document11 pagesManu 143 4 041004durgaraokamireddyNo ratings yet

- Problem No.:2 Cantilever T-Section Beam With Point Load at Free EndDocument1 pageProblem No.:2 Cantilever T-Section Beam With Point Load at Free EnddurgaraokamireddyNo ratings yet

- Continuum Mechanics: 2. Exercise Mathematical PreliminariesDocument1 pageContinuum Mechanics: 2. Exercise Mathematical PreliminariesdurgaraokamireddyNo ratings yet

- GATE Previous QuestionsDocument132 pagesGATE Previous QuestionsdurgaraokamireddyNo ratings yet

- Computing AssignmentDocument2 pagesComputing AssignmentdurgaraokamireddyNo ratings yet

- C Tutorial2Document1 pageC Tutorial2durgaraokamireddyNo ratings yet

- Matlab Gui TurorialDocument20 pagesMatlab Gui TurorialdurgaraokamireddyNo ratings yet

- Ex05 SolutionDocument5 pagesEx05 SolutiondurgaraokamireddyNo ratings yet

- Lec19 PDFDocument22 pagesLec19 PDFdurgaraokamireddyNo ratings yet

- Advanced Finite Element Analysis Prof. R. Krishnakumar Department of Mechanical Engineering Indian Institute of Technology, MadrasDocument22 pagesAdvanced Finite Element Analysis Prof. R. Krishnakumar Department of Mechanical Engineering Indian Institute of Technology, MadrasdurgaraokamireddyNo ratings yet

- C Tutorial2Document1 pageC Tutorial2durgaraokamireddyNo ratings yet

- C Tutorial2Document1 pageC Tutorial2durgaraokamireddyNo ratings yet

- C Tutorial1Document1 pageC Tutorial1durgaraokamireddyNo ratings yet

- Lec 17Document20 pagesLec 17abimanaNo ratings yet

- Me317 Design of Machine Elements - I: III Year B.Tech. Mechanical Engg. I - Semester L T P To CDocument2 pagesMe317 Design of Machine Elements - I: III Year B.Tech. Mechanical Engg. I - Semester L T P To CdurgaraokamireddyNo ratings yet

- Current Failure Theories For Composite LaminatesDocument30 pagesCurrent Failure Theories For Composite LaminatesdurgaraokamireddyNo ratings yet

- Classification of Metals: Iron OresDocument6 pagesClassification of Metals: Iron OresdurgaraokamireddyNo ratings yet

- AMOS Unit Wise ObjectivesDocument2 pagesAMOS Unit Wise ObjectivesdurgaraokamireddyNo ratings yet

- DME - 1 One Mark Q's (KDR)Document13 pagesDME - 1 One Mark Q's (KDR)durgaraokamireddyNo ratings yet

- Design of Machine Elements-I (DME-I)Document2 pagesDesign of Machine Elements-I (DME-I)durgaraokamireddyNo ratings yet

- DME-I Unit Wise ObjectiesDocument2 pagesDME-I Unit Wise ObjectiesdurgaraokamireddyNo ratings yet

- AMOS Unit Wise ObjectivesDocument2 pagesAMOS Unit Wise ObjectivesdurgaraokamireddyNo ratings yet

- DME-I Unit Wise ObjectiesDocument2 pagesDME-I Unit Wise ObjectiesdurgaraokamireddyNo ratings yet

- FDM MojoDocument2 pagesFDM MojodurgaraokamireddyNo ratings yet

- Type of ThreadsDocument1 pageType of ThreadsAnonymous QiMB2lBCJLNo ratings yet

- Rules of Thumb Microtunneling Part 1Document1 pageRules of Thumb Microtunneling Part 1mahaprakash0% (1)

- Compound & Chemical Change Trial ReportDocument2 pagesCompound & Chemical Change Trial ReportRS MANIKANDANNo ratings yet

- Compressor BearingsDocument55 pagesCompressor BearingsAnonymous OFP2ygPId100% (1)

- Senate Hearing, 111TH Congress - Energy and Water Development Appropriations For Fiscal Year 2010Document65 pagesSenate Hearing, 111TH Congress - Energy and Water Development Appropriations For Fiscal Year 2010Scribd Government DocsNo ratings yet

- Factory Parts Catalo: Product No. Base Model No. Series Color VoltsDocument23 pagesFactory Parts Catalo: Product No. Base Model No. Series Color VoltsaugustinehippoNo ratings yet

- Analytical Study On Tensile Strength of ConcreteDocument7 pagesAnalytical Study On Tensile Strength of ConcreteAshley Van Der WesthuizenNo ratings yet

- History of Rigid Frame BridgesDocument36 pagesHistory of Rigid Frame BridgesTamaduianu IoanNo ratings yet

- Flexible Pavement Design - Base DataDocument6 pagesFlexible Pavement Design - Base DataRenugopalNo ratings yet

- Home Painting ServicesDocument1 pageHome Painting ServicesThan SoeNo ratings yet

- Design Calculations For Aluminium CW ProfileDocument5 pagesDesign Calculations For Aluminium CW Profilemsiddiq1100% (1)

- Republic of The Philippines AJ: (0 - U - .zJJ1'rDocument2 pagesRepublic of The Philippines AJ: (0 - U - .zJJ1'rChesterMercadoNo ratings yet

- Purchase Spec. For Plates (Sa240 304L)Document3 pagesPurchase Spec. For Plates (Sa240 304L)Daison PaulNo ratings yet

- R.C.C. - Basics For Site EngineerDocument146 pagesR.C.C. - Basics For Site EngineerMuhannad AbdulRaoufNo ratings yet

- Eaton Fuller RTO 14613 Transmission Parts ManualDocument49 pagesEaton Fuller RTO 14613 Transmission Parts ManualDiego AlvarezNo ratings yet

- Plant EDG PerkinsDocument552 pagesPlant EDG PerkinsAseels PakNo ratings yet

- Iso 10721-1-1997Document119 pagesIso 10721-1-1997Jagannath SahuNo ratings yet

- Air Coled Mini ChillerDocument20 pagesAir Coled Mini ChillerchinitnNo ratings yet

- Leak Testing & Plugging Procedure For SYN. Loop Waste Heat BoilerDocument3 pagesLeak Testing & Plugging Procedure For SYN. Loop Waste Heat BoilerBESTINNo ratings yet

- Screw Fastenings and RivetsDocument53 pagesScrew Fastenings and RivetsAJ Bantay100% (1)

- How To Run Electrical Wires in A Finished WallDocument5 pagesHow To Run Electrical Wires in A Finished WallRi SovannaphumiNo ratings yet

- Sumithva DeveloperDocument2 pagesSumithva DeveloperSachin KothvalNo ratings yet

- JCT Standards Specs - NOT CompleteDocument87 pagesJCT Standards Specs - NOT Completemicana88No ratings yet

- Biophilic DesignsDocument3 pagesBiophilic DesignsNorvin Joseph Gomez100% (2)

- Manual UT Thickness Specific Exam From SAEP-1146 Name: Badge#: DateDocument5 pagesManual UT Thickness Specific Exam From SAEP-1146 Name: Badge#: DateMohamed IbrahimNo ratings yet

- Equator 2 BlueDocument1 pageEquator 2 Bluegetfarhan786No ratings yet

- Composite Materials DesignDocument72 pagesComposite Materials DesignGihanFernandoNo ratings yet

- ThyssenKrupp Drilling CatálogoDocument16 pagesThyssenKrupp Drilling Catálogoflasher_for_nokiaNo ratings yet